Académique Documents

Professionnel Documents

Culture Documents

Pvek DKMHPN500B102

Transféré par

seaqu3stDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pvek DKMHPN500B102

Transféré par

seaqu3stDroits d'auteur :

Formats disponibles

Tech Note

Electrical activation unit type PVEK and PVEK-DI for proportional valves PVG 32

DKMH.PN.500.B1.02 is new Introduction Danfoss is introducing a new electrical activation unit type PVEK. PVEK is one of a new series of electrical activation units - the PVE series 3 - for PVG 32. The features of PVEK are: Newly-developed electronics based on hybrid technology. Two solenoid valves plus two orifices instead of four solenoid valves. Standard AMP connector (IP66). No fault monitoring. Integrated direction indication as an option. PVEK has been developed for systems where low hysteresis has a higher priority than reaction time. Because of its design with only two NC solenoid valves, PVEK has hydraulic characteristics that differ from than those familiar in the PVE series 2, see technical description.

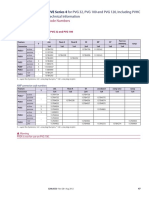

Versions and code numbers

Version

Desciption

Code number 12 Volt 24 Volt

PVEK 157B4911 (Without direction indication)

157B4912

PVEK-DI (With direction indication)

157B4913

157B4914

09-1999

DKMH.PN.500.B1.02 520L0257

Book 8 partition 3

www.danfoss.com/fluidpower

Function principles PVEK

PVEK is built up of both new and familiar components: Newly-developed electronics based on hybrid technology. Same inductive LVDT transducer as PVE series 2. Same hydraulic bridge as PVE series 2, but two of the solenoid valves have been replaced with two orifices(0.6 mm). The use of two solenoid valves and two orifices results in properties that deviate from those of PVM series 2 in the following respects: Low hysteresis Greater pilot oil flow. Pilot oil supply still able to sustain supply to a minimum of five activated PVEK units at the same time. Activation of PVM while voltage is being applied to the PVE (manual override) easier than with a PVEM.

To begin activation requires a force of 40 N (measured at the middle of the knob on a standard PVM). To obtain full activation requires a force of 55 N. Greater oil flow creates flow forces that may limit the travel of the main spool. Example: In systems with pressure control spools ( > D dimension), depending on the flow forces (QA/QB > 1.25), PVEK limits the velocity of a negative load when no pressure regulating valve is used. PVEK, is more sensitive to contamination than PVE series 2. In systems with strict safety requirements, it is recommended that PVEK-DI be used with direction indication connected to a safety system.

PVEK connections

Grey socket

1 2 3 4

Pin 1

Name Vin

2 3 4

Vbat+ VbatNot used

Description Signal voltage: 0,25% x Vbat+ to 0,75 x Vbat+ Voltage supply Frame -

DKMH.PN.500.B1.02 520L0257

Function principles PVEK-DI

As PVEK but with integrated direction indication (DI). For direction indication, signals A and B on the DI output are "high" in neutral.

If activated in direction A (oil out of port A), signal A falls from "high" to "low" while signal B remains "high" and vice versa:

Direction signals a1, a2 Max. load Dir_A, Dir_B Voltage in neutral Voltage on activation

Port A Port B 0,8 mm 0,4 mm 0,8 mm 0,4 mm 12V / 20 mA 24V / 20 mA Minimum: Vbat - 1,5 V Maximum: 0,2V

PVEK-DI connections

Grey socket

Black socket

1 2 3 4

1 2 3 4

Pin 1

Name Vin

Description Signal voltage: 0,25% x Vbat2+ to 0,75 x Vbat2+ Voltage supply for solenoid valves only. Can be switched off (e.g. emergency stop) without disconnection of direction indication. Frame -

Pin 1 2 3 4

Name Dir_B Dir_A VbatVbat+

2 3 4

Vbat2+ VbatNot used

Description Direction indication B Direction indication A Frame Voltage supply for electronics only (must always remain on).

