Académique Documents

Professionnel Documents

Culture Documents

Fluid Machinery - Centrifugal Pumps

Transféré par

Daniel PaulTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fluid Machinery - Centrifugal Pumps

Transféré par

Daniel PaulDroits d'auteur :

Formats disponibles

Fluid Machinery

Recommend 5.4k

CHAPTERS

Home Topics Chapter 1 : General Concepts Chapter 2 : Pelton Turbine Chapter 3 : Francis and Kaplan Turbine Chapter 4 : Centrifugal Pumps Chapter 5 : Similarity Relations and Performance Characteristics Chapter 6 : Reciprocating Pumps Chapter 7 : Hydraulic devices and Systems

Home

Chapter 4 : Centrifugal Pumps

Q. 1. Classify hydraulic pumps. Ans. Pumps may bi placed in one of the two general categories. (i) Dynamic pressure pumps: centrifugal pump, jet pump, propeller, and turbine. (ii) Positive, displacement pump: Piston plunger, gear, lab, vane, screw etc. Q. 2. Distinguish between the positive and nonpositive displacement pumps. Ans. Positive displacement pump: It causes a fluid to move by trapping a fixed amount of it then forcing (displacing) that trapped volume into the discharge pipe. E.g. Lobe, gear, screw, vage pump etc. Non-positive displacement pump (rotodynamic pump) - It is pump in which the dynamic motion of a fluid is increased by pump action. e.g. centrifugal, turbine, propeller etc. Q. 3. What is the principle of working of a Centrifugal Pump? Ans. It is very clear that the principle used for centrifugal pump is the centrifugal force in the form of dynamic pressure which is generated by rotary motion of one or more rotating wheels called the impellers. Q. 4. Sketch layout installation and label it. Ans. of a centrifugal pump

Q. 5. Distinguish between volute casing and vortex casing in a centrifugal pump. Ans. Volute casingThis is a spiral shaped whose area of cross-section gradually increases towards the delivery pipe. The velocity of liquid decreases as area increases along the path of flow. This arrangement converts K.E. into pressure energy. The efficiency of this casing is less than others. Larger amount of energy is lost due to formation of eddies.

Fig. Different types of casings. Vortex casingWhen a circular chamber is introduced between the impeller and casing, the casing is known as vortex casing. In this case, the liquid from the impeller enters into the vortex chamber and then through the volute chamber, in this arrangement, the eddy loss is

volute chamber, in this arrangement, the eddy loss is considerably reduced and the efficiency of conversion from K.E. into pressure energy is increased as compared with volute casing. Q. 6. Explain different types of impellers used in centrifugal pump with neat sketch. Ans. (1) Closed, semiclosed and open impellers in the closed impellers the vanes are covered with side plates (shrouds) on both sides. The back shroud is mounted into shaft and front shroud is coupled to the former by the vanes. The arrangement provides a smooth passage for the liquid; wear is reduced to minimum. This ensures full capacity operation with high efficiency for a prolonged running period.

Fig. (,) Open (ii) Semi-open (iii) Enclosed Semi-open impeller has a plate only on back side. The design is adopted to industrial pump problems which required a rugged pump to handle liquids containing fibrous material such as paper pulp, sugar molasses and sewage water etc. in open impeller, no shroud or plate is provided on either side i.e., the vanes are open on both sides. Such pumps are used where the pump has a very rough duty to perform i.e. to handle abrasive liquids etc. (ii) Axial, Radial and mixed flow impellersIn the axial flow pumps, the head is developed by the propelling or lift action of the vanes on the liquid which enters the impeller axially and discharges axially

Fig. Axial radial and mixed flow impellers. In radial flow impellers, the head is developed by the action of centrifugal force upon the liquid which enters the impeller axially at the centre and flows radially to the periphery. In the mixed flow impeller there is a combination of axial and radial flows. The head is developed partly by the action of centrifugal force and partly by axial propulsion. Q. 7. Draw velocity triangles for (i) Curved forward vanes. (ii) Radial vanes (iii) Curved backward vanes. How Eulers head varies with discharge? Also draw variation of power with discharge. Ans.

Eulers head variation with discharge: Is negative, so with increase in flow rate the Euler head rises. For radial vanes = 90 and cot = 0, so the head remains constant with variation in discharge. For curved backward vanes <90 and cot is positive. So with increase in mass flow rate the Eulers head falls.

Influence of impeller vane exit angle on power capacity relationship.

Q. 8. Define manometric head of a pump. Ans. The manometric head is defined as the head against which a centrifugal pump has to work. It is denoted by Hm. Q. 9. Define manometric efficiency. Ans. The ratio of manometric head to the head imported by the impeller to the water is known as manometric efficiency.

Q. 10. Define the following terms: (i) Suction head (ii) Delivery head (iii) Static head (iv) Manometric head (v) Hydraulic (vi) Manometric (viii) Volumetric (viii) Mechanical. Ans. 1.Suction head It is the vertical height of the centre line of the centrifugal pump above the water surface in the tank or pump from which water is to be lifted. This height is also called suction lift. 2. Delivery head -The vertical distance between the centre line of the pump and the water surface in the tank to which water is delivered is known as delivery head. 3. Static head-The sum of suction head and delivery head is known as static head. This is represented by H and is written as:

4. Manometric Head -The manometric head is defined as the head against which a centrifugal pump has to work. It is denoted by Hm. EFFICIENCIES OF A CENTRIFUGAL PUMP 1. Manometric efficiency -The ratio of the manometric head to the head imported by the impeller to the water is known as manometric efficiency. Mathematically, it is written as

2. Mechanical efficiencyMechanical losses in a pump represent the degradation of energy due to mechanical friction in packings, glands and bearings etc. it is defined as the ratio of the energy transferred to water by the rotor to the mechanical energy delivered at the shaft coupling.

