Académique Documents

Professionnel Documents

Culture Documents

Matrix solutions bangalore pipe sizing

Transféré par

Naveen PeteTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Matrix solutions bangalore pipe sizing

Transféré par

Naveen PeteDroits d'auteur :

Formats disponibles

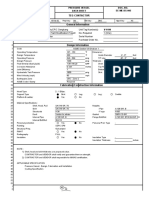

CLIENT : M/S LAXMI ORGANICS INDUSTRIAL LTD.

PROJECT : CAPTIVE POWER PLANT

DOC. NO.REV-00

MATERIAL SPECIFICATION

SPECIFIC VOLUME IN M3/Kg AT OPERATING

CONDITIONS

PIPE SIZE IN MM (OD)

PIPE THICKNESS AVAILABLE IN MM

SCHEDULE

PIPE SIZE NB CONSIDERED AS PER PROCESS

(NB)

ALLOWABLE STRESS IN KSI

ALLOWABLE STRESS IN KG/CM2

MINIMUM CALCULATED THICKNESS IN MM

CORROSION ALLOWANCE CONSIDERED

MINIMUM THICKNESS REQUIRED IN MM

MINIMUM THICKNESS AVAILABLE IN MM

BENDING TOLERANCE OR MARGIN

VELOCITY AS PER CONTRACT

ACTUAL VELOCITY

REMARKS

OPERATING

335 P11

Super heated

steam

495.0

505.0

69.2

83.076 50000

50000

SA 335

Gr.P11

0.04857830

168.3

14.27

120

150

9.299

653.8

10.18

1.5

11.68

12.49

6.94

40-60

43.98

OK

335 P21

Super heated

steam

495.0

505.0

69.2

83.04

50000

50000

SA 335

Gr.P11

0.04857830

168.3

14.27

120

150

9.001

632.8

10.49

1.5

11.99

12.49

4.12

40-60

43.98

OK

335 P22

Super heated

steam

495.0

505.0

69.2

83.04

50000

50000

SA 335

Gr.P11

0.04857830

168.3

14.27

120

150

10.8

759

8.82

1.5

10.32

12.49

20.98

20-30

43.98

OK

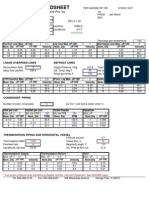

Bleed

Super heated

steam

385.0

395.0

24.8

29.748

5000

5000

SA106

Gr.B

0.11404300

88.9

5.49

40

80

13.7

963

1.36

1.5

2.86

4.80

68.18

30-40

33.22

OK

Extraction

Saturated steam

161.0

171.0

2.6

3.0996 30000

30000

IS 3589

0.54942600

457

6.3

20

450

12.74

896

0.79

1.5

2.29

5.51

140.79

30-40

29.52

OK

Extraction

Saturated steam

176.0

186.0

2.6

3.0996 30000

30000

IS 3589

0.57179800

457

6.3

20

450

12.74

896

0.79

1.5

2.29

5.51

140.79

30-40

30.72

OK

Extraction

Saturated steam

188.0

198.0

2.6

3.0996 30000

30000

IS 3589

0.58864400

457

6.3

20

450

12.74

896

0.79

1.5

2.29

5.51

140.79

30-40

31.63

OK

To Deaerator

Saturated steam

255.0

265.0

10.3

12.36

4000

4000

SA106

Gr.B

0.04593850

168.3

7.11

40

150

15

1054.6

0.98

1.5

2.48

6.22

150.69

20-30

2.74

velocity is less

To Process-1

Saturated steam

180.0

190.0

4.4

5.28

1000

1000

SA106

Gr.B

0.19384200

60.3

3.91

40

50

15

1054.6

0.15

1.5

1.65

3.42

107.27

20-30

24.89

OK

10

To Process-2

Saturated steam

180.0

190.0

2.6

3.096

30000

30000

SA106

Gr.B

0.19384200

323.9

6.35

20

300

15

1054.6

0.47

1.5

1.97

5.56

181.35

20-30

21.24

OK

11

PRDS

3(INLET)

