Académique Documents

Professionnel Documents

Culture Documents

Mechanical Ash Handling Systems: Metso

Transféré par

rmm99rmm99Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanical Ash Handling Systems: Metso

Transféré par

rmm99rmm99Droits d'auteur :

Formats disponibles

Metso

Mechanical Ash Handling Systems

Integrated systems approach

providing a competitive edge through greater

Metsos mechanical ash systems are safe, effective, reliable and performance-proven. We have installed complete ash handling systems for power plants, pulp and paper mills, waste to energy facilities, etc. Dry Drag Chain Conveyors

The dry drag chain conveyor can be applied to precipitators, fabric filters, boiler hoppers or cyclones for the collection of fly ash. For dust and fire control, these units handle fly ash in a dust-tight, air-tight construction. Our drag chain conveyors can move material 8 to 12 feet per minute to a storage location and/or disposal location and can have up to a 35-degree incline. Our conveyors occupy minimum space with maximum materials handling capabilities.

Our units are designed to handle bottom ash and fly ash efficiently, economically and dust-free. No matter what the application coal, wood, refuse ash, scrubber sludge or other our engineers can design an ash handling system to meet your specific specifications. We keep capital investment costs lower and maintenance and operating expenses to a minimum.

Metsos engineers are available on a 24 hour a day basis to assist you with your specific ash handling concerns.

2 Mechanical ash handling systems

capacity and efficiency

Submerged Chain Conveyors

Bottom ash is continually collected, cooled and dewatered with a submerged chain conveyor. Ash falls constantly from a boiler through a discharge hopper into a waterfilled chamber where the continuous-loop, dual-strand submerged chain conveyor cools it and transports it for disposal. Like the dry drag chain conveyors, our units move material approximately 8 to 12 feet per minute and can have up to a 35-degree incline. This incline section allows excess water to be drained from the material. For maintenance outages and easy access to the boiler, our submerged chain conveyors are designed on rollers.

Mechanical Conveying Offers:

Reduced capital costs Less space-consuming equipment Lower power consumption Less maintenance requirements

Mixer Conditioners

Metsos mixer conditioners provide uniform wetting of fly ash through an exclusive shaft and paddle configuration designed for consistent moisture content and reliable ash conditioning for transport. They are equipped with heavy duty releases for safety and aluminum covers for longer life and lower maintenance.

Mechanical ash handling systems 3

Our ranges: Equipment & Systems Bucketwheel Stacker/Reclaimers Cable Belt Overland Conveyors Complete Systems Continuous Barge Unloaders Equilibrated Unloaders Grab Type Unloaders Railcar Dumpers & Positioners Scraper Reclaimers Stackers (Radial/Linear)

Engineered Products Apron Feeders Ash Dry Chain Conveyors Ash Submerged Chain Conveyors Coal Preparation Equipment En-Masse Conveyors/Elevators Fly Ash Mixer Conditioners Railcar & Barge Pullers Railcar Indexers Throwers & Ship Trimmers Wobbler Feeders

Services Annual Service Agreements Breakdown Assistance Equipment Inspections Machine Upgrades/Retrofits Operations & Maintenance Training Replacement Parts Service Life Extension Projects Start-Up Assistance/Commissioning Troubleshooting Services

Metso Minerals Industries, Inc., 4000 Town Center Blvd., Ste. 400, Canonsburg, PA 15317, USA, tel +1 412 269 5000, fax +1 412 269 5070, www.metso.com

The information contained herein is a general description only, is not guaranteed and contains no warranties of any kind.

2316-08-09-MBL/Pittsburgh

Vous aimerez peut-être aussi

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- DustDocument18 pagesDustdefiunikasungtiPas encore d'évaluation

- Design of Riprap RevetmentDocument193 pagesDesign of Riprap RevetmentFrancis Domingo100% (1)

- Design of Riprap RevetmentDocument193 pagesDesign of Riprap RevetmentFrancis Domingo100% (1)

- Submerged Scraper Conveyor SystemDocument8 pagesSubmerged Scraper Conveyor Systemvraj_22_otPas encore d'évaluation

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentD'EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Mineral ProcessDocument12 pagesMineral ProcessdavidgloomPas encore d'évaluation

