Académique Documents

Professionnel Documents

Culture Documents

DC250 Fuser

Transféré par

chrisban35Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DC250 Fuser

Transféré par

chrisban35Droits d'auteur :

Formats disponibles

Written by www.partsdrop.

com (201)387-7776

Drawn from Articles by Britt Horvat; originally published in ENX magazine (www.enxmag.com)

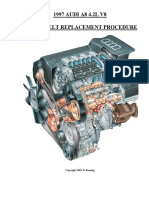

DocuColor 250 (DC250 style) Cooking Good.

Xerox Docucolor 240, 250, 242, 252, 260, WorkCentre 7655, 7665, 7675

Few Xerox models have earned as much praise as the DocuColor 250 series. The technicians who are working on them say they are reliable and very technician friendly. The machine is designed with a stack of access drawers which make replacing the various modules and parts easier than just about any model of machine in recorded history. The fuser module is naturally one of the more important pieces. Reports from the field say that more often than not, the Heat Roll fails early with the rest of the unit still being in good shape. Replacing the Heat Roll makes sense from both environmental and economic standpoints. This month well get a quick overview on the fusers and then well crack one of these babies open to see how best to replace the heat roller. This one ended up being far more daunting to disassemble than I had hoped but as is usually the case, the second time will likely prove a lot easier. Also, there is a trick or shortcut to replacing just the heat roll which is all that is usually needed. Read after the main procedure for info on how to sneak the heat roll in and out of there. Hopefully with some advanced knowledge gleaned from this article, youll find it less intimidating than I did. Its perhaps the most complex fuser weve tackled to date, with a total of 21 pins on the main fuser connector. There are a like number of wires leading away to 3 heat lamps, a ground point, 3 temperature sensors, 2 thermal fuses, an exit sensor and a pressure cam position sensor all onboard the fuser. The Pressure is applied not by a traditional press roll, but instead by a Pressure Belt inside of which is a pressure pad which pushes the belt against the heat roll where the paper passes between them. The Heat Sensors in this fuser are unusual. Theres one traditional thermistor near the front end of the heat roll which makes direct contact with the Heat Rolls surface. Then there are two other sensors which dont make contact directly but they do seem to monitor the surface temperature of the Heat Roll from a slight distance. There are a bunch of gears both on the front and rear ends which handle the heat roll drive and the pressure cam mechanism. One of the gears is on a spring loaded plunger which can engage the drive to the Pressure Cam mechanism when something in the machine pushes the plunger in from the rear (I would guess there would be a solenoid performing that function although I was unable to find the part on the Parts List pages). The Fuser Heat Roll has an aluminum core with a silicon sleeve over it. It has typical Heat Roll Bearings and Heat Sleeves (bushings). There are no Picker Fingers in this machine instead theres a stripper plate which helps the paper off of the heat roll when it exits.

Page 1 of 5

Written by www.partsdrop.com (201)387-7776

Drawn from Articles by Britt Horvat; originally published in ENX magazine (www.enxmag.com)

Now for a quick walk-through of how this thing comes apart

FUSER DISASSEMBLY: 1. Start with the Top Cover (2 screws on top from above, and 2 screws near the right side, also from above). This gives you easy access to both the Thermostat and the Fuser Reset Thermal Fuse as well as the thermistors (see Photo 1). The Thermostat is can-shaped and in-line with the fuser heat lamp circuits. The Thermal Fuse is a standard bullet-shaped fuse. It serve s as Photo 1: Top Cover off Temperature Sensors the Fuser Reset Fuse. When replaced, the machine will reset the Fuser Life to 100%. 2. Remove the Front End Cover (2 screws from the front) which exposes the pressure gear / cam mechanism and its home sensor 3. Remove the Rear End Cover (2 screws from rear, see Photos 4 & 5) Photo 2: Rear End Cover Photo 3: Rear End exposed 4. Remove the lower input baffle (a metallic plate on the left side which has a row of static elimination brushes on it which ride on the Pressure Belts surface. Pay attention at this point to the 2 clips on the lower rear edge of the fuser these clips occupy 2 out of 4 possible locations back there and Photo 4: Front End Cover Photo 5: Front End exposed they pop off kind of easily you will want to know where these go back if they pop off, because if my hunch is right, they are likely to be the way the fuser type is recognized by the machine. 5. Next youll work on releasing the pressure between Photo 6: Releasing Pressure Photo 7: Clam Release Screw