Super heated

steam

495.0

505.0

67.2

80.64

6000

6000

SA 335

Gr.P11

0.04973600

73

7.01

80

65

10.85

762.6

3.70

1.5

5.20

6.13

17.89

40-60

30.34

OK

12

PRDS

3(INLET)

Super heated

steam

495.0

505.0

67.2

80.64

6000

6000

SA 335

Gr.P11

0.04973600

60.3

5.54

80

50

10.85

762.6

3.06

1.5

4.56

4.85

6.33

40-60

43.57

OK

13

PRDS2

(INLET)

Super heated

steam

495.0

505.0

67.2

80.64

35000

35000

SA 335

Gr.P11

0.04973600

168.3

14.27

120

125

10.85

762.6

8.54

1.5

10.04

12.49

24.40

40-60

31.52

VELOCITY IS

LESS

14

PRDS

1(INLET)

Super heated

steam

495.0

505.0

67.2

80.64

8000

8000

SA 335

Gr.P11

0.04973600

73

7.01

80

65

10.85

762.6

3.70

1.5

5.20

6.13

17.89

40-60

40.45

OK

15

To Ejector

Saturated steam

250.0

260.0

10.3

12.36

500

500

SA106

Gr.B

0.04593850

26.7

3.91

80

20

15

1054.6

0.16

1.5

1.66

3.42

106.63

20-30

22.79

OK

16

Gland sealing

Saturated steam

255.0

265.0

10.3

12.36

500

500

SA106

Gr.B

0.04593850

26.7

3.91

80

20

15

1054.6

0.16

1.5

1.66

3.42

106.63

20-30

22.79

OK

DESIGNED

OPERATING

FLOW KG/hr

PRESSURE KG/Cm2 (g)

DESIGNED

MEDIUM

SL.NO

Matrix solutions

bangalore

TEMPERATURE IN DEG C

DESIGNED

SYSTEM DESCRIPTION

OPERATING

LINE SIZING

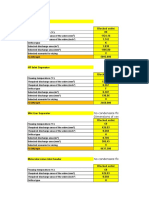

CLIENT : M/S LAXMI ORGANICS INDUSTRIAL LTD.

PROJECT : CAPTIVE POWER PLANT

DOC. NO.REV-00

OPERATING

DESIGNED

SPECIFIC VOLUME IN M3/Kg AT OPERATING

CONDITIONS

PIPE SIZE IN MM (OD)

PIPE THICKNESS AVAILABLE IN MM

PIPE SIZE NB CONSIDERED AS PER PROCESS

(NB)

