Académique Documents

Professionnel Documents

Culture Documents

Tubing Tables Referencias

Transféré par

ginozkyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tubing Tables Referencias

Transféré par

ginozkyDroits d'auteur :

Formats disponibles

WO 0102 Tubing Table Cover03 6/27/03 10:53 AM Page T-1

Tubing Reference

Tables 2003

Listings for

pipe sizes

to 5in. OD

Copyright 2003 Gulf Publishing Co. All rights reserved.

For additional copies contact Gulf Publishing Co. for complete details.

Phone: 713-520-4425. Fax: 713-520-4433. E-mail: reprints@gulfpub.com

Attention: Marie Faber

Mailing Address: Gulf Publishing Co., P.O. Box 2608, Houston, TX 77252, U.S.A.

WO 01 TUBING TABLES 2003-1 6/27/03 10:49 AM Page T-3

These tables are intended as a guide when planning tubing programs. However, individual manufacturer representatives should be consulted before making final decisions.

Minimum joint tension strengths are available in expanded

tables on our website at: www.worldoil.com.

About The Cover On Helmerich & Payne rig 181, a crew drills

with 3 12 -in., 533 tubing during December 2002.

The Shell E&P wellsite is in Hidalgo County, South Texas, near

the town of Linn. (Photo courtesy of Hydril Co.)

Contents

TKC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .T-16

TS-HP . . . . . . . . . . . . . . . . . . . . . . . . . . . .T-16

TS-HD . . . . . . . . . . . . . . . . . . . . . . . . . . . .T-16

SEAL-LOCK HT . . . . . . . . . . . . . . . . . . . . .T-17

Hydril . . . . . . . . . . . . . . . . . . . . . . . . .T-17 to T-18

Series 500 Type 533 . . . . . . . . . . . . . . . . .T-17

Series 500 Type 553 . . . . . . . . . . . . . . . . .T-17

Series 500 Type 503 . . . . . . . . . . . . . . . .T-17

Series 500 Type 563 . . . . . . . . . . . . . . . . .T-17

Series 500 Type 511 . . . . . . . . . . . . . . . . .T-18

Series 500 Type 513 . . . . . . . . . . . . . . . . .T-18

Kawasaki Steel/Hunting Oilfield Services. . .T-18

Fox Premium Connection . . . . . . . . . . . . .T-18

KSBEAR . . . . . . . . . . . . . . . . . . . . . . . . . .T-18

Mitsubishi Corp. . . . . . . . . . . . . . . . . . . . . . . .T-18

SUPERMAX . . . . . . . . . . . . . . . . . . . . . . . .T-18

Nippon Steel Corp. . . . . . . . . . . . . . . . . . . . . .T-20

NS-CT . . . . . . . . . . . . . . . . . . . . . . . . . . .T-20

Star Fiber Glass Systems, L.P. . . . . . . . . . . . .T-20

Advanced Composite Thread . . . . . . . . . .T-20

Tenaris . . . . . . . . . . . . . . . . . . . . . . . .T-20 to T-22

Formerly Dalmine, NKK and Siderca

Tenaris Blue . . . . . . . . . . . . . . . . . . . . . . .T-20

Antares MS . . . . . . . . . . . . . . . . . . . . . . .T-21

Antares MS28 . . . . . . . . . . . . . . . . . . . . .T-21

Antares MS XT/XC . . . . . . . . . . . . . . . . . .T-20

Antares MS28 XT/XC . . . . . . . . . . . . . . . . .T-21

Antares PJD Tubing . . . . . . . . . . . . . . . . .T-21

NK3SB . . . . . . . . . . . . . . . . . . . . . . . . . . .T-22

Atlas Bradford . . . . . . . . . . . . . . . . . .T-10 to T-12

Atlas Bradford HD-L . . . . . . . . . . . . . . . . .T-10

Atlas Bradford RTS-6 . . . . . . . . . . . . . . . .T-10

Atlas Bradford RTS-8 . . . . . . . . . . . . . . . .T-10

Atlas Bradford SB-6 . . . . . . . . . . . . . . . . .T-10

Atlas Bradford SB-8 . . . . . . . . . . . . . . . . .T-10

Atlas Bradford FL-4S . . . . . . . . . . . . . . . .T-10

Atlas Bradford ST-L . . . . . . . . . . . . . . . . .T-12

Atlas Bradford TC-4S . . . . . . . . . . . . . . . .T-12

Atlas Bradford TC-II . . . . . . . . . . . . . . . . .T-12

Benoit Machine, Inc. . . . . . . . . . . . . .T-12 to T-13

BTS-6 . . . . . . . . . . . . . . . . . . . . . . . . . . .T-12

BTS-6U . . . . . . . . . . . . . . . . . . . . . . . . . .T-12

BTS-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . .T-12

Echo/F4 . . . . . . . . . . . . . . . . . . . . . . . . . .T-13

Echo/SS . . . . . . . . . . . . . . . . . . . . . . . . . .T-13

CENTRON International Inc. . . . . . . . . . . . . . .T-13

DH Tubing . . . . . . . . . . . . . . . . . . . . . . . .T-13

DH8 Tubing . . . . . . . . . . . . . . . . . . . . . . .T-13

Halliburton Energy Services . . . . . . . . . . . . . .T-13

Oeco A&B . . . . . . . . . . . . . . . . . . . . . . . .T-13

Oeco C&D . . . . . . . . . . . . . . . . . . . . . . . .T-13

HSC Corporation . . . . . . . . . . . . . . . . . . . . . . .T-13

HSC Tubing . . . . . . . . . . . . . . . . . . . . . . .T-13

Hunting Oilfield Services. . . . . . . . . .T-16 to T-17

TKC 4040 . . . . . . . . . . . . . . . . . . . . . . . . .T-16

TKC Convertible . . . . . . . . . . . . . . . . . . . .T-16

SEAL-LOCK HD LOCK-IT . . . . . . . . . . . . . .T-16

TKC MMS . . . . . . . . . . . . . . . . . . . . . . . . .T-16

SEAL-LOCK FGL . . . . . . . . . . . . . . . . . . . .T-16

TPS Technitube Rhrenwerke . . . . . . . . . . . .T-22

TPS-Multiseal-TS 4 . . . . . . . . . . . . . . . . .T-22

TPS-Multiseal-TS 6/TS 6 TR . . . . . . . . . . .T-22

TPS-Non-Upset Optiflow . . . . . . . . . . . . . .T-22

TPS-Multiseal-TS 8/TS 8 TR . . . . . . . . . . .T-22

TPS-External-Upset Optiflow . . . . . . . . . . .T-22

Techniseal . . . . . . . . . . . . . . . . . . . . . . . .T-22

Tubular Fiberglass Corp. . . . . . . . . . . . . . . . .T-23

RED BOX Tubing . . . . . . . . . . . . . . . . . . . .T-23

VAM Family Vallourec & Mannesmann Oil & Gas

France, Vallourec & Mannesmann Oil & Gas Germany

GmbH, Vallourec Mannesman Oil & Gas UK Ltd., VAM

PTS, VAM Premium Connections, Prinver SA de CV,

Vallourec & Mannesmann Tubes - V&M do Brasil,

Vallourec & Mannesmann Tubes Corp., Sumitomo

Metal Industries, Ltd. . . . . . . . . . . . . .T-23 to T-26

NEW VAM . . . . . . . . . . . . . . . . . . . . . . . . .T-23

VAM ACE . . . . . . . . . . . . . . . . . . . . . . . . .T-23

VAM ACE Modified . . . . . . . . . . . . . . . . . . .T-23

VAM FJL . . . . . . . . . . . . . . . . . . . . . . . . . .T-26

VAM ACE XS/XS-C . . . . . . . . . . . . . . . . . .T-26

VAM PRO . . . . . . . . . . . . . . . . . . . . . . . . . .T-26

VAM TOP . . . . . . . . . . . . . . . . . . . . . . . . . .T-26

VAM TOP HT . . . . . . . . . . . . . . . . . . . . . . .T-26

Dimension nomenclature

D = Nominal OD of tube, in.

w = Tubing weight, lb/ft

d = ID (drift), in.

t = Tubing wall thickness, in.