Page 2 of 5

Written by www.partsdrop.com (201)387-7776

Drawn from Articles by Britt Horvat; originally published in ENX magazine (www.enxmag.com)

the Heat Roll and the Pressure Belt Assembly. First mark the Pressure set screws with a magic marker or tape so you can get them back to the same position later and then back the set screws out from the bottom using a 5.5mm hex driver (you might be tempted to use a flat head driver on the slot on the top of the screw but it is far too fragile). Once the Pressure set screws are removed, you can also remove the two screws near them from the top which hold the top and bottom halves together. 6. Remove the Upper Exit Baffle from the right side by pivoting it up far enough to escape its front and rear mounts grab the two large springs which keep it Photo 8: End of Pressure pushed down since they will no longer be captive. Belt Assembly 7. Release the large Main Fuser Connector from its mounts (2 screws) and disconnect one blue connector behind the Main Connector (this one has the wiring from the Exit Sensor which is the only electrical component on the lower half of the fuser). Now the upper assembly can pivot up and off of the lower half of the fuser. 8. The Pressure Belt Assembly can now lift out of the lower half and Photo 9: Upper Half (w/ Heat Roller, etc.) the Fuser Exit Roll can be easily replaced as can the Exit Sensor Assembly. If the Pressure Belt needs replacing, you can remove it now by first taking off the bearing at one end or the other (one screw from the outside holding it to the plastic cross-member). Then the Pressure Belt can slide off rather easily. You will want to be sure that there is adequate grease inside the sleeve (there is a pad inside which Photo 10: Removing the Stripper Plate dispenses some extra grease). This grease material must be a high temperature grease. 9. Now turn to the Heat Roll Stripper Plate on the Upper Half of the fuser. First release the two springs, then slide the two bushings toward the middle of the shaft

Page 3 of 5

Written by www.partsdrop.com (201)387-7776

Drawn from Articles by Britt Horvat; originally published in ENX magazine (www.enxmag.com)

they are on (see Photo 9). Finally pivot the Stripper Plate up until it clears its mountings and comes off for you. 10. To remove the Heat Roll Assembly, first disconnect the 3 Fuser Heat Lamps at either end and remove them. All 3 lamps are rated for 112V with one being 1050watts (red connector, marked 126K17292), a second being 870watts (white connector, marked 126K17302) and the third being 740watts (blue connector, marked 126K17312). Take off the Heat Roll Bearing retainer brackets (one front and one rear each has 1 screw holding it). The Heat Roll with its bearings and heat sleeves and drive gear will now lift out. Replace the Heat Roll and Heat Sleeves (bushings) and if needed the bearings as well. 10. Reassemble it all and test the heat lamps & thermal fuses to make sure none of them are blown. Thats it ! Now for a shortcut How to replace just the most critical parts Fuser Heat Roll & Fuser Reset Thermal Fuse Replacement: Remove the front, rear and top covers. Remove the rear Fuser lamp bracket and disconnect the 3 lamp connectors at the rear end and straighten out the wires as much as possible. The front connectors can remain connected. 3. Remove the Heat Roll Retaining Clips (front and rear) from the Heat Roller. 4. Release the pressure on the Heat Roll by turning the pressure cam gear until the sensor flag is sticking up in the air. 5. Temporarily push the roller towards the front to allow room to remove the Fuser Heat Roll Drive Gear, rear Heat Sleeve and rear Heat Roll Bearing. 6. Remove the fuser roller through the rear of the unit sliding it over the lamps 7. Install the new Fuser Heat Roller by sliding it over the lamps and through the front bushing/bearing far enough to allow the rear bushing, bearing and drive gear to be reinstalled. 8. Reinstall both Heat Roll Retaining Clips. 9. Reseat the front end of the Fuser Heat Lamps in the front end bracket. Then reinstall the rear bracket (Each lamp has its own position, so pay attention to get them in the right places in the bracket they are color coded). 10.Try turning the Heat Roll a few revolutions with the pressure back on to make sure the reassembly went well for you. 11. Replace the Fuser Reset Fuse (a thermal fuse on the top of the fuser).

Page 4 of 5

1. 2.

Written by www.partsdrop.com (201)387-7776

Drawn from Articles by Britt Horvat; originally published in ENX magazine (www.enxmag.com)

12. 13.

Reinstall the three covers. Test the Fuser Module in the machine. Running 20 pages will break in the new roller and will also ensure that the Fuser Reset Fuse blows as it should Its a thermal fuse, so the fuser needs to be good-and-hot before it will blow and reset the fuser count) Some models can also be reset from the Diagnostics go into Diagnostic Mode and choose DC135. Highlight the Fuser and reset it. 14. Its a good idea to enter the User Tools and check the Consumables to make sure the fuser life is back to 100% as it should be.

