Académique Documents

Professionnel Documents

Culture Documents

YD25DDTi and ZD30DDT Engines in NISSAN Repair Manuals

Transféré par

Moaed KanbarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

YD25DDTi and ZD30DDT Engines in NISSAN Repair Manuals

Transféré par

Moaed KanbarDroits d'auteur :

Formats disponibles

ENGINE MECHANICAL SECTION

MODIFICATION NOTICE:

YD25DDTi and ZD30DDT engine information have been added. For information not included here, refer to information for YD25DDTi and ZD30DDT engines in NISSAN model D22 series SERVICE MANUAL Supplement-VI 1st Revision (Publication No. SM1E-1D22FG1).

GI MA

EM

YD

LC EC FE

CONTENTS

YD CYLINDER HEAD............................................................2 Inspection.....................................................................2 CYLINDER BLOCK .........................................................3 Inspection.....................................................................3 ZD CAMSHAFT .....................................................................5 Removal and Installation .............................................5 Inspection.....................................................................5 VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTS...............................................................7 Adjustments .................................................................7 TIMING GEAR .................................................................8 Removal and Installation .............................................8 Inspection.....................................................................9 CYLINDER HEAD..........................................................10 Inspection...................................................................10 Disassembly and Assembly.......................................10 Inspection...................................................................10 CYLINDER BLOCK .......................................................12 Inspection...................................................................12

CL MT AT TF PD FA RA BR ST RS BT HA EL IDX

SERVICE DATA AND SPECIFICATIONS (SDS) ..........14 Cylinder Head ............................................................14 Cylinder Block............................................................15 Piston, Piston Ring and Piston Pin ...........................15 ZD SERVICE DATA AND SPECIFICATIONS (SDS) ..........16 Valve ..........................................................................16 Camshaft and Camshaft Bearing ..............................19 Crankshaft..................................................................19 Available Connecting Rod Bearing............................19

EM-1

CYLINDER HEAD Inspection

CYLINDER HEAD DISTORTION

YD

SEM496G

Clean surface of cylinder head. Use a reliable straightedge and feeler gauge to check the flatness of cylinder head surface. Check along six positions shown in the figure. Head surface flatness: Limit 0.1 mm (0.004 in) If beyond the specified limit, resurface or replace it. The limit for cylinder head resurfacing is determined by the cylinder block resurfacing. Resurfacing limit: Amount of cylinder head resurfacing is A. Amount of cylinder block resurfacing is B. The maximum limit: A + B = 0.07 mm (0.0028 in) After resurfacing cylinder head, check that camshaft rotates freely by hand. If resistance is felt, cylinder head must be replaced. Nominal cylinder head height: 153.9 - 154.1 mm (6.059 - 6.067 in)

EM-2

CYLINDER BLOCK Inspection

PISTON-TO-BORE CLEARANCE

YD

GI MA

JEM206G

1. Using a bore gauge, measure cylinder bore in X and Y directions at A, B and C for wear, out-of-round and taper. Cylinder bore inner diameter: Standard 89.000 - 89.030 mm (3.5039 - 3.5051 in) Wear limit 0.07 mm (0.0028 in) If it exceeds the limit, rebore all cylinders. Replace cylinder block if necessary. Out-of-round (Difference between X and Y): Limit 0.015 mm (0.0006 in) Taper (Difference between A and C): Limit 0.010 mm (0.0004 in) 2. Check for scratches and seizure. If seizure is found, hone it.

LC EC FE CL MT

SEM899G

SEM258C

3. Measure piston skirt diameter. Piston diameter A: Standard 88.925 - 88.955 mm (3.5010 - 3.5022 in) Measuring point a (Distance from the top): 59.0 mm (2.323 in) 4. Check that piston-to-bore clearance is within specification. Calculate the clearance by using outer diameter at piston skirt and inner diameter of cylinder (direction of X, point B): Piston-to-bore clearance = Cylinder bore Piston diameter A Standard [at room temperature 20C (68F)]: 0.065 - 0.085 mm (0.0026 - 0.0033 in) If the value is out of the specified range, replace piston and piston pin assembly.

AT TF PD FA RA BR ST RS

If cylinder block or pistons are replaced with new ones, select piston as follows: When using a new cylinder block: Identify the cylinder bore grade (No. 1, 2, or 3) on LH surface at the rear of cylinder block and select a piston of the same grade. The part No. of piston is specified together with the piston pin as an assembly.

