Académique Documents

Professionnel Documents

Culture Documents

Sample PQR

Transféré par

이상현Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sample PQR

Transféré par

이상현Droits d'auteur :

Formats disponibles

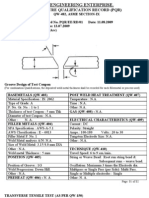

Procedure Qualification Record (PQR)

Code: AWS D1.1

Company Name: www.WPSAmerica.com Address: info@WPSAmerica.com, 1 (877) WPS-WELD

Welding Process:

SMAW

Sheet 1 of 4

PQR No.:

DEMO-PQR

Process Type:

Manual

Position:

Flat

WPS No.:

DEMO-WPS

Base Metal Part I (Material Spec., type or grade):

ASTM A 516 Grade 60

Base Metal Part II (Material Spec., type or grade):

ASTM A 516 Grade 60

Thickness and Diameter (Pipe):

Thickness of Test Coupon: 60 mm (2.36 in.), Plates

Diameter of Test Coupon: N/A

Filler Metals: AWS Classification/AWS Specification:

E7018 A5.1

Joint Details/Sketch:

Joint Design Used:

Root Opening G: mm (in) 0 to 1/8 in. Root Face RF : 3 mm (1/8 in.) Groove Angle: 60 (both sides) Radius (J-U): N/A

Weld Type:

Complete Joint Penetration Groove Weld

Joint Type:

Butt Joint

Backing Option:

Back-gouge to sound metal

Backing Material:

N/A

Back Gouging Method:

Mechanical (Grinding)

PQR No.: DEMO-PQR

Sheet 2 of 4

Electrical Characteristics: Current Type/Polarity: Transfer Mode (GMAW): Tungsten Electrode (GTAW):

Type: N/A Size: N/A

Shielding:

DCEP

N/A

Gas Composition (Flux for SAW): Gas Flow Rate: N/A Gas Cup Size: N/A

Welding Procedure

Weld Layer(s)

1 to 2 2 to n

Pass No.

1 to 3 4 to n

Process

SMAW SMAW

Filler Metal Classification

E7018 E7018

Filler Metal Diameter mm(in) 4.0 mm (5/32) 4.8 mm (3/16)

Current Amps

160-200 220-250

Current Wire Feed Type & Speed Polarity (in/min)

DCEP DCEP

N/A N/A

Volts

24-26 24-26

Travel Speed (in/min)

5-10 (in/min) 5-10 (in/min)

Remarks [Heat Input]

Root Pass Fill and Cap Passes

Technique:

Stringer or Weave Bead: Stringer and Weave Bead Initial/ Interpass Cleaning: Wire Brush, Grinding Number of Electrodes: Single Electrode Spacing: Longitudinal: N/A Lateral: N/A

Angle: N/A Contact Tube to Work Distance: N/A Peening: Not Required

Heat Treatment:

Preheat Temp. Min C (F): 150 C Postweld Heat Treatment: Temp. C (F): 600 to 620 C

Interpass Temp. Min/ Max: 150 C Time: 1 Hour per in.

Additional Notes:

See Postweld Heat Treatment (PWHT) Specification No. PWHT-SMAW-01

Manufacturer/ Contractor Welding Engineer :

Authorized by:

Name: Jim Clark Title: Welding Engineer Date: 12,12,2005

Name: John Smith Title: QA Manager Date: 12,13, 2005

PQR No.: DEMO-PQR

Sheet 3 of 4

PQR Heat Treatment (AWS Code's Guideline):

PREHEAT: AWS D1.1, Table 3.2 Prequalified Minimum Preheat and Interpass Temperature F (C): Thickness 3 to 20 mm (1/8 to 3/4 in.) incl.: 32F (0C) Over 20 thru 38 mm (3/4 to 1-1/2 in.) incl.: 50F (10C) Over 38 thru 65 mm (1-1/2 to 2-1/2 in.) incl.: 150F (65C) Over 65 mm (2-1/2 in): 225F (110C) For SMAW process, above preheat data is with low hydrogen electrodes. When the base metal temperature is below 32F (0C), preheated to a minimum of 70F (20C) Preheat and interpass temperature shall be sufficient to prevent cold cracking. Guideline on Alternative Methods for Determining Preheat/Interpass: See Annex I of AWS D1.1