Hopefully this will encourage some of you to tackle the fusers instead of tossing them. There is money to be made on these things.. Enjoy!

Page 5 of 5

Vous aimerez peut-être aussi

- AWWA M28 Rehabilitation of Water Mains 3rd Ed 2014Document133 pagesAWWA M28 Rehabilitation of Water Mains 3rd Ed 2014millini67% (3)

- Complete guide to removing and replacing your Jeep's evaporator/heater coreDocument41 pagesComplete guide to removing and replacing your Jeep's evaporator/heater corejeff.648251Pas encore d'évaluation

- Koltec Vapouriser RevisionDocument9 pagesKoltec Vapouriser RevisionZoli BorbelyPas encore d'évaluation

- GE Dryer Models DBL333 DCL333 and DVL233 Service ManualDocument37 pagesGE Dryer Models DBL333 DCL333 and DVL233 Service Manual911servicetechPas encore d'évaluation

- 2000 F150 Heater Core ReplacementDocument29 pages2000 F150 Heater Core ReplacementJeff ComfortPas encore d'évaluation

- Audi B5 S4 2.7T Turbo Swap GuidDocument14 pagesAudi B5 S4 2.7T Turbo Swap Guidmikey65150% (2)

- PassiontoPayoff Coaches Starter Guide EbookDocument74 pagesPassiontoPayoff Coaches Starter Guide Ebookchrisban35Pas encore d'évaluation

- Business Analysis TechniquesDocument37 pagesBusiness Analysis TechniquesMohammed Naushad S45% (20)

- BCM Guide for SMEsDocument24 pagesBCM Guide for SMEsannt91% (11)

- Xerox 7845 WRAPDocument2 pagesXerox 7845 WRAPchrisban35Pas encore d'évaluation

- Xerox DC250 Fuser RebuildingDocument5 pagesXerox DC250 Fuser RebuildingxeropartsPas encore d'évaluation

- C35 Style FUSERS Worthy of ServiceDocument3 pagesC35 Style FUSERS Worthy of ServicedacrysPas encore d'évaluation

- Xerox C123 FuserDocument5 pagesXerox C123 FuserVadineanu RamonaPas encore d'évaluation

- XEROX Fusor m15 20 c20 EtcDocument4 pagesXEROX Fusor m15 20 c20 EtcFrancisco LopezPas encore d'évaluation

- 7120 Fuser RebuildingDocument3 pages7120 Fuser RebuildingVinh VuPas encore d'évaluation

- Xerox C35 Style Copier RepairsDocument12 pagesXerox C35 Style Copier RepairsSean Reilly0% (1)

- Fan Rover75Document8 pagesFan Rover75UsurpéPas encore d'évaluation

- Xbox 360 - Three Red Lights of DeathDocument14 pagesXbox 360 - Three Red Lights of Deathgreglowe1Pas encore d'évaluation

- A8timingbeltreplacementDocument21 pagesA8timingbeltreplacementIvo Miguel Almeida CardosoPas encore d'évaluation

- Dc265 Style Repairing The Fuser ModulesDocument4 pagesDc265 Style Repairing The Fuser Modulestetraedro3fPas encore d'évaluation

- R107 Heater Blower Motor Unit Rebuild - FinalDocument16 pagesR107 Heater Blower Motor Unit Rebuild - Finalalbert zackPas encore d'évaluation

- Water Pump - T-Stat DIYDocument6 pagesWater Pump - T-Stat DIYNathan JamesPas encore d'évaluation

- X360 Red Light Repair GuideDocument8 pagesX360 Red Light Repair GuideNomena Rovasoa RajaonaryPas encore d'évaluation

- XBOX 360 Repair Guide - Three Red Lights of Death Repair ManualDocument9 pagesXBOX 360 Repair Guide - Three Red Lights of Death Repair ManualValerio Alves SantanaPas encore d'évaluation

- XBOX 360 Repair Guide - Three Red Lights of Death Repair Manual PDFDocument9 pagesXBOX 360 Repair Guide - Three Red Lights of Death Repair Manual PDFbong bernalbong100% (1)

- Technical Service ManualDocument13 pagesTechnical Service ManualGigi CostelusPas encore d'évaluation

- Nissan Skyline r33 GTST Cam Belt ChangeDocument9 pagesNissan Skyline r33 GTST Cam Belt Changestoopid_isPas encore d'évaluation