Dc = Connection OD, in.

Dsc = Connection OD (special

clearance or turned down), in.

At = Tubing wall critical crosssectional area, sq. in.

Dsc

Dc

Lm

Lm

Dc

Dc

Lm

Ac = Connection critical crosssectional area, sq in.

Lm = Make-up loss, in.

Dsc

World Oil JANUARY 2003

T-3

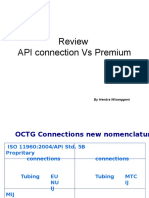

2003 Tubing Reference Tables

World Oils updated tables for pipe sizes to 5-in. OD or

production-tubing-specific couplings provide information

on premium connection dimensions and available steel

grades. Tables are organized by connnection manufacturing company name, and listings show page numbers for cutaway diagrams (not to scale) for visual cross reference with

tabular data. Coupling type and sealing mechanism follow

manufacturer and coupling name or designation. Critical

tubular and connection areas can be used with minimum

yield or ultimate strengths in designs and to calculate coupling tensile capacity. For your convenience, connection

manufacturer contact information appears on page T-27.

2003 Tubing Reference Tables

WO 01 TUBING TABLES 2003-1 6/27/03 10:49 AM Page T-4

D

d

D

d

ATLAS BRADFORD RTS-6,

PR and Special Clearance

connections have a two-step

thread that offers tensile,

burst and collapse ratings

equal to or exceeding that

of the pipe body. Metal seals

maintain pressure integrity

while straight thread profile

eliminates high connection

stresses. Shoulders provide

high compressive strength

and high torque capabilities.

For tubulars requiring internal plastic coating, a Teflon

and fiberglass ring (shown)

is incorporated in connection box.

ATLAS BRADFORD HD-L is

a premium flush OD connection that provides superior

pressure resistance and

structural integrity. Connector design features identical

5 radial metal-to-metal

internal and external pressure seals rated to API internal and collapse pressure

ratings for pipe body. It has a

robust hooked thread form

that resists cross-threading

and jump-out, equal critical

areas in tension and compression. It exhibits excellent resistance to cyclical,

combined loading including

bending, and has been successfully used for severe

applications in straight and

directional wells.

ATLAS BRADFORD RTS-8,

PR and Special Clearance

connections have a two-step

thread that offers tensile,

burst and collapse ratings

equal to or exceeding that of

the pipe body. Metal seals

maintain pressure integrity

while straight thread profile

eliminates high connection

stresses. Modified buttress

thread and multiple torque

shoulders provide high compressive strength and high

torque capabilities. Available

with PR ring.

D

d

ATLAS BRADFORD SB-6, 8

(Special Bore) is a version of

the RTS connection with

slightly increased diameter

allowing bored upset ID to

have a finished diameter

equal to pipe body nominal

ID, eliminating standard twostep tubing connector internal restriction. It offers

reduced turbulence, easier

wireline tool running, more

uniform plastic coating and

reduced wireline damage of

plastic coating, and is

machined on standard twostep upsets. Standard RTS

design features are incorporated, providing full pressure

and tension ratings.

ATLAS BRADFORD FL-4S

is a premium quality tubing

and casing connection featuring Quadraseal design

with metal-to-metal pin

flank seal, trapped Teflon

back-up seal, tapered modified buttress thread and

external shoulder with trapping angle for exclusive fourway protection against leakage. It provides high joint

strength, maximum running

clearance, flush OD and

optimum efficiency for every

wall thickness.

d

D

d

d

Dc

Dc

Lm

Lm

Lm

Lm

t

t

ATLAS BRADFORD TC-4S is

a high-integrity connection

that uses the Quadraseal system. Initial seal is a 15

reversed angle torque shoulder backed-up by metal-tometal pin flank and a back of

box seal that forms a second

mechanical seal. Patented

thread entrapped Teflon ring

forms a third barrier. Modified buttress thread for easy

stabbing, fast make-up and

built-in resistance to back off

forms the fourth multiple seal

system member.

T-4

ATLAS BRADFORD TC-II is

the latest generation premium

threaded and coupled tubing

and casing connection. Developed to replace the TC-4S, it

features modified buttress

tapered run-out thread,

metal-to-metal internal radial

flank seal, optional resilient

Teflon seal ring as backup to

primary metal-to-metal seal,

15 reverse internal torque

shoulder, smooth ID bore and

minimized coupling OD. Performance exceeds pipe body

ratings in internal pressure,

external pressure, tension and

compression.

JANUARY 2003 World Oil

BENOIT BTS is a two-step,

multiseal integral joint connection designed for superior performance and durability. It comes with six pitch

(BTS-6) and eight pitch (BTS8) threads and is available

with a protective ring for

coated tubing.

BENOIT ECHO/F4 is offered

in tubing sizes from 238 to 5

in. It has a flush OD with a

swaged and bored pin end.

Multiple seals include

trapped 15 torque shoulder/ external seal, metal-tometal pin flank seal, interference thread seal, optional

teflon ring, and features

maximum efficiency for

every weight.

BENOIT ECHO/SS is a premium integral connection for

applications requiring high

joint strength and maximum

resistance to leakage in

deep, high-pressure wells. It

has multiple seals, which

include shoulder, teflon and

interference thread seals. SS

is available with metal-tometal pin flank seal and PR

ring for coating.

ATLAS BRADFORD ST-L is a

flush OD premium tubing

connection featuring negative-angle load flanks and

twin lead threads to provide

superior strength. Radial

metal-to-metal seals and

optional seal ring provide

protection against internal

and external pressures.

Trapped 15 external torque

shoulder withstands high

make-up torque. Designed

for easy stabbing and fast

make-up.

WO 01 TUBING TABLES 2003-1 6/27/03 10:49 AM Page T-5

D

d

d

d

Dc

Lm

Dsc

Lm

Lm

Dc

Dc

Lm

Dsc

Dc

Lm

Lm

Dc

Dc

DH & DH8

CENTRON INTERNATIONAL

INC. tubing is available in

two joining systems: DH and

DH8 Centron's premium 4thread-per-inch connectors

feature a coarse, shallowangle thread form that is

rugged and more resistant

to stab damage and cross

threading. They feature Oring seals that prevent fluid

penetration into the threadseal area and keep dope in

place. Excess dope is prevented from entering the formation injection applications,

thus minimizing the need for

acidizing. The other joining

system, DH8, is the standard

API 8rd EUE connection.

HALLIBURTON Oeco Type A

is an integral joint, two-step

straight thread connection

with metal-to-metal pin flank

seal and outer tapered shoulder that provides a seal and

a make-up point. Straight

thread design minimizes

hoop stress, permitting fast

make-up and break-out.

Oeco Type B is an identical

connection with corrosion

protection ring.

