Académique Documents

Professionnel Documents

Culture Documents

Mocvd

Transféré par

Phan Thanh HoaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mocvd

Transféré par

Phan Thanh HoaDroits d'auteur :

Formats disponibles

ADVANCED INSTITUTE OF TECHNOLOGY

MOCVD

- Basics and Applications Photonics Lab

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Outline

BASICS OF MOCVD PROCESS Introduction to MOCVD/MOVPE/OMVPE Systems and Reactors Precursors Basic transport and growth mechanisms Applications Summary

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Introduction to MOCVD / MOVPE / OMVPE

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

MOCVD / MOVPE / OMVPE

MOCVD: Metal Organic Chemical Vapor Deposition Metal Organic Vapor Phase Epitaxy Organo Metallic Vapor Phase Epitaxy

MOVPE: OMVPE:

Often all three expressions are used interchangeably

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

What is MOCVD?

MOCVD is a method to grow/deposit thin solid films, usually semiconductors, on solid substrates (wafers) using organometallic compounds as sources. The films grown by MOCVD are mainly used for the fabrication of electronic and optoelectronic devices. The electronic and optoelectronic devices produced by MOCVD are used in cell phones (HBTs), optical communication, optical storage (CD, DVD, HD-DVD/BDLDs), traffic lights, bill boards (LEDs), lighting and satellites (solar cells). Major MOCVD vendors are AIXTRON, Thomas Swan, VEECO (Emcore), Nippon-Sanso, etc.

-Tutorial (2004.4.23) 5 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Overview of Epitaxy Techniques

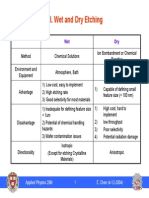

Technique LPE HVPE Strengths Simple High purity Well developed Large scale Simple process Uniform, Abrupt interface In-situ monitoring Most flexible, Large scale production Abrupt interface Simple reactor, High purity

6

Weaknesses Scale economies Inflexible, Non-uniformity No Al alloys Complex process/Control difficult, Hazardous sources As/P alloy difficult Expensive Low throughput Expensive sources Most parameters to control Accurately Hazardous precursors

Photonics Lab

MBE

MOCVD/ OMVPE

-Tutorial (2004.4.23)

ADVANCED INSTITUTE OF TECHNOLOGY

Why MOVPE?

Very high quality of grown layers (high growth rate and doping uniformity/reproducibility) High throughput and no ultra high vacuum needed (compared to MBE), therefore economically advantageous, high system up-time Different materials can be grown in the same system, therefore highest flexibility Growth of sharp interfaces possible - therefore very suitable for hetero-structures, e.g., multi quantum wells (MQW)

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Simplified Presentation of a Crystal Growth Process

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Crystal Structures

(1) (2) (3)

a a c

The group III nitrides GaN, AlN and InN can crystallize in the following three crystal structures: : (1) Wurtzite (2) Rock-salt and (3) Zinc-blende

-Tutorial (2004.4.23) 9 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

The World of Semiconductors

III IV V

Traditional semiconductors Si: DRAMs, Processors Compound semiconductors III-Vs: GaAs, AlGaAs, GalnP, AlGaInP, GaN, InGaN Speciality: SiC Enabling technology for: Advantages of compound semiconductors: faster, higher frequencies visible light, infrared high efficient photovoltaics heat and high power resistant

-Tutorial (2004.4.23) 10 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

How MOCVD Works

-Tutorial (2004.4.23)

11

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Components of a LP-MOCVD System

gas blending unit

reactor with heated susceptor

control unit

vacuum system

scrubbing system

12 Photonics Lab

-Tutorial (2004.4.23)

ADVANCED INSTITUTE OF TECHNOLOGY

Basic Principles of the MOVPE Process

Step 1: A gas mixture containing the precursors needed for growth, and if necessary for doping, is passed over a heated substrate. Step 2: The precursor molecules pyrolyze leaving the atoms, e.g., Ga and As atoms on the substrate surface. Step 3: The atoms bond to the substrate surface and a new crystalline layer is grown, in this case GaAs.