BT HA EL IDX

JEM208G

EM-3

CYLINDER BLOCK Inspection (Contd)

YD

When re-using a removed cylinder block: Measure the inner diameter of the cylinder block bore. Determine the bore grade by comparing the measurement with the values under Cylinder bore ID of the table below. Choose a piston of the same grade. Selective fitting for piston:

Unit: mm (in) Grade (punched) Cylinder bore ID

SEM508GB

1 89.000 - 89.010 (3.5039 - 3.5043) 88.925 - 88.935 (3.5010 - 3.5014)

2 89.010 - 89.020 (3.5043 - 3.5047) 88.935 - 88.945 (3.5014 - 3.5018)

3 89.020 - 89.030 (3.5047 - 3.5051) 88.945 - 88.955 (3.5018 - 3.5022)

Piston OD

5. Determine piston oversize according to amount of cylinder wear. For oversize pistons, 0.25 and 0.5 OS [0.25 mm (0.0098 in), 0.5 mm (0.0197 in) oversize] are available as service parts. Refer to SDS, EM-15. When using an oversize piston, hone cylinder so that the clearance between piston and cylinder becomes the specified value. Be sure to use appropriate oversize piston ring for the oversize piston. 6. Cylinder bore size is determined by adding piston-to-bore clearance to piston diameter A. Rebored size calculation: D = A + B C where, D: Bored diameter A: Piston diameter as measured B: Piston-to-bore clearance C: Honing allowance 0.02 mm (0.0008 in) 7. Cut cylinder bores. When any cylinder needs boring, all other cylinders must also be bored. Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter at a time. 8. Hone cylinders to obtain specified piston-to-bore clearance. 9. Measure finished cylinder bore for out-of-round and taper. Measurement should be done after cylinder bore cools down.

EM-4

CAMSHAFT Removal and Installation

ZD

GI MA

LC EC FE CL MT AT TF PD

SEM186H

FA RA BR ST RS

Inspection

CAMSHAFT END PLAY

Set the dial gauge to the front end of the camshaft. Measure the end play by moving the camshaft in the direction of the axle. Standard: 0.065 - 0.169 mm (0.0026 - 0.0067 in) Limit: 0.2 mm (0.0079 in)

PBIC0366E

Replace the following parts if outside the limit. a. Dimension A for camshaft (No. 2 journal) Standard: 19.455 - 19.507 mm (0.7659 - 0.7680 in) b. Dimension B for No. 2 camshaft bracket Standard: 19.338 - 19.390 mm (0.7613 - 0.7634 in) Replace camshaft and/or cylinder head referring to the standards above. NOTE: It is impossible to replace only the camshaft bracket as the camshaft bracket is manufactured with the cylinder head.

KBIA2318E

BT HA EL IDX

EM-5

CAMSHAFT Inspection (Contd)

VISUAL INSPECTION OF VALVE LIFTER

ZD

Check if surface of valve lifter has any wear or cracks. Replace valve lifter if necessary. Select the thickness of the head so that valve clearance is the standard when replacing. Refer to EM-117, Inspection in NISSAN model D22 series SERVICE MANUAL SUPPLEMENT-VI 1st Revision (Publication No. SM1E-1D22FG1).

KBIA2285E

VALVE LIFTER OUTER DIAMETER

Measure the outer diameter of the valve lifter with a micrometer. Standard: 34.455 - 34.465 mm (1.3565 - 1.3569 in)

KBIA2286E

LIFTER GUIDE INNER DIAMETER

Measure the lifter guide inner diameter of the cylinder head with an inside micrometer. Standard: 34.495 - 34.515 mm (1.3581 - 1.3589 in)

PBIC0367E

VALVE LIFTER CLEARANCE CALCULATIONS

Clearance = Lifter guide inner diameter Valve lifter outer diameter Standard: 0.030 - 0.060 mm (0.0012 - 0.0024 in) If it exceeds the standard value, refer to the outer diameter and bore diameter standard values and replace valve lifter and/or cylinder head.

EM-6

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTS Adjustments

ZD

Perform adjustment depending on selected head thickness of valve lifter. 1. Remove camshaft. Refer to EM-111, Removal in NISSAN model D22 series SERVICE MANUAL SUPPLEMENT-VI 1st Revision (Publication No. SM1E-1D22FG1). 2. Remove valve lifters at the locations that are outside the standard.