- E 36 CoolingDocument9 pagesE 36 CoolinglockednloadedsterPas encore d'évaluation

- Samsung SS 1400 Service ManualDocument104 pagesSamsung SS 1400 Service ManualwcualumniPas encore d'évaluation

- Ecksbot Electronics InstructionsDocument78 pagesEcksbot Electronics InstructionsjohnPas encore d'évaluation

- XBOX 360 - Three Red Lights of Death Repair ManualDocument8 pagesXBOX 360 - Three Red Lights of Death Repair ManualΘΑΝΑΣΗΣ ΒΑΚΟΥΦΤΣΗΣPas encore d'évaluation

- Detroit Diesel R&R ThermostatDocument11 pagesDetroit Diesel R&R ThermostatadrianPas encore d'évaluation

- Enx DC220fuserDocument8 pagesEnx DC220fusernafeesPas encore d'évaluation

- Repair household fans by replacing internal thermal fuseDocument16 pagesRepair household fans by replacing internal thermal fuseAris R. AlcantaraPas encore d'évaluation

- BMW Heater Core Replacement GuideDocument4 pagesBMW Heater Core Replacement GuideGerardo SchlossbergPas encore d'évaluation

- Install GM alternator GL1200 instructionsDocument2 pagesInstall GM alternator GL1200 instructionsCecil RhodesPas encore d'évaluation

- Guide to Disassembling a Copier HOME Chapter 5Document11 pagesGuide to Disassembling a Copier HOME Chapter 5minoltaep4050Pas encore d'évaluation

- Servicing & Reconditioning Xerox Brand 5340 Style Copy CartridgesDocument5 pagesServicing & Reconditioning Xerox Brand 5340 Style Copy CartridgesVinh VuPas encore d'évaluation

- Razr Adapter Retrofit Project: by Craig Hoy, Edmonton, AB, CanadaDocument12 pagesRazr Adapter Retrofit Project: by Craig Hoy, Edmonton, AB, CanadaDavid ALVESPas encore d'évaluation

- C4UrSHeaterCoreReplacementDIY Rev1Document31 pagesC4UrSHeaterCoreReplacementDIY Rev1Gustavo BrazPas encore d'évaluation

- Double Station Pneumatic Heat Press Machine Operation ManualDocument4 pagesDouble Station Pneumatic Heat Press Machine Operation ManualputrastevanofyPas encore d'évaluation

- E39 540i - Repair plastic timing chain guides to prevent failureDocument37 pagesE39 540i - Repair plastic timing chain guides to prevent failureEngine Tuning UpPas encore d'évaluation

- Manual For Filastruder ENGLISH PDFDocument10 pagesManual For Filastruder ENGLISH PDFstavroula zarkadoulaPas encore d'évaluation

- VW Passat B5 1.8T Timing Belt Replacement DIYDocument26 pagesVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- Electric Fan RepairDocument12 pagesElectric Fan RepairYsabelle Tagaruma33% (3)

- Coolant HosereplacementDocument13 pagesCoolant HosereplacementmicunekvPas encore d'évaluation

- How To Change A Processor: SuppliesDocument1 pageHow To Change A Processor: SuppliesMatthew UpchurchPas encore d'évaluation

- BMW E23 24 28 OdogearDocument9 pagesBMW E23 24 28 OdogearporkfacePas encore d'évaluation

- Instructables Com FAN RepairDocument9 pagesInstructables Com FAN RepairOtk ManuscriptPas encore d'évaluation

- Instruction Firefly Fitting J RangeDocument12 pagesInstruction Firefly Fitting J RangeСергей сергеевичPas encore d'évaluation

- Cleaning an Intake ManifoldDocument16 pagesCleaning an Intake ManifoldMike WaltersPas encore d'évaluation

- BMW X3 F25 Spark Plug DIYDocument11 pagesBMW X3 F25 Spark Plug DIYc3uoPas encore d'évaluation

- M-Tuned Reroute InstructionsDocument12 pagesM-Tuned Reroute InstructionsAnonymous dEfIaUPas encore d'évaluation

- Fan Circuit Tests InfoDocument21 pagesFan Circuit Tests InfomedPas encore d'évaluation

- Xrt300 and Xrt350 Ba Xr6 Turbo Upgrade Kit Fitting InstructionsDocument41 pagesXrt300 and Xrt350 Ba Xr6 Turbo Upgrade Kit Fitting InstructionstoeyazzPas encore d'évaluation

