Académique Documents

Professionnel Documents

Culture Documents

Gloria Material Technology Corp.: 1. Chemical Composition

Transféré par

pvdang0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues1 pageGRADE EVERCUT 304 spec. AIMING RABGE 2. CHEMICAL COMPOSITION: Condition SOLUTION Heat treated spec. Typical analysis Tensile Strength Ksi 75 min. 80 N / mm2 515 min. 551 0.2%Yield Strength Elongation Reduction of Area Brinell Grain Size Hardness NO. 4.QUALITY CERTIFICATE STATEMEMT: 1.SOLUTION ANNEALING TEMPERATURE AND TIME:

Description originale:

Titre original

A728Ed01

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentGRADE EVERCUT 304 spec. AIMING RABGE 2. CHEMICAL COMPOSITION: Condition SOLUTION Heat treated spec. Typical analysis Tensile Strength Ksi 75 min. 80 N / mm2 515 min. 551 0.2%Yield Strength Elongation Reduction of Area Brinell Grain Size Hardness NO. 4.QUALITY CERTIFICATE STATEMEMT: 1.SOLUTION ANNEALING TEMPERATURE AND TIME:

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues1 pageGloria Material Technology Corp.: 1. Chemical Composition

Transféré par

pvdangGRADE EVERCUT 304 spec. AIMING RABGE 2. CHEMICAL COMPOSITION: Condition SOLUTION Heat treated spec. Typical analysis Tensile Strength Ksi 75 min. 80 N / mm2 515 min. 551 0.2%Yield Strength Elongation Reduction of Area Brinell Grain Size Hardness NO. 4.QUALITY CERTIFICATE STATEMEMT: 1.SOLUTION ANNEALING TEMPERATURE AND TIME:

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

GLORIA MATERIAL TECHNOLOGY CORP.

EVERCUT 304

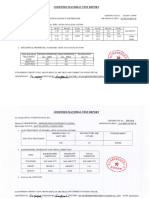

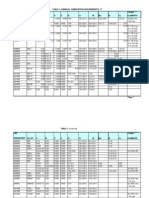

1. CHEMICAL COMPOSITION:

GRADE

EVERCUT 304 SPEC.

C max. 0.08 0.04 0.08

Si max. 1.00 0.20 0.50

Mn max. 2.00 1.40 1.90

P max. 0.040 max. 0.035

S 0.023 0.030 0.025 0.030

Ni 8.00 10.00 8.00 9.00

Cr 18.00 20.00 18.00 18.50

Mo max. 0.50 max. 0.50

Cu max. 0.50 max. 0.50

(wt%) N max. 0.10 0.05 0.10

Co max. 0.50 ---

AIMING RABGE

2. Mechanical Properties:

Condition Solution Heat treated spec. typical analysis Tensile Strength Ksi 75 min. 80 N / mm2 515 min. 551

0.2%Yield Strength Elongation

Reduction of Area

Brinell Grain Size Hardness

Ksi 30 min. 36

N / mm2 205 min. 246

% 40 min. 63

% 50 min. 77

HB 187 max. 149

ASTM E112 reported

NO.6

3.SPECIFICATION:

1.ASTM A484, A182, A276, A314, A473, A479 2.ASTM A193, Class 1, Grade B8 3.ASTM A194, Class 1, Grade 8/8A 4.ASTM A320, Class 1, Grade B8 5.ASME SA484 6.ASME SA193, Class 1, Grade B8 7.ASME SA320, Class 1, Grade B8 8.ASME SA182 9.ASME SA479 10.AMS 5639 11.QQ-S-763E, 763F 12.MIL-S-862B 13.MACE MR0175

4.QUALITY CERTIFICATE STATEMEMT:

1.SOLUTION ANNEALING TEMPERATURE AND TIME:1900F4HOUR, WATER COOLED. 2.CORROSION TEST:PASSED PER ASTM A262 PRACTICE A&E. 3.MATERIAL FREE FROM CONTINUOUS CARBIDE NETWORK. 4.MACRO/ MICRO STRUCTURE:GOOD. 5.MATERIAL FREE FROM KNOWN CONTACT WITH MERCURY & RADIUM. 6.MATERIAL FREE FROM WELDS OR WELD REPAIRS. 7.MELTING PROCESS: AOD OR VOD. THEN Ca-Si TREATED. 8.NO PRODUCT THAT CONTAIN OR WERE MADE WITH ODC'S. 9.EVERCUT 303 CONFIRMED FOR IMPROVED MACHINABILITY.