DKMH.PN.500.B1.02 520L0257

Technical data

Mineral-based oil with a viscosity of 21 mm2/s at a temperature of 50C must be used.

Reaction times and hysteresis

Function Reaction time from neutral position to max. spool travel Reaction time from max. spool travel to neutral position Reaction time from neutral position to max. spool travel Reaction time from max. spool travel to neutral position Hysteresis (frequency = 0,02 Hz) Voltage Vbat OFF (Neutr. switch) Vbat OFF (Neutr. switch) Vbat ON (Constant) Vbat ON (Constant) Min. 250 ms 300 ms 250 ms 150 ms Nominal 320 ms 400 ms 320 ms 200 ms 2% Max. 500 ms 550 ms 500 ms 250 ms 4%

Comparison of hysteresis, PVEM and PVEK

Pilot oil consumption

Function Pilot oil flow per PVEK Pilot oil flow per PVEK in locked position Pilot oil flow per PVEK for one full activation Voltage Off On On Oil flow 0 l/min 0,5 l/min 0,75 l/min

Electrical specification

Function Nominal voltage Supply voltage (UDC) range Supply voltage (UDC) max. ripple Supply voltage (UDC) overvoltage (max. 5 min) Current consumption (on activation) Signal voltage in neutral Signal voltage in regulation range Signal current Max. current load in Vbat+ (PVEK-DI) Input impedance at 0,5 x UDC Power consumption 12 12 V DC 11 - 15 V 5% 18 V 350 mA 0,25 x UDC 0,25 mA 35 mA 36 V 210 mA 0,5 x UDC to 0,75 x UDC 0,5 mA 55 mA 12 k 5W 24 24 V DC 22 - 30 V

Enclosure and socket

Function IEC 529 degree of protection Socket PVEK Socket PVEK-DI

AMP JPT-socket

IP 66 4-pole AMP 2 x 4-pole AMP

DKMH.PN.500.B1.02 520L0257

Vous aimerez peut-être aussi

- Pve Cross Reference NLDocument4 pagesPve Cross Reference NLdozer_kamilPas encore d'évaluation

- Buldoexcavator Hidromek HMK 102 B AlphaDocument2 pagesBuldoexcavator Hidromek HMK 102 B Alphadicon100% (1)

- TSX 17B 1428 Micro-PLC Follow-Up SheetDocument70 pagesTSX 17B 1428 Micro-PLC Follow-Up SheetMarco Calderon LaymePas encore d'évaluation

- Spare Parts List: Forward and Reversible PlateDocument40 pagesSpare Parts List: Forward and Reversible PlatePawelPas encore d'évaluation

- GetDoc - PDF MT X 1440AE3 ElectDocument242 pagesGetDoc - PDF MT X 1440AE3 ElectEdison PondaPas encore d'évaluation

- Käyttöohje JLG E3-SarjaDocument70 pagesKäyttöohje JLG E3-SarjaAnonymous R9Lpd68FTAPas encore d'évaluation

- F700a 800axp 26Document102 pagesF700a 800axp 26ניקולאי אין100% (1)

- Mrt2540 ElectricDocument136 pagesMrt2540 ElectricmarkPas encore d'évaluation

- Electrical Systems OverviewDocument28 pagesElectrical Systems OverviewcckasPas encore d'évaluation

- F155a F165axp 22Document112 pagesF155a F165axp 22ניקולאי איןPas encore d'évaluation

- Olympus Mini: Service ManualDocument110 pagesOlympus Mini: Service ManualGonçalo PereiraPas encore d'évaluation

- Installation: Imt Manual #Document16 pagesInstallation: Imt Manual #Arkadiusz ArkadiuszPas encore d'évaluation

- TRANSMISIONDocument2 pagesTRANSMISIONEdge CruzPas encore d'évaluation

- 12.4000677940 MF HT43RTJ Pro Us E09.17Document262 pages12.4000677940 MF HT43RTJ Pro Us E09.17Daniel Peña Vergara100% (1)