- Cam Heads HeadersInstallPart 1Document16 pagesCam Heads HeadersInstallPart 1Donnell JeffersonPas encore d'évaluation

- WAPU Overhaul BZB v2Document11 pagesWAPU Overhaul BZB v2Nedim ErkocevicPas encore d'évaluation

- Ins. Sd7v16Document3 pagesIns. Sd7v16cadelcastiPas encore d'évaluation

- 31-9118 Part2Document31 pages31-9118 Part2dreamyson1983Pas encore d'évaluation

- 2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualDocument24 pages2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualHenry ArguettPas encore d'évaluation

- Print Head Replacement HM1Document6 pagesPrint Head Replacement HM1joecentronePas encore d'évaluation

- Fan RepairDocument22 pagesFan RepairdonlynPas encore d'évaluation

- User Instructions For R1100S Gear Switch IndicatorDocument17 pagesUser Instructions For R1100S Gear Switch Indicatorbuzzz57Pas encore d'évaluation

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsD'EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsPas encore d'évaluation

- Sweetwater Tavern's MenuDocument4 pagesSweetwater Tavern's Menuchrisban35Pas encore d'évaluation

- George Washington's Rules of CivilityDocument40 pagesGeorge Washington's Rules of Civilitychrisban35Pas encore d'évaluation

- Mike's Steakhouse MenuDocument4 pagesMike's Steakhouse Menuchrisban35Pas encore d'évaluation

- How To Set Up Your New Coaching Practice: Brochure ContentsDocument22 pagesHow To Set Up Your New Coaching Practice: Brochure Contentschrisban35Pas encore d'évaluation

- FAX3320L DIfference Parts List (FAX3310)Document1 pageFAX3320L DIfference Parts List (FAX3310)chrisban35Pas encore d'évaluation

- Silverado's MenuDocument4 pagesSilverado's Menuchrisban35Pas encore d'évaluation

- Artie's MenuDocument4 pagesArtie's Menuchrisban35Pas encore d'évaluation

- 10OctPresentationHandouts PDFDocument59 pages10OctPresentationHandouts PDFChristen CastilloPas encore d'évaluation

- Putting Together A Training CourseDocument11 pagesPutting Together A Training Coursechrisban35100% (1)

- 10 Guidelines for Successful Executive CoachingDocument5 pages10 Guidelines for Successful Executive Coachingchrisban35Pas encore d'évaluation

- Prospective Business Coach: Self-AssessmentDocument3 pagesProspective Business Coach: Self-Assessmentchrisban35Pas encore d'évaluation

- DWP Bcframework Part3Document42 pagesDWP Bcframework Part3chrisban35Pas encore d'évaluation

- Business Assessment Strategic Planning1828Document18 pagesBusiness Assessment Strategic Planning1828chrisban35Pas encore d'évaluation

- Efi Fiery Xerox Exi c60c70 v2 FPP Ds en Us PDFDocument2 pagesEfi Fiery Xerox Exi c60c70 v2 FPP Ds en Us PDFchrisban35Pas encore d'évaluation

- Dec 2016 Jan 2017 PDFDocument61 pagesDec 2016 Jan 2017 PDFchrisban35Pas encore d'évaluation

- Efi Fiery Xerox Exi c60c70 v2 FPP Ds en UsDocument2 pagesEfi Fiery Xerox Exi c60c70 v2 FPP Ds en Uschrisban35Pas encore d'évaluation

- Top Reasons To Buy The Xerox EX C60/C70 Print Server v2.0Document6 pagesTop Reasons To Buy The Xerox EX C60/C70 Print Server v2.0chrisban35Pas encore d'évaluation

- Linkedin Groups Ebook PDFDocument21 pagesLinkedin Groups Ebook PDFchrisban35Pas encore d'évaluation

- Micro LearningDocument19 pagesMicro Learningaejaz_98100% (3)

- Xerox EX-i C60/C70 Print Server Powered by Fiery: World-Class Color With Workflow Tools That Put You in CommandDocument2 pagesXerox EX-i C60/C70 Print Server Powered by Fiery: World-Class Color With Workflow Tools That Put You in Commandchrisban35Pas encore d'évaluation

- MSP Benchmark Survey ReportDocument19 pagesMSP Benchmark Survey Reportchrisban35Pas encore d'évaluation

- MSP Benchmark Survey ReportDocument19 pagesMSP Benchmark Survey Reportchrisban35Pas encore d'évaluation

