Académique Documents

Professionnel Documents

Culture Documents

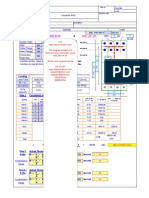

Cylinder Calculation

Transféré par

ash1968Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cylinder Calculation

Transféré par

ash1968Droits d'auteur :

Formats disponibles

recheck

GATE TOTAL THICK

RUNNE

DIE C

NUMB HEAT

EJEC

Side co LENGT

Side co RECTA

DIAME HEIG

STROK

CONTA ST Ef Piston

SPR

wire d

Component name Component no. component wt

TANK M421 00 01 CA 01

customer component matl.: no.of cavity

PRICOL ADC-12 SINGLE proj area in cm Circumference cm

1 PROJECTED AREA INPUTS I RECTANGLE LENGTH(mm) 500 WIDTH(mm) 100 ROUND DIAMETER(mm) TRIANGLE BASE(mm) HEIGHT(mm)

II 0 0

III 0 0

IV 0 0

V 0 0

60 500

65.6

0 1075.84

0 65.6

6.56 33.78138

0 0

0 0

0 0

0 0 0 0 sum pro area(cm2)

0 533.7814

2 PLUNGER DIA INPUTS HEIGHT OF COMPONENT(mm) WALL THICKNESS(mm) VOLUME(cm3) VOLUME OF RUNNER(cm3) BEFORE SQ ROOT PLUNGER DIA IN (cm)

9.5 2 133.4735 53.38938 237.8298 15.42173

4 EJECTION FORCE ST CIRCUMFERENCE OF MOULDING(cm)ds = 140.61677 CONTACT AREA(cm2) A = E (Kgf/cm2) = 688775.5 667.3673 MIEU T (cm) = Y Ef 0.45 0.2 0.34 191409.6 Kgf 1.518661

MCHINE SETTING

INSERT WALL THICKNESS weight of casting = 500 G 700 g To AL 0.068005 GATE AREA TOTAL WIDTH THICKNESS

grams

RUNNER CROSS SECTION AREA

DIE COOLING HOLE DIAMETER

NUMBER OF HOLE HEAT TO BE EXTRACTED

EJECTION FORCE SIDE CORE

TYPE

HYDRO MANSCO

MECH

CIRCUM(cm)

Side core dimension inside the component : LENGTH 225 WIDTH 119 height 80 68.8 DIAMETER 0 DEPTH 0 0 Side core + HOLDER dimension : RECTANGLE I-side core II-side core III-side core IV-side core V-side core volume(cm3) LENGTH(mm) 225 0 0 0 0 WIDTH(mm) 119 0 0 0 0 2142 HEIGHT 80 weight of side core (gram ROUND DIAMETER(mm) HEIGHT STROKE 100 1 1 1 1 0 0 0 0 0 0 0 0.007857

HYDRAULIC CYLINDER SPEC SMC CHD2-H-FY-63-C-( )-Nil-B-G5PW-Nil-double side cushion MANSCO MMT-63-22-( )-CB-FM-RT-02

CIRCUMFERENCE OF MOULDING(cm)ds = CONTACT AREA(cm2) A = 818.15 ST 0.74304 Ef 19184.05 Piston Dia 62.18546 mm 68.8

SPRING SPEC

wire dia= 3.0 ID = 13 pitch = 7.8 free length = 146

COMPLETED

umference cm

120

20.616768

140.616768

value is decreasing when wall thickness is increased

SUR AREA(cm2) 360 190.4 267.75 818.15

ht of side core (grams) 16921.86207

cushion

recheck

GATE TOTAL THICK

RUNNE

DIE C

NUMB HEAT

EJEC

Side co LENGT

Side co RECTA

DIAME HEIG

STROK

CONTA ST Ef Piston

SPR

wire d

Component name Component no. component wt

TANK M421 00 01 CA 01

customer component matl.: no.of cavity

PRICOL ADC-12 SINGLE proj area in cm Circumference cm

1 PROJECTED AREA INPUTS I RECTANGLE LENGTH(mm) 500 WIDTH(mm) 100 ROUND DIAMETER(mm) TRIANGLE BASE(mm) HEIGHT(mm)

II 0 0

III 0 0

IV 0 0

V 0 0

60 500

65.6

0 1075.84

0 65.6

6.56 33.78138

0 0

0 0

0 0

0 0 0 0 sum pro area(cm2)

