Académique Documents

Professionnel Documents

Culture Documents

Bolier Inspection Report

Transféré par

Hadi AlloucheCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bolier Inspection Report

Transféré par

Hadi AlloucheDroits d'auteur :

Formats disponibles

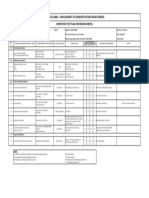

GENERAL SERVICES ADMINISTRATION PUBLIC BUILDINGS SERVICE

CITY AND STATE REGION NUMBER HEADQUARTERS

INSPECTION REPORT OF BOILER

(Make separate report for each boiler)

BUILDING DATE OF INSPECTION

1. NUMBER OF BOILERS IN BUILDING SUBJECT TO INSPECTION 3. MANUFACTURED'S NAME 4. TYPE OF BOILER STEAM HOT WATER 5. *TYPE OF SETTING 6. *DATE MANUFACTURED 8. MANUFACTURER'S RATING CAPACITY 6A. *DATE INSTALLED THIS LOCATION

2. PLANT BOILER NUMBER 3A. MANUFACTURER'S NUMBER

WATER TUBE PACKAGE TYPE

SCOTCH C. I. SECTIONAL

FIRE TUBE H.R.T. OTHER (Specify type)

FIRETUBE FIREBOX

7. *STATE SERVICE (Lighting, pumping, heating, power, etc.)

(B.H.P., SQ. FT. STEAM OR H.W., MBH. E.D.R. OR LB/HR) LBS./SQ. IN. LBS./SQ. IN.

MAXIMUM ALLOWABLE WORKING PRESSURE 9. MAXIMUM STEAM PRESSURE UNDER WHICH BOILER IS OPERATED 9A. HOT WATER SUPPLY TEMPERATURE

OF 10. HAS WORKING PRESSURE BEEN REDUCED, BASED ON AN OFFICIAL RECOMMENDATION? YES NO 12. NAME AND TITLE OF LAST INSPECTOR

9B. RETURN TEMPATURE OF (Minimum)

11. DATE OF LAST INSPECTION 13. FUEL USED COAL OIL GAS

14. *NUMBER AND LENGTH OF GENERATING TUBE 16. *MATERIAL AND GAUGE OF TUBES 17. *GIVE SIMILAR DATA ON WATER WALL TUBES IF FITTED 18. *NUMBER AND SIZE OF SECTIONS FOR C.I. BOILER 19. GENERAL CONDITION OF SETTING INSIDE 20. DOES BOILER CONTAIN GREASE? YES NO

15. *DIAMETER OF TUBES (O.D.)

OUTSIDE 20A. DOES BOILER CONTAIN SCALE? YES NO

20B. IF SO, IS QUANTITY OF GREASE OR SCALE CONSIDERED SERIOUS? YES NO

21. WAS EMBRITTLEMENT, GROOVING, PITTING, OR CORROSION APPARENT? YES NO

21A. IF SO, TO WHAT EXTENT OF EACH?

22. DOES BOILER SHOW SIGNS OF BAGS OR BLISTERS? YES NO

* To be recorded at first inspection only

GSA

FORM NOV 62

349

22A. IF SO, TO WHAT EXTENT

23. WAS HAMMER TEST MADE OF STAYS, RIVETS, ETC.? YES 23A. IF SO, STATE RESULTS NO

24. HAS BOILER BEEN RECEIVING FEED WATER TREATMENT? YES NO

24A. IF SO, WHAT TYPE AND TO WHAT EXTENT?

25. CONDITION OF TUBES 26. ARE THERE ANY WARPED TUBES? YES NO 27. CONDITION OF THE NIPPLES

28. HYDROSTATIC PRESSURE OF LBS./SQ. IN.WAS APPLIED 29. DID BOILER SHOW DEFECTS UNDER ABOVE PRESSURE? YES NO 29A. IF SO, WHERE, AND TO WHAT EXTENT?

30. WAS TEST PRESSURE 1 TIMES THE MAXIMUM ALLOWABLE PRESSURE AS RATED BY YES NO

30A. IF NOT, WHY WAS MAXIMUM PRESSURE NOT APPLIED?

31. RECOMMENDED MAXIMUM SAFE WORKING PRESSURE AS A RESULT OF THIS TEST LBS./SQ. IN. GAGE 32. *SAFETY VALUES NUMBER 33. CONDITION OF SAFETY VALVES TYPES SIZE

34. EACH SAFETY VALVE SET TO OPEN AT LBS. WATER PRESSURE 35. WAS PRESSURE TEST MADE OF SAFETY VALVES? YES NO 35A. RESULTS OF PRESSURE TEST, EACH VALVE OPEN

35B. RESULTS OF PRESSURE TEST, EACH VALVE CLOSED 36. WERE SAFETY VALVES RESET? YES NO LBS./SQ. IN. 37. CONDITION OF BOILER GAUGE 38. WHAT VARIATION IN PRESSURE EXISTED BETWEEN PRESSURE VESSEL GAUGE AND INSPECTOR'S TEST GAUGE AT WORKING PRESSURE? * To be recorded at first inspection only

36A. IF SO, FOR WHAT PRESSURE?