-Tutorial (2004.4.23) 13 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Systems and Reactors

-Tutorial (2004.4.23)

14

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

AIXTRON MOCVD System

transfer cabinet wafer handler vacuum pump (inside)

reactor + heater gas mixing system computer electronic control rack

-Tutorial (2004.4.23) 15 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Gas Blending System

run/vent stack Lauda bath for bubblers H2 purifier (Pd-cell)

-Tutorial (2004.4.23)

16

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

AIX 2600G3 MOCVD Reactor

-Tutorial (2004.4.23)

17

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Vacuum System Vacuum pump - Ebara dry pump

-Tutorial (2004.4.23)

18

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

AIXTOX Scrubbers: Principle

Chemical reaction between a liquid and a Gas in a counter-flowsetup Typically no reaction with carrier gas (e.g. H2 is not treated) A fast reaction is essential for efficient scrubbing

-Tutorial (2004.4.23)

19

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Planetary Reactor AIX 2600 G3 Susceptor (horizontal type)

wafer handler 4 wafer on rotating satellite main susceptor disk collector ring

-Tutorial (2004.4.23)

20

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

RF Heater in G3 Systems

-Tutorial (2004.4.23)

21

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Horizontal Tube Reactor AIX 200RF

-Tutorial (2004.4.23)

22

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Thomas Swan MOCVD system (Vertical type)

CCS(Close Coupled Showerhead) Reactor

-Tutorial (2004.4.23) 23 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Veeco(Emcore) MOCVD system (Vertical type)

Turbo Disc system

-Tutorial (2004.4.23)

24

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors

-Tutorial (2004.4.23)

25

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Example: Precursor Molecules

AsH3

DMZn - (CH3)2Zn

TMGa - (CH3)3Ga H C As Zn Ga

-Tutorial (2004.4.23)

26

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors - Definitions Pyrolysis:

Chemical decomposition of (metal)organic materials by heat in the absence of oxygen. E.g., for TMGa the decomposition takes place in steps from TMGaMMGa Ga. Each decomposition needs higher activation energy. The organic materials are transformed into volatile components (e.g., CH3 molecules in the case of TMGa or DMZn).

Ligand:

A molecule, ion, or atom that is bonded to the central metal atom of the metalorganic molecule (e.g., the CH3 molecules in the case of TMGa or DMZn).

-Tutorial (2004.4.23)

27

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors - Chemical Bonds Chemical bond strength

Determines: Pyrolysis temperature and long term stability, both increase with increasing bond strength The more C atoms are attached to the central metal atom, the weaker the bond The bond strength decreases with increasing molecule size (bond crowding effect) Precursor pyrolysis temp. increases from TBAs TEAs TMAs AsH3 or TEGa TMGa Decomposition sequence: TMGa MMGa Ga

General:

Example:

-Tutorial (2004.4.23)

28

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors - Reaction Types

Homogeneous Reactions

Reactions in the gas phase, e.g., in boundary layer May occur without or with collision of additional molecule (unimolecular or bimolecular)

Heterogeneous Reactions

Reactions at reactor walls or substrate surface The bonds of adsorbed molecules are weakened, e.g., the H bonds of AsH3 at the substrate surface Occur mostly at lower temperatures than homogeneous reactions

-Tutorial (2004.4.23)

29

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors - Precursor Properties Desirable properties of precursors:

Low toxicity Liquid at room temperature Suitable vapor pressure at room temperature Low carbon contamination in grown layer (avoid CH3 radicals), however, for some applications C doping is desired No parasitic reactions with other sources Good long term stability (should not decompose in bubbler) Pyrolysis temperature should match growth temperature Inexpensive for industrial mass production

-Tutorial (2004.4.23) 30 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Precursors - Carbon Incorporation Carbon contamination

Unintentional C doping from C containing precursors is called carbon contamination CH3 radicals (mostly available in methyl precursors) are responsible for C contamination of the growing film C2H5 from ethyl groups causes significantly less carbon contamination than CH3 radicals C contamination from MO source can be reduced by increasing AsH3 partial pressure (higher V/III ratio), more H to react with CH3 However, in some cases p-type doping with C from MO sources is desired

-Tutorial (2004.4.23) 31 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Group III MO Precursors