- Polycom HPGRDocument11 pagesPolycom HPGRWilson VicencioPas encore d'évaluation

- 17-Processing Iron Ore PDFDocument12 pages17-Processing Iron Ore PDFPortia Shilenge100% (1)

- Flexco Conveyor ProductsDocument32 pagesFlexco Conveyor ProductsDaniel KrismantoroPas encore d'évaluation

- Bag Filter PrincipleDocument3 pagesBag Filter PrincipleZahoor Ahmed71% (7)

- Circulating Fluidized Bed TechnologyDocument20 pagesCirculating Fluidized Bed Technologytsraja100% (2)

- Komptech CribusDocument12 pagesKomptech CribusbaleizaobzPas encore d'évaluation

- DeepConeThickeners BrochureDocument4 pagesDeepConeThickeners BrochureustavPas encore d'évaluation

- Fibo Mobile Concrete Plants-BrochureDocument4 pagesFibo Mobile Concrete Plants-BrochureHans Hans SadzPas encore d'évaluation

- Scomi Oiltools DWMS OverviewDocument16 pagesScomi Oiltools DWMS Overviewmojtaba_m007Pas encore d'évaluation

- Design of Pollution Control EquipmentDocument28 pagesDesign of Pollution Control EquipmentKvvPrasadPas encore d'évaluation

- Renold Cement Bucket ElevatorDocument23 pagesRenold Cement Bucket ElevatorLutfi IsmailPas encore d'évaluation

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshD'EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshPas encore d'évaluation

- A8 0 MineralsProcessing GBDocument6 pagesA8 0 MineralsProcessing GBAnonymous T8aah3JfPas encore d'évaluation

- Ball MillsDocument2 pagesBall MillsJuan GonzalezPas encore d'évaluation

- Coal Mill PartDocument59 pagesCoal Mill PartHazem DiabPas encore d'évaluation

- Washing Brochure TerexDocument21 pagesWashing Brochure TerexWashington HuallpaPas encore d'évaluation

- Bulk Material Handling: Practical Guidance for Mechanical EngineersD'EverandBulk Material Handling: Practical Guidance for Mechanical EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- PDMS Vs SmartPlantDocument24 pagesPDMS Vs SmartPlantrmm99rmm990% (1)

- Tenova Takraf Bulk Materials Handling enDocument16 pagesTenova Takraf Bulk Materials Handling engabriell_189100% (1)

- Digger: Ship UnloaderDocument16 pagesDigger: Ship UnloaderLeonardo CanditoPas encore d'évaluation

- Materials Handling Brochure-May2013Document12 pagesMaterials Handling Brochure-May2013negro83Pas encore d'évaluation

- Welcome: Advanced Bulk Material Conveying Technologies in Cement IndustryDocument15 pagesWelcome: Advanced Bulk Material Conveying Technologies in Cement Industry1977julPas encore d'évaluation

- Mining ThriveniDocument28 pagesMining ThriveniAnonymous GBge2ED1O100% (2)

- Capability DeliveredDocument24 pagesCapability DeliveredAlejandroAldaoGonzalez100% (1)

- Airlocks PPT 2005-02-18 DGLDocument35 pagesAirlocks PPT 2005-02-18 DGLAndrey ScholdeaPas encore d'évaluation

- Solutions For Sinter Plants enDocument20 pagesSolutions For Sinter Plants enRajat SahuPas encore d'évaluation

- KAT0400-0001-E Product Overview Conveyor SystemsDocument16 pagesKAT0400-0001-E Product Overview Conveyor Systemspithaloka100% (1)

- 1581 GB 03Document11 pages1581 GB 03hasan2525Pas encore d'évaluation

- Coal BlendingDocument2 pagesCoal BlendingDavid SimanungkalitPas encore d'évaluation

- Constant Pressure Vs Variable Pressure OperationDocument6 pagesConstant Pressure Vs Variable Pressure Operationank_mehra100% (1)

- ECM370 Operations Maintanence BookDocument114 pagesECM370 Operations Maintanence BookBruce Fillmore86% (14)

- Conveyor SystemDocument9 pagesConveyor SystemRahul MenariaPas encore d'évaluation