ALLOWABLE STRESS IN KSI

ALLOWABLE STRESS IN KG/CM2

MINIMUM CALCULATED THICKNESS IN MM

CORROSION ALLOWANCE CONSIDERED

MINIMUM THICKNESS REQUIRED IN MM

MINIMUM THICKNESS AVAILABLE IN MM

BENDING TOLERANCE OR MARGIN

VELOCITY AS PER CONTRACT

ACTUAL VELOCITY

REMARKS

DESIGNED

MATERIAL SPECIFICATION

SCHEDULE

OPERATING

Saturated steam

385.0

395.0

25.1

30.12

13600

13600

SA106

Gr.B

0.11404300

168.3

7.11

40

150

15.01

1055

2.38

1.5

3.88

6.22

60.53

20-30

23.11

OK

18

PRDS

OUTLET1

Saturated steam

380.0

390.0

25.1

30.129

8590

8590

SA106

Gr.B

0.11445700

114.3

6.02

100

40

13.7

963

1.77

1.5

3.27

5.27

61.29

20-30

33.25

Velocity ishigh

19

PRDS

OUTLET2

Saturated steam

188.0

198.0

2.6

3.12

44620

44620

SA106

Gr.B

0.16311200

356

11.13

350

40

15

1054.6

0.53

1.5

2.03

9.74

380.69

20-30

23.11

OK

20

PRDS

OUTLET3

Saturated steam

255.0

265.0

10.3

12.36

7600

7600

SA106

Gr.B

0.04593850

88.9

5.49

80

40

15

1054.6

0.52

1.5

2.02

4.80

137.98

20-30

20.34

OK

21

11 ATA

HEADER

Saturated steam

255.0

265.0

10.3

12.36

11600

11600

SA106

Gr.B

0.04593850

168.3

7.11

150

40

15.01

1055

0.98

1.5

2.48

6.22

150.73

20-30

7.94

Velocity is less

22

3.5ATA

HEADER

Saturated steam

188.0

198.0

10.3

12.36

75000

75000

IS 3589

0.58477600

508

9.53

500

20

12.74

896

3.48

1.5

4.98

8.34

67.29

20-30

64.89

Velocity ishigh

23

25 ATA

HEDAER

Saturated steam

380.0

390.0

24.8

29.757 13590

13590

SA106

Gr.B

0.11404300

168.3

7.11

150

40

13.7

963

2.57

1.5

4.07

6.22

52.91

20-30

23.09

Matrix solutions

bangalore

FLOW KG/hr

PRESSURE KG/Cm2 (g)

MEDIUM

TEMPERATURE IN DEG C

DESIGNED

25 ATA

HEDAER

SYSTEM DESCRIPTION

17

SL.NO

OPERATING

LINE SIZING

Vous aimerez peut-être aussi

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985D'EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Pas encore d'évaluation

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelPas encore d'évaluation

- PECO Filters PDFDocument12 pagesPECO Filters PDFG.SWAMI100% (1)

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarPas encore d'évaluation

- Condensate Flash Vessel HandbookDocument3 pagesCondensate Flash Vessel HandbookHari Gunawan NugrahaPas encore d'évaluation

- Filter Vessel Shell VelocityDocument12 pagesFilter Vessel Shell VelocityAye KywePas encore d'évaluation

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzPas encore d'évaluation

- Compress Report For Pressure VesselDocument394 pagesCompress Report For Pressure VesselgaurangPas encore d'évaluation

- Gas Line Capacity CalculationDocument2 pagesGas Line Capacity CalculationMario Mendoza100% (1)

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Document3 pagesLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadliePas encore d'évaluation

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasPas encore d'évaluation

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JosePas encore d'évaluation

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssPas encore d'évaluation

- Pipe Wall Thickness Under External PressureDocument1 pagePipe Wall Thickness Under External PressureAnonymous DJrec2Pas encore d'évaluation

- Line Size & Pressure Drop CalculationDocument3 pagesLine Size & Pressure Drop Calculationsj_scribdPas encore d'évaluation

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarPas encore d'évaluation

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanPas encore d'évaluation

- Liquid and Vapor Line Sizing CalculationsDocument12 pagesLiquid and Vapor Line Sizing CalculationsDana GuerreroPas encore d'évaluation

- Three Phase SeparatorDocument433 pagesThree Phase SeparatorAbdur Rehman100% (1)

- Centrifugal Pump SizingDocument11 pagesCentrifugal Pump SizingDavid Muñoz CastroPas encore d'évaluation

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanPas encore d'évaluation

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezPas encore d'évaluation

- Vessel - Vertical Sizing - IPunitsDocument25 pagesVessel - Vertical Sizing - IPunitsAnders FTPas encore d'évaluation

- Pressure RELIEF VALVE DATA SHEETDocument4 pagesPressure RELIEF VALVE DATA SHEETAlvin SmithPas encore d'évaluation

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiPas encore d'évaluation

- PSV Sizing TableDocument14 pagesPSV Sizing TablebadelitamariusPas encore d'évaluation

- CPF-010 Utility Line Sizing Attachment - 0Document31 pagesCPF-010 Utility Line Sizing Attachment - 0goodspeed_phPas encore d'évaluation

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveePas encore d'évaluation

- Stage 1 pipe sizing dataDocument21 pagesStage 1 pipe sizing datasj_scribdPas encore d'évaluation

- Air Cooler-Example 8-2Document3 pagesAir Cooler-Example 8-2citramuaraPas encore d'évaluation

- Gas Pressure Reduction StationDocument2 pagesGas Pressure Reduction StationMathias OnosemuodePas encore d'évaluation

- Line Sizing GuidelinesDocument32 pagesLine Sizing Guidelinesyunjun12100% (2)

- Pig Receiver Design CalculationDocument27 pagesPig Receiver Design CalculationAndreas SchlagerPas encore d'évaluation

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different Standardsadil alameenPas encore d'évaluation