Precursor Symbol

TMGa TEGa (CH3)3Ga (C2H5)3Ga

Advantages

liquid, high vapor pressure liquid, low carbon contamination, decomposes by -hydride elimination reaction, used in LP MOVPE systems solid, good vapor pressure for MOVPE, also exists as solution TMIn

Disadvantages

low vapor pressure, less stable than TMGa, strong parasitic reactions low vapor pressure

TMIn

(CH3)3In

TEIn TMAl TEAl

(C2H5)3In (CH3)3Al (C2H5)3Al liquid, good vapor pressure, good long term stability liquid, low carbon contamination

very unstable oxygen contamination low long term stability

TM = Trimethyl, TE = Triethyl (Ga = Gallium, In = Indium, Al = Aluminum)

-Tutorial (2004.4.23) 32 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Group V Precursors

Precursor Symbol

Arsine AsH3

Advantages

good pressure control for MOVPE, inexpensive good pressure control for MOVPE, inexpensive liquid, good vapor pressure for MOVPE, very low carbon contamin., good stability, low pyrolysis temperature (T1/2 = 380C) liquid, used to grow C doped GaAs liquid, good vapor pressure for MOVPE, good stability, low pyrolysis temperature (T1/2 = 450C) good stability, only practically available nitrogen precursor

Disadvantages

very toxic, high pyrolysis temperature (T1/2 = 600C) very toxic, high pyrolysis temperature (T1/2 = 850C) expensive for many applications

Phosphine

PH3

TBA

(C4H9)AsH2

TMA TBP

(CH3)3As (C4H9)PH2

expensive for many applications high pyrolysis temperature

Ammonia (for nitrides)

NH3

TM = Trimethyl, TB = Tertiarybutyl (A = arsine, P = phospine)

-Tutorial (2004.4.23) 33 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Dopant Precursors

Precursor

DMZn (p-dopant) Carbontetrachloride (p-dopant in GaAs)

Symbol Advantages

(CH3)2Zn liquid, high vapor pressure, very common Zn precursor liquid, C is shallow acceptor in GaAs, C has low diffusion coeff., used for sharp interfaces, e.g., for high p-type doping in HBTs used in similar applications as CCl4 used as n-dopant for electronic devices used in similar applications as SiH4, but lower pyrolysis temp., better doping uniformity than SiH4 liquid, used in LED production

Disadvantages

Zn often has very high diffusion coefficient in solid, diffuses via interstitials usage might be subject to legal regulation due to ozone depleting character of chemical same as for CCl4 gaseous, flammable, high pyrolysis temperature gaseous, flammable

CCl4

Carbontetrabromide (p-dopant ) Silane (n-dopant) Disilane (n-dopant)

CBr4 SiH4 Si2H6

DETe (n-dopant)

(C2H5)2Te

DM = Dimethyl, DE = Diethyl (Zn = Zinc, Te = Tellurium)

-Tutorial (2004.4.23) 34 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Doping Example: Doping of Silicon

undoped Si (intrinsic)

Si Si Si Si Si Si Si Si Si Si Si Si Si Si Si Si

Arsenic doped Si (n-type)

Si Si Si Si Si Si As Si Si Si Si Si Si Si Si Si

Boron doped Si (p-type)

Si Si Si Si Si Si B Si Si Si Si Si Si Si Si Si

bonding electron (covalent bond)

additional free electron As = donor

missing electron (hole) B = acceptor

-Tutorial (2004.4.23)

35

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Basic Transport and Growth Mechanisms

-Tutorial (2004.4.23)

36

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Principle of LP-MOVPE

H 2

gas blending

reactor

scrubbing system

H , N P=10-200 mbar 2 2

Ga (CH ) + AsH 3 3 3 Ga (CH ) + NH 3 3 3

GaAs GaN

+ 3CH + 3CH

4 4

vacuum pump

TMGa, AsH

TMAl, TMGa, TMIn , PH

5 - 100 rpm

throttle valve

TMGa, NH

filter unit GaAs , InP , sapphire substrate, T ~ 400 - 1200C

high purity, precise mixing

crystal quality, thickness uniformity, reproducibility

safety

-Tutorial (2004.4.23)