- Continuous MinersDocument8 pagesContinuous MinerssergioPas encore d'évaluation

- Atlas Copco Utilitary Vehicles - FamilyBrochure - ENGDocument12 pagesAtlas Copco Utilitary Vehicles - FamilyBrochure - ENGmasterandreis100% (2)

- Beumer Chain Bucket Elevator enDocument8 pagesBeumer Chain Bucket Elevator enArghya BasakPas encore d'évaluation

- Detroit Stoker CatalogDocument40 pagesDetroit Stoker CatalogPower Power100% (2)

- 140-Coal Handling & PreparationDocument12 pages140-Coal Handling & Preparationagai09Pas encore d'évaluation

- F175(M)021 Bag Filter User Manual袋收尘操作说明书Document96 pagesF175(M)021 Bag Filter User Manual袋收尘操作说明书Ali AlatasPas encore d'évaluation

- 1224fabric Dust CollectorsDocument2 pages1224fabric Dust Collectorsrmm99rmm99Pas encore d'évaluation

- Conveyor SystemDocument17 pagesConveyor Systemsujeetjagtap16Pas encore d'évaluation

- Brochure Conveying Systems en 001Document15 pagesBrochure Conveying Systems en 001jack-bc100% (1)

- Companybrochure UsaDocument8 pagesCompanybrochure UsaJosePas encore d'évaluation

- Large Pellet Mills PagedDocument12 pagesLarge Pellet Mills PagedNguyên Võ TriệuPas encore d'évaluation

- CB Materials Handling Brochure-May2010Document12 pagesCB Materials Handling Brochure-May2010Guglielmo CancelliPas encore d'évaluation

- Product Directory: Material Handling SolutionsDocument8 pagesProduct Directory: Material Handling Solutionsemuno008Pas encore d'évaluation

- Demag Waste Handling CranesDocument12 pagesDemag Waste Handling CranesAnand TornekarPas encore d'évaluation

- CementDocument3 pagesCementMadanKarkiPas encore d'évaluation

- Tunneling Conveyor SystemsDocument8 pagesTunneling Conveyor SystemsFrank Vega OrtegaPas encore d'évaluation

- Technical Characteristics - Apollo PlantDocument15 pagesTechnical Characteristics - Apollo PlantNidDouPas encore d'évaluation

- OVIVO EWT TracVac Sludge CollectorDocument4 pagesOVIVO EWT TracVac Sludge Collectormiguel_vera6592Pas encore d'évaluation

- DMW PowerDocument4 pagesDMW PowerHari Krishna.MPas encore d'évaluation

- Pneumatic Ship Unloader PDFDocument12 pagesPneumatic Ship Unloader PDFSosten MagwevaPas encore d'évaluation

- Optimizing Manganese Ore Sinter PlantDocument10 pagesOptimizing Manganese Ore Sinter Plantpark1423Pas encore d'évaluation

- A Conveyor System Is A Common Piece of Mechanical Handling Equipment That Moves Materials From One Location To AnotherDocument9 pagesA Conveyor System Is A Common Piece of Mechanical Handling Equipment That Moves Materials From One Location To AnotherDinesh SainiPas encore d'évaluation

- Bucket Elevators, Bucket Conveyors and MoreDocument22 pagesBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguPas encore d'évaluation

- Bulk Cargo Terminals - Buttimer Bulk EngineeringDocument8 pagesBulk Cargo Terminals - Buttimer Bulk EngineeringvenkateswarantPas encore d'évaluation

- Dangote CementDocument23 pagesDangote CementRobel FirewPas encore d'évaluation

- WB DTC BatchTypeTumblastENG 2011Document4 pagesWB DTC BatchTypeTumblastENG 2011skluxPas encore d'évaluation

- UCC Wet-To-Dry Brochure PDFDocument12 pagesUCC Wet-To-Dry Brochure PDFVăn phòng Phân xưởng Vận hành 1100% (1)

- Conveyor Systems PC SeriesDocument12 pagesConveyor Systems PC SeriesjsaulPas encore d'évaluation

- Conveyor Systems PDFDocument19 pagesConveyor Systems PDFJOHN UNIQUEPas encore d'évaluation

