Académique Documents

Professionnel Documents

Culture Documents

Introduction To The ASTM Designation System

Transféré par

major_duanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction To The ASTM Designation System

Transféré par

major_duanDroits d'auteur :

Formats disponibles

Page 1 of 6

Introduction to the ASTM Designation System

Abstract:

ASTM specifications represent a consensus among producers, specifiers, fabricators, and users of steel mill products. ASTMs designation system for metals consists of a letter (A for ferrous materials) followed by an arbitrary sequentially assigned number. These designations often apply to specific products, for example A548 is applicable to coldheading quality carbon steel wire for tapping or sheet metal screws.

Steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical components, industrial parts, and construction elements. The most widely used standard specifications for steel products in the United States are those published by ASTM (American Society for Testing and Materials). ASTM specifications represent a consensus among producers, specifiers, fabricators, and users of steel mill products. In many cases, the dimensions, tolerances, limits, and restrictions in the ASTM specifications are similar to or the same as the corresponding items in the standard practices contained in the AISI Steel Products Manuals. Many of the ASTM specifications have been adopted by the American Society of Mechanical Engineers (ASME) with little or no modification; ASME uses the prefix S and the ASTM designation for these specifications. For example, ASME-SA213 and ASTM A 213 are identical. ASTMs designation system for metals consists of a letter (A for ferrous materials) followed by an arbitrary sequentially assigned number. These designations often apply to specific products, for example A548 is applicable to cold-heading quality carbon steel wire for tapping or sheet metal screws. Metric ASTM standards have a suffix letter M. Examples of the ASTM ferrous metal designation system, describing its use of specification numbers and letters, are shown below: Example - ASTM A 582/A 582M-95b (2000), Grade 303Se-Free-Machining Stainless Steel Bars: A describes a ferrous metal, but does not sub classify it as cast iron, carbon steel, alloy steel, tool steel, or stainless steel; 582 is a sequential number without any relationship to the metals properties; M indicates that the standard A582M is written in rationalized SI units (the M comes from the word Metric), hence together 582/A582M includes both inch-pound and SI units; 95 indicates the year of adoption or last revision and a letter b following the year indicates the third revision of the standard in1995; (2000), a number in parentheses, indicates the year of last re-approval; Grade 300Se indicates the grade of the steel, and in this case, it has a Se (selenium) addition.

Within the steel industry, the terms Grade, Type, and Class are generally defined as follows: Grade is used to describe chemical composition; Type is used to define the deoxidation practice; and Class is used to indicate other characteristics such as strength level or surface finish. However, within the ASTM standards, these terms were adopted and used to identify a particular metal within a metal standard and used without any strict definition. Although there are differences between the ASTM and traditional definitions of these terms ASTM have applied some loose rules to the use of this terminology in their designation system : Example 1 - ASTM A 106-02a Grade A, Grade B, Grade C - Seamless Carbon Steel Pipe for High-Temperature Service: Typically an increase in alphabet (such as letters A, B, C) results in higher tensile or yield strength steels, and if its an unalloyed carbon steel, an increase in carbon content; In this case: Grade A:0.25%C (max), 48 ksi tensile strength (min); Grade B: 0.30%C (max), Types 304, 316, 410 and others are based on the SAE designation system for stainless steels (see SAE and former AISI description that follows). Another use of ASTM grade designators is found in pipe, tube, and forging products, where the first letter P refers to pipe, T refers to tube, TP may refer to tube or pipe, and F refers to forging. Examples are found in the following ASTM specifications: ASTM A 335/A335-03, Grade P22; Seamless Ferritic Alloy-Steel Pipe for High Temperature Service; ASTM A 213/A213M-03a, Grade T22; Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes; ASTM A 312/A312M-03, Grade TP304; Seamless and Welded Austenitic Stainless Steel Pipe; ASTM A 336/A336M-03a, Class F22-Steel Forgings, Alloy, for Pressure and HighTemperature Parts.

Introduction to the SAE-AISI Designation System

Abstract:

The SAE system uses a basic four-digit system to designate the chemical composition of carbon and alloy steels. The first digit (1), of this designation indicates a carbon steel; i.e., carbon steels comprise 1xxx groups in the SAE-AISI system and are subdivided into four categories due to the variance in certain fundamental properties among them.