- Actuador Electrohidraulico Pve Serie4 CodigosDocument5 pagesActuador Electrohidraulico Pve Serie4 CodigosLuis PimentelPas encore d'évaluation

- Mercedes-Benz Axor Fuel System Service ManualDocument20 pagesMercedes-Benz Axor Fuel System Service ManualErik SilvaPas encore d'évaluation

- FEND VARIO 922-936 - Инструкция по эксплуатации-сторінки- - карта смазкиDocument2 pagesFEND VARIO 922-936 - Инструкция по эксплуатации-сторінки- - карта смазкиСергій БоженкоPas encore d'évaluation

- Trans Diagram Ml260Document2 pagesTrans Diagram Ml260ferneyPas encore d'évaluation

- Bodas Controller RC: Series 20Document20 pagesBodas Controller RC: Series 20Irina VarzouPas encore d'évaluation

- MAMCING-01 CingoDocument130 pagesMAMCING-01 CingoNicoleta CosteaPas encore d'évaluation

- Operator's Manual: H28TJ+ (HB86TJ+) H43TPX (HB135JRT)Document112 pagesOperator's Manual: H28TJ+ (HB86TJ+) H43TPX (HB135JRT)Krum KashavarovPas encore d'évaluation

- Chap 70Document150 pagesChap 70Farid Rezig100% (2)

- Bar Cargolift-Letak BC 1500h42, BC 2000h42Document4 pagesBar Cargolift-Letak BC 1500h42, BC 2000h42NikNik1976Pas encore d'évaluation

- Pve Cross Reference en PDFDocument4 pagesPve Cross Reference en PDFIvailo ZapryanovPas encore d'évaluation

- Sauer-Danfoss Mcx103b Position TransducerDocument4 pagesSauer-Danfoss Mcx103b Position TransducerJosé Fidencio Carrillo MorenoPas encore d'évaluation

- Functional Description: Spicer Off-HighwayDocument13 pagesFunctional Description: Spicer Off-HighwayАнатолій Гуменюк100% (4)

- Kubota Excavator: Engine Output: 63.2 PS Machine Weight: 8240 KGDocument12 pagesKubota Excavator: Engine Output: 63.2 PS Machine Weight: 8240 KGMarin Grgurica100% (1)

- PVG 32Document246 pagesPVG 32Cesar MarquesPas encore d'évaluation

- Specs CASE 921E Series PDFDocument6 pagesSpecs CASE 921E Series PDFDian SikumbangPas encore d'évaluation

- Rugged Multi-Axis Joystick Controls Heavy EquipmentDocument11 pagesRugged Multi-Axis Joystick Controls Heavy Equipmentdjoko123Pas encore d'évaluation

- Instruction Manual Safety SystemDocument99 pagesInstruction Manual Safety SystemAndrey AndreyPas encore d'évaluation

- 030a 202a enDocument60 pages030a 202a enSunthron Somchai0% (1)

- t8. Fault CodesDocument33 pagest8. Fault CodesjuanPas encore d'évaluation

- Complete Hire Sydney Terex TA6 6t Dump Truck 6000kg Operators ManualDocument140 pagesComplete Hire Sydney Terex TA6 6t Dump Truck 6000kg Operators ManualDavid Eduardo Apaza CairaPas encore d'évaluation

- Catalogo Hiab 122Document4 pagesCatalogo Hiab 122Daniel Gonzalez MuñozPas encore d'évaluation

- Manitou MLA 628 Series 3 E2Document636 pagesManitou MLA 628 Series 3 E2Dobos Levente SzilveszterPas encore d'évaluation

- Dynapac CA 250 Operation: Box 504, SE-371 23 Karlskrona, Sweden Phone: +46 455 30 60 00, Fax: +46 455 30 60 30Document28 pagesDynapac CA 250 Operation: Box 504, SE-371 23 Karlskrona, Sweden Phone: +46 455 30 60 00, Fax: +46 455 30 60 30ErmiasPas encore d'évaluation