39. WAS GAUGE CORRECTED? YES NO 41. CONDITION OF FUSIBLE PLUGS

40. WERE FUSIBLE PLUGS RENEWED? YES NO

42. CONDITION OF GAUGE GLASS, WATER COLUMN AND TRY COCKS 43. CONDITION OF BOTTOM BLOW-OFF VALVES, AND LINE

44. CONDITION OF SURFACE BLOW AND/OR CONTINUOUS BLOW IF FITTED

45. WHAT TYPE OF BOILER FEEDING APPARATUS IS USED (PUMP, INJECTOR, RETURN TRAP, GRAVITY, ETC.) 45A. DESCRIBE SAME 46. CONDITION OF BOILER FEEDING APPARATUS

47. GENERAL INTERNAL CONDITION OF BOILER

47A. GENERAL EXTERNAL CONDITION OF BOILER

48. CONDITION OF THE BAFFLES 49. CONDITION OF THE CALKING BETWEEN TUBE HEADERS

50. GENERAL CONDITION OF THE MOUNTING, ATTACHMENTS, SETTINGS, BREECHING, BAROMETRIC DAMPER, STACK, ETC.

51. IF COAL IS USED FOR FUEL, HOW IS BOILER FIRED? HAND STOKER 52. IF STOKER, DESCRIBE SAME: GIVE CONDITION, INCLUDING SAFETY CONTROLS

53. IF OIL OR GAS IS USED FOR FUEL, DESCRIBE SAME: GIVE CONDITION, INCLUDING SAFETY CONTROLS

53A. FIRING EFFICIENCY %CO

2

53B. FLUE GAS TEMPERATURE

54. IF HAND FIRED, GIVE TYPE, SIZE AND CONDITION OF GRATES

55. WHAT REPAIRS OR ALTERATIONS HAVE BEEN MADE SINCE LAST INSPECTION AND WHY WERE THEY MADE?

56. HAS ADEQUATE PROVISIONS BEEN MADE FOR FIRE FIGHTING?

57. HOW DO PERSONNEL IN CHARGE OF THIS EQUIPMENT GRADE? COMPETENT DOUBTFUL INCOMPETENT

GIVE RECOMMENDATIONS REGARDING PERSONNEL

58. IN YOUR OPINION IS THIS BOILER IN A SAFE CONDITION TO BE OPERATED? YES NO

58A. IF ANSWER TO QUESTION 58 IS NO, THE INSPECTOR WILL NOTIFY THE CUSTODIAN, OR BUILDING SUPERINTENDENT, IMMEDIATELY IN WRITING, NOT TO USE SAME, AND GIVE COMPLETE DETAILS TO REGIONAL OFFICE BY WIRE 59. RECOMMENDATIONS AND REMARKS BY THE INSPECTOR (Include alterations, additions or repairs considered necessary)

59a. SIGNATURE OF INSPECTOR

59B. TITLE OF INSPECTOR

60. RECOMMENDATIONS AND REMARKS BY LOCAL OFFICER OR ENGINEER IN CHARGE

60A. SIGNATURE OF OFFICER IN CHARGE

60B. OFFICIAL TITLE OF OFFICER IN CHARGE

NOTE: Use additional sheets, if necessary, to supplement the above remarks

GSA WASH DC 63-6854

Vous aimerez peut-être aussi

- Mechanical Boiler Inspection ReportDocument1 pageMechanical Boiler Inspection ReportAfzal pathanPas encore d'évaluation

- Boiler Inspection PDFDocument2 pagesBoiler Inspection PDFsajuherePas encore d'évaluation

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesPas encore d'évaluation

- Inspecton ProcedureDocument3 pagesInspecton ProcedureSanthosh ReddyPas encore d'évaluation

- Hydrotest Procedure for WHR CPP BoilersDocument12 pagesHydrotest Procedure for WHR CPP BoilersJOHnPas encore d'évaluation

- 3LPE Repair ProcedureDocument3 pages3LPE Repair Procedurelhanx2Pas encore d'évaluation

- Utility Boiler Inspection PlanDocument3 pagesUtility Boiler Inspection PlanGanesh EshwarPas encore d'évaluation

- All about steam boiler hydrostatic testingDocument2 pagesAll about steam boiler hydrostatic testingRoland NicolasPas encore d'évaluation

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmPas encore d'évaluation

- Final Inspection Report for Venturi Pin LinersDocument1 pageFinal Inspection Report for Venturi Pin LinersSenthil KumarPas encore d'évaluation

- Boiler Regulations and Efficiency FactorsDocument9 pagesBoiler Regulations and Efficiency FactorsSathish KumarPas encore d'évaluation

- Sprinkler System - General InformationDocument5 pagesSprinkler System - General InformationshahidenterPas encore d'évaluation

- Floating Head Heat Exchanger Hydrotest ProcedureDocument15 pagesFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezPas encore d'évaluation

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdPas encore d'évaluation

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanPas encore d'évaluation

- Boiler InspectionDocument115 pagesBoiler InspectionKanphong.sm100% (1)

