Académique Documents

Professionnel Documents

Culture Documents

Got Liners

Transféré par

Seungmin PaekDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Got Liners

Transféré par

Seungmin PaekDroits d'auteur :

Formats disponibles

Liners are used to protect the bellows element of an expansion joint assembly.

Its not always a cheap accessory so be sure a liner is needed before specifying one. Heres what you need to know: Go With the Flow Excessively high flow velocity of air, steam, or fluids across the inside of a bellows will cause it to vibrate and fail prematurely. In extreme cases the bellows will resonate at its natural frequency and fracture catastrophically (for a cool demonstration of harmonic structural failures, perform a web search on tacoma bridge). Liners prevent such problems. The EJMA guidelines recommend liners when flow velocities exceed the following values:

Air, Steam and other Gases Up to 6 in. dia. 4ft./sec./inch of diameter Over 6 in. diameter 25 ft./sec. Water and other Liquids Up to 6 in. diameter 2 ft./sec./in. of diameter Over 6 in. diameter 10 ft./sec.

need to be thick or lined itself by an abrasion resistant surface. (i.e., hard coating or refractory). A liner can also be used to drop the bellows temperature by creating a partial dead air space. Even greater temperature drops can be achieved by using a ceramic based insulation.

Mind the Gap One end of the liner is fixed; the other is free to move. When the bellows flexes due to lateral or angular movement, the liner is designed with enough gap so as not to collide with the I.D. of the pipe or flange. Small diameter bellows deflect laterally quite well, but when the liner is gapped for that large movement its diameter is too restrictive for proper flow. Also be aware that for large axial movements the liner will stroke past the expansion joint over-all length and into the attached piping. Take care to avoid adjacent fittings. Also remember, the fixed end is always installed upstream of the flow. In summary; use a liner when flow velocities are high, abrasive particles are present, or insulation is needed.

Liners are not needed for flow rates below these guidelines.

The Gritty Details Abrasives, such as sand or catalyst, can chew up the inside of a piping system. The bellows is much thinner than the pipe and so it will wear faster. The liner will

Next Month Why an Expansion Joint Works: The Physics Behind a Metal Bellows, Part I

The Bellows Bottom Line is a publication of Oakridge Bellows For expansion joint information Greg Perkins can be contacted at gperkins@oakridgebellows.com or (830) 626-7773

Vous aimerez peut-être aussi

- Installation Guide For PVC PipeDocument43 pagesInstallation Guide For PVC Pipeb1gm3nPas encore d'évaluation

- Water StopperDocument6 pagesWater StopperMF YousufPas encore d'évaluation

- Distillations From The WholeDocument5 pagesDistillations From The WholeJesus MoralesPas encore d'évaluation

- Sanitary Drainage SystemsDocument25 pagesSanitary Drainage Systemspepito manalotoPas encore d'évaluation

- Plugs and Profiles: - Types - Running - Pulling - ProblemsDocument43 pagesPlugs and Profiles: - Types - Running - Pulling - Problemsdriller22Pas encore d'évaluation

- Sluice CatalogueDocument40 pagesSluice CatalogueLungisaniPas encore d'évaluation

- Vortex TrapDocument6 pagesVortex Trapsilvioap100% (1)

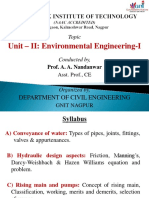

- Unit - II: Environmental Engineering-I: TopicDocument53 pagesUnit - II: Environmental Engineering-I: Topicbharatiya technologyPas encore d'évaluation

- Plumbing Ventilation and TrapsDocument5 pagesPlumbing Ventilation and TrapscessPas encore d'évaluation

- Bondstrand Series 7000 M Installation ManualDocument84 pagesBondstrand Series 7000 M Installation ManualPavel Vicentiu0% (1)

- Reskem ResinmediatrapsDocument2 pagesReskem ResinmediatrapsdeyprasenPas encore d'évaluation

- Coiled TubingDocument6 pagesCoiled Tubingneal d fearless dreamerPas encore d'évaluation

- PackingDocument20 pagesPackingOpayan SarkarPas encore d'évaluation

- Coil Tubing: Lecture Notes by Prof - Sushanta SarkarDocument32 pagesCoil Tubing: Lecture Notes by Prof - Sushanta Sarkarnishant41288100% (1)

- So If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingDocument1 pageSo If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingKarim MohamedPas encore d'évaluation

- Sub Surface ToolDocument64 pagesSub Surface ToolPrithiraj KalitaPas encore d'évaluation

- Sediment Control: Silt FencesDocument7 pagesSediment Control: Silt FencesShah ImaPas encore d'évaluation

- Almacenamiento de TuberiaDocument4 pagesAlmacenamiento de TuberiaYesid Cruz Yesid CruzPas encore d'évaluation

- Velocity StringsDocument2 pagesVelocity StringsCarlos LiscanoPas encore d'évaluation

- Velocity StringsDocument2 pagesVelocity StringsDedy DayatPas encore d'évaluation

- Hydro Testing ProcedureDocument12 pagesHydro Testing ProcedureGaapchuPas encore d'évaluation

- Casing PDFDocument5 pagesCasing PDFRohan Chunara100% (3)

- Sliplining SewersDocument3 pagesSliplining SewersDavid NavarretePas encore d'évaluation