For many years, certain grades of carbon and alloy steels have been designated by a four-digit AISE/SAE numerical index system that identified the grades according to standard chemical compositions. Since the American Iron and Steel Institute (AISI) ceased writing material specifications, the relationship between AISI and grade designations has been discontinued. From point of edition of the 1995 Iron and Steel Society (ISS) Strip Steel Manual, the four-digit designations are referred to solely as SAE Designations. The SAE system uses a basic four-digit system to designate the chemical composition of carbon and alloy steels. The simplest system for designation of steel is schematically shown in Figure 1.

Figure 1: Schematic Representation of AISI/SAE Steel Designation System Figure 1 demonstrates that the SAE-AISI system uses a four-digit number to designate a carbon and alloy steel and refers to its specific chemical composition. It is worth noting however, that there are also certain types of alloy steels that are designated by five digits (51XXX; 52XXX). The first digit (1), of this designation indicates a carbon steel; i.e., carbon steels comprise 1xxx groups in the SAE-AISI system and are subdivided into four categories due to the variance in certain fundamental properties among them. Thus the plain carbon steels are comprised within the 10xx series (containing 1.00% Mn maximum); resulfurized carbon steels within the 11xx series; resulfurized and rephosphorized carbon steels within the 12xx series; and nonresulfurized high-manganeze (up-to 1.65%) carbon steels which are produced for applications requiring good machinability are comprised within the 15xx series. The SAE-AISI system then classifies all other alloy steels using the same four digit index as follows: 2 - Nickel steels; 3 - Nickel-chromium steels; 4 - Molybdenum steels; 5 - Chromium steels; 6 - Chromium-vanadium steels; 7 - Tungsten-chromium steels; 9 - Silicon-manganese steels.

The second digit of the series indicates the concentration of the major element in percentiles (1 equals 1%). The last two digits of the series indicate the carbon concentration to 0.01%. Example: SAE 5130 indicates a chromium steel alloy, containing 1% of chromium and 0.30% of carbon. Table 1 shows the SAE/AISI steel Numbering designation system Additional letters added between the second and third digits include B when boron is added (between 0.0005 and 0.003%) for enhanced hardenability, and L when lead is added (between 0.15 and 0.35%) for enhanced machinability. The prefix M is used to designate merchant quality steel (the least restrictive quality descriptor for hot-rolled steel bars used in noncritical parts of structures and machinery). The prefix E (electric-furnace steel) and the suffix H (hardenability requirements) are mainly applicable to alloy steels. The full series of classification groups is shown in Table 2-4. Table 1: The SAE/AISI steel numbering designation system 10XX 11XX Carbon steels 12XX 15XX Manganese steels 13XX 23XX Nickel steels 25XX 31XX 32XX Nickel-chromium steels 33XX 34XX 40XX Molybdenum steels 44XX Chromium-molybdenum steels 41XX 43XX Nickel-chromium-molybdenum steels 47XX 46XX Nickel-molybdenum steels 48XX 50XX 51XX Chromium steels 50XXX 51XXX 52XXX Chromium-vanadium steels 61XX Tungsten-chromium steels 72XX 81XX 86XX Nickel-chromium-molybdenum steels 87XX 88XX Silicon-manganese steels 92XX 93XX 94XX Nickel-chromium-molybdenum steels 97XX 98XX Plain carbon, Mn 1.00% max Resulfurized free machining Resulfurized/rephosphorized free machining Plain carbon, Mn 1.00-1.65% Mn 1.75% Ni 3.50% Ni 5.00% Ni 1.25%, Cr 0.65-0.80% Ni 1.75%, Cr 1.07% Ni 3.50%, Cr 1.50-1.57% Ni 3.00%, Cr 0.77% Mo 0.20-0.25% Mo 0.40-0.52% Cr 0.50-0.95%, Mo 0.12-0.30% Ni 1.82%, Cr 0.50-0.80%, Mo 0.25% Ni 1.05%, Cr 0.45%, Mo 0.20-0.35% Ni 0.85-1.82%, Mo 0.20-0.25% Ni 3.50%, Mo 0.25% Cr 0.27-0.65% Cr 0.80-1.05% Cr 0.50%, C 1.00% min Cr 1.02%, C 1.00% min Cr 1.45%, C 1.00% min Cr 0.60-0.95%, V 0.10-0.015% W 1.75%, Cr 0.75% Ni 0.30%, Cr 0.40%, Mo 0.12% Ni 0.55%, Cr 0.50%, Mo 0.20% Ni 0.55%, Cr 0.50%, Mo 0.25% Ni 0.55%, Cr 0.50%, Mo 0.35% Si 1.40-2.00%, Mn 0.65-0.85%, Cr 0-0.65% Ni 3.25%, Cr 1.20%, Mo 0.12% Ni 0.45%, Cr 0.40%, Mo 0.12% Ni 0.55%, Cr 0.20%, Mo 0.20% Ni 1.00%, Cr 0.80%, Mo 0.25%