5.Manufacturing range: 590mm

Gloria Material Technology Corp.

5,HSIN CHUNG RD. HSIN YING, TAINAN, TAIWAN 730 TEL:886-6-6520000 FAX:886-6-6520088 http://www.gmtc.com.tw

GMTC

R O U P

Vous aimerez peut-être aussi

- D 01Document1 pageD 01pvdangPas encore d'évaluation

- Evercut 303: Gloria Material Technology CorpDocument1 pageEvercut 303: Gloria Material Technology CorppvdangPas encore d'évaluation

- 316 PDFDocument1 page316 PDFViswanathan SrkPas encore d'évaluation

- ASTM Materials - CHINA MaterialsDocument29 pagesASTM Materials - CHINA MaterialsHema HemaPas encore d'évaluation

- Gloria Material Technology Corp.: 2205 (UNS S31803) Duplex Stainless SteelDocument1 pageGloria Material Technology Corp.: 2205 (UNS S31803) Duplex Stainless SteelpvdangPas encore d'évaluation

- MTR - HT# 52154Document1 pageMTR - HT# 52154ColinPas encore d'évaluation

- Bhel Welding GuidelinesDocument64 pagesBhel Welding Guidelinesashutoshsachan100% (3)

- Gloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecDocument1 pageGloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecpvdangPas encore d'évaluation

- Alloy Steels: GMTC GMTCDocument2 pagesAlloy Steels: GMTC GMTCpvdangPas encore d'évaluation

- WS410Document7 pagesWS410Martin OusephPas encore d'évaluation

- UntitledDocument11 pagesUntitledzaxaxazPas encore d'évaluation

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Document1 pageC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용Pas encore d'évaluation

- Bolts Material Selection PDFDocument10 pagesBolts Material Selection PDFskarapournos100% (1)

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiPas encore d'évaluation

- 420C Stainless Steel Spec.: Gloria Material Technology CorpDocument1 page420C Stainless Steel Spec.: Gloria Material Technology CorppvdangPas encore d'évaluation

- Specifications For PlatesDocument4 pagesSpecifications For PlatesRv VaghasiaPas encore d'évaluation

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykPas encore d'évaluation

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiPas encore d'évaluation

- AISI Type 304 Stainless Steel: Material NotesDocument1 pageAISI Type 304 Stainless Steel: Material Notesunnamed90Pas encore d'évaluation

- Certif Tu inDocument18 pagesCertif Tu inSri GangaPas encore d'évaluation

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy Detailcharles_boyle_3Pas encore d'évaluation

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoPas encore d'évaluation

- Certified Material Test Report 1Document2 pagesCertified Material Test Report 1Nam Nguyen HuuPas encore d'évaluation

- T, RTFF ": Technical DataDocument1 pageT, RTFF ": Technical DataNirmit GandhiPas encore d'évaluation

- Kamal Cement Test CertificateDocument115 pagesKamal Cement Test CertificateKuldeep ChakerwartiPas encore d'évaluation

- Stainless Steel Bolts ManufacturerDocument3 pagesStainless Steel Bolts ManufacturerRajtilak MetalPas encore d'évaluation

- Stainless Steel - Grade 304: Chemical Formula Topics CoveredDocument4 pagesStainless Steel - Grade 304: Chemical Formula Topics CoveredvibishnanPas encore d'évaluation

- Consolidation TestDocument4 pagesConsolidation TestsunartililikPas encore d'évaluation

- High Speed Tool Steel: GMTC GMTCDocument2 pagesHigh Speed Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- Indian Standard Steel SectionsDocument9 pagesIndian Standard Steel SectionsAmitava SilPas encore d'évaluation

- Sepction - 2Document4 pagesSepction - 2k koradiaPas encore d'évaluation

- Botl and Nut SpecificationDocument17 pagesBotl and Nut SpecificationganeshPas encore d'évaluation

- Aisi 340 Info PDFDocument3 pagesAisi 340 Info PDFAn DikaPas encore d'évaluation

- Dunaferr - Cold - RolledDocument12 pagesDunaferr - Cold - RolledMihály PálffyPas encore d'évaluation

- Normas de Acero - Grupo 3Document11 pagesNormas de Acero - Grupo 3JoseAndresAAPas encore d'évaluation

- WS412Document7 pagesWS412Martin OusephPas encore d'évaluation

- Coupler Plate RM Pipe TCDocument1 pageCoupler Plate RM Pipe TCshindemitesh17Pas encore d'évaluation

- Stainless Steel Grade 304 (UNS S30400)Document5 pagesStainless Steel Grade 304 (UNS S30400)Gangsar DwikaPas encore d'évaluation

