Académique Documents

Professionnel Documents

Culture Documents

Radiographic Requirements On Api 650tanks

Transféré par

sbmmlaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Radiographic Requirements On Api 650tanks

Transféré par

sbmmlaDroits d'auteur :

Formats disponibles

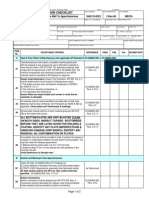

RADIOGRAPHIC REQUIREMENTS ON API 650TANKS

SHELL BUTT WELDS WELD AT BASE PLATES

WELD AT SHELL OPENINGS

CIRCUMFERENTIAL

LONGITUDINAL

ONE SPOT RT FOR FIRST 10' WELD OF THE SAME TYPE AND THICKNESS, THEREAFTER FOR EACH ADDITIONAL 200' OR MAJOR FRACTION IRRESPECTIVE OF No OF WELDERSa Cl# 6.1.2.3

PL THICK <3/8"

NOTE: 1

INSERT TYPE MANHOLE OR OPENING. FIG 3-4B RT ALL AROUND BUTTWELDED PERIPHERY Cl# 6.1.2.2, d

ANNULAR PLATES

DOUBLE BUTT WELD JOINT

3/8"<PL THICK < 1"

ONE SPOT RT AT 10% OF RADIAL JOINTS Cl# 6.1.2.9, a

NOTE: 2

PL THICK> 1"

NOTE: 3 SHELL OPENING OR RE-INFO PAD OF SHELL OPENING FALLS ON SHELL BUTT WELD. FIG 3-6

SINGLE SIDE WELD WITH BACKING BAR

100% RT ON BUTT WELD AT NOZZLE NECK Cl# 3.7.8.11

FLUSH TYPE SHELL CONNECTION WITH BUTT WELDED NOZZLE NECK. FIG 3-11.

100% RT FOR A LENGTH OF 3 X DIA OF OPENING EXCLUDING CUT OUT LENGTH Cl# 3.7.3.4

ONE SPOT RT AT 50% OF RADIAL JOINTS PREFERABLY WHERE SHELL PLATE JOINS ANNULAR PLATE Cl# 6.1.2.9, b

NOTE 1a: (A) ONE SPOT RT IN THE FIRST 10' OF WELD LENGTH FOR EACH TYPE AND THICKNESS WELDED BY EACH WELDER, THEREAFTER ONE IN EACH 100', IRRESPECTIVE OF No OF WELDERS, 25% OF SPOTS ON TEES, MINIMUM 2 TEE PER TANK. Cl# 6.1.2.2 a (B) ONE SPOT RT ON EACH VERT SEAM IN LOWEST COURSE, (FIG 6-1). SPOT RT FOR (A) FOR LOWEST COURSE MAY BE USED TO SATISFY (B)

NOTE 2a: (A) ONE SPOT RT IN THE FIRST 10' OF WELD LENGTH FOR EACH TYPE AND THICKNESS WELDED BY EACH WELDER, THEREAFTER ONE IN EACH 100', IRRESPECTIVE OF No OF WELDERS 25% OF SPOTS ON TEES, MINIMUM 2 TEES PER TANK. Cl# 6.1.2.2 a (B) ONE SPOT RT ON EACH VERTICAL SEAM IN LOWEST COURSE,(FIG 6-1). SPOT RT FOR (A) FOR LOWEST COURSE MAY BE USED TO SATISFY (B) (C) ALL TEES TO BE RT' D (D) TWO SPOT RT ON EACH LOWEST VERT. JOINT, ONE TO BE AS CLOSE TO BOTTOM AS POSSIBLE, OTHER AT RANDOM,Cl#6.1.2.2b NOTE 3a:(A) FULL RT AT VERT. WELDS (B) ALL TEES TO BE RT'D.Cl#6.1.2.2.c a.REFER FIG 6-1 SPOT RT: MIN 3" WELD LENGTH. 2" WELD LENGTH SHALL BE ON VERT SEAM

Vous aimerez peut-être aussi

- Weld Repair of Grade 91 Piping and Components in PDocument27 pagesWeld Repair of Grade 91 Piping and Components in PKyi HanPas encore d'évaluation

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Document15 pagesSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarPas encore d'évaluation

- Chapter3API653 Tank InspectionDocument106 pagesChapter3API653 Tank InspectioniraprobotPas encore d'évaluation