Click on the link to see a list of AISI-SAE standards covering the following material categories: Group of standards for structural and constructional steels Group of standards for stainless and heat resisting steels Group of standards for steel castings

Metal Composition

Generally, all metals can be classified such as ferrous, non-ferrous and alloys. Ferrous group of metals is composed mainly of iron. They may have small amounts of other metals or other elements added such as carbon, manganese, nickel, chromium, silicon, titanium, tungsten etc., to give the required properties. Non-Ferrous are metals which do not contain any iron as a component. The common pure metals are: aluminum, copper, lead, zinc, tin, silver and gold. Alloys: An alloy is a new metal which is formed by mixing two or more metals and sometimes other elements together. The most used metals are: Iron, Aluminum, Copper, Titanium, Zinc, Magnesium etc. Iron is the basic component of steel. When carbon, a nonmetal is added to iron in amounts to 2.1 %, the result is an alloy known as steel. In connection with mentioned above steel is an alloy composed by iron and other elements such as carbon, manganese, phosphorus, sulfur, nickel, chromium, tungsten, niobium (columbium), titanium etc. Each element that is added to the basic constituent of iron has some effect on the properties of the steels. The alloying additions are responsible for many differences between the various types or grades of steels. Based on carbon content, the steels are divided into three main groups: low carbon steels /AISI1005 to AISI 1026, IF, HSLA, TRIP, TWIP steels etc/, middle carbon steels /AISI 1029 to AISI 1053/, and high carbon steels /AISI1055 to AISI1095/. On the other hand, according to EN standard, the steel grades are divided into following steel groups: non alloy steels /EN DC01-DC06; S235; S275, etc./, alloy steels /2CrMo4; 25CrMo4 etc./, stainless steels, tool steels /DIN-EN 1.1545; AISI/SAE W110; DIN/EN 1.2436 AISI/SAE D6/, steels for sheet and strip, and steels for electrical sheet and strip /EN 1.0890; EN 1.0803 etc./. On the other hand, the most widely used non-ferrous metals are aluminum, copper, titanium, gold etc. The aluminum industry uses aluminum as cast and wrought aluminum alloys. These two classes can be further subdivided into families of alloys based on chemical composition and on temper designation. According to common accepted CEN standard designation systems, the most common aluminum grades are:

1xxx Series: / 1050, 1060, 1100, 1145, 1200, 1230, 1350 etc./ 2xxx Series: /2011, 2014, 2017, 2018, 2124, 2219, 2319, 201.0; 203.0; 206.0; 224.0; 242.0 etc./ 3xxx Series: /3003, 3004, 3105, 383.0; 385.0; A360; 390.0/ 4xxx Series: /4032, 4043, 4145, 4643 etc./ 5xxx Series: /5005, 5052, 5083, 5086 / 6xxx Series: /6061, 6063/ 7xxx Series: /7075, 7050, 7049, 710.0; 711.0 etc/ 8xxx Series: /8006; 8111; 8079; 850.0; 851.0; 852.0/ Regarding to the properties, titanium and titanium alloys can be divided into three main groups: 8Al-1Mo-1V. High temperature alloys like Ti-6Al-2Sn-4Zr-2Mo, Ti-6Al-2Sn-4Zr-6Mo, Ti-11Sn-5Zr-2.5Al1Mo-0.2Si (IMI679), Ti-6Al-5Zr-0.5Mo-Si (IMI685), Ti-5.5Al-3.5Sn-Zr-1Nb (IMI829), Ti5.8Al-4Sn-3.5Zr-0.7Nb (IMI 834), TIMETAL 1100 etc. The purity or fineness of gold in the jewelry is indicated by its karat number. 24 karat (24K or 24 K) gold is as pure as gold for jewelry gets. 24K gold is also called fine gold and it is greater than 99.7% pure gold. Proof gold is even finer, with over 99.95% purity, but it is only used for standardization purposes and is not available for jewelry. The most widely used Copper and its alloys are in forms of brasses and bronzes. A Brass is a copper-zinc alloy with 5 - 42 % zinc (CuZn28, CuZn37, CuZn42 etc.). The German name is Messing (Ms58 = CuZn42). Brasses are usually yellow in color. A bronze is an alloy of copper and other metals, most often tin (CuSn6, CuSn10, CuSn14 etc.), phosphorus (PB1C, PB4C, PB3, LPB1C etc.), Manganese(HTB1, HTB2, HTB3 ), but also aluminum (AB1C, AB2C) and leaded (LG1C, LG2C,LG3C, etc.).