POSTWELD HEAT TREATMENT: PWHT requirements shall be based on Welding Procedure Specification (WPS). AWS D1.1, 5.8 Stress-Relief Heat Treatment: Where required by the contract drawings or specifications, welded assemblies shall be stress relieved by heat treating. (See AWS D1.1, 5.8.1, Requirements for stress-relief treatment; Table 5.2, Minimum Holding Time; Table 5.3, Alternate Stress-Relief Heat Treatment) See AWS D1.1, 5.8.3, Steels Not Recommended for PWHT

PQR Qualified Range (AWS Code's Guideline):

Qualified Position: F (CJP/PJP Groove, Fillet) on Plate, Pipe, Box Tube (Table 4.1 AWS D1.1) Qualified Thicknesses (CJP Groove): 1/8 in. (3 mm) Min., Unlimited Plus any size of fillet or PJP groove weld for any thicknesses (Table 4.2 AWS D1.1) WPS Base Metal Group Allowed by PQR: Any Group I Steels to Any Group I Steels in Table 3.1 of AWS D1.1 (Table 4.8 AWS D1.1) Qualified WPS Filler Metal Allowed by PQR: For SMAW process, only same electrode type (change from low hydrogen to non-low hydrogen is not allowed). Also same (or lower) strength electrode tested in PQR for SMAW process. No increase in diameter from size tested in PQR allowed, except that an increase on electrode size of only 1/32 in. (0.8 mm) in SMAW is acceptable for use in WPS. (Table 4.5 AWS D1.1)

PQR No.: DEMO-PQR

PROCEDURE QUALIFICATION RECORDS

Test Results TENSILE TEST

Sheet 4 of 4

Specimen No.

TA1 TA2 TB1 TB2

Area Width Thickness Ultimate Tensile Load Ultimate Unit Character of Failure sq. mm mm (in) mm (in) kg (lb) Stress, MPa (psi) and Location (in)

25,1 25,1 25 25,1

30 30 30 30

753 753 750 753

36212 Kg 36712 Kg 35712 Kg 35612 Kg

471 (MPa) 477 (Mpa) 466 (MPa) 463 (MPa)

Ductile out Weld Ductile out Weld Ductile out Weld Ductile out Weld

GUIDED BEND TEST

Specimen No.

T1 T2 T3 T4

Type of Bend

Side bend Side bend Side bend Side bend

Results

Satisfactory Satisfactory Satisfactory Satisfactory

Remarks

Ductile Ductile Ductile Ductile

VISUAL INSPECTION:

Appearence: Good appearance Undercut: No Piping porosity: No Convexity: Acceptable Test Date: 11,11, 2005 Witnessed By: Jim Clark

Radiographic-ultrasonic examination:

RT report no: 1230-RT UT report no: 2310-UT

Result: O.K. Result: O.K.

FILLET WELD TEST RESULTS:

Max. size single pass: Macrotech 1: N/A

Min. size multiple pass: Macrotech 1: N/A 2: _ 3: _

Other Tests (Notes):

2: _ 3: _

All-weld-metal tension test:

Tensile strength, MPa (psi): N/A Yield point/strength, MPa (psi): _ Elongation in 2 in.,%: _ Laboratory test no.: _

Welders name: Welder Guy Tests conducted by: Quality Weld Lab, Inc. Laboratory Tests Number: TN-46547

Per: WPSAmerica.com

Clock No.: 123-12-1234

Stamp No.: JS-02

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with the requirements of Section 4 of AWS D1.1, (Year:2004) Structural Welding Code Steel.