GI MA

LC

3. Measure the center thickness of the removed valve lifters with a micrometer.

EC FE CL MT

KBIA0057E

4. Use the equation below to calculate valve lifter thickness for replacement. Valve lifter thickness calculation: Thickness of replacement valve lifter = t1 + (C1 - C2) t1 = Thickness of removed valve lifter C1 = Measured valve clearance C2 = Standard valve clearance: When engine is cool [Approximately 20C (68F)] Intake and exhaust: 0.35 mm (0.014 in)

AT TF PD FA

KBIA2292E

Thickness of a new valve lifter can be identified by stamp marks on the reverse side (inside the cylinder). Stamp mark 535 indicates 5.35 mm (0.2106 in) in thickness. Available thickness of valve lifter: 15 sizes with range 5.35 to 6.05 mm (0.2106 to 0.2382 in) in steps of 0.05 mm (0.0020 in) (when manufactured at factory). Refer to EM-17, AVAILABLE VALVE LIFTER. 5. Install the selected valve lifter. 6. Install camshaft. Refer to EM-114, Installation in NISSAN model D22 series SERVICE MANUAL SUPPLEMENT-VI 1st Revision (Publication No. SM1E-1D22FG1). 7. Manually turn crankshaft pulley a few turns. 8. Make sure that valve clearances for cold engine are within specifications by referring to the specified values. Valve clearance: When engine is cool [Approximately 20C (68F)] Intake and exhaust 0.30 - 0.40 mm (0.012 - 0.016 in)

RA BR ST RS BT HA EL IDX

EM-7

TIMING GEAR Removal and Installation

2 idler gears are shown in this chapter. Idler gear (A) has scissors gear, and idler gear (B) does not.

ZD

SEM187H

EM-8

TIMING GEAR Inspection

BALANCER SHAFT OIL CLEARANCE Outer diameter of balancer shaft journal

ZD

GI MA

FEM039

Measure the outer diameter of the balancer shaft journal with a micrometer. Standard: Front side 50.875 - 50.895 mm (2.0029 - 2.0037 in) dia. Rear side 50.675 - 50.695 mm (1.9951 - 1.9959 in) dia.

LC EC FE CL MT

Inner diameter of balancer shaft bearing

Measure the inner diameter of the balancer shaft bearing using a bore gauge. Standard: Front side 50.955 - 50.980 mm (2.0061 - 2.0071 in) dia. Rear side 50.755 - 50.780 mm (1.9982 - 1.9992 in) dia.

FEM040A

Oil clearance calculations

Oil clearance = Bearing inner diameter Journal outer diameter Standard: 0.060 - 0.105 mm (0.0024 - 0.0041 in) Limit: 0.180 mm (0.0071 in) Replace the balancer shaft and/or cylinder block if it exceeds the limit. NOTE: It is impossible to replace only balancer shaft bearing because balancer shaft bearing is manufactured with cylinder block.

AT TF PD FA RA BR ST RS BT HA EL IDX

EM-9

CYLINDER HEAD Inspection

IDLER GEAR OIL CLEARANCE

ZD

FEM057

Measure the inner diameter (d1) of idler gear shaft hole. Standard: 26.000 - 26.020 mm (1.0236 - 1.0244 in) Measure the outer diameter (d2) of idler shaft. Standard: 25.967 - 25.980 mm (1.0223 - 1.0228 in) Calculate gear clearance. Clearance = d1 d2 Standard: 0.020 - 0.053 mm (0.0008 - 0.0021 in) Replace idler gear and/or idler shaft if it is outside the limit.

Disassembly and Assembly

PBIC1749E

Inspection

VALVE DIMENSION

Using micrometer, measure the dimensions of each part. Standard

Unit: mm (in)

a b

PBIC0413E

c d D

Intake valve 113.5 (4.468) 3.8 - 4.2 (0.150 - 0.165) 1.5 (0.059) 6.962 - 6.977 (0.2741 - 0.2747) 31.9 - 32.1 (1.256 - 1.264) 4500 - 4530

Exhaust valve 113.5 (4.468) 3.8 - 4.2 (0.150 - 0.165) 1.5 (0.059) 6.945 - 6.960 (0.2734 - 0.2740) 29.9 - 30.1 (1.177 - 1.185) 4500 - 4530

EM-10

CYLINDER HEAD Inspection (Contd)

VALVE GUIDE CLEARANCE

ZD

Calculate the clearance by measuring valve stem outer diameter and valve guide inner diameter.

Unit: mm (in)

Standard Intake Exhaust 0.023 - 0.056 (0.0009 - 0.0022) 0.040 - 0.073 (0.0016 - 0.0029) Limit 0.18 (0.0071) 0.10 (0.0039)

GI MA

SEM938C

If the measured value exceeds the limit, replace valve guide and/or valve.

LC EC FE CL MT AT TF PD FA RA BR ST RS BT HA EL IDX

EM-11

CYLINDER BLOCK Inspection

SELECTIVE PISTON COMBINATION

ZD

Selective combination chart New pistons are classified into 4 weight classes at factory. The same class pistons are used on a engine.