0 533.7814

2 PLUNGER DIA INPUTS HEIGHT OF COMPONENT(mm) WALL THICKNESS(mm) VOLUME(cm3) VOLUME OF RUNNER(cm3) BEFORE SQ ROOT PLUNGER DIA IN (cm)

9.5 2 133.4735 53.38938 237.8298 15.42173

4 EJECTION FORCE ST CIRCUMFERENCE OF MOULDING(cm)ds = 140.61677 CONTACT AREA(cm2) A = E (Kgf/cm2) = 688775.5 667.3673 MIEU T (cm) = Y Ef 0.45 0.2 0.34 191409.6 Kgf 1.518661

MCHINE SETTING

INSERT WALL THICKNESS weight of casting = 500 G 700 g To AL 0.068005 GATE AREA TOTAL WIDTH THICKNESS

grams

RUNNER CROSS SECTION AREA

DIE COOLING HOLE DIAMETER

NUMBER OF HOLE HEAT TO BE EXTRACTED

EJECTION FORCE SIDE CORE

TYPE

HYDRO MANSCO

MECH

CIRCUM(cm)

Side core dimension inside the component : LENGTH 157 WIDTH 130 height 121 57.4 DIAMETER 0 DEPTH 0 0 Side core + HOLDER dimension : RECTANGLE I-side core II-side core III-side core IV-side core V-side core volume(cm3) LENGTH(mm) 157 0 0 0 0 WIDTH(mm) 130 0 0 0 0 2469.61 HEIGHT 121 weight of side core (gram ROUND DIAMETER(mm) HEIGHT STROKE 100 1 1 1 1 0 0 0 0 0 0 0 0.007857

HYDRAULIC CYLINDER SPEC SMC CHD2-H-FY-80-C-( )-Nil-B-G5PW-Nil-double side cushion MANSCO MMT-80-28-( )-CB-FM-RT-02

CIRCUMFERENCE OF MOULDING(cm)ds = CONTACT AREA(cm2) A = 898.64 ST 0.61992 Ef 25256.3 Piston Dia 71.35157 mm 57.4

SPRING SPEC

wire dia= 3.0 ID = 13 pitch = 7.8 free length = 146

COMPLETED

umference cm

120

20.616768

140.616768

value is decreasing when wall thickness is increased

SUR AREA(cm2) 379.94 314.6 204.1 898.64

ht of side core (grams) 19509.98107

cushion

CALCULATION FOR DIE CASTING DIE

1

COMPONENT MATERIAL

AL

MACHINE TO BE USED TONNAGE REQ FOR COMP.

125T

(IN TONS)

MIN: MAX.:

13.312 19.968

PLUNGER DIAMETER TO BE USED

LOCATING DIAMETER 85mm DEPTH 10mm MINIMUM PLUNGER DIA FOR THE COMPONENT =

FALSE

1008.928 MM

EJECTION FORCE DIE COOLING HOLE DIAMETER

NUMBER OF HOLE HEAT TO BE EXTRACTED

MCHINE SETTING

I PHASE LENGTH SPEED TIME PRESSURE TOTAL CYCLE TIME IIPHASE IIIPHASE

7 HYDRAULIC CYLINDER SPEC MANSCO SMC 8 SPRING SPEC 9 INSERT WALL THICKNESS SIDES BOTTOM 10 GATE AREA TOTAL WIDTH THICKNESS