Vous aimerez peut-être aussi

- Welding Practice For Duplex-1 PDFDocument18 pagesWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Asme I-2013 Section 62Document28 pagesAsme I-2013 Section 62ahmed messallamPas encore d'évaluation

- Sa 516Document4 pagesSa 516Vipul ShahPas encore d'évaluation

- QU AL ITY: Material Data SheetDocument5 pagesQU AL ITY: Material Data SheetAlex007Pas encore d'évaluation

- Astm A 450Document10 pagesAstm A 450Telmo VianaPas encore d'évaluation

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Pas encore d'évaluation

- Piping - Spec - 요약본 Rev1Document3 pagesPiping - Spec - 요약본 Rev1vangie3339515Pas encore d'évaluation

- Astm A494-A494m-17Document7 pagesAstm A494-A494m-17Gabriel Perez CruzPas encore d'évaluation

- BS3100 CastingDocument1 pageBS3100 Castingrakesh100% (1)

- Heat Treatment: Prepared by Approved byDocument20 pagesHeat Treatment: Prepared by Approved byBhanu Pratap ChoudhuryPas encore d'évaluation

- TRD 301 Annex 1 Design PDFDocument14 pagesTRD 301 Annex 1 Design PDFarjun prajapatiPas encore d'évaluation

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyPas encore d'évaluation

- Afnor 28 CDV 5-08 SteelDocument1 pageAfnor 28 CDV 5-08 SteelMagoroku D. YudhoPas encore d'évaluation

- Asme Sa 106 Grade B PipesDocument1 pageAsme Sa 106 Grade B PipesFerroPipEPas encore d'évaluation

- Tubular Heat ExchangerDocument4 pagesTubular Heat Exchangerprashant_dc_inPas encore d'évaluation

- Aa10208 FINAL - 1Document139 pagesAa10208 FINAL - 1Surendra MalasanePas encore d'évaluation

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivPas encore d'évaluation

- 09 - Replication&Met Evaluation PDFDocument61 pages09 - Replication&Met Evaluation PDFSACHIN PETKARPas encore d'évaluation

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamPas encore d'évaluation

- Astm A193 PDFDocument12 pagesAstm A193 PDFjoserodriguezherazoPas encore d'évaluation

- SB 111-SB 111MDocument14 pagesSB 111-SB 111MRoberto Faustino FaustinoPas encore d'évaluation

- KubotaDocument12 pagesKubotaFebri Ramdani NugrahaPas encore d'évaluation

- ISO 7005-1 2011 Pipe Flanges - Part 1 Steel Flanges For Industrial and General Service Piping SystemsDocument16 pagesISO 7005-1 2011 Pipe Flanges - Part 1 Steel Flanges For Industrial and General Service Piping SystemsSergeyPas encore d'évaluation

- Astm A 494Document7 pagesAstm A 494Rodrigo BarrosPas encore d'évaluation

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasPas encore d'évaluation

- EPRI 3002001465 - Grade 91 Steel HandbookDocument120 pagesEPRI 3002001465 - Grade 91 Steel HandbookWillie NeptunePas encore d'évaluation

- Asme Section II A Sa-302 Sa-302mDocument4 pagesAsme Section II A Sa-302 Sa-302mAnonymous GhPzn1xPas encore d'évaluation

- Type 347-347H Stainless SteelDocument2 pagesType 347-347H Stainless SteelPravin PawarPas encore d'évaluation