Weight grade symbol E F G H Weight class g (oz) 615 - 620 (21.7 - 21.9) 620 - 625 (21.9 - 22.0) 625 - 630 (22.0 - 22.2) 630 - 635 (22.2 - 22.4)

CRANKSHAFT RUNOUT

Place V-block onto surface plate to support No. 2 and No. 4 journals. Position dial indicator vertically onto No. 1, No. 3 and No. 5 journals. Rotate crankshaft to read needle movement on dial indicator. (Total indicator reading) Standard: Less than 0.01 mm (0.0004 in) Limit: 0.03 mm (0.0012 in) Replace crankshaft if it exceeds the limit.

PBIC1756E

CONNECTING ROD BEARING CRUSH HEIGHT

Tighten connecting rod caps to the specified torque with connecting rod bearings installed. : 79 - 83 Nm (8.0 - 8.5 kg-m, 58 - 61 ft-lb) Remove connecting rod caps. The connecting rod bearing end must then be higher than the flat surface. Standard: Crush height must exist. If out of specification, replace connecting rod bearings.

PBIC1646E

OIL JET

Check nozzle for deformation and damage. Blow compressed air from nozzle, and check for clogs. Standard: No deformation and no damage. Replace oil jet if it is out of the standard.

PBIC0392E

EM-12

CYLINDER BLOCK Inspection (Contd)

OIL JET RELIEF VALVE

ZD

Press check valve in oil jet relief valve using a clean plastic stick. Make sure that valve moves smoothly with proper reaction force. Standard: Valve moves smoothly with proper reaction force. Replace oil jet relief valve if it is out of the standard.

GI MA

EMT0186D

LC EC FE CL MT AT TF PD FA RA BR ST RS BT HA EL IDX

EM-13

SERVICE DATA AND SPECIFICATIONS (SDS) Cylinder Head

YD

Unit: mm (in) Standard Head surface distortion Less than 0.03 (0.0012) Limit 0.1 (0.004)

JEM204G

EM-14

SERVICE DATA AND SPECIFICATIONS (SDS) Cylinder Block

YD

Unit: mm (in)

GI MA

LC

SEM899G

EC FE CL MT AT

Standard Surface flatness Limit Grade No. 1 Standard Cylinder bore Inner diameter Grade No. 3 Wear limit Out-of-round (Difference between X and Y) Taper (Difference between A and C) Grade No. 2

Less than 0.03 (0.0012) 0.1 (0.004) 89.000 - 89.010 (3.5039 - 3.5043) 89.010 - 89.020 (3.5043 - 3.5047) 89.020 - 89.030 (3.5047 - 3.5051) 0.07 (0.0028) Less than 0.015 (0.0006) Less than 0.010 (0.0004)

Piston, Piston Ring and Piston Pin

AVAILABLE PISTON

Unit: mm (in)

TF PD FA RA BR

SEM882E

Grade No. 1 Grade No. 2 Piston skirt diameter A Standard Grade No. 3 0.25 (0.0098) oversize (Service) 0.50 (0.0197) oversize (Service) a dimension Piston clearance to cylinder block

88.925 - 88.935 (3.5010 - 3.5014) 88.935 - 88.945 (3.5014 - 3.5018) 88.945 - 88.955 (3.5018 - 3.5022) 89.175 - 89.205 (3.5108 - 3.5120) 89.425 - 89.455 (3.5207 - 3.5218) 59.0 (2.323) 0.065 - 0.085 (0.0026 - 0.0033)

ST RS BT HA EL IDX

EM-15

SERVICE DATA AND SPECIFICATIONS (SDS) Valve

VALVE

ZD

Unit: mm (in)

PBIC0413E

Intake Valve length a Exhaust Intake b Exhaust Intake Valve margin c Exhaust Intake Valve stem diameter d Exhaust Intake Valve head diameter D Exhaust Intake Valve seat angle Exhaust 4500 - 4530 29.9 - 30.1 (1.177 - 1.185) 6.945 - 6.960 (0.2734 - 0.2740) 31.9 - 32.1 (1.256 - 1.264) 6.962 - 6.977 (0.2741 - 0.2747) 1.5 (0.059) 3.8 - 4.2 (0.150 - 0.165) 113.5 (4.468)

VALVE CLEARANCE

Unit: mm (in) Items Intake and exhaust *: Approximately 20C (68F) Cold* 0.30 - 0.40 (0.012 - 0.016)

EM-16

SERVICE DATA AND SPECIFICATIONS (SDS) Valve (Contd)