11 RUNNER CROSS SECTION AREA DEPTH WIDTH 12

INPUT AGAIN

Vous aimerez peut-être aussi

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckManish542Pas encore d'évaluation

- Weight Estimation of Vessels AppsDocument28 pagesWeight Estimation of Vessels AppsAlvin Smith60% (5)

- Ultrasonic Testing Report For PipingDocument54 pagesUltrasonic Testing Report For Pipingeldobie3Pas encore d'évaluation

- Ring Girder (Japan-1)Document26 pagesRing Girder (Japan-1)ewanz89100% (2)

- FOOTING DESIGN Excel SheetDocument2 pagesFOOTING DESIGN Excel SheetHarish Ram100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Extractor For Multi Value Class Characteristic Values Using Function ModuleDocument13 pagesExtractor For Multi Value Class Characteristic Values Using Function ModuleEliseo Abad Camacho CPas encore d'évaluation

- Pecah Model - 50 kVA YNyn0 Cu-Cu Type DDocument1 pagePecah Model - 50 kVA YNyn0 Cu-Cu Type DkoprasyPas encore d'évaluation

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Beam Column+Splice+and+End+Plate+ +connectionDocument5 pagesBeam Column+Splice+and+End+Plate+ +connectionSeifeldin Ali MarzoukPas encore d'évaluation

- Bar Bending Schedule: Contract: Department: Name of Work:-Reinforcement Detail of P.C. Girder ContractorDocument21 pagesBar Bending Schedule: Contract: Department: Name of Work:-Reinforcement Detail of P.C. Girder ContractorJeet Pawar100% (3)

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghPas encore d'évaluation

- Machine Design Formulas PDFDocument8 pagesMachine Design Formulas PDFCabanes GerluzPas encore d'évaluation

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiPas encore d'évaluation

- Beam - Roof Beam - GM1Document20 pagesBeam - Roof Beam - GM1FrederickV.VelascoPas encore d'évaluation

- FOOTING Excel SheetDocument2 pagesFOOTING Excel SheetAbdul KabasyPas encore d'évaluation

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymPas encore d'évaluation

- Building 7 TesDocument11 pagesBuilding 7 TesFauzankalibataPas encore d'évaluation

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23Pas encore d'évaluation

- Gear CalculationDocument2 pagesGear CalculationAli AbdoPas encore d'évaluation

- Pressure Loss - TG BuildingDocument1 pagePressure Loss - TG Buildingkarthikraja21Pas encore d'évaluation

- CalculationDocument37 pagesCalculationParomita Mukherjee Misra100% (1)

- Isolated FootingDocument1 pageIsolated FootingSanjeev Kumar PillaiPas encore d'évaluation

- Details of Hanger Clamps Table For Mut Project: BCPA-W-4-C1Document2 pagesDetails of Hanger Clamps Table For Mut Project: BCPA-W-4-C1manu_gitePas encore d'évaluation

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Rotating Drum CalculationDocument12 pagesRotating Drum Calculationمحمد أزها نو الدينPas encore d'évaluation

- Pressure Loss - Transformer YardDocument1 pagePressure Loss - Transformer Yardkarthikraja21Pas encore d'évaluation

- Calculation LugDocument20 pagesCalculation LugKartika ZuhraPas encore d'évaluation

- Re17017 2008-08Document72 pagesRe17017 2008-08toothtoothtoothPas encore d'évaluation

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroPas encore d'évaluation

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JosePas encore d'évaluation

- Continuous Beam Staad ReportDocument14 pagesContinuous Beam Staad ReportMuhammad Shukri Bin SaharinPas encore d'évaluation

- Ast BeamDocument13 pagesAst Beamabdul kareePas encore d'évaluation

- Reinforce Concrete DesignDocument13 pagesReinforce Concrete DesignWangTF100% (1)

- Darcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataDocument1 pageDarcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataSomi KhanPas encore d'évaluation