HALLIBURTON Oeco Type C

thread is designed for

medium weight pipe. It provides the same integral joint,

sealing, fast make/break and

over 100% efficiency as Type

A, but the heavier make-up

shoulder makes it especially

suitable for workstrings and

completions. Type D provides

corrosion protection ring.

Dsc

Dc

Lm

Dc

Lm

HSC CORP. HSC tubing is a

non-upset threaded and coupled premium connection

with a tapered thread and

metal-to-metal seal. The seal

is maximized by storing the

torqued energy across the

20 shoulder. With the HSC

coupling, joint performance

exceeds the tensile strength

of the pipe body.

d

d

Lm

Lm

Dc

Lm

Dsc

t

t

Hunting Oilfield Services

TKC MMS is a holiday-free,

internal flush tubing connection when used in conjunction with properly coated API

EUE pipe. Applications with

severe corrosion such as wet

CO2 injection and disposal

wells benefit most. It combines a proprietary coupling

and gauging system to precisely assemble connections,

which reduces average compressive stresses in pin and

allows use of a polymeric

center seal to bridge coated

pin surfaces. This seal has

been proven to withstand

repeated make/break.

Hunting Oilfield Services

SEAL-LOCK HD LOCK-IT is

threaded and coupled on

plain end, non-upset tubes.

Special clearances are available. Tension strength, even

hand tight, exceeds full pipe

body yield strength of the for

all sizes, weights and grades.

Auxiliary resilient pressure

seal rings are available. Low

stress assemblies are suitable for corrosive environments. Negative load flank

threads provide for operating loads to pipe body yield as

a minimum.

Dc

Dc

Dsc

Hunting Oilfield Services

SEAL-LOCK LOCK-IT-EIGHT

is an economical plain end,

non-upset thread-ed and

coupled connection for light

weights of 1.5 through 3.5-in.

pipe. Hooked threads and

gas-tight metal-to-metal seal

provide tensile and internal

pressure ratings equal to pipe

body yield. Clearance coupling diameters are standard.

Hunting Oilfield Services

TKC Convertible upgrades

coupling for critical applications. Converter ring is press

fit into J area of coupling

and provides a smooth bore

and positive torque stop that

is ideal for workstring. With

torque adjustment, to allow

for sufficient bearing pressure, converter ring produces

a metal-to-metal seal with

pressure integrity in excess

of pipe body in tubing sizes.

D

d

Dsc

Hunting Oilfield Services

SEAL-LOCK FGL combines

performance and pressure

integrity of metal-to-metal

sealing with corrosion resistance of fiberglass lining. This

plain end threaded and coupled connection is mated

with Rice Engineerings DUOLINE liner for unsurpassed

performance in CO2 injection/prodution applications.

Hunting Oilfield Services

TKC 4040 tubing connections provide superior durability in non-upset configuration. Converter ring is

press-fit into J area of coupling and provides an internal torque stop and an axially

loaded metal-to-metal seal.

Hunting Oilfield Services

TKC is a simplified version

of standard TKC 8RD, featuring straight counterbore,

bevelled OD and shorter

length. It continues to provide proper make-up when

used with API 8RD threads.

Internal shoulder provides

positive torque stop and

metal-to-metal seal when

using pins meeting TKC pin

end finish specification. It can

withstand bending and torsional loads downhole within

design parameters. Separate

internal seals block pressure

from thread-ed area allowing threads to serve principally as tensile members.

World Oil JANUARY 2003

T-5

2003 Tubing Reference Tables

2003 Tubing Reference Tables

WO 01 TUBING TABLES 2003-1 6/27/03 10:49 AM Page T-6

D

d

D

d

Dc

Lm

Dc

Lm

Dc

Dc

Hunting Oilfield Services

TS-HP and TS-HD are upset,

integral, two-step tubing connections designed for critical well applications. The

parallel/non-interference

thread form ensures fast,

easy-running characteristics

while allowing for multipletrip capability. Multiple,

metal-to-metal seals and a

large torque shoulder provide rugged, dependable critical well service. An optional

ring is available for plastic

coating applications.

Hunting Oilfield Services

SEAL-LOCK HT is a new

threaded and coupled tubing connection designed for

high torque and deviated

hole applications. It utilizes a

patented hooked thread

design for sealing and a

unique pin to pin torque

shoulder to provide enhanced torsional and bending capabilities. A rugged

thread form and advanced

connection geometry results

in deep stabbing and quick

make-up without cross

threading. High performance

and cost-effective.

Hydril Series 500 Type 533

Tubing is recommended for

most demanding production

tubing and workstring applications. An integral connection machined on internal/

external upset ends, Type

533 provides pipe body

strength combined with the

sealing reliability of a metal

seal. Type 533 is available

with optional CB feature and

is interchangeable with Types

503, 553 and 563.

D

D

d

Hydril Series 500 Type 553

Tubing is recommended for

production tubing applications and workstring service. It combines benefits of

an integral connection with

the reduced cost of one end

internal/external upset (OEU)

pipe. It provides excellent

structural characteristics of

the dovetail Wedge Thread

with the high-pressure gas

sealing reliability of a metalto-metal seal. Type 553 is

available with optional CB

feature and is interchangeable with Types 503, 533

and 563.

Hydril Series 500 Type 503

Tubing is offered on the

lightest API tubing weights

for production tubing and

workstring applications. It is

an integral connection

machined on long API external upset ends providing pipe

body strength along with a

metal seal. Type 503 is interchangeable with Types 533,

553 and 563 in a given size

and weight.

Dc

Lm

Dc

Dc

Dc

Lm

dc

Lm

Lc

Dsc

Dc

Type 511 & 513

Hydril Series 500 Type 511

and Type 513 in tubing

sizes is recommended for

repair string, scab liner and

horizontal applications.

Machined on non-upset

threads, their overall structural capability with integral

connections combined with

pipe-body OD allow these

types to be used for horizontal liners in re-entry

wells, relatively long repair

strings and slimhole liners.

T-6

JANUARY 2003 World Oil

KAWASAKI STEEL/HUNTING OILFIELD SERVICES/

HUNTING Fox is a premium

coupled connection plain end

tubing and casing, providing

full pipe-rated strength in

tension, burst, collapse and

bending. Advanced contoured seal and shoulder

design provide superior sealing performance and high

resistance to over-torque.

Design resists back-off from

thermal shock and impact by

storing a high level of energy

in mating parts during makeup. A unique change in

thread pitch reduces highstress concentrations and

provides a more even load

distribution among threads.

MITSUBISHI CORP. SUPERMAX is a non-upset, coupled

type connection that outperforms API EUE with lesser

cost. Both flanks engage to

provide leak resistance equivalent to pipe body and 2

degrees load flank and runout thread provide tensile

strength equal to pipe body

making this an ideal alternative for API EUE applications,

low pressure gas well applications, applications requiring

smaller OD than EUE but

higher joint strength than NUE

and ideal for reclamation of

EUE tubing with insufficient

upset length.

NIPPON STEEL CORP. NS-CT

is a field-proven, high-performance threaded and coupled connection. It combines

the rugged buttress thread

form with a patented two-step

pin nose and high-pressure,

gas-tight metal-to-metal seal.

It provides a joint strength

greater than pipe-body yield

strength on API tubing while

maintaining low hoop stress in

the coupling, which is ideal

for H2S environments. The

recess-free bore allows for

less turbulent flow. Excellent

anti-gall performance for carbon and high chrome materials is demonstrated in API 5C5

testing and in the field. NSCT has full interchange ability

in a size range.

STAR FIBER GLASS SYSTEMS ACT Coupled casing

features premium molded API

8RD EUE long form threaded

and coupled connection.