3. Volumetric efficiencyLet Q denote the actual discharge at the pump outlet and. q represent the internal leakage, then the total or theoretical volume flowing through the impeller is (Q + q). Volumetric efficiency is defined as the ratio of actual to theoretical discharge.

4. Hydraulic efficiencyHydraulic losses due to fluid separation and energy consumed by friction in the flow. Hydraulic efficiency is defined as the ratio of actual head to the theoretical or Euler head.

Where

=No of blades, = Euler head

Q. 11. Define the term Gross head.

Ans. Gross head: The Gross head or Total head is the difference between the water level at the reservoir (also known as head race) and the level at the tail race. Q. 12. Justify the statement centrifugal pumps having backward curved blades are preferred as compared to those having radial and forward curved blades. Ans. An angle of blades, > 90 leads to backward curved <900 means

90 means radial blades and

forward blades. It is found that with small angle means also a large absolute speed. The transformation of this speed energy in pressure energy in the peeler is connected with substantial losses. It is better to choose 90 for getting lower absolute speed c. In addition a large angle has the disadvantage that it requires with same delivery head a larger circumferential speed and so it causes larger wheel friction losses. Because if the larger difference of pressure between entrance and exit of the impeller, larger gap leakages are caused, these disadvantages cannot cover crucially better hydraulic efficiency. Therefore in centrifugal pumps only backward curved blades with angle> 900 (140160) are used. Q. 13. Discuss the influence of exit blade angle on the performance and efficiency of a centrifugal pump. Assume radial flow at entrance. Ans. Blade angle centrifugal pump When affects the efficiency of the > 90 efficiency - 75% 90 efficiency - 80% to 85% <90 efficiency 85% to 90% It is clear from the above results that when the exit angle of the blade is more than 90the efficiency is very less i.e. only 75% and as the angle decrease the efficiency increase. Efficiency is greater for acutes angles of the exit blades. When > 90 the speed is slow

When

> 90 the speed is slow = 90 the speed is medium <90 0 the speed is

high We know that efficiency depends upon the velocity, as the velocity increases efficiency also increases Q. 14. What compressor? is slip factor of centrifugal

Ans. Liquid is trapped between the impeller vanes. So there is no assurance that the actual fluid will follow the blade shape and leave the impeller in a radial direction. There is usually a sligh slippage of the fluid with respect to the blade rotation. If ) is called as slip. is reduced to then (

Slip factor Q. 15. What is priming of centrifugal pump? Ans. The filling of suction pipe, impeller casing and delivery pipe upto delivery valve by the liquid from outside source before starting the pump is known as priming. The air is removed and that portion is filled with the liquid to be pumped. Q. 16. How is the minimum starting speed of a centrifugal pump computed? Ans. The expression is given by: Starting speed, N Where = Manometric efficiency = whirl velocity = diameters Q. 17. What do you understand by characteristic curves of single stage centrifugal pump?

curves of single stage centrifugal pump? Ans. A centrifugal pump works under its maximum efficiency conditions. However when the pump is run at conditions different from design conditions, it performs differently. Therefore to predict the behavior of the pump under varying conditions of speeds, heads, discharges or powers, tests are usually conducted. So characteristic curves of centrifugal pumps are defined as those curves which are plotted from the results of a number of tests on the centrifugal pump. Performance characteristics of a pump fall into following categories. 1. Main characteristic curves 2. Operating characteristic curves 3. Constant efficiency or muschel curves 4. Constant head and constant discharge curves. 1. Main characteristic curvesThe main characteristic curves of a centrifugal pump consist of a variation of head (Hm), power and discharge with respect to speed as shown in figure (a).

For plotting curves of manometric head versus speed,

For plotting curves of manometric head versus speed, discharge is kept constant. For plotting curves of discharge versus speed, manometric head (Hm) is kept constant and for plotting the curves between power and speed the manometric head and discharge are kept constant. 2. Operating characteristic curves-The curves plotted from the results of a number of tests on a pump while running at its design speed are referred as characteristic curves. Fig. (b) shows the operating characteristic curves of a pump. The curves indicate the rotation between efficiency, power and head with respect to discharge. These are plotted for only one speed. Constant efficiency curves or Muschel curvesThe constant curves are also called the ISO-efficiency curves; depict the performance of a pump over its entire range

Constant efficiency curves of a pump of operation. Data for plotting these curves is obtained from main characteristic curves i.e. Vs. Q and H Vs. Q. As shown in figure (b) for particular efficiency a horizontal line is drawn which intersects the curves for different pump speeds on the Q plot. From the points of intersection the corresponding discharge valves are obtained. This information is thus transferred to H Vs. Q curve for corresponding speeds. Like wise for another value of efficiency, the points are obtained and protected. Points corresponding to one efficiency, are

protected. Points corresponding to one efficiency, are smoothly joined to get a constant efficiency curve. A cure for best performance is obtained when peak points to various ISO efficiency curves are joined. Constant efficiency curves help to locate the regions where the pump would operate with maximum efficiency. 4. Constant head and constant discharge curves-The performance of a variable speed pump for which the speed constantly varies can be determined by these curves.