- Liebherr PR 764 Litronic Operating ManualDocument248 pagesLiebherr PR 764 Litronic Operating ManualAlain DefoePas encore d'évaluation

- JLG-460SJ - Operation and Safety ManualDocument152 pagesJLG-460SJ - Operation and Safety ManualMOTOR POOL100% (1)

- Cummins: Fault Code: 376 PID: P1691Document2 pagesCummins: Fault Code: 376 PID: P1691Enrrique LaraPas encore d'évaluation

- Specificatii Komatsu WB97S 2Document8 pagesSpecificatii Komatsu WB97S 2Paco HidalgoPas encore d'évaluation

- Aw 1120Document11 pagesAw 1120carlosalazarsanchez_Pas encore d'évaluation

- Fig. Control Valves Wiring LoomDocument1 pageFig. Control Valves Wiring LoomLacatusu MirceaPas encore d'évaluation

- Smoothshift Transmission: Clutch Pack Calibration (AEB)Document1 pageSmoothshift Transmission: Clutch Pack Calibration (AEB)morusPas encore d'évaluation

- Manual RT760EDocument159 pagesManual RT760EgriffithPas encore d'évaluation

- Esquema Electrico 420F-430F-432F-444F (A4)Document28 pagesEsquema Electrico 420F-430F-432F-444F (A4)Axel GodinesPas encore d'évaluation

- Operator's Manual: HTL 4010 - HTL 3510 (HTL 7732) - HTL 3010Document224 pagesOperator's Manual: HTL 4010 - HTL 3510 (HTL 7732) - HTL 3010Тарас Фірак100% (1)

- ZF Transsion Electrical SystemDocument12 pagesZF Transsion Electrical Systemhector agueroPas encore d'évaluation

- Manitou MLT 735 120 LsuDocument2 pagesManitou MLT 735 120 LsugeorgePas encore d'évaluation

- Handbook of Repair: Manufacturer: "Mecalac Sas"Document70 pagesHandbook of Repair: Manufacturer: "Mecalac Sas"Farid RezigPas encore d'évaluation

- Terex 860 SX, 860 EliteDocument2 pagesTerex 860 SX, 860 EliteYogan100% (1)

- Formacion Valvulas PVG32 (Bobcat)Document25 pagesFormacion Valvulas PVG32 (Bobcat)HANSELL MIRANDA ALVAPas encore d'évaluation

- CatDocument13 pagesCatDammiam GaticaPas encore d'évaluation

- Pr6mxy36s e ScanrecoDocument1 pagePr6mxy36s e ScanrecoGenaro Montes Flores100% (1)

- TXL 300-2Document6 pagesTXL 300-2deyviPas encore d'évaluation

- PVEB electric actuator tech noteDocument4 pagesPVEB electric actuator tech noteseaqu3stPas encore d'évaluation

- APW7165Document20 pagesAPW7165Jorge BulacioPas encore d'évaluation

- LM5007 High Voltage (80V) Step Down Switching Regulator: FeaturesDocument17 pagesLM5007 High Voltage (80V) Step Down Switching Regulator: FeaturesbhushanchittaragiPas encore d'évaluation

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84Pas encore d'évaluation

- LCD Bias Power Integrated With WLED Backlight Drivers: FeaturesDocument31 pagesLCD Bias Power Integrated With WLED Backlight Drivers: FeaturesJoseph BernardPas encore d'évaluation

- Hollow Bar PTG 600 ChemicalDocument2 pagesHollow Bar PTG 600 Chemicalseaqu3stPas encore d'évaluation

- PVEB electric actuator tech noteDocument4 pagesPVEB electric actuator tech noteseaqu3stPas encore d'évaluation