- Ar 300ZD TDSDocument1 pageAr 300ZD TDSemrah turerPas encore d'évaluation

- Astm 588 PDFDocument1 pageAstm 588 PDFbalramkinage100% (2)

- Background: Table 1. Composition Ranges For 304 Grade Stainless SteelDocument4 pagesBackground: Table 1. Composition Ranges For 304 Grade Stainless SteelsupermannonPas encore d'évaluation

- S235JR Sau OL 37Document1 pageS235JR Sau OL 37Pișta GonzalesPas encore d'évaluation

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17Pas encore d'évaluation

- Table 1 Chemical Composition Requirements, %: UNS DesignationDocument5 pagesTable 1 Chemical Composition Requirements, %: UNS DesignationQuraPas encore d'évaluation

- Plastic Mould Steel: GMTC GMTCDocument3 pagesPlastic Mould Steel: GMTC GMTCpvdangPas encore d'évaluation

- D0 F04 D 01Document1 pageD0 F04 D 01pvdangPas encore d'évaluation

- GMTC GMTC: Gloria Material Technology CorpDocument1 pageGMTC GMTC: Gloria Material Technology CorppvdangPas encore d'évaluation

- Shock Resistant Tool Steel: GMTC GMTCDocument2 pagesShock Resistant Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- Hot Work Tool Steel: GMTC GMTCDocument2 pagesHot Work Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- High Speed Steel: GMTC GMTCDocument3 pagesHigh Speed Steel: GMTC GMTCpvdangPas encore d'évaluation

- Gloria Material Technology Corp.: XM-25 Precipitation Harding Stainless Steel SpecDocument1 pageGloria Material Technology Corp.: XM-25 Precipitation Harding Stainless Steel SpecpvdangPas encore d'évaluation

- B3 EECd 01Document1 pageB3 EECd 01pvdangPas encore d'évaluation

- As 1554 Part 3 - Welding Reinforcing SteelDocument29 pagesAs 1554 Part 3 - Welding Reinforcing Steelpvdang50% (2)

- High Speed Tool Steel: GMTC GMTCDocument2 pagesHigh Speed Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- Plastic Mould Steel: GMTC GMTCDocument3 pagesPlastic Mould Steel: GMTC GMTCpvdangPas encore d'évaluation

- Hot-Work Tool Steel: GMTC GMTCDocument3 pagesHot-Work Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- Gloria Material Technology Corp.: AISI 403 Martensitic Stainless SteelDocument1 pageGloria Material Technology Corp.: AISI 403 Martensitic Stainless SteelpvdangPas encore d'évaluation

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpDocument1 pageAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangPas encore d'évaluation

- High Speed Tool Steel: GMTC GMTCDocument2 pagesHigh Speed Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- 440C Martensitic Stainless Steel: Gloria Material Technology CorpDocument1 page440C Martensitic Stainless Steel: Gloria Material Technology CorppvdangPas encore d'évaluation

- 420C Stainless Steel Spec.: Gloria Material Technology CorpDocument1 page420C Stainless Steel Spec.: Gloria Material Technology CorppvdangPas encore d'évaluation

- Shock Resistant Tool Steel: GMTC GMTCDocument2 pagesShock Resistant Tool Steel: GMTC GMTCpvdangPas encore d'évaluation

- Gloria Material Technology Corp.: AISI 416 Stainless SteelDocument1 pageGloria Material Technology Corp.: AISI 416 Stainless SteelpvdangPas encore d'évaluation

- Gloria Material Technology Corp.: 1. Chemical CompositionDocument1 pageGloria Material Technology Corp.: 1. Chemical CompositionpvdangPas encore d'évaluation

- Fe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationDocument1 pageFe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationpvdangPas encore d'évaluation

- Gloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecDocument1 pageGloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecpvdangPas encore d'évaluation

- Ni-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationDocument2 pagesNi-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationpvdangPas encore d'évaluation

- Plastic Mould Steel: GMTC GMTCDocument2 pagesPlastic Mould Steel: GMTC GMTCpvdangPas encore d'évaluation

- High Speed Steel: GMTC GMTCDocument2 pagesHigh Speed Steel: GMTC GMTCpvdangPas encore d'évaluation

- Alloy Steels SCM440Document2 pagesAlloy Steels SCM440Shamik Chowdhury100% (1)

- Alloy Steels: GMTC GMTCDocument2 pagesAlloy Steels: GMTC GMTCpvdangPas encore d'évaluation