Fig. Curves of a centrifugal pump Q. 18. Assuming the flow velocity to be constant, prove that manometric head of a centrifugal pump running at speed N and having discharge Q can be expressed as Where A, B and C are constants. Ans. Applying Bernoulls equation between inlet and outlet edges respectively; of the impeller for points 1 and 2

Energy at inlet = energy at outlet - work input

Energy at inlet = energy at outlet - work input

Pressure rise From the outlet velocity vector. (1)

(2)

Invoking the trigonometrical relationship, and simplifying

Assuming radial entry of fluid,

Neglecting gravitational effects, any friction losses, and assuming radial entry of water

As derived above,

And

Presuming that velocity of flow remains constant

Where a (1 + k), b = Also So Hence proved

Q. 19. Show that the pressure rise in the impeller of a centrifugal pump where friction and other losses in the pump are neglected is given by

Provided flow is radial at inlet, velocity of flow is constant through-out and outlet angle of impeller vane is 45. Solution. Refer to Q. No. We have Given And So

[ w=pg] Hence proved. Q.20. Set up the following relation for increase in pressure head across the impeller of a centrifugal pump;

Where u is peripheral velocity, is the relative velocity, y is datum height and P is pressure. The subscripts 1 parameters. and 2 refer to inlet and outlet

Solution. The Euller equation for theoretical head generated by centrifugal impeller

By Bernoullis equation between (suffix 1) and outer (suffix 2) edge of the impeller. H= Hence =H-

= increase in piezometric head (hence proved) Q. 21. Explain mixed flow centrifugal pumps. Ans. Centrifugal pump consists of two or more impellers, the pump is called a multistage centrifugal pump. There are two types of arrangements. 1. Multistage centrifugal pump for high heads or

impellers in series. 2.Multistage centrifugal pump for high discharge or impellers in parallel. 3.Impellers in seriesFor developing a high head a number of impellers are mounted in series or on the same shaft as shown in figure below.

Fig. Two-stage pumps with impellers in series. The water from suction pipe enters the 1st impellers at inlet and discharged at outlet with increased pressure. The water then from 1st impeller taken to inlet of the 2nd impeller with the help of connecting pipe. So at outlet of 2nd impeller pressure of water will be more. Total head developed= n Where n = no. of impellers in series. (ii) Impellers in parallelFor obtaining high discharge the pumps can be connected in parallel. Each of the pumps lifts the water from a common pump and discharges water to a common pipe to which the delivery pipes of each pump is connected.

Fig. Pumps in parallel. Each of the pump is working against the same head. Total discharge =nQ

1. Suction Head, 2. Delivery Head,

= =

3. Total external Head= 4. Monometric. Head, = =

5. NPSH (Net Positive Suction Head) = 6. Torque = = Energy Transfer.

6. Torque =

= Energy Transfer.

Problem 1. A centrifugal pump is required to lift water against total head of 40 m at the rate of 50.liters per second. Find the power of the pump, if the overall efficiency is 62%. Solution: Given Head, H=40 m Discharge, Q= 50 = Overall eff., We know that = 62% = 0.62

liters/second

Overall efficiency,

= 0.62 =

(Take p = 1000 kg/

Power = 31612.9 watt = 31 .612 KW Ans.

Problem 2. A centrifugal pump having outer diameter equal to two times the inner diameter and running at 1000 r.p.m. works against a total head of 40 m. The velocity of flow through the impeller is constant and equal to 2.5 m/s. The vanes are set back at an angel of 40 at outlet. If the outer diameter of the impeller is 50 mm and width at the outlet is 50 mm, determine. 1. Vane angle at inlet 2. Work done by impeller on water per second 3. Manometric efficiency.

Solution: Given N = 1000 r.p.m.

Head,

=40 m = 2.5m/s = 40

Velocity of flow, Vane angle at outlet, = 500 mm = 0.50 m

Inner dia. of impeller,

=0.25 m

width at outlet

= 50 mm = 0.05 m

=13.09 m/s

= =26.18 m/s Discharge is given by, Q 2.5 (1)Vane angle at inlet = x 0.50 x 0.05 x

From inlet velocity triangle, tan

= 0.191 =

= 0.191 48

(2) Work done by impeller on water per second

But from outlet velocity triangle, we have

26.18-

=2.979

= 26.18 2.979 = 23.2 m/s

Substituting this value of

in equation

We get the work done by impeller as x 23.2 X 26.18 = 119227.9 Nm/s Ans.

Problem

3.

centrifugal

pump

impeller

has

diameter of 60 cm and width of 6 cm at the outlet. The pump runs at 1450 rpm and delivers 0.8 against a head of 80 m. The leakage loss after the impeller is 4% of discharge, the external mechanical loss is 10 kW and hydraulic efficiency is 80%. Determine the blade angle at outlet, the power required and the overall efficiency of the pump.