Signed (Manufacturer): Name: Title: Date:

John Smith QA Manager 12,12,2005

Vous aimerez peut-être aussi

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmPas encore d'évaluation

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserPas encore d'évaluation

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungPas encore d'évaluation

- Essential and Non-Essential Variables For WPS - PQRDocument4 pagesEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanPas encore d'évaluation

- P1 To P8Document9 pagesP1 To P8Pat AuffretPas encore d'évaluation

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 page22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforPas encore d'évaluation

- Preguntas Al Comite API 1104Document12 pagesPreguntas Al Comite API 1104alefeli26Pas encore d'évaluation

- Enrollment Form - How To Fill UpDocument3 pagesEnrollment Form - How To Fill UpRaja Guru100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliPas encore d'évaluation

- Astm A 384Document2 pagesAstm A 384Shandy HaykalzPas encore d'évaluation

- Welding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument11 pagesWelding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh raja100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasPas encore d'évaluation

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaPas encore d'évaluation

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoPas encore d'évaluation

- Welding Domex SteelsDocument16 pagesWelding Domex Steelspozolab100% (1)

- TWI CL Eye Sight Test Form 2016Document2 pagesTWI CL Eye Sight Test Form 2016Savad Alwye100% (2)

- BS en 287Document7 pagesBS en 287Chris Thomas0% (1)

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielPas encore d'évaluation

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingPas encore d'évaluation

- p999999 100zd11 000 zd0001 - 0 Welding StandardDocument25 pagesp999999 100zd11 000 zd0001 - 0 Welding StandardJennyPas encore d'évaluation

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaPas encore d'évaluation

- 1143 EWF IIW Diploma Overview - August 2013Document2 pages1143 EWF IIW Diploma Overview - August 2013Sean ฌอนPas encore d'évaluation

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterPas encore d'évaluation

- Asme Section Ix InterpretationsDocument77 pagesAsme Section Ix Interpretationsippon_osoto100% (1)

- Cswip 3.1 Exam Instructions and Course ContentDocument3 pagesCswip 3.1 Exam Instructions and Course Contentravindra_jivaniPas encore d'évaluation

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87Pas encore d'évaluation

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiPas encore d'évaluation

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- 10 Procedure For PWHTDocument5 pages10 Procedure For PWHTSachin S. SalunkhePas encore d'évaluation

- Preguntas AwsDocument7 pagesPreguntas AwsRoman Roa MachucaPas encore d'évaluation

- WPS Format For ISO 9606-1 WelderDocument2 pagesWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- RT Exm Astar PDFDocument1 pageRT Exm Astar PDFSASIPas encore d'évaluation

- Electrode SelectionDocument1 pageElectrode SelectionMel gibsonPas encore d'évaluation

- CSWIP - WIS5-90516b PART 1Document24 pagesCSWIP - WIS5-90516b PART 1Ehsan KhanPas encore d'évaluation

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaPas encore d'évaluation

- Application Form For CSWIP 5 Year Renewal (Overseas) No LogbookDocument8 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) No Logbook04352Pas encore d'évaluation

- Api - 1104 - 1Document2 pagesApi - 1104 - 1aditya bhidePas encore d'évaluation

- Welder NIMI Q 2Document30 pagesWelder NIMI Q 2Mahesh SonarPas encore d'évaluation

- Top 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersDocument3 pagesTop 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersJlkKumarPas encore d'évaluation

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsDocument11 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DarePas encore d'évaluation

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantPas encore d'évaluation

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταPas encore d'évaluation

- Api 577Document1 pageApi 577HIIOJGFPas encore d'évaluation

- WPQR6Document3 pagesWPQR6Dimitris NikouPas encore d'évaluation

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniPas encore d'évaluation

- Bend Test Acceptance CriteriADocument1 pageBend Test Acceptance CriteriAGowrisanthosh PalikaPas encore d'évaluation

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohPas encore d'évaluation

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينPas encore d'évaluation

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocument7 pagesMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimPas encore d'évaluation

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityPas encore d'évaluation

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiPas encore d'évaluation

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- PChem Manual Ed 2023Document73 pagesPChem Manual Ed 2023rebecca niilonga fotolelaPas encore d'évaluation

- Commpany Profile - Hipack LabelprinDocument4 pagesCommpany Profile - Hipack LabelprinAzharul FuadPas encore d'évaluation

- In Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and MortarDocument13 pagesIn Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and Mortardummy dumdumPas encore d'évaluation

- Experiment 3 - Themodynamic Functions From EMF MeasurementsDocument5 pagesExperiment 3 - Themodynamic Functions From EMF MeasurementsjojoPas encore d'évaluation