- M2-CV-RC-D-005 (R1)Document22 pagesM2-CV-RC-D-005 (R1)ksshashidharPas encore d'évaluation

- PilecapDesign-ISCODE FINALDocument3 pagesPilecapDesign-ISCODE FINALAnonymous FHmGcSA8Pas encore d'évaluation

- Design of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignDocument1 pageDesign of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignAnonymous YDwBCtsPas encore d'évaluation

- Calculation - MWIDocument9 pagesCalculation - MWIfarhan_82Pas encore d'évaluation

- 11 Steel Connection Design As Per AISC 23052014Document2 pages11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri67% (3)

- Composite Steel GirderDocument10 pagesComposite Steel GirdersorowarePas encore d'évaluation

- Discharge PR Drop Pipe SizeDocument5 pagesDischarge PR Drop Pipe SizemohdnazirPas encore d'évaluation

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruPas encore d'évaluation

- Tube Mill Work Order Mill No.: 2: REV.: MohdDocument1 pageTube Mill Work Order Mill No.: 2: REV.: Mohdkrishnasharma_me5542Pas encore d'évaluation

- Conical Water TankDocument64 pagesConical Water TankRiyaz Siddique100% (1)

- Design Guidelines for Surface Mount TechnologyD'EverandDesign Guidelines for Surface Mount TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Design and Analysis of Centrifugal CompressorsD'EverandDesign and Analysis of Centrifugal CompressorsPas encore d'évaluation

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionD'EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionPas encore d'évaluation

- Mining Engineering Diploma Engineering MCQD'EverandMining Engineering Diploma Engineering MCQÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Manufacturing Engineering Diploma Engineering MCQD'EverandManufacturing Engineering Diploma Engineering MCQÉvaluation : 5 sur 5 étoiles5/5 (1)

- Promises Are The Uniquely Human Way of Ordering The Future, Making It Predictable and Reliable To The Extent That This Is Humanly Possible. Hannah ArendtDocument8 pagesPromises Are The Uniquely Human Way of Ordering The Future, Making It Predictable and Reliable To The Extent That This Is Humanly Possible. Hannah Arendtash1968Pas encore d'évaluation

- Lpg-Tank Wagon CodeDocument30 pagesLpg-Tank Wagon Codejoefrizal100% (1)

- Basic Switching CircuitsDocument19 pagesBasic Switching Circuitsash1968Pas encore d'évaluation

- Prediction of Residual Strength and Curvilinear Crack Growth in Aircraft FuselagesDocument9 pagesPrediction of Residual Strength and Curvilinear Crack Growth in Aircraft FuselagesnagpalanishPas encore d'évaluation

- Management Means, in The Last Analysis, The Substitution of Thought For Brawn and Muscle, of Knowledge For Folkways and Superstition, and of Cooperation For Force. Peter F. DruckerDocument7 pagesManagement Means, in The Last Analysis, The Substitution of Thought For Brawn and Muscle, of Knowledge For Folkways and Superstition, and of Cooperation For Force. Peter F. Druckerash1968Pas encore d'évaluation

- The Self Is Not Something Ready-Made, But Something in Continuous Formation Through Choice of Action. John DeweyDocument7 pagesThe Self Is Not Something Ready-Made, But Something in Continuous Formation Through Choice of Action. John Deweyash1968Pas encore d'évaluation

- Straightness With AutocollimatorDocument5 pagesStraightness With Autocollimatorash1968Pas encore d'évaluation

- Tubular Member Design CalculationDocument19 pagesTubular Member Design Calculationash1968Pas encore d'évaluation

- We Are All Inclined To Judge Ourselves by Our Ideals Others, by Their Acts. Harold NicolsonDocument10 pagesWe Are All Inclined To Judge Ourselves by Our Ideals Others, by Their Acts. Harold Nicolsonash1968Pas encore d'évaluation