Solution: Peripheral velocity of impeller at outlet, = 45.53 m/s Total quantity of water flowing through the impeller (Q+q) =0.8+0.04x0.8 =0.832 Flow velocity at impeller outlet

Flow velocity at impeller outlet

==7.36 m/s

Fig. Velocity vector diagrams of a centrifugal impeller

; 0.8=

221.546m

=3.258 Vane angle of impeller outlet, (3.258) = 17.06

Ideal head = 100 m Rotor or impeller power = w (Q + q) x 100) x

= (9810 x 0.832

= 816.2 kW

Shaft power = rotor power + mechanical losses

Shaft power = rotor power + mechanical losses = 816.2 + 10 = 826.2kW

Mechanical 98.88%

efficiency

0.9888

Volumetric efficiency, =0.961=96.1% Now, overall efficiency, = 0.8 x 0.961 x 0.988 = 0.76 or 76%

Problem 4. A three stage centrifugal pump has impellers 40 cm in diameter and 2 cm wide at outlet. The vane angle at out is 45 and reduce the circumferential, area by 10%. If the pump delivers 50 liters per second when running at 1000 r.p.m., determine (i) Power of the pump (ii) Manometric head. Assume manometric efficiency as 90% and overall efficiency as 80%. Solution: 1. Number of stages n 2. Dia. of impeller at outlet, 3. Width at outlet, 4. Vane angle at outlet, 5. Reduction in area at outlet 6. Area of flow at outlet 0.02 = 0.02262 Manometric efficiency, = 90% = 0.90 Overall efficiency, = 80% = 0.80 Speed, =N 1000 r.p.m.

=3 =40 cm = 0.40 m = 2 cm = 0.02 m = 45 = 10% = 0.1 = 0.9 x 0.9 x 0.4 x

Speed, =N 1000 r.p.m. Discharge Q = 50 liters/s = 0.05 /s Velocity of flow at outlet = = Tangential velocity of impeller at outlet =2.21m/s

=20.94 m/s From velocity triangle at outlet

2.21m/s 2.21 = 20.94 2.21 = 18.73 m/s 10.90 = =35.98m For total head generated by pump = n x =3x35.98=107.94m Power outlet of the pump =

= 52.94 kW We have

So =66.175kW

Shaft power =

Problem 5. This diameter of the impeller of a centrifugal pump is 800 mm. The pump delivers water at the rate of 90 /min. The head raised by is 72 m and the speed is 900 rpm. Peripheral

by is 72 m and the speed is 900 rpm. Peripheral area of the outlet is 0.3 The vanes of the impeller are curved back at 30 to the tangential direction. The leakage loss is 2.5%.; the input head is reduced by 20% kW. Find the power input and the overall efficiency of the pump. Solution: Given: m D = 800 mm = 0.8 Q =90 /min H =72m N = 900 r.p.m. Leakage loss = 2.5% Loss in input head = 20% of theoretical head Mechanical losses = 30 kW Now, Peripheral velocity, m/s = 37.69

Total quantity of water through impeller, (Q + q) 90 + 90 /s 92.25 /min = 1.53

We know

= 1.53

Whirl component of velocity, 5.1 cot 30 =28.85 m/s Theoretical head = water Total head against shaft has to work

= 37.69-

= 110.84 m of

= 72 + 110.84 x = 94.108 m of water

So, shaft power = Rotor power + mechanical losses = w (Q + q) Hi + mechanical losses = 9810 (1.53) x 94.168 + 30 x

= 9810 (1.53) x 94.168 + 30 x = 1443.39 kW Mechanical efficiency,

= 0.9792 = 97.92% Volumetric efficiency, = 98.039% Hydraulic efficiency, 64.95% Overall efficiency, 0.9792 = 0.6495 = = 0.6495 x 0.98039 x = 0.623 = 62.3%. Problem 6. The outer diameter of an impeller of a centrifugal pump is 400 mm and outlet width 50 mm. The pump is running at 800 r.p.m. and is working against a total head of 15 m. The vanes angle at outlet is 75%. Determine and manometric efficiency is = 0.98039

1. Velocity of flow at outlet 2. Velocity of water leaving this vane 3. Angle made by the absolute velocity at outlet with the direction of motion at outlet 4. Discharge Solution:

Outer diameter, Width at outlet, Speed, N

= 400 mm = 0.4 m =50 mm = 0.05 m = 800 r.p.m.

Speed, N Head, Vane angle at outlet,

= 800 r.p.m. =15m = 40

Manometric efficiency, = 75% = 0.75 Tangential velocity of impeller at outlet

=16.75 m/s

0.75

=11.71m/s From the outlet velocity triangle, we have

(1) (2) Velocity of water leaving the vane

=12.45 m/s (3) Angle made by absolute velocity at outlet = 0.36 0.36= 19.80 or 19 48 Ans. (4) Discharge through pump is given by

0.4x0.05x4.23

Problem 7. Find the rise in pressure in the impeller of a centrifugal pump through which water is flowing at the rate of 0.01 the

internal and external diameters of. The impellers are 15 cm and 30 cm respectively. The widths of the impellers at inlet and outlet are 1.2 cm and 0.6 cm. The pump is running at 1500 r.p.m. The water enters the impeller radially at inlet and impeller vane angle at outlet, is through the impeller. Solution. Given, Discharge Q =10 = 0.15 m External dia. = 0.012 m, Width at outlet 1500 r.p.m. Vane angle at inlet, Velocity of flow at inlet, = 450 = 0.006m, speed N = , Internal dia. Neglect losses

= 0.30 m, width at inlet

=1.768m/s Velocity of flow at outlet, 1.768. m/s Tangential velocity of impeller at outlet =

=23.56 m/s Pressure rise

Pressure rise = 28.13 m Problem 8. A centrifugal pump with 1.2

diameter runs at 200 r.p.m. and discharge 1880 litters/s the average lift being 6m. The angle which the vanes make at exit with the tangent to the impeller is 26 and radial velocity of flow is 2.5 m/s. Determine the manometric efficiency and the least speed to start pumping against a head of 6 m, the inner diameter of the impeller being 0.6 m. Ans. (a) Peripheral or tangential velocity of impeller at outlet, = 12.56 m/s Whirl component = 7.43 m/s Manometric efficiency (b) Minimum speed, Now H, 2 and so =6; =6.26 m/s Also 6.26 =12.56 - 2.5 cot 25

=0.63 or 63%.