37

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

MOVPE Growth Mechanisms

(simplified) horizontal gas flow

CH3 H2 H H2

H N

H

H2

Ga

CH3 CH3

CH3

H2

gas phase

boundary layer

CH3 -radical H H H

Ga

CH3 CH3 CH3radical CH4 = CH3 + H

N

H + H = H2

mass transport to the surface by diffusion precursor decomposition adsorption wafer surface

atomic step

-Tutorial (2004.4.23)

surface diffusion and reaction

38

incorporation and growth

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Boundary Layer Model

D p * pi J= RT 0

Mass transport limited growth regime:

rg = const (PTMGa (v/ptotal)1/2) J

Flux

pi = 0

Temperature dependency of growth rate for mass transport limited growth:

D Diffusion coefficient

p * Input partial pressure of group-III precursor p i Group-III partial pressure at the interface

Thickness of boundary layer Growth rate

D = D (T ) 0 = 0 (T , v)

R Gas constant

rg

v T

Gas velocity Temperature

-Tutorial (2004.4.23)

39

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Transport Mechanisms in Horizontal System

boundary layer

Convective transport by flow

Diffusion in cross-flow direction

longitudinal depletion is governed by:

consumption of nutrients development of boundary layer

rg

... can be controlled by, e.g.

total flow rate gas density and diffusion properties reactor aspect ratio & inlet design

wafer

Depletion profile of growth rate

-Tutorial (2004.4.23) 40 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Growth Rate Uniformity

inlet

fer rota tion

wa

outlet

Viewgraphs: predicted growth rate profiles of AlGaAs on the AIX200 susceptor (T=700C, p = 20 mbar); static wafer vs. rotated wafer

longitudinal non-uniformity (1) lateral non-uniformity (2)

depletion of nutrients parabolic flow profile in rectangular duct

lateral non-uniformity only partially compensated by rotation

-Tutorial (2004.4.23) 41 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Example: GaAs Growth Rate

3 Growth Rate [m/hour]

5 Group III flow rate [mole/min]

10

In the mass transport limited regime the growth rate is almost independent of temperature. It mainly depends on the group III molar flow rate. Changing the group III flow rate will change the growth rate, but not the V/III ratio at the interface, and not the solid stoichiometry.

-Tutorial (2004.4.23)

42

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Example: GaAs Growth Efficiency

Growth Efficiency [m/mole]

104 B C 103 A A - Kinetically limited growth B - Mass transport limited growth

102 0.6

1.0 1000/T [K-1]

1.4

-Tutorial (2004.4.23)

43

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Wafer Surface Orientation

CH3

CH3 CH3

Ga

CH3

Ga

CH3

CH3

Ga As

on-axis substrate

misoriented substrate, net surface diffusion of atoms to the left - from high to low steps

44

MOVPE growth of conventional III-V semiconductors is usually performed on substrates misoriented by 2-3 toward a certain crystallographic direction (e.g., <100> 2 <110>. This yields better quality films and higher growth rates, since atoms easier incorporate at step edges.

-Tutorial (2004.4.23)

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Surface Diffusion

The diffusion of atoms on a surface is affected by atomic steps on the surface:

Atoms preferentially move from high to low steps Wide steps allow long diffusion, while narrow steps reduce the diffusion coefficient (step width depends on degree of misorientation)

-Tutorial (2004.4.23)

45

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

What is important for successful Epitaxy?

Thermal management in the reactor effects

Transport coefficient Reaction rates Incorporation of dopants Composition of multi-component material systems

Composition of the gas phase

For InxGa1-xN LEDs, the In/Ga-ratio determines the color of the LED. Therefore calibrated and stable MFCs and PCs are needed for reproducible LED colors. Bubbler temperature determines vapor pressure of MO

-Tutorial (2004.4.23)

46

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Applications

-Tutorial (2004.4.23)

47

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Products made by MOVPE

Semiconductor AlGaInP InGaN Application displays, DVD, automotive, traffic lights blue LED, Violet LD displays, BD, White-LED automotive, Indoor/outdoor lighting LD CD, telecomm., solar cells satellites, transistors, ICs cellular phones, radar

48 Photonics Lab

Device LED, LD

AlGaAs GaAs GaInP

-Tutorial (2004.4.23)

ADVANCED INSTITUTE OF TECHNOLOGY

Materials and Applications

-Tutorial (2004.4.23)

49

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

LEDs 15000 LEDs on a 2-Wafer Chip size : 0.35 x 0.35mm

The optoelectronic properties of the different compound semiconductors determine the illuminated color of an LED: red to yellow/green green/blue AlGaAs, AlGaInP (In)GaN

White light is generated by combining blue LEDs with fluorescent dyes.