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33Pas encore d'évaluation

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterPas encore d'évaluation

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Table-1 Scope of Work Supply (MR For ACHE)Document6 pagesTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaPas encore d'évaluation

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoPas encore d'évaluation

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639Pas encore d'évaluation

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoPas encore d'évaluation

- Calculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehDocument9 pagesCalculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehCast Ed IvPas encore d'évaluation

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitPas encore d'évaluation

- C06 006 Process Calculation (02V 6010) RevEDocument6 pagesC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamPas encore d'évaluation

- Line SizingDocument1 pageLine Sizingayuzme123Pas encore d'évaluation

- SeparatorDocument9 pagesSeparatorGelorawan AditPas encore d'évaluation

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanPas encore d'évaluation

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiPas encore d'évaluation

- PSV Sizing (Liquid)Document2 pagesPSV Sizing (Liquid)Saeid Rahimi Mofrad50% (2)

- Flange DesignDocument12 pagesFlange DesignSantoshPas encore d'évaluation

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuPas encore d'évaluation

- Separator Sizing and DesignDocument44 pagesSeparator Sizing and DesignKay EenPas encore d'évaluation

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyPas encore d'évaluation

- 3 PhaseDocument7 pages3 PhaseMufleh IdrisPas encore d'évaluation

- Material Take-Off List: RemarksDocument1 pageMaterial Take-Off List: Remarks龙琦Pas encore d'évaluation

- Boiler Technical Diary - Draft1Document41 pagesBoiler Technical Diary - Draft1Hariharasudhan AnnaduraiPas encore d'évaluation

- Notes:: FORM NO: PEM-6101-0. Document Title Document No. Project TitleDocument1 pageNotes:: FORM NO: PEM-6101-0. Document Title Document No. Project TitleTanmay MajhiPas encore d'évaluation

- SIF (C2 Vs ANSYS)Document6 pagesSIF (C2 Vs ANSYS)Rockny2011Pas encore d'évaluation

- Cold Spring of Restrained Piping SystemDocument5 pagesCold Spring of Restrained Piping Systemsateesh chandPas encore d'évaluation

- Bonney Forge SIFs VariousFittingsDocument45 pagesBonney Forge SIFs VariousFittingscamellias2010100% (2)

- Adding Branch Fittings (Weld-O-Lets & Bosses) : This Is A Small Portion of Chapter 7 From The Piping & Tubing Design GuideDocument5 pagesAdding Branch Fittings (Weld-O-Lets & Bosses) : This Is A Small Portion of Chapter 7 From The Piping & Tubing Design GuideNaveen PetePas encore d'évaluation

- Bonney Forge SIFs VariousFittingsDocument45 pagesBonney Forge SIFs VariousFittingscamellias2010100% (2)

- Bonney Forge SIFs VariousFittingsDocument45 pagesBonney Forge SIFs VariousFittingscamellias2010100% (2)

- SIF (C2 Vs ANSYS)Document6 pagesSIF (C2 Vs ANSYS)Rockny2011Pas encore d'évaluation

- Adding Branch Fittings (Weld-O-Lets & Bosses) : This Is A Small Portion of Chapter 7 From The Piping & Tubing Design GuideDocument5 pagesAdding Branch Fittings (Weld-O-Lets & Bosses) : This Is A Small Portion of Chapter 7 From The Piping & Tubing Design GuideNaveen PetePas encore d'évaluation

- Pressure Drop Due To FrictionDocument1 pagePressure Drop Due To FrictionNaveen PetePas encore d'évaluation

- Asme B31.1 Case No.21 (Power Piping)Document4 pagesAsme B31.1 Case No.21 (Power Piping)api-19847681Pas encore d'évaluation

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationNaveen Pete100% (1)

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationNaveen Pete100% (1)

- The 40 Best FoodsDocument11 pagesThe 40 Best FoodsBenedict Sia100% (2)

- Biradar Residence ModelDocument1 pageBiradar Residence ModelNaveen PetePas encore d'évaluation

- Biradar Residence ModelDocument1 pageBiradar Residence ModelNaveen PetePas encore d'évaluation