Minimum rotational speed, N =

=199.36 r.p.m.

Problem 9. The impeller of a centrifugal pump has a diameter of 10cm and breadth 3.5 cm at the inner periphery; the corresponding dimensions at the outer periphery are 20 cm and 1.7 cm respectively. The pump runs at 1500 rpm, has 7 vanes with vane angle at entry and exit equal to 16 and 30 respectively. Calculate: (i) the theoretical discharge for shockless entrance, (ii) the theoretical head developed, (iii) the actual

the theoretical head developed, (iii) the actual head produced, the losses and the power required to drive the pump. Neglect the effect of vane thickness and presume that the hydraulic efficiency is 85% and the overall efficiency is 75%. Solution. For the nomenclature and velocity vector diagrams, The peripheral speeds are =7.85 m/s. = 15.70 m/s. (i) From the inlet velocity triangle, tan 160 = 2.25m/s x 0.1 x 0.035 x 2.25 = 0.0247 (ii) 2.31 m/s cot 30 = 11.69 m/s For shockless entry, the theoretical or Euler head given by] = 18.71 m (iii) The slip factor can be found from the relation is = = 15.7 2.31 = 7.85

1.34 Slip factor, = 1/1.34 = 0.746 The actual head produced is H =18.71 x0746 x 0.85 = 11.86 m The hydraulic losses are = 0.85) = 2.09 m Power required to drive the pump, P = 18.71 x 0.746 x (1

= 3831.68 W = 3.832 kW. Problem 10. A centrifugal pump has to discharge 225 liter of water per second against a head of 25 m when the impeller rotates at a speed of 1,500 r. p.m. Determined (a) the impeller diameter, and (b) the vane angle at the outlet edge of the impeller Assume that 0.75 ; the loss of head in pump in meters due to fluid resistance is 0.03 ; where m/s is the absolute velocity of water leaving the impeller, t1 area of the impeller outlet surface is (1.2. ) , where is the impeller diameter m, and water enters the impeller without whirl. Solution: = 33.33 m The manometric head is losses of head in the pump. Losses in the pump = (33.33 25) = 8.33 m Thus 0.03 =8.33 =16.66 m/s

Substituting the above value of

in (i)

Now from the outlet velocity triangle of Fig. 24.5 Or

Or

= 0.2534 m or 253.4 mm. Thus And =2.93 m/s; = 16.42 m/s = [2.93/ (19.90 16.42)] = 0.8420 = 19.90 m/s

Problem 11. The internal and external diameter of the impeller of a centrifugal pump which is running at 1000 rpm are 200 mm and 400mm respectively. The discharge through the pump is 0.04 and velocity of flow is constant and equal to 2.0 m/s. The diameters of the suction and delivery pipes are 150 mm and 100 mm respectively and suction and delivery heads are 6m (abs.) and 30 m (abs.) of water respectively. If the outlet vane angle is 45 and the power required to determine: derive the pump is 16.186 kW

(a) Vane angle of the impeller at inlet. (b) The overall efficiency of the pump and (c) Manometric efficiency of the pump. Ans. Given:

Speed, N Internal dia., External dia., Discharge, Q Velocity of flow, Dia. of suction pipe,

= 1000 r.p.m. = 200 mm = 0.2 m = 400 mm 0.4 m = 0.04

= 150 mm = 0.15 m

Dia. of suction pipe, Dia. of delivery pipe, Suction head, Delivery head, Outlet vane angle,

= 150 mm = 0.15 m = 100 mm 0.10 m = 6 m (abs.) 30m (abs.) = 45

Power required to drive the pump, P = 16.186/ kW (a) Vane angle of the impeller at inlet From inlet velocity, we have tan Where =10.47 m/s = 0.191 or .191 = 1048 Ans. (b) Overall efficiency of the pump

We know Where S.P. = Power required to derive the pump and equal to P here.

(1) = 0.02424 Now is given by equation as

(2) Where = 30 m = Velocity head at outlet of pump = = Pressure head at outlet of pump

= Pressure head at inlet of pump = =6 m = Velocity head at inlet of pump =

= Vertical height of outlet and inlet of pump from datum line. If as then equation (ii) becomes

(3)

Now =5.9m/s

And 2.26 m/s Substituting these values in equation (iii), we get

= (30+ 132) (6 + .26) = 31.32 6.26 25.06 m. Substituting the value of in equation (i), we get = .02424 x 25.06 = 0.6074 60.74%. Ans. Problem 12. The internal and external diameters of the impeller of a centrifugal pump are 200 mm and 400 mm respectively. The pump is running at 1200 rpm. The vane angles of the impeller at inlet and outlet are 20 and 30 respectively. The water enters the impeller radially and velocity of flow is constant. Determine the work done by the impeller per unit weight of water. Solution.