Threads are molded for

smooth, sealed, corrosionresistant thread surface with

graphite and ceramic reinforcement, which provides

lower breakout torque values.

Precision threads use graphite

as an added lubricant to avoid

damage and wear. It is

designed and manufactured

to resist creep, maximize tensile strength and guarantee

breakout. Laminate handles

up to 4,000 psi at 200F.

Hydril Series 500 Type 563

Tubing is recommended for

moderate- to very-heavy wall

pipe for production tubing

applications. This threaded

and coupled connection

combines the structural characteristics of the dovetail

Wedge Thread with the sealing reliability of a metal seal.

It has been selected for use

on high alloy and stainless

steels as well as on carbon

steel where upsets are not

available. Type 563 is available with optional CB feature

and is interchangeable with

Types 503, 533 and 553.

WO 01 TUBING TABLES 2003-1 6/27/03 10:50 AM Page T-7

D

d

d

d

Lm

Dc

Lm

Dc

Lm

Dc

Dc

Lm

Dsc

STAR FIBER GLASS SYSTEMS ACT Integral casing

features premium molded API

8RD EUE long form integral

joint connection. Threads are

molded for smoother, sealed,

corrosion-resistant thread

surface with graphite and

ceramic reinforcement, which

provide lower breakout torque

values. Precision threads use

graphite as an added lubricant to avoid thread damage

and wear. It is designed and

manufactured to resist creep,

maximize tensile strength and

guarantee breakout. Laminate

handles up to 4,000 psi at

200F.

D

d

TENARIS BLUE is a high performance premium connection specially designed to

cover demanding service

conditions. Optimized thread

and seal design provide

excellent sealing performance

and structural capacity under

high compression, bending

and overtorque requirements.

The dopeless option reduces

environmental impact by

avoiding standard dopes.

TenarisBlue is suitable for use

with carbon steel and CRA

steel grades. Available in tubing and casing sizes from 2 38

in. to 13 38 in.

D

d

TENARIS ANTARES MS

and MS XT/XC (metal seal)

is an improved metal-tometal seal connection that

out performs other single

metal seal and API connections. Coupled efficiency is

equivalent to pipe body. Pin

end, with protected tapered

sealing surface, is cut on

pipe body. Box end energizes tapered sealing surface through reverse angle

internal torque shoulder.

TENARIS ANTARES MS28

and MS28 XT/XC tubing

connections fill requirements

of deep, sour hydrocarbon

wells. It is designed for easy

stabbing and make-up and to

withstand field handling. It

is capable of withstanding

high mechanical stress while

providing gas-tight sealing

at full pressure rating in the

worst possible conditions,

and is for use with corrosionresistant alloys (CRA).

D

d

D

d

TENARIS PJD (Premium

Joint Dalmine) is an integral

joint, upset tubing connection. Turned OD and bored

ID allow maximum clearance

and product flow. Primary

external torque shoulder and

secondary reverse angle

shoulder ensure proper

make-up and stress resistance. High-performance,

conical modified buttress

threads exceed pipe body

strength. Internal metal-tometal seal remains fully functional after repeated makeup, providing excellent leak

resistance for high-pressure

wells.

TENARIS NK3SB is a

threaded and coupled type

premium connection for

standard wall non-upset tubing designed to maintain high

leak resistance without pipeend work because of proper

thickness in main-seal area.

It has a smooth bore, sliding

with tangent point contact

and internal shoulder metalto-metal seals, positive

torque stop, 0 load flank

and 45 stabbing flank for

leak proof, high joint

strength, easy stabbing and

running, and repeatable

make-up.

D

d

Dc

Dc

Lm

Lm

Dc

TPS TECHNITUBE TPS Multiseal-TS-4 is a high-performance, premium, two-step

integral joint connection for

high-pressure service. Available with medium and heavyweight tubing. Thread profile

with multiple metal-to-metal

seals and torque shoulders

utilizes four threads per in.

Increased upset length guarantees 90% repairability by

recutting in case of thread

damage.

TPS TECHNITUBE TPS-Multiseal-TS6 is a high performance, two-step integral

connection for high-pressure

service, and medium and

heavy weights of tubing. Twostep non-interference thread

profile with multiple metalto-metal pressure seals and

torque shoulders uses a

thread pitch of six threads

per in. Increased upset length

guarantees 90% repairability by recutting in case of

thread damage. TS 6 TR version includes a teflon ring.

TPS TECHNITUBE TPS-Optiflow couplings for standard

API EUE and NUE tubing are

gas-tight and eliminate flow

turbulence, particularly on

internally plastic-coated tubing. Modified, closer tolerance API 8RD threads incorporate pin-to-pin recess

cross bridge for of interior

surface and coating continuity. Two profiled HG-seal rings

placed in special profiled

grooves in coupling thread

profiles protect against corrosive attacks.

TPS TECHNITUBE TPS-Multiseal-TS8 is a high-performance, premium, two-step

integral joint connection for

high-pressure service and

standard weight tubing.

Thread profile incorporates

multiple pressure seals and

torque shoulders for optimum

sealing integrity, easy stabbing and fast make-up. Tension, yield and collapse

strength exceed tube body.

Increased upset length guarantees 90% repairability by

recutting in case of thread

damage. TS 8 TR version

includes a teflon ring.

TPS TECHNITUBE TPS-Techniseal is a high-performance,

non-upset tubing and casing

coupling with buttress-type

threads, high-compession

tapered metal-to-metal seal

and reverse angle shoulder.

Full pipe strength is provided

for tension, compression,

bending, and internal and

external pressures. It will withstand repeated make/break

and is fast running, and flush

ID minimizes corrosion/erosion. It is also recommended

for high-strength and special

alloy materials.

World Oil JANUARY 2003

T-7

2003 Tubing Reference Tables

2003 Tubing Reference Tables

WO 01 TUBING TABLES 2003-1 6/27/03 10:50 AM Page T-8

D

d

d

Dc

Lm

Lm

Dc

Lm

Dc

Dc

Lm

Lm

Dc

TUBULAR FIBERGLASS

RED BOX fiberglass tubing

is an external upset, integral connection. It features

conventional API 8RD LTC

threads that allow direct tiein to packers and wellhead

equipment without changeovers. Laminate construction holds pressure without

use of a sealing liner. Highly

corrosion resistant, it is

available in multiple pressure classifications up to

3,000 psi at 210F. Tubing

features reusable fiberglass

connection that can be

installed with controlled

torque power tongs.

VAM ACE MODIFIED has the

same design and performance as the VAM ACE

except for a sturdier reverseangle torque shoulder that

makes this connection ideal

for high-torque applications.

VAM ACE (All Critical Environments) is a new type of

connection, the heart of

which is a reliable metal-tometal configuration. This low

angle-tapered interference

seal is further energized by

reverse angle torque shoulder and self energized by

internal pressure. It was

designed for use with CRA

material. Copper plating process applied to coupling

allows rejection rate during a

stainless steel tubing completion to be as low as carbon steel. Design systematically offers greater than

100% efficiency compared

to pipe body.

NEW VAM is a non-upset

connection with a tapered

metal-to-metal seal energized by reverse angle shoulder. Buttress-type thread and

coverage of vanishing

threads allow maximum efficiency. Standard coupling is

designed for greater than

100% efficiency. 6 mating

chamfer reduces tolerances

ID, and a long shoulder minimizes turbulence and energy

losses inside tubing. T and C

design allows easy repair. It

can be delivered with 20

bevel on couplings.