- Pressure Vessel RT TestDocument4 pagesPressure Vessel RT TestalokbdasPas encore d'évaluation

- MD PV Asme v0.1Document35 pagesMD PV Asme v0.1Kamlesh LuharPas encore d'évaluation

- Shop Fabrication Inspection: 1 Material Receiving Inspection ReportDocument7 pagesShop Fabrication Inspection: 1 Material Receiving Inspection ReportManoj PrabakaranPas encore d'évaluation

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaPas encore d'évaluation

- Quality Control ManualDocument77 pagesQuality Control ManualsbmmlaPas encore d'évaluation

- Highlights-ASME Guides Preheat-PWHT-VIII PDFDocument5 pagesHighlights-ASME Guides Preheat-PWHT-VIII PDFEr Manish JadaunPas encore d'évaluation

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87Pas encore d'évaluation

- Api 650Document4 pagesApi 650arif99pak100% (1)

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- Piping Inspection-MTDocument73 pagesPiping Inspection-MTInstech Premier Sdn BhdPas encore d'évaluation

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaPas encore d'évaluation

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULPas encore d'évaluation

- Brochure API 510 (150128)Document4 pagesBrochure API 510 (150128)wisnu_bayusaktiPas encore d'évaluation

- Storage Tank Weld JointsDocument16 pagesStorage Tank Weld JointsDilip Varadharajan100% (1)

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaPas encore d'évaluation

- Plumbness Inspection ReportDocument3 pagesPlumbness Inspection ReportDoris DorisPas encore d'évaluation

- Tank Bottoms in Atmospheric Storage TanksDocument5 pagesTank Bottoms in Atmospheric Storage TankslsatchithananthanPas encore d'évaluation

- Basic Exam Qustion SetDocument20 pagesBasic Exam Qustion SetsbmmlaPas encore d'évaluation

- Project Standards and Specifications Design of Furnace Systems Rev01Document10 pagesProject Standards and Specifications Design of Furnace Systems Rev01siddiquiee74Pas encore d'évaluation

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varughesePas encore d'évaluation

- API 510-Kuwait Petroleum TrainingDocument160 pagesAPI 510-Kuwait Petroleum Trainingsbmmla100% (1)

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- Film Defects - AMERONDocument94 pagesFilm Defects - AMERONER RaviPas encore d'évaluation

- Api653 Question N°06 ResponsesDocument3 pagesApi653 Question N°06 ResponseskorichiPas encore d'évaluation

- API - 510 Points To Remember - 6Document3 pagesAPI - 510 Points To Remember - 6EswaranPas encore d'évaluation

- Tank Selection COde - API 650Document2 pagesTank Selection COde - API 650Suresh Yadav0% (1)

- Quick Guide To API 510Document27 pagesQuick Guide To API 510ABDULLAH SHAHABPas encore d'évaluation

- Damage Mechanisms For API 653Document10 pagesDamage Mechanisms For API 653Saran KumarPas encore d'évaluation

- API 510 - API571 Damage Mechanisms Summary-Sep 2016 ExamDocument20 pagesAPI 510 - API571 Damage Mechanisms Summary-Sep 2016 Examdfz138Pas encore d'évaluation

- DNV Os-E403Document38 pagesDNV Os-E403ReadersmoPas encore d'évaluation

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outgplese0Pas encore d'évaluation

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 pagesInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiPas encore d'évaluation

- SAIC-A-2026 Rev 2Document5 pagesSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Acceptable Std. For NDTDocument4 pagesAcceptable Std. For NDTHarshaVeeragandhamPas encore d'évaluation

- API 653 NotesDocument3 pagesAPI 653 NotesPavan_yoyoPas encore d'évaluation

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Boiler & Pressure Vessel Inspection Report PDFDocument1 pageBoiler & Pressure Vessel Inspection Report PDFEslam KhamisPas encore d'évaluation

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Ansi-Aws A5 - 18-93Document37 pagesAnsi-Aws A5 - 18-93skrkulachiPas encore d'évaluation

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013Pas encore d'évaluation

- Pressure Vessel Plate InspectionDocument5 pagesPressure Vessel Plate InspectionSadashiw PatilPas encore d'évaluation

- API 653 Effectivity SheetDocument1 pageAPI 653 Effectivity SheetIsmail MemonPas encore d'évaluation