-Tutorial (2004.4.23) 50 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

LED - Colors

-Tutorial (2004.4.23)

51

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

GaN LED Test Structures grown by MOCVD

-Tutorial (2004.4.23)

52

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

LED Media Boards

~ 1000 m2 LEDs

= 19 mil. LEDs

Times Square, New York

-Tutorial (2004.4.23) 53 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Cost Comparison

Incandescent No. of lamps Cost of lamps Power requirements Energy consumption (kWhr/yr) Annual electrical bill (at $0.10/kWhr) Payback period 1 $2.50 150 W 788 $78.80 LED 280 $42.00 20 W 105 $10.50

< 1 year

Source: European Semiconductor, Vol. 22, No. 1, Jan. 2000

Standard in several US states; pilot projects in UK, S, CH, Au, F Germany: pilot projects in Munich, Frankfurt, Aachen

-Tutorial (2004.4.23) 54 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

LEDs for Lighting

(1998)

(Siemens - Osram)

signal/traffic interior lighting

(1996) (Hewlett Packard - Philips) signal/traffic interior lighting

-Tutorial (2004.4.23)

55

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

SAITs InGaN LEDs and LDs

1st LD operation (98. 12)

LED lamps (98. 10)

30mW-InGaN LD (03. 10)

-Tutorial (2004.4.23) 56 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Laser Diodes

Three main wavelength ranges: short wave length 360nm to 475nm - InGaN/AlGaN mid wave length 635nm to 1060nm AlGaInP, GaAs / AlGaAs long wavelength 1250nm to 1650nm - InP / InGaAsP / InGaAs Particular wavelengths are achieved by changing the alloy composition and, in the case of quantum well designs, the thickness of the active layer.

-Tutorial (2004.4.23)

57

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Enabled by Compound Semiconductors

LED blinker

LED dashboard illumination

GPS CD-Player Wireless com. (GSM) LED stop lights Fiber optic data transmission Distronic

-Tutorial (2004.4.23)

58

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

HBT and HEMT Transistors

HBT - Heterojunction Bipolar Transistor HEMT - High Electron Mobility Transistor HBT products :

Small High Speed High Power Low Noise

-Tutorial (2004.4.23) 59 Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

N on P Ga0,51In0,49P/GaAs-tandem solar cell

Cell 1: spectral absorption between 300 - 660 nm

Cell 2: spectral absorption between 660 - 890 nm

-Tutorial (2004.4.23)

60

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

GaAs Space Solar Cell

MOCVD: AIX 2600G3

TiO2/MgF2 ARC Grid contact AlGaAs window GaAs emitter GaAs base

Conversion Efficiency: AM 1.5 AM 0

30

= 24.2 % = 21.9 %

Current (mA)

20

AlGaAs/GaAs DBR Substrate

10

FF = 85.1 %

0,2 0,4 0,6 0,8 1,0

0 0,0

Back side contact

Voltage (V)

Solar Cell Structure

-Tutorial (2004.4.23) 61

I-V curve at AM 1.5 one sun

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Requirements of Compound Semiconductor Industry

Uniformity of layer thickness and composition of 1% on the wafer Temperature uniformity on wafer T = 1C within a wide temperature range Wafer to wafer and run to run reproducibility Low cost of ownership, high wafer capacity, high uptime ratio

-Tutorial (2004.4.23)

62

Photonics Lab

ADVANCED INSTITUTE OF TECHNOLOGY

Summary

Discussed topics:

MOCVD systems and reactors Properties of commonly used precursors Fundamental MOVPE growth principles Devices made by MOVPE

-Tutorial (2004.4.23)

63

Photonics Lab

Vous aimerez peut-être aussi

- Smart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningD'EverandSmart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningRakesh SehgalPas encore d'évaluation

- Physics of Radio Frequency Plasmas PDFDocument395 pagesPhysics of Radio Frequency Plasmas PDFdada12100% (1)

- UltraWAVE Application BookDocument37 pagesUltraWAVE Application BookAngela MoraPas encore d'évaluation