- Openstax - Chemistry - Answer Key (Odds)Document75 pagesOpenstax - Chemistry - Answer Key (Odds)Windel AventuradoPas encore d'évaluation

- Paints Pigments and Industrial CoatingsDocument10 pagesPaints Pigments and Industrial CoatingsRaymond FuentesPas encore d'évaluation

- Weld Strength and Design PDFDocument47 pagesWeld Strength and Design PDFkhairulPas encore d'évaluation

- Chapter 1 Introduction To The Study of GeneticsDocument31 pagesChapter 1 Introduction To The Study of GeneticsCassieGrecoPas encore d'évaluation

- Active Matter in Anionic Surfactants by Potentiometric TitrationDocument4 pagesActive Matter in Anionic Surfactants by Potentiometric Titrationmkaseem74Pas encore d'évaluation

- Final Key WednesdayDocument7 pagesFinal Key WednesdayThanh LêPas encore d'évaluation

- (Martin Moeller, Krzysztof Matyjaszewski) PolymerDocument1 052 pages(Martin Moeller, Krzysztof Matyjaszewski) PolymerGrayPas encore d'évaluation

- EDF SK 1-1 - 1HYB800001-090B (Latest)Document130 pagesEDF SK 1-1 - 1HYB800001-090B (Latest)ashton.emsliePas encore d'évaluation

- Selection of Pectin As Pharmaceutical Excepient On The Basis of Rheological BehaviorDocument3 pagesSelection of Pectin As Pharmaceutical Excepient On The Basis of Rheological BehaviorВладимир КондратенкоPas encore d'évaluation

- Sodium Chloride - CrystallizationDocument8 pagesSodium Chloride - CrystallizationVatra ReksaPas encore d'évaluation

- Topic: Insects Pests Of: Cotton and Their IPMDocument15 pagesTopic: Insects Pests Of: Cotton and Their IPMG Janardana ReddyPas encore d'évaluation

- TorqueDocument25 pagesTorquesami4330100% (3)

- Sist Iso 293 1996Document8 pagesSist Iso 293 1996rtplemat lemat100% (1)

- Physical Properties of Group 18, Group 1 and Group 17 ElementsDocument2 pagesPhysical Properties of Group 18, Group 1 and Group 17 ElementsJames Chua Hong KhengPas encore d'évaluation

- Iso 13734 2013 (E)Document18 pagesIso 13734 2013 (E)Freddy Santiago Cabarcas LandinezPas encore d'évaluation

- Types of Electrical CablesDocument41 pagesTypes of Electrical CablesAbdullah NasirPas encore d'évaluation

- Horizontal Laminar Flow HoodDocument3 pagesHorizontal Laminar Flow HoodRichard Balicat Jr.Pas encore d'évaluation

- Technical Data Sheet R32 ENGLISHDocument6 pagesTechnical Data Sheet R32 ENGLISHreddy PrasadPas encore d'évaluation

- F2150.20907 - Caracterización ScaffoldsDocument12 pagesF2150.20907 - Caracterización ScaffoldsCamiloSilva100% (2)

- DoymaDocument28 pagesDoymaMariusPas encore d'évaluation

- KS3 Science 2009 L3 6 1Document32 pagesKS3 Science 2009 L3 6 1Beamerglitz0% (1)

- Enthusiast Score-I 2021-22Document1 pageEnthusiast Score-I 2021-22Aarya Vardhan ShandilyaPas encore d'évaluation

- Ancient and Modern Paper CharacterizatioDocument20 pagesAncient and Modern Paper CharacterizatioVornicu NicoletaPas encore d'évaluation

- Rsia Artha Mahinrus: Jl. Pasar 3 No. 151 - Terusan Tuasan, 20237Document15 pagesRsia Artha Mahinrus: Jl. Pasar 3 No. 151 - Terusan Tuasan, 20237Rabyatul Maulida NasutionPas encore d'évaluation

- Gardex Catalogue 2010Document35 pagesGardex Catalogue 2010dongheep811Pas encore d'évaluation

- 03.-Pulse Oximetry NotesDocument8 pages03.-Pulse Oximetry NotesAlexander Martínez PasekPas encore d'évaluation