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanPas encore d'évaluation

- 2015 Pinnacle 580 Training FlyerDocument2 pages2015 Pinnacle 580 Training FlyerAlbertoPas encore d'évaluation

- API 510 Rerating Extract PDFDocument3 pagesAPI 510 Rerating Extract PDFmjmehta81Pas encore d'évaluation

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothPas encore d'évaluation

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani HamdaniPas encore d'évaluation

- Api 577Document1 pageApi 577HIIOJGFPas encore d'évaluation

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaPas encore d'évaluation

- SAIC-W-2078 Review PWHT Proc For TankDocument5 pagesSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaPas encore d'évaluation

- Genral Information For API 570 ExamDocument30 pagesGenral Information For API 570 ExamAbdulateaf Abdulrazig SattiPas encore d'évaluation

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraPas encore d'évaluation

- Ad 036633 001Document1 pageAd 036633 001narutothunderjet216Pas encore d'évaluation

- Api650 Questionn°03 Open Book ResponseDocument2 pagesApi650 Questionn°03 Open Book ResponsekorichiPas encore d'évaluation

- Daily Points To Recall (DAY 1) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (DAY 1) : Professional Training and Consultationraobabar21Pas encore d'évaluation

- UBE Automotive Lot CatalogDocument28 pagesUBE Automotive Lot CatalogQuan Huynh0% (1)

- Sy - 2Document1 pageSy - 2cherif yahyaouiPas encore d'évaluation

- 6 - CABLE-1-ModelDocument1 page6 - CABLE-1-ModelAbhas GuptaPas encore d'évaluation

- Datasheet Capacitor YAGEODocument10 pagesDatasheet Capacitor YAGEOrafaelfernandes183Pas encore d'évaluation

- To-101175 OspDocument5 pagesTo-101175 OspSIVAPas encore d'évaluation

- RT Hand Written BookDocument22 pagesRT Hand Written BooksbmmlaPas encore d'évaluation

- Basic InstrumentDocument85 pagesBasic InstrumenthaseebmonPas encore d'évaluation

- Types of Pressure TermsDocument10 pagesTypes of Pressure TermssbmmlaPas encore d'évaluation

- Welding DefectsDocument8 pagesWelding DefectssbmmlaPas encore d'évaluation

- Site Inspection ChecklistDocument3 pagesSite Inspection ChecklistsbmmlaPas encore d'évaluation

- SOP NM ReportingDocument2 pagesSOP NM ReportingsbmmlaPas encore d'évaluation

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaPas encore d'évaluation

- Pamphlet On Safety Precautions For Steel Erection WorkDocument4 pagesPamphlet On Safety Precautions For Steel Erection WorksbmmlaPas encore d'évaluation

- PT 3 Types of Cleaning, Equipment's and MaterialsDocument13 pagesPT 3 Types of Cleaning, Equipment's and MaterialssbmmlaPas encore d'évaluation

- Standard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved byDocument4 pagesStandard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved bysbmmla100% (1)

- Piping Dimension Chart UsefulDocument1 pagePiping Dimension Chart UsefulrizkiPas encore d'évaluation

- Swaged End - NormalisingDocument1 pageSwaged End - NormalisingsbmmlaPas encore d'évaluation

- Sop Piping Tubes Standard Repair ProcedureDocument3 pagesSop Piping Tubes Standard Repair ProceduresbmmlaPas encore d'évaluation

- Sop Duplex MCDocument3 pagesSop Duplex MCsbmmlaPas encore d'évaluation

- Downcomer Nozzle To Drum Welding Procedure: 1.0 ScopeDocument1 pageDowncomer Nozzle To Drum Welding Procedure: 1.0 ScopesbmmlaPas encore d'évaluation

- Standard Operating Procedure (Membrance Panels) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Membrance Panels) : Prepared By: Checked by Approved bysbmmlaPas encore d'évaluation

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaPas encore d'évaluation

- Tube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopeDocument1 pageTube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopesbmmlaPas encore d'évaluation

- Nozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1Document1 pageNozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1sbmmlaPas encore d'évaluation

- Pre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DateDocument1 pagePre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DatesbmmlaPas encore d'évaluation

- Standard Operating Procedure (Headers) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Headers) : Prepared By: Checked by Approved bysbmmlaPas encore d'évaluation