- Thin Film Phenomena: Kasturi L. ChopraDocument11 pagesThin Film Phenomena: Kasturi L. ChopraSubham AdhikariPas encore d'évaluation

- Finite Element Modeling and Simulation For BendingDocument5 pagesFinite Element Modeling and Simulation For BendingAnand RasPas encore d'évaluation

- Digital Integrated CircuitDocument33 pagesDigital Integrated CircuitottoporPas encore d'évaluation

- Science Test Paper 2Document18 pagesScience Test Paper 2Sonia NWODO100% (1)

- MOCVD Manual v100Document107 pagesMOCVD Manual v100Vipin KalaPas encore d'évaluation

- Vacuum Heat Treatment For Epitaxy Susceptor Cleaning Furnace Type COVDocument4 pagesVacuum Heat Treatment For Epitaxy Susceptor Cleaning Furnace Type COVDgek LondonPas encore d'évaluation

- GaN MOCVD-MBEDocument37 pagesGaN MOCVD-MBEDamla-Kerem YıldırımPas encore d'évaluation

- Mocvd PrecusorDocument32 pagesMocvd PrecusorSiyuan GuPas encore d'évaluation

- Epitaxial GrowthDocument31 pagesEpitaxial GrowthdomPas encore d'évaluation

- Chemical Vapor DepositionDocument9 pagesChemical Vapor Depositioncoolrsk17Pas encore d'évaluation

- GaN 1Document21 pagesGaN 1Jesus AguilarPas encore d'évaluation

- Class6.CVD and PVDDocument30 pagesClass6.CVD and PVDSaquib HeshamPas encore d'évaluation

- TCAD SimulationDocument46 pagesTCAD SimulationmahdichiPas encore d'évaluation

- Crystal Defects, Growth and EpitaxyDocument51 pagesCrystal Defects, Growth and EpitaxymaikosPas encore d'évaluation

- Research Repot On A123 Battery ModelingDocument30 pagesResearch Repot On A123 Battery ModelingM VetriselviPas encore d'évaluation

- 02 TCAD Laboratory Sentaurus TCAD GBB OLDDocument23 pages02 TCAD Laboratory Sentaurus TCAD GBB OLDarunPas encore d'évaluation

- Electrical Engineer - LAM ResearchDocument2 pagesElectrical Engineer - LAM ResearchAyush KumarPas encore d'évaluation

- Plasma Diagnostics: Surface Analysis and InteractionsD'EverandPlasma Diagnostics: Surface Analysis and InteractionsOrlando AucielloPas encore d'évaluation

- MOCVDDocument42 pagesMOCVDYogie SanjayaPas encore d'évaluation

- Leybold Spin ResonancecatalogDocument2 pagesLeybold Spin ResonancecatalogRodrigo LimaPas encore d'évaluation

- Lead Free Reliability Study by BoeingDocument23 pagesLead Free Reliability Study by Boeingsmtdrkd100% (1)

- Clean Snowmobile Chassis PosterDocument1 pageClean Snowmobile Chassis Posterapi-284995772Pas encore d'évaluation

- Lecture 4 - Wafer CleanDocument24 pagesLecture 4 - Wafer Cleanimage05Pas encore d'évaluation

- Integrated PhotonicsDocument211 pagesIntegrated PhotonicsCanPas encore d'évaluation

- BMS Lab Final PDFDocument28 pagesBMS Lab Final PDFKalyani ShindePas encore d'évaluation

- Full Vehicle Simulation With MATLAB/Simulink/SimscapeDocument71 pagesFull Vehicle Simulation With MATLAB/Simulink/SimscapeAtharva Joshi.Pas encore d'évaluation

- AVX RF Microwave ProductsDocument242 pagesAVX RF Microwave ProductsLuke GomezPas encore d'évaluation

- Cell Product Specification: Microvast Power Systems Co.,LtdDocument3 pagesCell Product Specification: Microvast Power Systems Co.,LtdAngelo DenidisPas encore d'évaluation

- Modeling and Simulation of Poly (Lactic Acid) PolymerizationDocument140 pagesModeling and Simulation of Poly (Lactic Acid) PolymerizationCamilo Botero ZapataPas encore d'évaluation