- Line Pipe: Astm A106 GRB Api 5L GRB Api 5Lx 52NDocument2 pagesLine Pipe: Astm A106 GRB Api 5L GRB Api 5Lx 52Nseaqu3stPas encore d'évaluation

- Hydraulic Cylinder Tubes and ServicesDocument6 pagesHydraulic Cylinder Tubes and Servicesseaqu3stPas encore d'évaluation

- 520L0465 Biodegradable Hydraulic Fluids Applications TI 01-2004Document6 pages520L0465 Biodegradable Hydraulic Fluids Applications TI 01-2004seaqu3stPas encore d'évaluation

- PVSP DKMHPN570R102Document8 pagesPVSP DKMHPN570R102seaqu3stPas encore d'évaluation

- Energy BrochureDocument44 pagesEnergy BrochureMohsen GdPas encore d'évaluation

- Hot Finished Seamless: Chemical Composition (Ladle Analysis)Document8 pagesHot Finished Seamless: Chemical Composition (Ladle Analysis)seaqu3stPas encore d'évaluation

- Electric Resistance Welded: Chemical Composition (Ladle Analysis)Document4 pagesElectric Resistance Welded: Chemical Composition (Ladle Analysis)seaqu3stPas encore d'évaluation

- Solenoid Control Hk66o102Document40 pagesSolenoid Control Hk66o102seaqu3stPas encore d'évaluation

- Cold Finished Seamless: MechanicalDocument8 pagesCold Finished Seamless: Mechanicalseaqu3stPas encore d'évaluation

- 9887B Fluids and FiltrationDocument28 pages9887B Fluids and Filtrationseaqu3stPas encore d'évaluation

- Cold Finished Seamless: Analysis) Chemical Composition (Ladle Analysis)Document4 pagesCold Finished Seamless: Analysis) Chemical Composition (Ladle Analysis)seaqu3stPas encore d'évaluation

- Boiler Tube 01 PDFDocument2 pagesBoiler Tube 01 PDFseaqu3stPas encore d'évaluation

- Driveline Component Selection GuideDocument32 pagesDriveline Component Selection Guideseaqu3stPas encore d'évaluation

- PVPV DKMHPN500DC02Document4 pagesPVPV DKMHPN500DC02seaqu3stPas encore d'évaluation

- SpeDocument12 pagesSpeseaqu3stPas encore d'évaluation

- LS Compensating Valve PVFC Tech NoteDocument4 pagesLS Compensating Valve PVFC Tech Noteseaqu3stPas encore d'évaluation

- SDM 143 eDocument20 pagesSDM 143 eseaqu3st100% (1)

- Sds 150 eDocument16 pagesSds 150 eseaqu3stPas encore d'évaluation

- REMOTE CONTROL CATALOGDocument12 pagesREMOTE CONTROL CATALOGseaqu3stPas encore d'évaluation

- Pvek DKMHPN500B102Document4 pagesPvek DKMHPN500B102seaqu3stPas encore d'évaluation

- SV Hydraulic Pilot Control Valves CatalogueDocument28 pagesSV Hydraulic Pilot Control Valves Catalogueseaqu3stPas encore d'évaluation

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stPas encore d'évaluation

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stPas encore d'évaluation

- SDM140EDocument36 pagesSDM140Eseaqu3stPas encore d'évaluation

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stPas encore d'évaluation

- SD 18 eDocument32 pagesSD 18 eseaqu3stPas encore d'évaluation

- SD 25 eDocument20 pagesSD 25 eseaqu3stPas encore d'évaluation

- SD 16 eDocument20 pagesSD 16 eseaqu3stPas encore d'évaluation

- LTE Parameter RelatedDocument47 pagesLTE Parameter RelatedsalafrfPas encore d'évaluation

- NamoDocument3 pagesNamomadhurPas encore d'évaluation

- Pentasonic Corporation Surveillance & Security SystemDocument2 pagesPentasonic Corporation Surveillance & Security SystemearvngPas encore d'évaluation