D

d

Lm

Dc

Lm

Dc

Lm

VAM ACE XS-C, an upset

integral version of XS,

includes features of VAM

ACE XS and is coatable.

Elastomer ring located at

internal shoulder enables

reliable and easy internal

plastic coating for use with

highly corrosive fluids.

T-8

JANUARY 2003 World Oil

VAM PRO is a highly versatile T&C premium connection for gas-tight sealing of

tubing and casing in medium

to deep wells. This connection was specifically

designed to enhance rig

operating costs by maximizing ease of handling, ensuring running reliability and

reducing running time.

VAM TOP provides tubing

performances in casing sizes

and is now also available for

tubing sizes. New steep taper

metal-to-metal seal design

ensures gas-tight pressure

integrity for large-OD tubing

and production casing

strings, even under severe

mechanical and thermal

combine loads. It is suitable

for all types of materials and

ideal for horizontal or deviated wells.

VAM TOP HT has the same

design and performance as

the VAM TOP except for an

enhanced torque shoulder.

This design is ideal for applications where high torque is

anticipated.

VAM FJL is a flush joint liner

connection providing maximum running clearance and

optimum strength for moderate depths. It offers true

flush OD for maximum clearance, ID bored to greater

than drift diameter and

recess-free ID to reduce turbulence. Interference tapered

thread has 15 reverse load

flank for load transmission

and jump-out prevention, and

45 stabbing flank for easy

running and resistance to

damage. It also provides

resistance to cross-threading. It is designed for 65%

efficiency under tension on

medium wall tubing.

2003 Tubing Reference Tables

WO 01 TUBING TABLES 2003-1 6/27/03 10:50 AM Page T-10

Atlas Bradford HD-L

Type: Integral flush joint

D

w

d

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

5.000

5.30

5.95

6.20

7.70

6.50

7.90

8.70

9.50

10.70

9.30

10.30

12.95

15.80

11.00

11.60

13.40

11.60

12.75

13.50

15.10

16.90

19.20

21.60

15.00

18.00

20.30

20.80

21.40

22.40

23.20

24.10

1.845

1.773

1.759

1.609

2.347

2.229

2.165

2.101

1.997

2.867

2.797

2.625

2.423

3.351

3.303

3.215

3.875

3.833

3.795

3.701

3.615

3.515

3.375

4.283

4.151

4.059

4.031

4.001

3.951

3.919

3.875

Diagram p. T-4

Seal: Metal-to-metal

t

Dc

0.218

0.254

0.261

0.336

0.217

0.276

0.308

0.340

0.392

0.254

0.289

0.375

0.476

0.262

0.286

0.330

0.250

0.271

0.290

0.337

0.380

0.430

0.500

0.296

0.362

0.408

0.422

0.437

0.462

0.478

0.500

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

5.000

Dsc

At

Ac

Lm

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.477

1.692

1.733

2.152

1.812

2.254

2.484

2.708

3.058

2.590

2.915

3.682

4.522

3.077

3.337

3.805

3.338

3.600

3.836

4.407

4.918

5.498

6.283

4.374

5.275

5.886

6.069

6.264

6.587

6.791

7.069

0.710

0.885

0.913

1.139

0.885

1.194

1.349

1.467

1.727

1.392

1.717

1.970

2.790

1.695

1.861

2.046

1.773

1.901

2.023

2.316

2.641

3.194

3.979

2.013

2.736

3.317

3.500

3.695

3.987

4.191

4.469

2.53

3.12

3.21

4.66

2.55

3.62

4.38

3.70

3.90

3.45

4.25

3.72

4.88

3.39

3.76

3.62

3.34

3.51

3.68

4.26

3.61

3.98

5.09

3.19

3.68

4.03

4.29

4.58

4.39

4.65

4.99

Atlas Bradford RTS-6

Type: Upset integral joint

D

w

d

2.375

2.375

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

4.70

5.95

6.50

7.90

7.70

9.30

10.30

12.95

9.50

11.00

11.60

9.50

10.50

11.00

11.60

12.75

13.50

11.50

13.00

15.00

18.00

1.901

1.773

2.347

2.229

2.943

2.867

2.797

2.625

3.423

3.351

3.303

3.965

3.927

3.901

3.875

3.833

3.795

4.435

4.369

4.283

4.151

Diagram p. T-4

Seal: Metal-to-metal

t

Dc

0.190

0.254

0.217

0.276

0.216

0.254

0.289

0.375

0.226

0.262

0.286

0.205

0.224

0.237

0.250

0.271

0.290

0.220

0.253

0.296

0.362

2.375

2.375

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

Dsc

At

Ac

Lm

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.304

1.692

1.812

2.254

2.228

2.590

2.915

3.682

2.680

3.077

3.337

2.766

3.009

3.174

3.338

3.600

3.836

3.304

3.773

4.374

5.275

0.531

0.877

0.751

1.175

0.927

1.343

1.458

2.312

1.111

1.615

1.746

1.136

1.253

1.327

1.728

1.879

2.012

1.370

1.958

2.298

3.310

1.52

2.05

1.47

2.10

1.64

2.05

2.13

3.85

1.68

2.07

2.12

1.59

1.67

1.73

2.11

2.05

2.13

1.65

2.06

2.14

3.82

Atlas Bradford RTS-8

Type: Upset integral joint

D

w

d

1.050

1.050

1.315

1.315

1.660

1.660

1.660

1.900

1.900

1.900

2.063

2.063

2.375

2.375

2.875

3.500

3.500

4.000

4.500

4.500

T-10

1.20

1.50

1.80

2.25

2.40

3.02

3.24

2.90

3.64

4.19

3.25

4.50

4.70

5.30

6.50

9.30

10.30

11.00

12.75

13.50

0.730

0.648

0.955

0.863

1.286

1.184

1.170

1.516

1.406

1.368

1.657

1.519

1.901

1.845

2.347

2.867

2.797

3.351

3.833

3.795

Diagram p. T-4

Seal: Metal-to-metal

t

Dc

0.113

0.154

0.133

0.179

0.140

0.191

0.198

0.145

0.200

0.219

0.156

0.225

0.190

0.218

0.217

0.254

0.289

0.262

0.271

0.290

JANUARY 2003 World Oil

1.327

1.327

1.552

1.600

1.883

1.927

1.927

2.113

2.162

2.179

2.330

2.460

2.700

2.750

3.210

3.915

3.915

4.417

4.920

4.955

Dsc

At

Ac

Lm

1.300

....

1.525

....

1.858

....

....

2.094

....

....

2.295

2.407

2.655

2.700

3.166

3.859

....