Internal diameter,

= 200 mm = 0.2 m

External diameter, = 400 mm = 0.4 m Speed, N = 1200 rpm Vane angle at inlet, = 20 Vane angle at outlet, = 30 =0

Water enters rodially means, a 90, Velocity of flow,

=12.56m/s = 25.13 m/s From inlet triangle, =12.56 tan = 12.56 x tan 20 4.57 m/s = 4.57 m/s

25.13 -

= 7.915

= 25.13 - 7.915 = 17.215 m/s The work done per kg per second = 44.1 Nm/s

Vous aimerez peut-être aussi

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesD'EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Performance Test of A Non-Positive Displacement PumpDocument7 pagesPerformance Test of A Non-Positive Displacement PumpBOSS BabyPas encore d'évaluation

- HW 1 2Q1314 QuestionaireDocument1 pageHW 1 2Q1314 QuestionairejenninajubanPas encore d'évaluation

- Fluid Machinery PDPDocument39 pagesFluid Machinery PDPOstwald GarciaPas encore d'évaluation

- Fans and Blowers Practice ProblemsDocument2 pagesFans and Blowers Practice ProblemsFour AyesPas encore d'évaluation

- Fluid Machine ProblemsDocument2 pagesFluid Machine ProblemsFuji0% (1)

- Introduction To PumpsDocument33 pagesIntroduction To PumpsArgie CayabyabPas encore d'évaluation

- Melab1 Exp3Document11 pagesMelab1 Exp3privateziel100% (1)

- Fluid Machinery ProblemsDocument5 pagesFluid Machinery ProblemsJohnlloyd BarretoPas encore d'évaluation

- Chapter 5Document14 pagesChapter 5Ben AhmedPas encore d'évaluation

- Problems On Hydraulic TurbineDocument8 pagesProblems On Hydraulic TurbinePedro Henrique Augusto MotaPas encore d'évaluation

- Fluid Machinery Lecture NotesDocument38 pagesFluid Machinery Lecture NotesMohit KulkarniPas encore d'évaluation

- CombinepdfDocument108 pagesCombinepdfAlessandra TanPas encore d'évaluation

- LECTURE ON AFFINITY LAWS FinalDocument9 pagesLECTURE ON AFFINITY LAWS FinalAriel Gamboa0% (1)

- Gecolea, ME143-2 Sample QuestionsDocument25 pagesGecolea, ME143-2 Sample QuestionsJazztine Andrei GecoleaPas encore d'évaluation

- Educspace - Pumps - Problems SetDocument3 pagesEducspace - Pumps - Problems SetMatthew John SyPas encore d'évaluation

- Me152l - Experiment 6 - AmahmudDocument25 pagesMe152l - Experiment 6 - AmahmudAli Requiso MahmudPas encore d'évaluation

- Stepped PulleyDocument4 pagesStepped PulleyKram YnarPas encore d'évaluation

- PIPE Ch19Document105 pagesPIPE Ch19JvPas encore d'évaluation

- Ceng 231 Tutor 1Document11 pagesCeng 231 Tutor 1lawekushPas encore d'évaluation

- PUMPS Part 2Document11 pagesPUMPS Part 2Kaiser CarloPas encore d'évaluation

- Mega-Ultra Ps Compilation5.0-1Document550 pagesMega-Ultra Ps Compilation5.0-1Eman Lampago AntoPas encore d'évaluation

- Steam CycleDocument11 pagesSteam CycleRowin Mark SabornidoPas encore d'évaluation

- Introduction to Fans, Blowers, and Air CompressorsDocument4 pagesIntroduction to Fans, Blowers, and Air CompressorsJustin Alvin P. CaballaPas encore d'évaluation

- ClutchesDocument14 pagesClutchesCllyan ReyesPas encore d'évaluation

- BRAKESDocument4 pagesBRAKESAjayBravo0% (1)

- Cams PDFDocument16 pagesCams PDFJhed PabloPas encore d'évaluation

- FINAL-MANUSCRIPT-test RigDocument34 pagesFINAL-MANUSCRIPT-test RigMarc Danielle G Josue IIPas encore d'évaluation

- BASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDDocument14 pagesBASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDAnimesh ManiPas encore d'évaluation

- (x4) Problem 5 - 9 Multi Stage CompressionDocument15 pages(x4) Problem 5 - 9 Multi Stage CompressionLester Alfred M. OlasimanPas encore d'évaluation

- MEF 312 - EXAMPLE PROBLEMS SOLUTIONSDocument6 pagesMEF 312 - EXAMPLE PROBLEMS SOLUTIONSAJPas encore d'évaluation

- Mechanism Design: Quick Return, Timing ChartsDocument6 pagesMechanism Design: Quick Return, Timing ChartsAsim AshrafPas encore d'évaluation

- Manufacturing Processes of Helicopters and MotorcyclesDocument28 pagesManufacturing Processes of Helicopters and MotorcyclesKent LabajoPas encore d'évaluation

- Final Exam Me155Document1 pageFinal Exam Me155Mr GreedyPas encore d'évaluation

- Parato Ipe 02 Prob.08Document2 pagesParato Ipe 02 Prob.08Neal Christian Parato100% (1)

- Prinsip Thermo MekfluDocument31 pagesPrinsip Thermo MekfluGhany RadifanPas encore d'évaluation

- Deophantine 1 ProblemsDocument69 pagesDeophantine 1 ProblemsCaro Kan LopezPas encore d'évaluation

- S Announcement 8755 PDFDocument1 pageS Announcement 8755 PDFKiah Taliwan100% (1)

- Activity Fluid Flow in PipesDocument2 pagesActivity Fluid Flow in PipesJoshua MeraPas encore d'évaluation

- Me 313b Fluid Machineries Module Week 10 13 PDF FreeDocument60 pagesMe 313b Fluid Machineries Module Week 10 13 PDF FreeChris TopherPas encore d'évaluation

- Maibarara Geothermal Power Plant ProfileDocument7 pagesMaibarara Geothermal Power Plant ProfilePhillip GaitePas encore d'évaluation