- 139-Bulk Materials Handling Equipment enDocument14 pages139-Bulk Materials Handling Equipment enhbookPas encore d'évaluation

- Belt For Tyre IndustryDocument12 pagesBelt For Tyre IndustryVictor MoralesPas encore d'évaluation

- mc4000 Conveyors PDFDocument8 pagesmc4000 Conveyors PDFAde SPas encore d'évaluation

- Kuenz TrashRackCleaningDocument5 pagesKuenz TrashRackCleaningjamjam75Pas encore d'évaluation

- Alpha ProfileDocument2 pagesAlpha ProfileGovind SinghPas encore d'évaluation

- OpenFX TutorialsDocument59 pagesOpenFX Tutorialsrmm99rmm99Pas encore d'évaluation

- 3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk MaterialsDocument4 pages3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk Materialsrmm99rmm99Pas encore d'évaluation

- 3229environmentally Sound Ash Handling Technologies. Case StudyDocument4 pages3229environmentally Sound Ash Handling Technologies. Case Studyrmm99rmm99100% (1)

- 3227internal Ash Conveying PlantsDocument3 pages3227internal Ash Conveying Plantsrmm99rmm99Pas encore d'évaluation

- Slope Deflection MethodDocument87 pagesSlope Deflection MethodFian ArdiyanaPas encore d'évaluation

- 3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power PlantsDocument6 pages3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power Plantsrmm99rmm99Pas encore d'évaluation

- 3224contact Free Measuring of The Level in Liquids and Bulk Mediums in Industrial Tanks Using Short Range Radar MethodsDocument3 pages3224contact Free Measuring of The Level in Liquids and Bulk Mediums in Industrial Tanks Using Short Range Radar Methodsrmm99rmm99Pas encore d'évaluation

- 3227internal Ash Conveying PlantsDocument3 pages3227internal Ash Conveying Plantsrmm99rmm99Pas encore d'évaluation

- 3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk MaterialsDocument4 pages3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk Materialsrmm99rmm99Pas encore d'évaluation

- 3221technological Options For Removal of Fly Ash at TPPs in IndiaDocument4 pages3221technological Options For Removal of Fly Ash at TPPs in Indiarmm99rmm99100% (1)

- 3222experience of Implementing Clyde Bergemann Technologies of Ash RemovalDocument3 pages3222experience of Implementing Clyde Bergemann Technologies of Ash Removalrmm99rmm99Pas encore d'évaluation

- 843operation of Small and MicroHPPsDocument1 page843operation of Small and MicroHPPsrmm99rmm99Pas encore d'évaluation

- 842hydroturbine EquipmentDocument1 page842hydroturbine Equipmentrmm99rmm99Pas encore d'évaluation

- 1222fly Ash ScrubbersDocument1 page1222fly Ash Scrubbersrmm99rmm99Pas encore d'évaluation

- 1223electrostatic PrecipitatorsDocument6 pages1223electrostatic Precipitatorsrmm99rmm99Pas encore d'évaluation

- 1221inertial Ash CollectorsDocument1 page1221inertial Ash Collectorsrmm99rmm99Pas encore d'évaluation

- 311list of Coal-Fired TPPs and Boiler-HousesDocument6 pages311list of Coal-Fired TPPs and Boiler-Housesrmm99rmm99Pas encore d'évaluation

- 841methods of Small HPPs ConstructionDocument1 page841methods of Small HPPs Constructionrmm99rmm99Pas encore d'évaluation

- 321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsDocument4 pages321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsrmm99rmm99Pas encore d'évaluation

- RPI TP 0200 v1 2007Document17 pagesRPI TP 0200 v1 2007rmm99rmm99100% (1)

- RPI TP 0184 v1 2003Document7 pagesRPI TP 0184 v1 2003rmm99rmm99Pas encore d'évaluation

- 321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsDocument4 pages321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsrmm99rmm99Pas encore d'évaluation

- RPI TP 0192 v1 2005Document24 pagesRPI TP 0192 v1 2005rmm99rmm99Pas encore d'évaluation

- Pressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"Document18 pagesPressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"rmm99rmm99100% (1)