- Brochure For SAE J518 O-Ring Assortment KitsDocument1 pageBrochure For SAE J518 O-Ring Assortment KitsChristopher RuizPas encore d'évaluation

- WB 36Document21 pagesWB 36Nitin BajpaiPas encore d'évaluation

- Case 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Document1 pageCase 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Alevj Db100% (1)

- En 13121-3:2008+a1:2010 (E)Document1 pageEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITEPas encore d'évaluation

- Astm A216Document3 pagesAstm A216Ruth Sarai YañezPas encore d'évaluation

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulPas encore d'évaluation

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xPas encore d'évaluation

- AISI 4140 Alloy Steel (UNS G41400) : Topics CoveredDocument3 pagesAISI 4140 Alloy Steel (UNS G41400) : Topics Covereda.mohamedlathifPas encore d'évaluation

- Stellite Welding Will Always Crack PDFDocument4 pagesStellite Welding Will Always Crack PDFsathishjeyPas encore d'évaluation

- CD4 PDFDocument1 pageCD4 PDFMayrym Rey ConPas encore d'évaluation

- BechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiDocument7 pagesBechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiStephen XuPas encore d'évaluation

- Asme Section I Int Vol 57Document25 pagesAsme Section I Int Vol 57dalvarezPas encore d'évaluation

- Effect Chlorine in FreshWaterDocument5 pagesEffect Chlorine in FreshWaterEl Ehsan Abinya FatihPas encore d'évaluation

- Minfm67141 Astm A182 Grade F6a 1 PDFDocument4 pagesMinfm67141 Astm A182 Grade F6a 1 PDFGỗ MộcPas encore d'évaluation

- Alloy286 - ASTM A453 660 DatasheetDocument2 pagesAlloy286 - ASTM A453 660 Datasheetn1ghtfallPas encore d'évaluation

- Duplex Stainless Steel 2507-Spec-SheetDocument2 pagesDuplex Stainless Steel 2507-Spec-SheetAnoob NarayananPas encore d'évaluation

- Sa 351Document6 pagesSa 351Anil0% (1)

- API Standard 660: Shell-and-Tube Heat ExchangersDocument3 pagesAPI Standard 660: Shell-and-Tube Heat ExchangersJessy Prior0% (2)

- Section I 2015Document33 pagesSection I 2015ferds2599Pas encore d'évaluation

- Material Comparisons For Astm and JisDocument2 pagesMaterial Comparisons For Astm and JisNitesh GargPas encore d'évaluation

- Asme II - Part D - ViejaDocument795 pagesAsme II - Part D - ViejafedemochileroPas encore d'évaluation

- Steel 17-4PH MmpdsDocument18 pagesSteel 17-4PH MmpdsManoj ManoharanPas encore d'évaluation

- Asset Integrity Management A Complete Guide - 2020 EditionD'EverandAsset Integrity Management A Complete Guide - 2020 EditionPas encore d'évaluation

- p91 WeldingDocument5 pagesp91 Weldingsaji_t1984100% (1)

- A723A723M-18a 1.05 PDFDocument5 pagesA723A723M-18a 1.05 PDFist93993Pas encore d'évaluation

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- Interpretation System Numbering Material AstmDocument4 pagesInterpretation System Numbering Material AstmAmr ElsayedPas encore d'évaluation

- Standard Designation Metals-2Document12 pagesStandard Designation Metals-2Agustin BolopàPas encore d'évaluation

- Steel Coding SystemDocument5 pagesSteel Coding SystemWell LojuminPas encore d'évaluation

- VPE WorkbenchDocument27 pagesVPE Workbenchmajor_duanPas encore d'évaluation

- EM 1110-1-4008 Engineer Manual, Design Liquid Process Piping (US Army 1999)Document244 pagesEM 1110-1-4008 Engineer Manual, Design Liquid Process Piping (US Army 1999)Bogdan BulgariuPas encore d'évaluation

- Aveva NetDocument8 pagesAveva Netnod1714392Pas encore d'évaluation

- Applying The ASME OM CodeDocument31 pagesApplying The ASME OM Codemajor_duanPas encore d'évaluation

- Introduction To The ASTM Designation SystemDocument6 pagesIntroduction To The ASTM Designation Systemmajor_duanPas encore d'évaluation