- 2SB688Document2 pages2SB688aurelioewane2022Pas encore d'évaluation

- TPC8016-H: High Speed and High Efficiency DC-DC Converters Notebook PC Applications Portable Equipment ApplicationsDocument7 pagesTPC8016-H: High Speed and High Efficiency DC-DC Converters Notebook PC Applications Portable Equipment ApplicationsqwertyuiPas encore d'évaluation

- Contemporary Device TreeDocument25 pagesContemporary Device TreeChairil AnwarPas encore d'évaluation

- TVME8240A 8400 ManualsDocument92 pagesTVME8240A 8400 ManualsarcbalaPas encore d'évaluation

- Microprocessors and Applications GuideDocument3 pagesMicroprocessors and Applications GuideImmanuel VinothPas encore d'évaluation

- Schenck Fip 401Document4 pagesSchenck Fip 401jaxlrosePas encore d'évaluation

- Industrial Automation 1Document41 pagesIndustrial Automation 1Chandan Chandan100% (2)

- Embedded Controlled Drip Irrigation SystemDocument5 pagesEmbedded Controlled Drip Irrigation SystemInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Aicte FDP Vlsi BrouchureDocument2 pagesAicte FDP Vlsi BrouchureVenkatesh VakucherlaPas encore d'évaluation

- MANET-Physical Layer IIDocument32 pagesMANET-Physical Layer IItanyagoswami11Pas encore d'évaluation

- OscilloscopeDocument7 pagesOscilloscopewaar lockPas encore d'évaluation

- Diasonic 2011 CatalogueDocument12 pagesDiasonic 2011 CatalogueredchillpillPas encore d'évaluation

- TechRef SoftstarterDocument11 pagesTechRef SoftstarterCesarPas encore d'évaluation

- Control de Nivel Frio ALKAR 2 Matrix+LLC+Bulletin+515Document4 pagesControl de Nivel Frio ALKAR 2 Matrix+LLC+Bulletin+515Lucas Sebastian PusichPas encore d'évaluation

- PWMDocument30 pagesPWMMelissa MillerPas encore d'évaluation

- Analysis and Design of Coupled Line Couplers PDFDocument11 pagesAnalysis and Design of Coupled Line Couplers PDFcuonglanchiPas encore d'évaluation

- Cyclo ConverterDocument17 pagesCyclo ConverterSai Pranahita KulithalaiPas encore d'évaluation

- Amp Net Connect Emea Catalog 2009Document148 pagesAmp Net Connect Emea Catalog 2009ellappan2238Pas encore d'évaluation

- Panasonic TC 20kl03a 29kl03a mx5zbDocument48 pagesPanasonic TC 20kl03a 29kl03a mx5zbAriel SantosPas encore d'évaluation

- Fall in Love With I2C LCD Displays PDFDocument7 pagesFall in Love With I2C LCD Displays PDFbluesky_1976Pas encore d'évaluation

- User Manual SE6197 EB1007 V3Document109 pagesUser Manual SE6197 EB1007 V3ArnauPas encore d'évaluation

- ITT Project: On Introduction To ComputersDocument32 pagesITT Project: On Introduction To ComputersprateekPas encore d'évaluation

- FM ANT AM ANT H5104/9 circuit diagramDocument32 pagesFM ANT AM ANT H5104/9 circuit diagramMelquisedec MartínezPas encore d'évaluation

- Ar9331 Highly-Integrated and Cost Effective Ieee 802.11N 1X1 2.4 GHZ Soc For Ap and Router PlatformsDocument1 pageAr9331 Highly-Integrated and Cost Effective Ieee 802.11N 1X1 2.4 GHZ Soc For Ap and Router Platformsazawierucha_10775110Pas encore d'évaluation

- Assignment 1 Comp314Document6 pagesAssignment 1 Comp314Lam DerekPas encore d'évaluation

- Service: ManualDocument98 pagesService: ManualmardoniusPas encore d'évaluation