- DSL Self Installation GuideDocument20 pagesDSL Self Installation Guidechrisban35Pas encore d'évaluation

- DJ800 Users Reference GuideDocument246 pagesDJ800 Users Reference Guidecwalters7Pas encore d'évaluation

- Quick start guide for Verizon high speed internetDocument1 pageQuick start guide for Verizon high speed internetchrisban35Pas encore d'évaluation

- Kip 700 Product Information GuideDocument24 pagesKip 700 Product Information Guidechrisban35Pas encore d'évaluation

- Operational Transconductance Amplifier ThesisDocument6 pagesOperational Transconductance Amplifier ThesislaurahallportlandPas encore d'évaluation

- Pitfalls of HIV Infection - Dr. Rizqi Amalia, Sp.ADocument46 pagesPitfalls of HIV Infection - Dr. Rizqi Amalia, Sp.AandreknhPas encore d'évaluation

- Starter Unit Basic Vocabulary: Smart Planet 3Document21 pagesStarter Unit Basic Vocabulary: Smart Planet 3Rober SanzPas encore d'évaluation

- Smart Asthma ConsoleDocument35 pagesSmart Asthma ConsoleMohamad Mosallam AyoubPas encore d'évaluation

- Mercy PlansDocument126 pagesMercy Plansdharry8108Pas encore d'évaluation

- ABB Price Book 714Document1 pageABB Price Book 714EliasPas encore d'évaluation

- Traxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Document62 pagesTraxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Wilson ChimPas encore d'évaluation

- US Army TV Course - Documentation Cinematography SS0536Document49 pagesUS Army TV Course - Documentation Cinematography SS0536innerethosPas encore d'évaluation

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDocument2 pagesAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoPas encore d'évaluation

- 0580 w15 QP 42Document16 pages0580 w15 QP 42Shahrizan Noor100% (1)

- Macroeconomics II: Search and Matching: Luiz BrotherhoodDocument18 pagesMacroeconomics II: Search and Matching: Luiz BrotherhoodMartin GutovskiePas encore d'évaluation

- Chocolate - Useful Physical ConstantsDocument2 pagesChocolate - Useful Physical ConstantsJuan CPas encore d'évaluation

- Chem Tech South 2013 - ConferenceDocument5 pagesChem Tech South 2013 - ConferenceAbirami PriyadharsiniPas encore d'évaluation

- ArtsDocument5 pagesArtsRhovi Christine AbandoPas encore d'évaluation

- Orpheus' Tragic Love and Quest to Save EurydiceDocument3 pagesOrpheus' Tragic Love and Quest to Save EurydiceShiedrose Allaina ArangorinPas encore d'évaluation

- Boston Acoustic PDFDocument12 pagesBoston Acoustic PDFAdam StarkPas encore d'évaluation

- Return SectionDocument1 pageReturn SectionDaniel Pouso DiosPas encore d'évaluation

- AkzoNobel-Trigonox 239Document6 pagesAkzoNobel-Trigonox 239Wafa AjiliPas encore d'évaluation

- Kathrein 80010375Document2 pagesKathrein 80010375klamar5Pas encore d'évaluation

- Motherboards Tuf z270 Mark 2Document70 pagesMotherboards Tuf z270 Mark 2Jonah HexPas encore d'évaluation

- Pharmaceutics | Water Solubility and Dissolution RateDocument11 pagesPharmaceutics | Water Solubility and Dissolution RateAnnisa AgustinaPas encore d'évaluation

- Copeland CompressorDocument135 pagesCopeland CompressorsugirinPas encore d'évaluation

- Mahavir Glass Proforma InvoiceDocument2 pagesMahavir Glass Proforma Invoicemahendra patelPas encore d'évaluation

- ECC Report: Mobile Coverage ObligationsDocument77 pagesECC Report: Mobile Coverage ObligationsRedamichael JemberuPas encore d'évaluation

- General Science EnvironmentDocument28 pagesGeneral Science EnvironmentHamza MujahidPas encore d'évaluation

- ASSIGNMENTDocument10 pagesASSIGNMENTKoleen Lopez ÜPas encore d'évaluation

- Water System BOQ 16.12.2023 R0Document144 pagesWater System BOQ 16.12.2023 R0moinu85Pas encore d'évaluation

- Homework Helpers - Chemistry PDFDocument311 pagesHomework Helpers - Chemistry PDFTamby100% (1)

- 800-40 Suspencion ChalmersDocument7 pages800-40 Suspencion ChalmersJhonatan Velasquez CastellanosPas encore d'évaluation