- Income Tax Calculation Self Assessement Proforma From Year 2009 - 2010 Assessement Year2010-2011Document2 pagesIncome Tax Calculation Self Assessement Proforma From Year 2009 - 2010 Assessement Year2010-2011ash1968Pas encore d'évaluation

- Beam Load CalculationDocument15 pagesBeam Load Calculationash1968Pas encore d'évaluation

- Advancements in ESP - MR Yatindra Nadkarni, Ionisation Filteration Industries PVT LTDDocument10 pagesAdvancements in ESP - MR Yatindra Nadkarni, Ionisation Filteration Industries PVT LTDash1968Pas encore d'évaluation

- Cylinder CalculationDocument14 pagesCylinder Calculationash1968Pas encore d'évaluation

- Stress Analysis Using Actual Coke DrumDocument11 pagesStress Analysis Using Actual Coke Drumash1968Pas encore d'évaluation

- Coke Drum Remaining LifeDocument4 pagesCoke Drum Remaining Lifeash1968Pas encore d'évaluation

- SL No Process Flow Total PDF Total Tiff Man HoursDocument2 pagesSL No Process Flow Total PDF Total Tiff Man Hoursash1968100% (2)

- Delayed Coker Drum CrackingDocument26 pagesDelayed Coker Drum Crackingash1968Pas encore d'évaluation

- CHART CryogenicDocument47 pagesCHART Cryogenicvardarec100% (1)

- Economiser Failure in A High Pressure BoilerDocument3 pagesEconomiser Failure in A High Pressure Boilerash1968Pas encore d'évaluation

- Exercise For StressDocument6 pagesExercise For Stressash1968Pas encore d'évaluation

- The Therapeutic Use of Magnets For The Health Practitioner: by Jackie Christensen, MSHH, HHP, MH, NCDocument25 pagesThe Therapeutic Use of Magnets For The Health Practitioner: by Jackie Christensen, MSHH, HHP, MH, NCash1968100% (7)

- Gs4 Revalidation Guideline enDocument17 pagesGs4 Revalidation Guideline enash1968Pas encore d'évaluation

- Item NO. Part Number Description QTY Per Assy Total QTYDocument6 pagesItem NO. Part Number Description QTY Per Assy Total QTYash1968Pas encore d'évaluation

- Maximum Minimum Component Factored Component Tolerance Total Tolerance Monte Tolerance Squared CarloDocument10 pagesMaximum Minimum Component Factored Component Tolerance Total Tolerance Monte Tolerance Squared Carloash1968Pas encore d'évaluation

- Area CalculationsDocument11 pagesArea Calculationsash1968Pas encore d'évaluation

- Advancements in ESP - MR Yatindra Nadkarni, Ionisation Filteration Industries PVT LTDDocument10 pagesAdvancements in ESP - MR Yatindra Nadkarni, Ionisation Filteration Industries PVT LTDash1968Pas encore d'évaluation

- Delayed Coker Drum CrackingDocument26 pagesDelayed Coker Drum Crackingash1968Pas encore d'évaluation

- SummaryDocument50 pagesSummarygirjesh kumarPas encore d'évaluation

- Determinant Lesson PlanDocument2 pagesDeterminant Lesson PlanMr. Barry R. Grauman100% (3)

- Solution Thermo Part 1Document9 pagesSolution Thermo Part 1Oh DausPas encore d'évaluation

- Commands Guide Tutorial For SolidWorks 2012Document64 pagesCommands Guide Tutorial For SolidWorks 2012Jelena Misimovic100% (1)

- 05 2013 1072 Sredanovic 04 PDFDocument7 pages05 2013 1072 Sredanovic 04 PDFOcta RioPas encore d'évaluation

- PENDULUMEXPERIMENTDocument14 pagesPENDULUMEXPERIMENTUyenPas encore d'évaluation

- I Can Statements - 4th Grade CC Math - NBT - Numbers and Operations in Base Ten Polka DotsDocument13 pagesI Can Statements - 4th Grade CC Math - NBT - Numbers and Operations in Base Ten Polka DotsbrunerteachPas encore d'évaluation