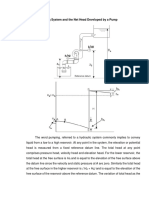

- General Pumping System and the Net Head Developed by a PumpDocument9 pagesGeneral Pumping System and the Net Head Developed by a PumpKim BagotPas encore d'évaluation

- Fluid Compressors Machinery Types Models CyclesDocument12 pagesFluid Compressors Machinery Types Models CyclesRenneil De PabloPas encore d'évaluation

- Steam Power Reviewer Terms and Problem SolvingDocument9 pagesSteam Power Reviewer Terms and Problem SolvingCherry May Basinang-RamosPas encore d'évaluation

- MD ProbsetDocument27 pagesMD ProbsetRicky AlamoPas encore d'évaluation

- MachineDocument15 pagesMachinemaria katherine pantojaPas encore d'évaluation

- Compressor - Problem SolvingDocument11 pagesCompressor - Problem SolvingLorenz Banada0% (1)

- Industrial Plant Engineering Reviewer Complete PDFDocument93 pagesIndustrial Plant Engineering Reviewer Complete PDFNovaCastillo100% (2)

- Net Positive Suction Head (NPSH) theory and cavitation preventionDocument3 pagesNet Positive Suction Head (NPSH) theory and cavitation preventionOstwald GarciaPas encore d'évaluation

- Machine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDocument21 pagesMachine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDeniell Joyce MarquezPas encore d'évaluation

- Reciprocating PumpsDocument10 pagesReciprocating PumpsMae Ann Dolor EstrellanaPas encore d'évaluation

- SOLVED COMPRESSOR PROBLEMSDocument18 pagesSOLVED COMPRESSOR PROBLEMSKaustubhPas encore d'évaluation

- Centrifugal Pumps:: VR Ri Ui U IDocument31 pagesCentrifugal Pumps:: VR Ri Ui U IValeed Khan100% (1)

- Centrifugal PumpDocument36 pagesCentrifugal PumpshubhamPas encore d'évaluation

- Hydraulic Machinery Characteristic Curves and their EffectsDocument8 pagesHydraulic Machinery Characteristic Curves and their EffectsAbdul AhadPas encore d'évaluation

- Debre Markos University Institute of Technology School of Mechanical and Industrial Engineering Meng3201Document59 pagesDebre Markos University Institute of Technology School of Mechanical and Industrial Engineering Meng3201birliePas encore d'évaluation

- Centrifugal Pump: How it WorksDocument6 pagesCentrifugal Pump: How it Works962943415xPas encore d'évaluation

- Chapter 7 Centrifugal PumpDocument37 pagesChapter 7 Centrifugal Pump01fe20bme014Pas encore d'évaluation

- Applications of Pumps in MinesDocument21 pagesApplications of Pumps in MinesAnshul yadavPas encore d'évaluation

- Autonomos College Mannual Final 16122022 PDFDocument114 pagesAutonomos College Mannual Final 16122022 PDFSourav SircarPas encore d'évaluation

- Michael Genesereth, Introduction To Logic-Morgan (2017)Document161 pagesMichael Genesereth, Introduction To Logic-Morgan (2017)HnzDPas encore d'évaluation

- Schaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaDocument807 pagesSchaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaJ Andres Gonzalez83% (23)

- Ice MachineDocument1 pageIce MachineDaniel PaulPas encore d'évaluation

- Stoichiometry and Process CalculationsDocument610 pagesStoichiometry and Process CalculationsDaniel PaulPas encore d'évaluation

- Introduction To Material HandlingDocument244 pagesIntroduction To Material HandlingAreda100% (3)

- A General Introduction To The BIBLEDocument501 pagesA General Introduction To The BIBLERuben Beniamin Ghidanac88% (42)

- Passion Prayer of Jesus The ChristDocument158 pagesPassion Prayer of Jesus The Christbeccabills_nig100% (3)

- Structure and Properties of GlutenDocument10 pagesStructure and Properties of GlutenDaniel PaulPas encore d'évaluation

- Jam, Jelly, Squash, MarmaladeDocument16 pagesJam, Jelly, Squash, MarmaladeDaniel PaulPas encore d'évaluation

- Fluids MechanicsDocument180 pagesFluids MechanicsAnonymous BW2VsFifi9Pas encore d'évaluation

- Puff Biscuits ChapterDocument6 pagesPuff Biscuits ChapterDaniel PaulPas encore d'évaluation

- Heat LecturesDocument89 pagesHeat LecturespalashagrawalPas encore d'évaluation

- Cold Storage HandbookDocument69 pagesCold Storage HandbookManish ParatanePas encore d'évaluation

- TocDocument8 pagesTocDaniel PaulPas encore d'évaluation

- Food Production Trends and Programmes Course OutlineDocument100 pagesFood Production Trends and Programmes Course OutlineRemya PillaiPas encore d'évaluation

- 10.1023 A 1009504209276Document16 pages10.1023 A 1009504209276Daniel PaulPas encore d'évaluation

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrPas encore d'évaluation

- Guidelines For Writing Thesis or DissertationDocument8 pagesGuidelines For Writing Thesis or DissertationCzerina CartelPas encore d'évaluation

- Ca & MaDocument11 pagesCa & MaKafeel Khan PathanPas encore d'évaluation

- Determination of Saponification Number.: PrincipleDocument3 pagesDetermination of Saponification Number.: PrincipleDaniel PaulPas encore d'évaluation