AVAILABLE VALVE LIFTER

ZD

Unit: mm (in) Identification mark 535 540 545 550 555 560 565 570 575 580 585 590 595 600 605 Thickness 5.35 (0.2106) 5.40 (0.2126) 5.45 (0.2146) 5.50 (0.2165) 5.55 (0.2185) 5.60 (0.2205) 5.65 (0.2224) 5.70 (0.2244) 5.75 (0.2264) 5.80 (0.2283) 5.85 (0.2303) 5.90 (0.2323) 5.95 (0.2343) 6.00 (0.2362) 6.05 (0.2382)

GI MA

LC EC FE CL MT AT TF PD FA

KBIA2292E

RA

VALVE LIFTER

Unit: mm (in) Valve lifter outer diameter Lifter guide inner diameter Clearance between lifter and lifter guide 34.455 - 34.465 (1.3565 - 1.3569) 34.495 - 34.515 (1.3581 - 1.3589) 0.030 - 0.060 (0.0012 - 0.0024)

BR ST RS BT HA EL IDX

EM-17

SERVICE DATA AND SPECIFICATIONS (SDS) Valve (Contd)

VALVE GUIDE

ZD

Unit: mm (in)

FEM071

Standard Outer diameter Valve guide Inner diameter (Finished size) Cylinder head valve guide hole diameter Interference fit of valve guide Intake Stem to guide clearance Exhaust Projection length 0.040 - 0.073 (0.0016 - 0.0029) 12.8 - 13.2 (0.5309 - 0.5197) 7.000 - 7.018 (0.2756 - 0.2763) 10.996 - 10.975 (0.4329 - 0.4321) 0.027 - 0.059 (0.0011 - 0.0023) 0.023 - 0.056 (0.0009 - 0.0022) 11.023 - 11.034 (0.4340 - 0.4344)

Limit 0.18 (0.0071) 0.10 (0.0039)

EM-18

SERVICE DATA AND SPECIFICATIONS (SDS) Camshaft and Camshaft Bearing

ZD

Unit: mm (in) Standard Camshaft end play 0.065 - 0.169 (0.0026 - 0.0067) Limit 0.2 (0.008)

GI MA

LC EC FE

KBIA2318E

CL MT AT TF

Camshaft (No. 2 journal) A dimension No. 2 camshaft bracket B dimension

19.455 - 19.507 (0.7659 - 0.7680) 19.338 - 19.390 (0.7613 - 0.7634)

Valve timing

PD FA

PBIC0517E

Unit: degree a 232 b 220 c 6 d 34 e 50

RA BR ST

Crankshaft

Unit: mm (in) Standard Runout [TIR*] Limit *: Total indicator reading 0.03 (0.0012) Less than 0.01 (0.0004)

RS BT

Unit: mm (in)

Available Connecting Rod Bearing

BALANCER SHAFT BEARING

Front Balancer shaft journal outer diameter Rear Front Balancer shaft bearing inner diameter Rear Standard Balancer shaft journal oil clearance Limit 0.180 (0.0071) 50.755 - 50.780 (1.9982 - 1.9992) 0.060 - 0.105 (0.0024 - 0.0041) 50.675 - 50.695 (1.9951 - 1.9959) 50.955 - 50.980 (2.0061 - 2.0071) 50.875 - 50.895 (2.0029 - 2.0037)

HA EL IDX

EM-19

Vous aimerez peut-être aussi

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (2)

- Em - Engine Mechanical PDFDocument24 pagesEm - Engine Mechanical PDFMoaed Kanbar86% (21)

- ZD30Document9 pagesZD30Moaed Kanbar60% (5)

- Manual Yd25ddtiDocument299 pagesManual Yd25ddtiCato del Rio86% (44)

- Navara D40Document576 pagesNavara D40Daniel Stuparek100% (25)

- Motor YD25 y KA24 PDFDocument211 pagesMotor YD25 y KA24 PDFClareth Antonio Rodriguez LopezPas encore d'évaluation

- NISSAN YD25 Manual de MotorDocument146 pagesNISSAN YD25 Manual de MotorMiguel Angel Sancho94% (50)

- ZD30 CRD 2008 1Document74 pagesZD30 CRD 2008 1powermanager96% (28)

- Nissan Navara Workshop Manual - Automatic TransmissionDocument350 pagesNissan Navara Workshop Manual - Automatic Transmissionbdsisira83% (29)

- Nissan Patrol ZD30 Y61 Reference Document - ColourDocument129 pagesNissan Patrol ZD30 Y61 Reference Document - ColourIurie Maxim92% (12)

- Factory Workshop Manual of Nissan Zd30ddtiDocument2 pagesFactory Workshop Manual of Nissan Zd30ddtiCollin Tjizu20% (15)