- List of Itp新 for HrsgDocument16 pagesList of Itp新 for HrsgzhangPas encore d'évaluation

- VBTDocument5 pagesVBTMohdHuzairiRusliPas encore d'évaluation

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusPas encore d'évaluation

- Storage Tank Shell Banding Quality Control and Inspection Report FormDocument1 pageStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoPas encore d'évaluation

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariPas encore d'évaluation

- Test Certificate 01Document1 pageTest Certificate 01Anoop RaghuPas encore d'évaluation

- Inspection and Test Plan For Water Tube BoilerDocument13 pagesInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaPas encore d'évaluation

- Hydrostatic Test Procedure: 1. ScopeDocument5 pagesHydrostatic Test Procedure: 1. ScopeHassan SleemPas encore d'évaluation

- Hottaping FURMANITEDocument85 pagesHottaping FURMANITEAriz Joelee ArthaPas encore d'évaluation

- Boiler Inspection and Test PlanDocument13 pagesBoiler Inspection and Test Plandoley_pranab100% (3)

- Types of Boilers ExplainedDocument112 pagesTypes of Boilers ExplainedAldy Bagus PratamaPas encore d'évaluation

- ITP Boiler PDFDocument13 pagesITP Boiler PDFMúhámmád ÁbrorPas encore d'évaluation

- Annexure 3 External Inspection ChecklistDocument5 pagesAnnexure 3 External Inspection Checklistankur100% (1)

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcPas encore d'évaluation

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocument13 pagesJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaPas encore d'évaluation

- IAETSD-PREPARATION OF W.P.S FOR STAINLESS STEEL (Ni, CR, Mo, Nu) WELDING PDFDocument3 pagesIAETSD-PREPARATION OF W.P.S FOR STAINLESS STEEL (Ni, CR, Mo, Nu) WELDING PDFiaetsdiaetsd100% (1)

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreePas encore d'évaluation

- Floating Suction Assembly SpecificationDocument2 pagesFloating Suction Assembly Specificationbecpavan100% (1)

- SAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTDocument5 pagesSAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTZoran ObradovicPas encore d'évaluation

- Water SoftenersDocument11 pagesWater Softenersadel rihanaPas encore d'évaluation

- Boiler MountingsDocument12 pagesBoiler MountingsvikramnikhilanshiPas encore d'évaluation

- Thermal Power Plant Color Code For Piping PDFDocument11 pagesThermal Power Plant Color Code For Piping PDFalwynnithinherbert50% (4)

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDocument21 pagesCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaPas encore d'évaluation

- Hydrostatic Test in Steam BoilerDocument2 pagesHydrostatic Test in Steam BoilerUjang SonjayaPas encore d'évaluation

- Vizag Bed Coil Replacement ProcedureDocument8 pagesVizag Bed Coil Replacement ProcedureMahadev KovalliPas encore d'évaluation

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21Pas encore d'évaluation

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonPas encore d'évaluation

- Jun 2018 153707867T2JQPG3GPFRDocument61 pagesJun 2018 153707867T2JQPG3GPFRANIL KUMARPas encore d'évaluation

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanPas encore d'évaluation

- Chapter 6 Leak Detection Methods and RatesDocument21 pagesChapter 6 Leak Detection Methods and RatesDurgamadhaba Mishra100% (1)

- Hydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)Document1 pageHydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)mansih457100% (1)

- Pressure TestingDocument9 pagesPressure TestingSanjay SinghPas encore d'évaluation

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- LPG Tank Commissioning Training NotesDocument32 pagesLPG Tank Commissioning Training NotesKajubi Edris100% (1)

- Sec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)Document5 pagesSec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)حمودي معز100% (2)

- Hydrostatic Test of Pandi WaterDocument7 pagesHydrostatic Test of Pandi WaterOscar C. GabinayPas encore d'évaluation

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamPas encore d'évaluation

- Inspection, Maintenance and Testing of Fired HeatersDocument27 pagesInspection, Maintenance and Testing of Fired HeatersVicente Regulez FernandezPas encore d'évaluation

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Boiler Checklist ReportDocument4 pagesBoiler Checklist ReportgedearthanaPas encore d'évaluation

- Gas Turbine Operation, Maintenance & InspectionDocument57 pagesGas Turbine Operation, Maintenance & Inspectionromadhinho100% (3)

- Asme PTC 4.1Document5 pagesAsme PTC 4.1dgmprabhakarPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Nuclide Safety Data Sheet for Iridium-192Document2 pagesNuclide Safety Data Sheet for Iridium-192Hadi AllouchePas encore d'évaluation

- Asme Section II A Sa-106 Page 5Document1 pageAsme Section II A Sa-106 Page 5Hadi AllouchePas encore d'évaluation

- Acceptance Criteria Asme B31 3Document1 pageAcceptance Criteria Asme B31 3Hadi Allouche100% (9)

- Acceptance Criteria Asme B31 3Document1 pageAcceptance Criteria Asme B31 3Hadi Allouche100% (9)