4.359

4.861

4.890

0.333

0.433

0.494

0.639

0.669

0.881

0.909

0.799

1.068

1.157

0.935

1.299

1.304

1.477

1.812

2.590

2.915

3.077

3.600

3.836

0.333

0.433

0.494

0.639

0.669

0.881

0.909

0.799

1.068

1.157

0.935

1.299

1.304

1.477

1.812

2.590

2.915

3.077

3.600

3.836

2.22

2.22

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.31

2.31

2.39

2.84

2.84

2.84

2.89

2.89

Atlas Bradford SB-6

Type: Upset integral joint

D

w

d

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

4.000

4.000

4.500

4.500

5.000

5.000

5.95

6.20

7.70

7.90

8.70

9.50

10.70

12.95

15.80

13.40

14.80

15.50

19.20

15.00

18.00

1.773

1.759

1.609

2.229

2.165

2.101

1.997

2.625

2.423

3.215

3.115

3.701

3.515

4.283

4.151

Diagram p. T-4

Seal: Metal-to-metal

t

Dc

0.254

0.261

0.336

0.276

0.308

0.340

0.392

0.375

0.476

0.330

0.380

0.337

0.430

0.296

0.362

2.906

2.938

3.125

3.438

3.500

3.625

3.688

4.313

4.500

4.625

4.725

5.125

5.313

5.370

5.455

Dsc

At

Ac

Lm

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.692

1.733

2.152

2.254

2.484

2.708

3.058

3.682

4.522

3.805

4.322

4.407

5.498

4.374

5.275

1.692

1.733

2.152

2.254

2.484

2.708

3.058

3.682

4.522

3.805

4.322

4.407

5.498

3.999

4.902

3.05

3.05

3.05

3.03

3.03

3.03

3.03

3.35

3.35

3.35

3.35

3.39

3.39

3.14

3.14

Atlas Bradford SB-8

Type: Upset integral joint

D

w

d

2.375

2.375

2.875

3.500

3.500

4.000

4.500

4.500

4.70

5.30

6.50

9.30

10.30

11.00

12.75

13.50

1.901

1.845

2.347

2.867

2.797

3.351

3.833

3.795

Diagram p. T-4

Seal: Metal-to-metal

t

Dc

0.190

0.218

0.217

0.254

0.289

0.262

0.271

0.290

2.700

2.750

3.210

3.915

3.915

4.417

4.920

4.955

Dsc

At

Ac

Lm

....

....

....

....

....

....

....

....