- Erli Chen Fabrication III - EtchingDocument18 pagesErli Chen Fabrication III - EtchingLuke D'ImperioPas encore d'évaluation

- 2 Manufacture of Ammonia, Nitric Acid and Calcium Ammonium NitrateDocument14 pages2 Manufacture of Ammonia, Nitric Acid and Calcium Ammonium NitrateKarez MartoPas encore d'évaluation

- Silicon Photonics Packaging: Ino OffersDocument2 pagesSilicon Photonics Packaging: Ino OffersLau Weng LoonPas encore d'évaluation

- Molecular Beam EpitaxyD'EverandMolecular Beam EpitaxyBrian R. PamplinPas encore d'évaluation

- UltraCapacitors in Electric VehiclesDocument7 pagesUltraCapacitors in Electric VehiclesShardulPas encore d'évaluation

- PHD Thesis 20150520 Rev1 Til OrbitDocument200 pagesPHD Thesis 20150520 Rev1 Til OrbitShruti JainPas encore d'évaluation

- Electronics Based On 2D MaterialsDocument13 pagesElectronics Based On 2D MaterialsShyamRamamoorthyPas encore d'évaluation

- Chemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsDocument69 pagesChemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsMomentum PressPas encore d'évaluation

- Electrical and Electronic Materials Science 14.1Document239 pagesElectrical and Electronic Materials Science 14.1Krishnamani TiwariPas encore d'évaluation

- MOCVDDocument13 pagesMOCVDAadil WaseemPas encore d'évaluation

- Sadao Adachiauth. Physical Properties of III-V Semiconductor Compounds InP, InAs, GaAs, GaP, InGaAs, and InGaAsPDocument330 pagesSadao Adachiauth. Physical Properties of III-V Semiconductor Compounds InP, InAs, GaAs, GaP, InGaAs, and InGaAsPEmerson KohlrauschPas encore d'évaluation

- Fundamental Research in Materials Science PDFDocument316 pagesFundamental Research in Materials Science PDFTeerakorn KongkaewPas encore d'évaluation

- Working With Ultra High Vacuum (UHV)Document34 pagesWorking With Ultra High Vacuum (UHV)Doris Giovanna MitrePas encore d'évaluation

- CH 6 PhotodetectorsDocument18 pagesCH 6 PhotodetectorsNikhil GuptaPas encore d'évaluation

- Fuel CellDocument12 pagesFuel CellsaisenthPas encore d'évaluation

- Manufacture of 2032-Type Lithium Secondary Battery (Pre Report)Document4 pagesManufacture of 2032-Type Lithium Secondary Battery (Pre Report)Tony XRahmanxPas encore d'évaluation

- TCADDocument33 pagesTCADvpsampathPas encore d'évaluation

- Sputtering Targets and Evaporation Materials MarketDocument19 pagesSputtering Targets and Evaporation Materials MarketChemicals IndustryARCPas encore d'évaluation

- IC Packaging 2008Document26 pagesIC Packaging 2008Angelo CorderoPas encore d'évaluation

- State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications Issues and RecommendationsDocument17 pagesState-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications Issues and RecommendationshyvasPas encore d'évaluation

- Anode MaterialsDocument23 pagesAnode MaterialsMeruyert KarimPas encore d'évaluation

- En CD00201961 PDFDocument39 pagesEn CD00201961 PDFIrini Fountouli - LadopoulouPas encore d'évaluation

- Homework 1Document3 pagesHomework 1Elizabeth Wachs50% (2)

- Comsol Electric SimulationDocument32 pagesComsol Electric SimulationDott PalmitoPas encore d'évaluation

- A Critical Review of Thermochemical Energy Storage SystemsDocument5 pagesA Critical Review of Thermochemical Energy Storage SystemsAjith KrishnanPas encore d'évaluation

- Supervised Learning With Hyperspectral ImageryDocument134 pagesSupervised Learning With Hyperspectral Imagerysoumya_cuPas encore d'évaluation

- Review of Li - Ion Battery Thermal Management Methods and Mitigating Techniques: 2/3 W Electric Vehicle For Tropical Climatic ConditionDocument12 pagesReview of Li - Ion Battery Thermal Management Methods and Mitigating Techniques: 2/3 W Electric Vehicle For Tropical Climatic ConditionIJRASETPublicationsPas encore d'évaluation