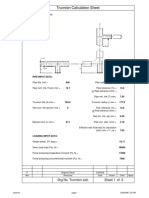

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation SheetRafael SequeiraPas encore d'évaluation

- Stress AnalysisDocument6 pagesStress Analysisapi-3836286100% (4)

- ACI - 318 - 05 Design of Slab PDFDocument24 pagesACI - 318 - 05 Design of Slab PDFtaz_taz3Pas encore d'évaluation

- Piping Inspection HandbookDocument26 pagesPiping Inspection HandbookMdsr Hasan100% (2)

- Piping Inspection HandbookDocument26 pagesPiping Inspection HandbookMdsr Hasan100% (2)

- IRIS IR Inline SeparatorDocument6 pagesIRIS IR Inline SeparatorNistha ChakrabortyPas encore d'évaluation

- List of Indian StandardsDocument3 pagesList of Indian StandardsGarima GuptaPas encore d'évaluation

- Aliplast Katalog enDocument140 pagesAliplast Katalog enJelena GraovčevićPas encore d'évaluation

- Kouga MaintainanceDocument28 pagesKouga MaintainancematshonaPas encore d'évaluation

- Syngo X Workplace EpdDocument8 pagesSyngo X Workplace Epdahmed_galal_waly1056Pas encore d'évaluation

- 2000 Evtm RangerDocument121 pages2000 Evtm RangertheclockworkPas encore d'évaluation

- Level Based Training OutlineDocument11 pagesLevel Based Training OutlinesureshchitraPas encore d'évaluation

- Roofing BrochureDocument15 pagesRoofing BrochureMark ManayonPas encore d'évaluation

- Motorreductores BaldorDocument52 pagesMotorreductores BaldorADRIAN MENDEZ RICARIOPas encore d'évaluation

- Hydro Test ProcedureDocument17 pagesHydro Test Procedureyaser elgoharyPas encore d'évaluation

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Document168 pages(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbidePas encore d'évaluation

- Fuel Oil SystemDocument11 pagesFuel Oil SystemNawin Kumar100% (2)

- MIL-PRF-81309 REV. H - Part17Document1 pageMIL-PRF-81309 REV. H - Part17David WongPas encore d'évaluation

- Sulphur and Its CompoundsDocument3 pagesSulphur and Its CompoundsvinayncskphbPas encore d'évaluation

- Full Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions ManualDocument36 pagesFull Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions Manualardellazusman100% (37)

- CanberraDocument4 pagesCanberraBooksPas encore d'évaluation

- Molded Case Circuit Breakers Vol04 - Tab02Document432 pagesMolded Case Circuit Breakers Vol04 - Tab02susanalopzPas encore d'évaluation

- Model 400A Hydrocarbon Analyzer: Instruction ManualDocument90 pagesModel 400A Hydrocarbon Analyzer: Instruction ManualFB'ne Khoriq Ragil DwPas encore d'évaluation

- Robertson #3 Liq 2021 LiqDocument27 pagesRobertson #3 Liq 2021 LiqRenathielly Fernanda da SilvaPas encore d'évaluation

- 9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏDocument80 pages9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏnabil160874100% (2)

- PDF Data Sheet Rigoft Lamibind 420Document2 pagesPDF Data Sheet Rigoft Lamibind 420kavilvPas encore d'évaluation

- Textile Finishing IntroductionDocument14 pagesTextile Finishing IntroductionSENTHIL KUMAR100% (6)

- DL8000 Emerson PDFDocument322 pagesDL8000 Emerson PDFAgustin AguilarPas encore d'évaluation

- HT 521 86151 307 ENDocument5 pagesHT 521 86151 307 ENEdward AguillónPas encore d'évaluation

- Improved Chulhas - Final-1Document60 pagesImproved Chulhas - Final-1erkiruthirajPas encore d'évaluation

- AEC Air Eraser Parts ListDocument2 pagesAEC Air Eraser Parts Listspaced_boyPas encore d'évaluation

- Aluminum Cladding Part 03Document7 pagesAluminum Cladding Part 03Anonymous ELujOV3Pas encore d'évaluation

- Cantilever PriceDocument3 pagesCantilever Pricelangit biruPas encore d'évaluation

- CALOR EMAG Bag.1 PDFDocument10 pagesCALOR EMAG Bag.1 PDFAditya AgasiPas encore d'évaluation