1.304

1.477

1.812

2.590

2.915

3.077

3.600

3.836

1.304

1.477

1.812

2.590

2.915

3.077

3.600

3.836

2.30

2.30

2.38

2.83

2.83

2.85

2.89

2.89

Atlas Bradford FL-4S

Type: Integral flush joint

D

w

d

2.375

2.375

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

4.70

5.95

6.50

7.90

7.70

9.30

10.30

12.95

9.50

11.00

11.60

9.50

10.50

11.00

11.60

12.75

13.50

11.50

13.00

15.00

18.00

1.901

1.773

2.347

2.229

2.943

2.867

2.797

2.625

3.423

3.351

3.303

3.965

3.927

3.901

3.875

3.833

3.795

4.435

4.369

4.283

4.151

Diagram p. T-4

Seal: Metal-to-metal, threaded, resilient

t

Dc

Dsc

At

0.190

0.254

0.217

0.276

0.216

0.254

0.289

0.375

0.226

0.262

0.286

0.205

0.224

0.237

0.250

0.271

0.290

0.220

0.253

0.296

0.362

2.375

2.375

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.304

1.692

1.812

2.254

2.228

2.590

2.915

3.682

2.680

3.077

3.337

2.766

3.009

3.174

3.338

3.600

3.836

3.304

3.773

4.374

5.275

Ac

Lm

0.531

0.877

0.751

1.175

0.927

1.343

1.458

2.312

1.111

1.615

1.746

1.136

1.253

1.327

1.728

1.879

2.012

1.370

1.958

2.298

3.310

1.52

2.05

1.47

2.10

1.64

2.05

2.13

3.85

1.68

2.07

2.12

1.59

1.67

1.73

2.11

2.05

2.13

1.65

2.06

2.14

3.82

2003 Tubing Reference Tables

WO 01 TUBING TABLES 2003-1 6/27/03 10:50 AM Page T-12

Atlas Bradford ST-L

Type: Integral flush joint

D

w

d

2.375

2.375

2.875

2.875

2.875

3.500

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

5.000

4.70

5.95

6.50

7.90

8.70

7.70

9.30

10.30

12.95

15.80

9.50

11.00

11.60

13.40

9.50

10.50

11.00

11.60

12.75

13.50

15.10

13.00

15.00

18.00

20.30

20.80

21.40

23.20

24.20

1.901

1.773

2.347

2.229

2.165

2.943

2.867

2.797

2.625

2.423

3.423

3.351

3.303

3.215

3.965

3.927

3.901

3.875

3.833

3.795

3.701

4.369

4.283

4.151

4.059

4.031

4.001

3.919

3.875

Diagram p. T-4

Seal: Metal-to-metal, threaded, optional resilient

t

Dc

Dsc

At

Ac

0.190

0.254

0.217

0.276

0.308

0.216

0.254

0.289

0.375

0.476

0.226

0.262

0.286

0.330

0.205

0.224

0.237

0.250

0.271

0.290

0.337

0.253

0.296

0.362

0.408

0.422

0.437

0.478

0.500

2.375

2.375

2.875

2.875

2.875

3.500

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

5.000

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.304

1.692

1.812

2.254

2.484

2.228

2.590

2.915

3.682

4.522

2.680

3.077

3.337

3.805

2.766

3.009

3.174

3.338

3.600

3.836

4.407

3.773

4.374

5.275

5.886

6.069

6.264

6.791

7.069

0.575

0.903

0.892

1.243

1.408

1.144

1.295

1.643

2.380

3.015

1.259

1.696

1.885

2.223

1.345

1.460

1.698

1.762

2.011

2.181

2.597

2.054

2.494

3.103

3.892

3.729

4.184

4.588

4.071

Lm

2.02

3.10

2.54

3.47

3.87

2.75

3.00

3.73

4.31

5.34

2.50

3.42

3.75

4.34

2.45

2.63

3.09

2.87

3.57

3.83

4.47

3.25

3.86

3.16

4.75

4.00

5.07

5.52

3.57

Atlas Bradford TC-II

Type: Coupled

D

w

2.375

2.375

2.375

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

4.60

5.10

5.95

6.40

7.70

8.60

7.70

9.20

10.20

12.70

9.50

10.90

13.00

14.80

10.50

11.60

12.75

13.50

15.10

16.90

15.00

18.00

20.30

20.80

21.40

23.20

24.10

Diagram p. T-4

Seal: Metal-to-metal, threaded, optional resilient

d

t

Dc

Dsc

At

1.901

1.845

1.773

2.347

2.229

2.165

2.943

2.867

2.797

2.625

3.423

3.351

3.215

3.115

3.927

3.875

3.833

3.795

3.701

3.629

4.283

4.151

4.059

4.031

4.001

3.919

3.875

0.190

0.218

0.254

0.217

0.276

0.308

0.216

0.254

0.289

0.375

0.226

0.262

0.330

0.380

0.224

0.250

0.271

0.290

0.337

0.373

0.296

0.362

0.408

0.422

0.437

0.478

0.500

2.675

2.716

2.766

3.211

3.297

3.342

3.827

3.887

3.940

4.062

4.356

4.414

4.518

4.581

4.855

4.898

4.932

4.962

5.035

5.089

5.428

5.533

5.603

5.624

5.646

5.705

5.736

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.304

1.477

1.692

1.812

2.254

2.484

2.228

2.590

2.915

3.682

2.680

3.077

3.805

4.322

3.009

3.338

3.600

3.836

4.407

4.836

4.374

5.275

5.886

6.069

6.264

6.791

7.069

Benoit Machine, Inc.BTS-6

Atlas Bradford TC-4S

Type: Coupled

D

w

2.375

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

5.000

5.000

5.000

5.000

5.000

T-12

4.70

5.30

5.95

6.20

7.70

6.50

7.90

8.70

9.50

11.00

11.65

9.30

10.30

12.95

15.80

16.70

17.05

9.50

11.00

11.60

13.40

19.00

12.75

13.50

15.50

16.90

19.20

21.60

13.00

15.00

18.00

20.80

21.40

23.20

24.20

Diagram p. T-4

Seal: Metal-to-metal, threaded, resilient

d

t

Dc

Dsc

1.90

1.85

1.77

1.76

1.61

2.35

2.23

2.17

2.10

1.97

1.90

2.87

2.80

2.63

2.42

2.36

2.32

3.42

3.35

3.30

3.21

2.88

3.83

3.80

3.70

3.63

3.51

3.38

4.37

4.28

4.15

4.03

4.00

3.92

3.88

0.190

0.218

0.254

0.261

0.336

0.217

0.276

0.308

0.340

0.405

0.440

0.254

0.289

0.375

0.476

0.510

0.530

0.226

0.262

0.286

0.330

0.500

0.271

0.290

0.337

0.373

0.430

0.500

0.253

0.296

0.362

0.422

0.437

0.478

0.500

JANUARY 2003 World Oil

2.750

2.750

2.800

2.800

2.900

3.250

3.375

3.375

3.450

3.500

3.550

3.950

3.950

4.100

4.200

4.250

4.300

4.400

4.450

4.450

4.525

4.800

4.950

4.950

5.100

5.100

5.200

5.300

5.375

5.450

5.550

5.650

5.750

5.750

5.750

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

At

Ac

Lm

1.304

1.477

1.692

1.733

2.152

1.812

2.254

2.484

2.708

3.143

3.366

2.590

2.915

3.682

4.522

4.791

4.945

2.680

3.077

3.337

3.805

5.498

3.600

3.836

4.407

4.836

5.498

6.283

3.773

4.374

5.275

6.069

6.264

6.791

7.069

1.304

1.477

1.692

1.733

2.152

1.812

2.254

2.484

2.708

3.143

3.366

2.590

2.915

3.682

4.522

4.791

4.945

2.680

3.077

3.337

3.805

5.498

3.600

3.836

4.407

4.836

5.498

6.283

3.447

4.048

4.949

5.743

5.938

6.465

6.743

3.08

3.08

3.08

3.08

3.08

3.33

3.33

3.33

3.33

3.33

3.33

3.71

3.71

3.71

3.71

3.71

3.71

3.71

3.88

3.88

3.88

3.88

4.00

4.00

4.00

4.00

4.00

4.00

4.38

4.38

4.38

4.38

4.38

4.38

4.38

Ac

Lm

1.304

1.477

1.692

1.812

2.254

2.484

2.228

2.590

2.915

3.682

2.680

3.077

3.805

4.322

3.009

3.338

3.600

3.836

4.407

4.836

4.374

5.275

5.886

6.069

6.264

6.791

7.069

2.30

2.30

2.30

2.54

2.54

2.54

3.16

3.16

3.16

3.16

3.03

3.03

3.03

3.73

3.10

3.10

3.10

3.10

3.10

3.10

4.35

4.35

4.35

4.35

4.35

4.35

4.35

Diagram p. T-4

Type: Integral, upset Seal: Metal-to-metal

D

w

d

t

Dc

Dsc

At

Ac

Lm

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

4.000

4.500

4.500

2.782

2.794

3.002

3.312

3.365

3.419

3.595

4.189

4.474

4.514

5.021

5.170

1.692

1.733

2.152

2.254

2.484

2.708

3.058

3.682

4.522

3.805

4.407

5.498

1.856

1.885

2.290

2.444

2.672

2.910

3.237

4.395

5.216

4.117

4.743

5.922

3.05

3.05

3.05

3.03

3.03

3.03

3.03

3.35

3.35

3.32

3.34

3.34

5.95

6.20

7.70

7.90

8.70

9.50

10.70

12.95

15.80

13.40

15.50

19.20

1.867

1.853

1.703

2.323

2.259

2.195

2.091

2.750

2.548

3.340

3.826

3.640

0.254

0.261

0.336

0.276

0.308

0.340

0.392

0.375

0.476

0.330

0.337

0.430

2.906

2.938

3.125

3.438

3.500

3.625

3.688

4.313

4.500

4.625

5.125

5.313

Benoit Machine, Inc.BTS-6U

Diagram p. T-4

Type: Integral, upset Seal: Metal-to-metal

D

w

d

t

Dc

Dsc

At

Ac

Lm

5.500

5.500

5.500

-------

4.962

5.828

6.630

4.981

5.834

6.632

3.52

3.52

3.52

17.00

20.00

23.00

4.892

4.778

4.670

0.304

0.361

0.415

5.920

6.000

6.090

Benoit Machine, Inc.BTS-8

Diagram p. T-4

Type: Integral, upset Seal: Metal-to-metal

D

w

d

t

Dc

Dsc

At

Ac

Lm

1.050

1.050

1.315

1.315

1.660

1.660

1.660

1.900

1.900

1.900

2.063

2.063

2.375

2.375

2.875

3.500

3.500

4.000

4.500

4.500

1.300

....

1.525

....

1.858

....

....

2.094

....

....