- A. Permutation of N Different Objects, Taken All or Some of ThemDocument8 pagesA. Permutation of N Different Objects, Taken All or Some of ThemChristina Corazon GoPas encore d'évaluation

- Final DBMS Lab ManualDocument15 pagesFinal DBMS Lab ManualSantosh DewarPas encore d'évaluation

- Codeforces Problems DPDocument17 pagesCodeforces Problems DPZulqarnayn0% (1)

- Chapter 2 - DataDocument10 pagesChapter 2 - DataDR NORHISAM BULOTPas encore d'évaluation

- Bernice HuangDocument25 pagesBernice HuangbhuuangPas encore d'évaluation

- MYJAVACAFE - Java Interview Questions (Delivered by Nageswara Rao From Inetsolv Institute of Hyderabad)Document21 pagesMYJAVACAFE - Java Interview Questions (Delivered by Nageswara Rao From Inetsolv Institute of Hyderabad)haibye424Pas encore d'évaluation

- Math 8 System of Linear EquationDocument17 pagesMath 8 System of Linear EquationMark Raniel Rimpillo PasalosdosPas encore d'évaluation

- Bazzucchi Campolmi ZattiDocument47 pagesBazzucchi Campolmi ZattiFilippoPippoCampolmiPas encore d'évaluation

- SicpDocument90 pagesSicppcdanenbPas encore d'évaluation

- Local Binary PatternDocument4 pagesLocal Binary PatternFaisal IzharPas encore d'évaluation

- Quality Control: To Mam Dr. Sumaira Naeem by Muhammad Muzammal Roll No. 20014107-039Document26 pagesQuality Control: To Mam Dr. Sumaira Naeem by Muhammad Muzammal Roll No. 20014107-039Muhammad MUZZAMALPas encore d'évaluation

- Source CodingDocument8 pagesSource CodingAmith periyapatnaPas encore d'évaluation

- Lesson Plan With RubricDocument3 pagesLesson Plan With Rubricapi-317228431Pas encore d'évaluation

- Analisis Kelayakan Finansial Usaha Peningkatan Produktivitas Kopi Melalui Perancangan Silvikultur Secara EkologisDocument53 pagesAnalisis Kelayakan Finansial Usaha Peningkatan Produktivitas Kopi Melalui Perancangan Silvikultur Secara EkologisHarisa Bilhaqqi QalbiPas encore d'évaluation

- HubbleDocument2 pagesHubbleAlam AhmedPas encore d'évaluation

- Bit HacksDocument44 pagesBit HacksRavi KanthPas encore d'évaluation

- Delphi XE2 Foundations - Part 1 - Rolliston, ChrisDocument160 pagesDelphi XE2 Foundations - Part 1 - Rolliston, ChrisJoel Quezada100% (2)

- Numerical Optimization of Flow-Heat Ducts With Helical Micro-Fins, Using Entropy Generation Minimization (EGM) MethodDocument8 pagesNumerical Optimization of Flow-Heat Ducts With Helical Micro-Fins, Using Entropy Generation Minimization (EGM) MethodPablo Vicente Vargas CortésPas encore d'évaluation

- Alexander Graham - Kronecker Products and Matrix Calculus With ApplicationsDocument129 pagesAlexander Graham - Kronecker Products and Matrix Calculus With ApplicationsErik ZamoraPas encore d'évaluation

- TheModelEngineersHandbook TubalCainDocument226 pagesTheModelEngineersHandbook TubalCainDan Agu100% (21)

- 2.1 Random Variables 2.1.1 Definition: PX PX XDocument13 pages2.1 Random Variables 2.1.1 Definition: PX PX XMichael Hsiao100% (1)

- Problems On SRSS MethodDocument4 pagesProblems On SRSS MethodSADAIF ANDRABIPas encore d'évaluation