- Fundamentals of the Pickett Plot: Recognizing Reservoir PatternsDocument9 pagesFundamentals of the Pickett Plot: Recognizing Reservoir PatternsAngelMeso100% (1)

- 11 TransportationDocument61 pages11 TransportationWindi Astuti0% (1)

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 pagesGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresPas encore d'évaluation

- Heat ActivityDocument3 pagesHeat ActivityMG Untalan Bauzon0% (1)

- ME 555 Stress Analysis Unit 4Document57 pagesME 555 Stress Analysis Unit 4TheoPas encore d'évaluation

- MFIX On of Discrete Element MethodDocument30 pagesMFIX On of Discrete Element MethodkamranianPas encore d'évaluation

- Magnetic Field Intensity (H)Document5 pagesMagnetic Field Intensity (H)M HASIN ISHMAM JEETPas encore d'évaluation

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2Pas encore d'évaluation

- ES 15 Lec 9 Dimensional Analysis and SimilitudeDocument28 pagesES 15 Lec 9 Dimensional Analysis and SimilitudeAngela Mae LopezPas encore d'évaluation

- Purmelt QR 3317 BR 2Document2 pagesPurmelt QR 3317 BR 2Mikel Pacheco IglesiasPas encore d'évaluation

- NNPC Recruitment Past Questions GuideDocument64 pagesNNPC Recruitment Past Questions GuidenwabukingzPas encore d'évaluation

- cO2CH4 Permselective GassensorDocument5 pagescO2CH4 Permselective GassensorKartik RamasubramanianPas encore d'évaluation

- Basic Simulation LabDocument69 pagesBasic Simulation LabkamalahasanmPas encore d'évaluation

- 0 Physics SyllabusDocument2 pages0 Physics Syllabusiffat fatima patilPas encore d'évaluation

- Analytical PS A01 A10 Solutions 2Document14 pagesAnalytical PS A01 A10 Solutions 2MariePas encore d'évaluation

- Sublimation and Melting Point DeterminationDocument3 pagesSublimation and Melting Point DeterminationRhone RoquePas encore d'évaluation

- The Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru ODocument8 pagesThe Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru OAnggit Tri AtmajaPas encore d'évaluation

- General Physics 1 1st Quarter Module 1 ActivitiesDocument16 pagesGeneral Physics 1 1st Quarter Module 1 ActivitiesMica LopezPas encore d'évaluation

- Chemical BondingDocument6 pagesChemical BondingNoongju AbdullahPas encore d'évaluation

- Determining Dielectric Constants Using A Parallel Plate CapacitorDocument5 pagesDetermining Dielectric Constants Using A Parallel Plate CapacitorAhmAd GhAziPas encore d'évaluation

- Hvs-313. Maximum Demand ControllerDocument3 pagesHvs-313. Maximum Demand ControllerHari BabuPas encore d'évaluation

- Time Allowed: 20 Minutes Marks: 12: Section - ADocument3 pagesTime Allowed: 20 Minutes Marks: 12: Section - AAliPas encore d'évaluation

- Gate Solved Paper - Me: y X X X P P P P X FX A B V Ydx P y X A B V XDX P XDX PDocument33 pagesGate Solved Paper - Me: y X X X P P P P X FX A B V Ydx P y X A B V XDX P XDX PHarish Jahan MohanPas encore d'évaluation

- Led t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaDocument3 pagesLed t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaNailza BizerraPas encore d'évaluation

- Weather in Kuttiadi - Google SearchDocument1 pageWeather in Kuttiadi - Google Searchsorry Its My StylePas encore d'évaluation

- Guide To CMSDocument46 pagesGuide To CMSecdtcenterPas encore d'évaluation

- EagleBurgmann Statotherm P Foil 9591 P enDocument1 pageEagleBurgmann Statotherm P Foil 9591 P enkeyur1109Pas encore d'évaluation

- Air Preheater Technical PaperDocument21 pagesAir Preheater Technical Paperchekoti koushikPas encore d'évaluation

- ELIMINATION REACTIONS: AN OVERVIEWDocument19 pagesELIMINATION REACTIONS: AN OVERVIEWSyuhadah NoordinPas encore d'évaluation

- Signal TransductionDocument33 pagesSignal TransductiongilmeanualexmihaiPas encore d'évaluation