- YD25 CR Fault Diagnosis PDFDocument101 pagesYD25 CR Fault Diagnosis PDFWayne Mcmeekan83% (46)

- Nissan Navara Workshop ManualDocument12 pagesNissan Navara Workshop Manualbdsisira78% (9)

- Nissan Navara Workshop Manual CLDocument22 pagesNissan Navara Workshop Manual CLbdsisira89% (9)

- Em PDFDocument287 pagesEm PDFDavid Mayahua Ortega67% (3)

- D-22 Engine MechanicalDocument136 pagesD-22 Engine MechanicalJose Figueroa60% (5)

- YD25 CR Fault Diagnosis PDFDocument101 pagesYD25 CR Fault Diagnosis PDFMaurihuaanaa Navarro Santana100% (7)

- Navara Engine Maintenance (Yd25ddti)Document50 pagesNavara Engine Maintenance (Yd25ddti)MTK2016100% (6)

- Engine Manual Nissan MR18Document116 pagesEngine Manual Nissan MR18HeverzonYairPeñalozaLozano76% (17)

- Lan Navara d40Document152 pagesLan Navara d40Bryan marcelino Figueroa peñaPas encore d'évaluation

- Nissan Navara D22 Zd30 Repair Manual: Read/DownloadDocument2 pagesNissan Navara D22 Zd30 Repair Manual: Read/DownloadChew Lay43% (23)

- EM Yd 25 Ddti (d40 2014) PDFDocument152 pagesEM Yd 25 Ddti (d40 2014) PDFAlex Polo Luis100% (2)

- Y61 CRD TMDocument83 pagesY61 CRD TMjuanmanuel_4615958100% (12)

- Motor Ford Ranger PDFDocument782 pagesMotor Ford Ranger PDFPedro Aguilera100% (1)

- Especificaciones Nissan ZD30 TD DIDocument2 pagesEspecificaciones Nissan ZD30 TD DIGuilherme Tyska56% (9)

- Nissan Td42 EngineDocument100 pagesNissan Td42 Enginearjun c75% (4)

- Ec - Engine Control System PDFDocument75 pagesEc - Engine Control System PDFMoaed Kanbar88% (8)

- Motor Nissan Hr16deDocument127 pagesMotor Nissan Hr16deAdriánSchumm92% (12)

- .Archivetempengine - ZD30DDTi Diesel Engine Maintenance ManualDocument70 pages.Archivetempengine - ZD30DDTi Diesel Engine Maintenance ManualEduardoGaleano75% (8)

- At Nissan NavaraDocument217 pagesAt Nissan NavaraMaurihuaanaa Navarro Santana100% (4)

- 4JH1-TC MecánicaDocument69 pages4JH1-TC MecánicaClaudio Oporto75% (28)

- 4wd Nissan NavaraDocument70 pages4wd Nissan Navararomeo_mec100% (3)

- Workshop Manual Puma 2.2LDocument152 pagesWorkshop Manual Puma 2.2LGaston Como100% (6)

- Nissan Frontier Yd25 Engine ManualDocument4 pagesNissan Frontier Yd25 Engine Manualjose43% (14)

- Nissan Urvan Repair Manual PDFDocument3 pagesNissan Urvan Repair Manual PDFJillian Marie Livioco36% (11)

- Nissan D 40 ECDocument959 pagesNissan D 40 ECHarlinton descalzi100% (8)

- Engine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDocument4 pagesEngine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDavid R PaucaraPas encore d'évaluation

- 5l-E Engine EletricalDocument246 pages5l-E Engine EletricalMagno Dias96% (23)

- 1kd FTV OverhaulDocument37 pages1kd FTV OverhaulJehuty8897% (34)

- d22 ManualDocument1 paged22 ManualIsrael AGPas encore d'évaluation

- Nissan TD 42 Manual de ServicioDocument23 pagesNissan TD 42 Manual de ServicioFerran AlfonsoPas encore d'évaluation

- Manual Repair Nissan QuestDocument18 pagesManual Repair Nissan QuestALONDRA NATALI GONAZLEZ CANCHEPas encore d'évaluation

- Reglaje de ValvulasDocument15 pagesReglaje de ValvulasJuan Antonio Ochoa PadronPas encore d'évaluation

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevPas encore d'évaluation

- Procedimietos CulataDocument15 pagesProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATOPas encore d'évaluation

- Crankshaft AssemblyDocument80 pagesCrankshaft AssemblyGreg HannaPas encore d'évaluation

- Medidas e Torques (C15 C18)Document50 pagesMedidas e Torques (C15 C18)caiocunhaconquista100% (1)