- RPI TP 0087 v1 1990Document13 pagesRPI TP 0087 v1 1990rmm99rmm99Pas encore d'évaluation

- Pulsar Pre InstallDocument50 pagesPulsar Pre Installnorin1373Pas encore d'évaluation

- 800 - 1000kgs Per Hour - Rotary DryerDocument8 pages800 - 1000kgs Per Hour - Rotary DryerAli KhalidPas encore d'évaluation

- Enviornmental Education & Disaster Management SPVC Practice Test Series P.R.S Educational Trust Module-IiDocument18 pagesEnviornmental Education & Disaster Management SPVC Practice Test Series P.R.S Educational Trust Module-IiAkhil SharmaPas encore d'évaluation

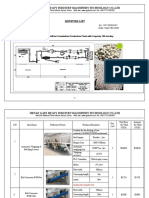

- Detailed Quotation 100 TPDDocument16 pagesDetailed Quotation 100 TPDBenjamin OsccoPas encore d'évaluation

- Group: Lampiran Penawaran Spesifikasi AlatDocument2 pagesGroup: Lampiran Penawaran Spesifikasi AlatChairy KarimPas encore d'évaluation

- NAPCA TrainingDocument149 pagesNAPCA TrainingalejandroPas encore d'évaluation

- Assignment 2 Air PollutionDocument8 pagesAssignment 2 Air PollutionPradhumna AdhikariPas encore d'évaluation

- Kiln Feed+ Kiln+ Cooler+ DPC and Clinker Silo Top Daily Check ListDocument12 pagesKiln Feed+ Kiln+ Cooler+ DPC and Clinker Silo Top Daily Check ListVinod Kumar VermaPas encore d'évaluation

- EPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFDocument50 pagesEPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFVampireSuicidePas encore d'évaluation

- Blastrac - SteelBlaster - 500E - ENG - LR PDFDocument2 pagesBlastrac - SteelBlaster - 500E - ENG - LR PDFMayerlis Mejia JiménezPas encore d'évaluation

- Blastrac BDC-854 DCI / DCS: Professional Dust CollectorDocument1 pageBlastrac BDC-854 DCI / DCS: Professional Dust CollectorMaría Juliana PiedrahitaPas encore d'évaluation

- A Study Report On The Production Process and Status of Cement Industires in NepalDocument29 pagesA Study Report On The Production Process and Status of Cement Industires in NepalRojan PradhanPas encore d'évaluation

- Deltamaxx Nanofiber Technology Outperforms Donaldson-Torit'S UltrawebDocument2 pagesDeltamaxx Nanofiber Technology Outperforms Donaldson-Torit'S UltrawebSaeid MirPas encore d'évaluation

- PAL Equipment List Criticality Analysis 190228Document63 pagesPAL Equipment List Criticality Analysis 190228Ariawan HasnanPas encore d'évaluation

- AD1015 - Pulverized Coal in Power PlantsDocument16 pagesAD1015 - Pulverized Coal in Power PlantsNenad JerinicPas encore d'évaluation

- Ac4.4 High Performance Bag FiltersDocument2 pagesAc4.4 High Performance Bag FiltersLuis MiguelPas encore d'évaluation

- AspenIcarusV7 1 RefDocument918 pagesAspenIcarusV7 1 RefdavinciPas encore d'évaluation

- Fabric Filter 2016 DEF TAMA AernovaDocument11 pagesFabric Filter 2016 DEF TAMA AernovanarjesPas encore d'évaluation

- How Well Do You Know Your Dust?: by Tony Supine, Farr Air Pollution ControlDocument6 pagesHow Well Do You Know Your Dust?: by Tony Supine, Farr Air Pollution ControlRajkumar TandurPas encore d'évaluation

- Techmaflex Assembly Machines Catalogue 2019 v1.0Document100 pagesTechmaflex Assembly Machines Catalogue 2019 v1.0Claudiu MorarPas encore d'évaluation

- Bag Filter Vs ESPDocument5 pagesBag Filter Vs ESPAmerMahmutbegovicPas encore d'évaluation

- (C30) Technical Specification - ENDocument14 pages(C30) Technical Specification - ENhicham1963Pas encore d'évaluation