2.295

2.407

2.655

2.700

3.166

3.859

3.914

4.359

4.861

4.890

0.333

0.433

0.494

0.639

0.669

0.881

0.909

0.799

1.068

1.157

0.935

1.299

1.304

1.477

1.812

2.590

2.915

3.077

3.600

3.836

0.527

0.527

0.576

0.729

0.747

0.909

0.943

0.864

1.074

1.185

1.024

1.407

1.392

1.558

1.847

2.755

2.982

3.264

3.827

3.979

2.22

2.22

2.22

2.22

2.22

2.22

2.22

2.22

2.22

2.22

2.23

2.23

2.31

2.31

2.39

2.84

2.84

2.84

2.89

2.89

1.20

1.50

1.80

2.25

2.40

3.02

3.24

2.90

3.64

4.19

3.25

4.50

4.70

5.30

6.50

9.30

10.30

11.00

12.75

13.50

0.824

0.742

1.049

0.957

1.380

1.278

1.264

1.610

1.500

1.462

1.751

1.613

1.995

1.939

2.441

2.992

2.922

3.476

3.958

3.920

0.113

0.154

0.133

0.179

0.140

0.191

0.198

0.145

0.200

0.219

0.156

0.225

0.190

0.218

0.217

0.254

0.289

0.262

0.271

0.290

1.327

1.327

1.552

1.600

1.883

1.927

1.927

2.113

2.162

2.179

2.335

2.460

2.705

2.750

3.220

3.915

3.915

4.405

4.920

4.955

WO 01 TUBING TABLES 2003-1 6/27/03 10:50 AM Page T-13

Diagram p. T-4

Type: Flush Seal: Metal-to-metal, seal ring

D

w

d

t

Dc

Dsc

At

Ac

Lm

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.304

1.692

1.843

1.812

2.254

2.484

2.858

2.590

2.915

3.682

4.522

2.680

3.077

3.337

3.805

2.766

3.009

3.174

3.338

3.600

3.836

4.407

4.836

5.498

4.374

5.275

0.531

0.877

0.960

0.751

1.175

1.307

1.805

1.343

1.458

2.312

2.800

1.111

1.615

1.746

2.004

1.136

1.253

1.327

1.728

1.879

2.012

2.320

3.046

3.470

2.298

3.310

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

4.43

5.75

6.26

6.16

7.66

8.44

9.72

8.81

9.91

12.52

15.37

9.11

10.46

11.34

12.93

9.40

10.23

10.79

11.35

12.24

13.04

14.98

16.44

18.69

14.87

17.93

1.995

1.867

1.815

2.441

2.323

2.259

2.151

2.992

2.922

2.750

2.548

3.548

3.476

3.428

3.340

4.090

4.052

4.026

4.000

3.958

3.920

3.826

3.754

3.640

4.408

4.276

0.190

0.254

0.280

0.217

0.276

0.308

0.362

0.254

0.289

0.375

0.476

0.226

0.262

0.286

0.330

0.205

0.224

0.237

0.250

0.271

0.290

0.337

0.373

0.430

0.296

0.362

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

4.500

4.500

4.500

5.000

5.000

Benoit Machine, Inc.ECHO/SS

Diagram p. T-4

Type: Integral, upset Seal: Threaded, seal ring

D

w

d

t

Dc

Dsc

At

Ac

Lm

1.050

1.050

1.315

1.660

1.660

1.660

1.900

2.063

2.063

2.375

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

3.500

3.500

0.333

0.433

0.494

0.669

0.881

0.909

0.799

0.937

1.299

1.304

1.477

1.692

1.733

2.152

1.812

2.254

2.484

2.708

3.143

3.366

2.590

2.915

3.621

3.682

4.304

4.522

0.415

0.47

0.558

0.726

0.928

0.928

0.848

1.076

1.411

1.487

1.640

1.896

1.907

2.346

2.084

2.479

2.708

2.951

3.363

3.534

2.953

3.178

3.832

4.197

4.546

4.974

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

1.20

1.50

1.80

2.40

3.02

3.24

2.90

3.25

4.50

4.70

5.30

5.95

6.20

7.70

6.50

7.90

8.70

9.50

11.00

11.65

9.30

10.30

12.80

12.95

15.50

15.80

0.824

0.742

1.049

1.380

1.278

1.264

1.610

1.750

1.613

1.995

1.939

1.867

1.853

1.703

2.441

2.323

2.259

2.195

2.065

1.995

2.992

2.922

2.764

2.750

2.602

2.548

0.113

0.154

0.133

0.140

0.191

0.198

0.145

0.156

0.225

0.190

0.218

0.254

0.261

0.336

0.217

0.276

0.308

0.340

0.405

0.440

0.254

0.289

0.368

0.375

0.449

0.476

1.325

1.350

1.562

1.893

1.960

1.960

2.123

2.340

2.460

2.710

2.710

2.910

2.910

3.135

3.230

3.385

3.510

3.635

3.760

3.760

3.875

3.947

4.260

4.260

4.385

4.385

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

CENTRON International Inc.DH Tubing

Type: Integral, upset Seal: Resilient

D

w

d

t

Dc

1.500

1.500

1.500

1.500

1.500

2.375

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

4.500

4.500

4.500

4.500

4.500

0.93

1.15

1.30

1.63

1.75

1.15

1.45

1.72

2.04

2.18

1.55

1.85

2.40

2.80

1.75

1.90

2.65

2.90

2.50

2.70

3.50

4.50

5.40

1.60

1.60

1.60

1.60

1.60

1.95

1.95

1.95

1.95

1.95

2.48

2.48

2.48

2.48

2.98

2.98

2.98

2.98

3.98

3.98

3.98

3.98

3.98

0.175

0.210

0.230

0.275

0.290

0.180

0.220

0.275

0.310

0.330

0.190

0.230

0.300

0.350

0.190

0.230

0.280

0.310

0.200

0.230

0.290

0.370

0.430

2.95

3.05

3.15

3.25

3.40

3.35

3.45

3.55

3.65

3.70

4.00

4.20

4.40

4.50

4.50

4.70

4.85

4.90

5.55

5.60

5.75

5.85

6.00

CENTRON International Inc.

DH8 Tubing

Type: Upset, integral

D

w

2.375

2.375

2.375

2.375

2.875

2.875

3.500

3.500

3.500

3.500

4.500

4.500

4.500

Seal: Metal-to-metal

d

t

1.15

1.45

1.72

2.04

1.55

1.85

1.75

1.90

2.65

2.90

2.50

2.70

3.50

1.95

1.95

1.95

1.95

2.48

2.48

2.98

2.98

2.98

2.98

3.98

3.98

3.98

0.180

0.220

0.275

0.310

0.190

0.230

0.190

0.230

0.280

0.310

0.200

0.230

0.290

Diagram p. T-5

Dc

Dsc

At

Ac

Lm

3.27

3.37

3.47

3.57

3.92

4.12

4.42

4.62

4.77

4.82

5.47

5.52

5.67

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

3.120

3.120

3.120

3.120

3.375

3.375

3.625

3.625

3.625

3.625

4.000

4.000

4.000

Halliburton Energy Services

Oeco A & B

Diagram p. T-5

Type: Upset Seal: Metal-to-metal

D

w

d

t

Dc

Dsc

At

Ac

Lm

1.315

1.315

1.660

1.660

1.660

1.900

1.900

1.900

2.063

2.063

2.375

2.375

2.875

3.500

3.500

4.500

4.500

1.552

1.600

1.883

1.927

1.927

2.113

2.162

2.179

2.330

2.460

2.700

2.750

3.210

3.915

3.980

4.920

4.955

1.525

.....

1.858

.....

.....

2.094

.....

.....

2.295

2.407

2.655

2.700

3.166

3.859

3.914

4.861

4.890

0.494

0.639

0.669

0.909

0.881

0.799

1.068

1.157

0.935

1.299

1.304

1.477

1.812

2.590

2.915

3.600

3.836

0.574

0.727

0.717

0.938

0.904

0.861

1.071

1.182

1.012

1.394

1.377

1.543

1.848

2.744

2.971

3.792

3.944

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.23

2.31

2.31

2.39

2.84

2.84

2.89

2.89

1.80

2.25

2.40

3.02

3.24

2.90

3.64

4.19

3.25

4.50

4.70

5.30

6.50

9.30

10.30

12.75

13.50

0.955

0.848

1.286

1.184

1.184

1.516

1.406

1.368

1.657

1.519

1.901

1.845

2.347

2.867

2.797

3.833

3.795

0.133

0.179

0.140

0.198

0.191

0.145

0.200

0.219

0.156

0.225

0.190

0.218

0.217

0.254

0.289

0.271

0.290

Halliburton Energy Services

Oeco C & D

Diagram p. T-5

Type: Upset Seal: Metal-to-metal

D

w

d

t

Dc

Dsc

At

Ac

Lm

2.375

2.375

2.375

2.875

2.875

2.875

2.875

3.500

3.500

4.000

4.500

4.500

2.906

2.938

3.125

3.438

3.500

3.625

3.688

4.313

4.500

4.625

5.125

5.313

2.782

2.794

3.002

3.312

3.365

3.419

3.595

4.189

4.367

4.514

5.021

5.170

1.692

1.733

2.152

2.254

2.484

2.708

3.058

3.682

4.522

3.805

4.407

5.498

1.868

1.896

2.301

2.458

2.686

2.924

3.251

4.401

5.222

4.111

4.722

5.901

3.064

3.064

3.064

3.043

3.043

3.043

3.043

3.376

3.376

3.342

3.356

3.356

5.95

6.20

7.70

7.90

8.70

9.50

10.70

12.95

15.80

13.40

15.50

19.20

1.773

1.759

1.609

2.229

2.165

2.101

1.997

2.625

2.423

3.215

3.701

3.515

0.254

0.261

0.336

0.276

0.308

0.340

0.392

0.375

0.476

0.330

0.337

0.430

Diagram p. T-5

Dsc

At

Ac

Lm

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....

....