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaPas encore d'évaluation

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicPas encore d'évaluation

- Suzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoDocument248 pagesSuzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoLolok Tiviyanto100% (3)

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- 1HD-T 2Document37 pages1HD-T 2HERMAWAN100% (2)

- Derbi Technical Training 2010 (125 4T 4V)Document48 pagesDerbi Technical Training 2010 (125 4T 4V)Manualles73% (22)

- 19d Impeller SpacingDocument9 pages19d Impeller Spacingbtgottlieb100% (1)

- Motor3 Suzuki VL800Document20 pagesMotor3 Suzuki VL800Crisan SorinPas encore d'évaluation

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustVictor NunezPas encore d'évaluation

- Mazda FE y F2Document27 pagesMazda FE y F2jads30117971% (14)

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozPas encore d'évaluation

- Engine Base & BlockDocument47 pagesEngine Base & Blockkr_abhijeet7235658750% (2)

- c18 Folga de ValvulasDocument4 pagesc18 Folga de ValvulasNewman CardosoPas encore d'évaluation

- Manual Transmission: (M5/6Cfx-1)Document10 pagesManual Transmission: (M5/6Cfx-1)Moaed Kanbar100% (2)

- PB MDPS EngDocument9 pagesPB MDPS EngMoaed KanbarPas encore d'évaluation

- Denoxtronic PDFDocument29 pagesDenoxtronic PDFanshel100% (2)

- الأزمنة في الإنكليزيDocument23 pagesالأزمنة في الإنكليزيMoaed KanbarPas encore d'évaluation

- اسئلة تمهيدي انكليزي من 2014 -2020Document114 pagesاسئلة تمهيدي انكليزي من 2014 -2020Moaed KanbarPas encore d'évaluation

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarPas encore d'évaluation

- PB SRS EngDocument18 pagesPB SRS EngMoaed KanbarPas encore d'évaluation

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarPas encore d'évaluation

- PB Engine U-II EngDocument12 pagesPB Engine U-II EngMoaed Kanbar100% (1)

- PB Air Conditioning EngDocument18 pagesPB Air Conditioning EngMoaed KanbarPas encore d'évaluation

- In-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHDocument1 pageIn-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHMoaed Kanbar100% (1)

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocument5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GeneralsadiksnmPas encore d'évaluation

- Manual 6488 OTCDocument6 pagesManual 6488 OTCjr100100100% (1)

- صمام التمددDocument5 pagesصمام التمددnazar750Pas encore d'évaluation

- Acl Pistonproducts Pp99Document275 pagesAcl Pistonproducts Pp99Moaed Kanbar100% (1)

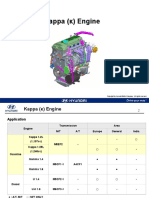

- PB Engine Kappa EngDocument15 pagesPB Engine Kappa EngMoaed Kanbar50% (2)

- PB Engine Gamma EngDocument14 pagesPB Engine Gamma EngMoaed Kanbar100% (3)

- Piston Ring Assembly Tips 4strk - Ringinstall2!24!05Document2 pagesPiston Ring Assembly Tips 4strk - Ringinstall2!24!05michaelmangaaPas encore d'évaluation

- 28-01008 2254-2262 PDFDocument9 pages28-01008 2254-2262 PDFMoaed KanbarPas encore d'évaluation

- Cross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)Document107 pagesCross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)bogdanxp2000100% (4)

- 05Document7 pages05Moaed KanbarPas encore d'évaluation

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 pagesMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- 28-01008 2254-2262 PDFDocument9 pages28-01008 2254-2262 PDFMoaed KanbarPas encore d'évaluation

- SSP 275 Phaeton Air Suspension 3 PDFDocument21 pagesSSP 275 Phaeton Air Suspension 3 PDFMoaed Kanbar0% (1)

- Fuel InjectionDocument37 pagesFuel InjectionBence M ZoltanPas encore d'évaluation

- Continuous Variable Valve Timing (CVVT), FunctionDocument2 pagesContinuous Variable Valve Timing (CVVT), FunctionMoaed KanbarPas encore d'évaluation

- Variable Valve TimingDocument19 pagesVariable Valve TimingShrigopal PrajapatPas encore d'évaluation

- Variable Valve TimingDocument3 pagesVariable Valve TimingAjay AgarwalPas encore d'évaluation

- Eng 2013031916240410Document6 pagesEng 2013031916240410Moaed KanbarPas encore d'évaluation

- Clean and Cool PDFDocument4 pagesClean and Cool PDFMoaed KanbarPas encore d'évaluation