- Handbook of Thin-FilmDocument12 pagesHandbook of Thin-Filmdhook_mmmPas encore d'évaluation

- Advanced Machining ProcessDocument1 pageAdvanced Machining Processsunilsharma8533800% (1)

- Pyro MeterDocument78 pagesPyro Meterjackel.intouch481Pas encore d'évaluation

- 2012 Issue 334Document204 pages2012 Issue 334Fabiano MonteiroPas encore d'évaluation

- MS 18ME34 NotesDocument16 pagesMS 18ME34 NotesSUNIL SWAMY SPas encore d'évaluation

- DOCK/CHEMICALS Is Semiconductors DecisionDocument2 pagesDOCK/CHEMICALS Is Semiconductors DecisionAlexandra HartPas encore d'évaluation

- Diamond ChipDocument2 pagesDiamond ChipNabil MuhammedPas encore d'évaluation

- Grade 11 Physics Module6Document83 pagesGrade 11 Physics Module6JohnRenzoMolinarPas encore d'évaluation

- MSDS E7018Document1 pageMSDS E7018Ahmad Abu Basil Izzuddin Nur Al AslamPas encore d'évaluation

- Hydrolysis of Polydimethylsiloxane Uids in Controlled Aqueous SolutionsDocument8 pagesHydrolysis of Polydimethylsiloxane Uids in Controlled Aqueous SolutionsGrey ParrotPas encore d'évaluation

- Amity School of Engineering and Technology (Tutorial Sheet) Vlsi Processing and Technology TUTE-1Document16 pagesAmity School of Engineering and Technology (Tutorial Sheet) Vlsi Processing and Technology TUTE-1Vipul ChauhanPas encore d'évaluation

- Assgn 1 Muhammad Azim IzzudinDocument4 pagesAssgn 1 Muhammad Azim Izzudinazim izzudinPas encore d'évaluation

- 05 - SPSF1 08 B6Document19 pages05 - SPSF1 08 B6Zulkifli Yusof100% (1)

- Whitewares (Class-04)Document40 pagesWhitewares (Class-04)Zahid HasanPas encore d'évaluation

- 01 Energy Band and SemiconductorsDocument50 pages01 Energy Band and SemiconductorsVikas PsPas encore d'évaluation

- OCP TestDocument7 pagesOCP TestlandimarduartePas encore d'évaluation

- Periodic TableDocument1 pagePeriodic TableJoshua Andrew BatonghinogPas encore d'évaluation

- Colour Metallography of Cast IronDocument9 pagesColour Metallography of Cast IronJoaquim Pedroso SilvaPas encore d'évaluation

- 2.2 Bonding and Structure QPDocument42 pages2.2 Bonding and Structure QPabisolafaluyi5Pas encore d'évaluation

- 2nd Year Mcqs (Full Book)Document69 pages2nd Year Mcqs (Full Book)M Anas AbbasPas encore d'évaluation

- Solar Cell Report New PDFDocument31 pagesSolar Cell Report New PDFGURU prasad100% (1)

- 2007 Deventer Reaction MecanismsDocument8 pages2007 Deventer Reaction MecanismsChi ĐặngPas encore d'évaluation

- Structure of CeramicsDocument20 pagesStructure of CeramicsDong Tri Nguyen ThiPas encore d'évaluation

- ExamDocument16 pagesExamquimicosorioPas encore d'évaluation

- Barang DipakaiDocument21 pagesBarang Dipakaisasa dhaniarPas encore d'évaluation

- 2002 Improved Slag Formation in The BFDocument14 pages2002 Improved Slag Formation in The BFB V S KumarPas encore d'évaluation

- Form 4 Chapter 8Document60 pagesForm 4 Chapter 8Rabbi 08Pas encore d'évaluation

- Wannier TutorialDocument7 pagesWannier TutorialWendel PazPas encore d'évaluation

- Week 19 Separate Chemistry Cycle TestDocument13 pagesWeek 19 Separate Chemistry Cycle Testhansdermann269Pas encore d'évaluation

- UntitledDocument791 pagesUntitledMayra RodriguezPas encore d'évaluation