- 40 02 08Document6 pages40 02 08Daniel PaulPas encore d'évaluation

- BoilersDocument38 pagesBoilersAshlin Augusty92% (24)

- Meeting Minutes For VCDocument1 pageMeeting Minutes For VCDaniel PaulPas encore d'évaluation

- Boe Vip Vip 1Document8 pagesBoe Vip Vip 1gorakhdagadePas encore d'évaluation

- Cavitation in Centrifugal PumpsDocument2 pagesCavitation in Centrifugal PumpsArun KumarPas encore d'évaluation

- Victor CVDocument1 pageVictor CVDaniel PaulPas encore d'évaluation

- Speed Torque Power RelationshipDocument1 pageSpeed Torque Power RelationshipDaniel PaulPas encore d'évaluation

- Cavitation in Centrifugal PumpsDocument2 pagesCavitation in Centrifugal PumpsArun KumarPas encore d'évaluation

- Is 13349Document20 pagesIs 13349raji357100% (1)

- Forces Acting On A Dam StructureDocument7 pagesForces Acting On A Dam StructureSantosh RaiPas encore d'évaluation

- Permeability and SeepageDocument41 pagesPermeability and SeepageJayakumar JanardhananPas encore d'évaluation

- Standpost DesignDocument93 pagesStandpost Designdeerws anaparthiPas encore d'évaluation

- Draught PDFDocument30 pagesDraught PDFVinay MaisuriyaPas encore d'évaluation

- Hydro 1 Module 2Document13 pagesHydro 1 Module 2Jericho Alfred Rullog Sapitula100% (1)

- 2012 Bes Patterson Mehta PDFDocument8 pages2012 Bes Patterson Mehta PDFآكوجويPas encore d'évaluation

- Fire Water Pump Rules Nfpa 20Document8 pagesFire Water Pump Rules Nfpa 20kenoly123Pas encore d'évaluation

- Vdocuments - MX Design of A Barrage MsDocument66 pagesVdocuments - MX Design of A Barrage MsBhaskar ReddyPas encore d'évaluation

- Water Distribution ManualDocument20 pagesWater Distribution ManualOxfamPas encore d'évaluation

- Topics NO No of Hours Marks Weightage in ExamDocument8 pagesTopics NO No of Hours Marks Weightage in ExamSaeed cecos1913Pas encore d'évaluation

- FISHERIES TECHNOLOGIST REVIEWER 2018Document85 pagesFISHERIES TECHNOLOGIST REVIEWER 2018Bevelyn NaulPas encore d'évaluation

- Final Report of Group 6 Sundarijal HPPDocument57 pagesFinal Report of Group 6 Sundarijal HPPPratikShahiThakuri50% (2)

- Me2204 Unit Wise QuestionsDocument18 pagesMe2204 Unit Wise QuestionsMohanraj Subramani0% (1)

- Fundamentals of Fluid Flow Fundamentals of Fluid Flow: X X X XDocument40 pagesFundamentals of Fluid Flow Fundamentals of Fluid Flow: X X X XTâm NguyễnPas encore d'évaluation

- Hydraulic model studies help optimize Oroville Dam powerplant intake designsDocument64 pagesHydraulic model studies help optimize Oroville Dam powerplant intake designsBhaskar ReddyPas encore d'évaluation

- Soil Mechanics Labmanual 11Document24 pagesSoil Mechanics Labmanual 11Von LumboyPas encore d'évaluation

- Hydraulic Plant AnalysisDocument21 pagesHydraulic Plant AnalysispippoPas encore d'évaluation

- Objectives of HydrologyDocument30 pagesObjectives of HydrologykrunalPas encore d'évaluation

- Head loss calculation for circulation pumpDocument1 pageHead loss calculation for circulation pumpKarthy Ganesan100% (1)

- Fluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterDocument20 pagesFluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterMahdi GharibPas encore d'évaluation

- CE 14 HYDRAULICS SEMI-FINAL EXAMDocument4 pagesCE 14 HYDRAULICS SEMI-FINAL EXAMYedda M IlaganPas encore d'évaluation

- ME8694 - Hydraulics and Pneumatics Question BankDocument14 pagesME8694 - Hydraulics and Pneumatics Question BankelabalajiPas encore d'évaluation

- Pagano Fontanella Sica Desideri2010SFDocument14 pagesPagano Fontanella Sica Desideri2010SFIsabela BalanPas encore d'évaluation

- Production and Cost Estimating For Trailing Suction Hopper DredgeDocument105 pagesProduction and Cost Estimating For Trailing Suction Hopper DredgeEko SuherPas encore d'évaluation

- Design of Hydromechanical Component For Sustainability of Hydropower Structures: A Case Study of Bifurcation For Daraudi Khola Hydropower Project, NepalDocument10 pagesDesign of Hydromechanical Component For Sustainability of Hydropower Structures: A Case Study of Bifurcation For Daraudi Khola Hydropower Project, NepalRaviKoiralaPas encore d'évaluation

- Condition of Setting Surge Tanks in Hydropower Plants - A Review PDFDocument12 pagesCondition of Setting Surge Tanks in Hydropower Plants - A Review PDFEng Bagaragaza RomualdPas encore d'évaluation

- Pump System Analysis and SizingDocument157 pagesPump System Analysis and Sizingtachet100% (1)

- Warsak Dam by Waqar YounasDocument24 pagesWarsak Dam by Waqar YounasAteeq ur RaufPas encore d'évaluation

- AWWA M51 SummaryDocument10 pagesAWWA M51 Summaryvtsusr fv0% (1)