- Inline Check Sieve: High-Quality End ProductsDocument2 pagesInline Check Sieve: High-Quality End ProductsGreere Oana-NicoletaPas encore d'évaluation

- JEEP 4.0L Fastener Torque SpecsDocument2 pagesJEEP 4.0L Fastener Torque Specssplint_slpa50% (8)

- CE-415 Reinforced Concrete Design-2: Engr. Shehryar AhmedDocument40 pagesCE-415 Reinforced Concrete Design-2: Engr. Shehryar AhmedJamal ShahPas encore d'évaluation

- A318-A319-A320-A321 - (A320-SRM) (53-00-11 Pageblock 201 SKIN PLATES - SKIN PLATES)Document119 pagesA318-A319-A320-A321 - (A320-SRM) (53-00-11 Pageblock 201 SKIN PLATES - SKIN PLATES)Violet ParisPas encore d'évaluation

- Department of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIDocument22 pagesDepartment of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIswarup babalsurePas encore d'évaluation

- Procurement Monitoring TemplateDocument13 pagesProcurement Monitoring TemplateHermantoro W. PradanaPas encore d'évaluation

- Qdoc - Tips - Flange Asme VIIIDocument41 pagesQdoc - Tips - Flange Asme VIIIHormedo RodriguezPas encore d'évaluation

- Pawl Hubs (370, 370TA) Technical ManualDocument54 pagesPawl Hubs (370, 370TA) Technical ManualArthur PabloPas encore d'évaluation

- 08 Exhaust Valve System (Sep 2015) PDFDocument21 pages08 Exhaust Valve System (Sep 2015) PDFValeriy Domashenko100% (1)

- SEBF 8174 коромысла 3500Document13 pagesSEBF 8174 коромысла 3500Евгений АбрамовPas encore d'évaluation

- Catalogue DX SPLIT UNIT CarrierDocument25 pagesCatalogue DX SPLIT UNIT CarrierZiad Ragab89% (9)

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRAPas encore d'évaluation

- Sunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Document1 pageSunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Nova VanoPas encore d'évaluation

- Circuit Breaker Safety Interlock Systems ExplainedDocument13 pagesCircuit Breaker Safety Interlock Systems ExplainedArif KhanPas encore d'évaluation

- CalcManualGoldEng Dentadas PDFDocument72 pagesCalcManualGoldEng Dentadas PDFGabriel AraujoPas encore d'évaluation

- Lecture 5-Gears - General - 4-L - Helical and Bevel ForceDocument41 pagesLecture 5-Gears - General - 4-L - Helical and Bevel ForceAhmed Al SayedPas encore d'évaluation

- Sample, Boq of Steel Columns, Platform, Roof, Staircase (Proj-Transmittal, P.d.laboratory)Document11 pagesSample, Boq of Steel Columns, Platform, Roof, Staircase (Proj-Transmittal, P.d.laboratory)Rohan JaiswalPas encore d'évaluation

- BrochureDocument10 pagesBrochureArchana ChavanPas encore d'évaluation

- SSC-JE 2022: Staff Selection Commision-Junior EngineerDocument12 pagesSSC-JE 2022: Staff Selection Commision-Junior EngineerAsheesh KumarPas encore d'évaluation

- Sa 455Document4 pagesSa 455Widya widya0% (1)

- Euro - Props According To DIN EN 1065 Manual: Euro Props Class B/D With Male ThreadDocument1 pageEuro - Props According To DIN EN 1065 Manual: Euro Props Class B/D With Male Threadmohd firdaus bin ibrahimPas encore d'évaluation

- TR100 7831Document550 pagesTR100 7831cesar100% (1)

- Fabricated Basket Strainers: Features OptionsDocument3 pagesFabricated Basket Strainers: Features OptionsmusaveerPas encore d'évaluation

- Renewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredDocument5 pagesRenewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredArkidPas encore d'évaluation

- Kindrick Torque WrenchDocument4 pagesKindrick Torque WrenchGibbs PerPas encore d'évaluation

- Schade DCI Jun09Document4 pagesSchade DCI Jun09Herberth SilitongaPas encore d'évaluation

- SCR15 20PM Spare Parts List 2Document17 pagesSCR15 20PM Spare Parts List 2YaroslavPas encore d'évaluation

- Travel Drive FAT 325P129: Installation ManualDocument37 pagesTravel Drive FAT 325P129: Installation ManualŁukasz AdamczakPas encore d'évaluation

- TG Probes-Acc PL 0111Document7 pagesTG Probes-Acc PL 01117043578600Pas encore d'évaluation

- Estimate of Site OfficeDocument6 pagesEstimate of Site OfficeAnil PuvadaPas encore d'évaluation