- 5th Week ReportDocument13 pages5th Week ReportMuhammad AwaisPas encore d'évaluation

- Making of Most of ValvesDocument12 pagesMaking of Most of ValvesShaikh MateenPas encore d'évaluation

- Chapter 20 - FishingDocument21 pagesChapter 20 - FishingBlanca OrtegaPas encore d'évaluation

- Proceso de Soldadura PVC George FisherDocument10 pagesProceso de Soldadura PVC George FisherMarco Antonio Hernandez MotaPas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Traps and SoventDocument32 pagesTraps and SoventEdwin LoquinaPas encore d'évaluation

- 4 Guidance On Valve Type SelectionDocument86 pages4 Guidance On Valve Type SelectionKrista OneillPas encore d'évaluation

- Valve Election GuidanceDocument85 pagesValve Election GuidanceMecirdi Mohamed el AminePas encore d'évaluation

- Installation Instructions Spool Type Elastomer Expansion JointsDocument2 pagesInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaPas encore d'évaluation

- Plumbing 10Document4 pagesPlumbing 10Stanley Scott ArroyoPas encore d'évaluation

- Lecture 14-15 - Gas-Liquid Contact EquipmentDocument11 pagesLecture 14-15 - Gas-Liquid Contact EquipmentMihir Kumar MechPas encore d'évaluation

- Overview Of+sewer Rehabilitation TechniquesDocument23 pagesOverview Of+sewer Rehabilitation TechniquesPeterLOW0218Pas encore d'évaluation

- Guidance On Valves Type Selection VALVEDocument86 pagesGuidance On Valves Type Selection VALVEjacquesstrappe06Pas encore d'évaluation

- Mass Transfer EquipmentsDocument32 pagesMass Transfer EquipmentsAjaykumarPas encore d'évaluation

- CasingDocument4 pagesCasingParth VPas encore d'évaluation

- Steam Mains and Drainage Spirax PDFDocument19 pagesSteam Mains and Drainage Spirax PDFsachin nagavkarPas encore d'évaluation

- BP Flowback ProceduresDocument10 pagesBP Flowback ProceduresAlexander KlmPas encore d'évaluation

- Manual HidraulicaDocument5 pagesManual HidraulicasimonsecurityPas encore d'évaluation

- Vessel Internals: 1 WeirDocument2 pagesVessel Internals: 1 WeirPrie TeaPas encore d'évaluation

- Pages - Steam Mains and DrainageDocument10 pagesPages - Steam Mains and DrainageSPK 27Pas encore d'évaluation

- Process Column & Internals Part II (Packed Column) Rev-1Document51 pagesProcess Column & Internals Part II (Packed Column) Rev-1sinner123Pas encore d'évaluation

- ASPE PSD - CleanoutsDocument2 pagesASPE PSD - CleanoutsNiong DavidPas encore d'évaluation

- TEMA Terminology:: o o o o oDocument5 pagesTEMA Terminology:: o o o o oNathanianPas encore d'évaluation

- Flow in Packed BedsDocument54 pagesFlow in Packed BedsleasturbaPas encore d'évaluation

- Water PipelinesDocument8 pagesWater PipelinesBilal AmjadPas encore d'évaluation

- Air Distribution Systems GuideDocument3 pagesAir Distribution Systems GuidejchuatsonPas encore d'évaluation

- Lec 1-Piping-System 2018Document62 pagesLec 1-Piping-System 2018Arwa Hussein100% (2)

- Bioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesDocument23 pagesBioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesssfoodtechPas encore d'évaluation

- (Paul E. Minton) Handbook of Evaporation Technology - 170-182Document13 pages(Paul E. Minton) Handbook of Evaporation Technology - 170-182Ahmad Asfahani100% (1)

- Hydrostatic Pressure Testing of Plastic Piping SystemsDocument12 pagesHydrostatic Pressure Testing of Plastic Piping SystemsezzataPas encore d'évaluation

- Durapipe Abs Product BrochureDocument8 pagesDurapipe Abs Product Brochureapi-36492444Pas encore d'évaluation

- Failure Mode of Hydraulic HosesDocument9 pagesFailure Mode of Hydraulic HosesAhmat RamadaniPas encore d'évaluation

- 007 UTube CleaningDocument2 pages007 UTube CleaninggshdavidPas encore d'évaluation

- Absorption EquipmentsDocument33 pagesAbsorption EquipmentsMohana Murali33% (3)

- Catalogue - New QPF PDFDocument32 pagesCatalogue - New QPF PDFShaiju EbrahimPas encore d'évaluation

- Simple Plumbing Repairs for the Home and FarmsteadD'EverandSimple Plumbing Repairs for the Home and FarmsteadPas encore d'évaluation

- Understanding Your Boats Systems and Choices.D'EverandUnderstanding Your Boats Systems and Choices.Évaluation : 3 sur 5 étoiles3/5 (1)

- (CAT) 메가플랙슨 - Rubber Expansion JointDocument10 pages(CAT) 메가플랙슨 - Rubber Expansion JointSeungmin PaekPas encore d'évaluation

- (CAT) 성화산업 - Pipe Support & Hanger (Acessories)Document199 pages(CAT) 성화산업 - Pipe Support & Hanger (Acessories)Seungmin Paek100% (1)

- SimonFreese Journal ArticleDocument9 pagesSimonFreese Journal ArticleSeungmin PaekPas encore d'évaluation

- CAESAR II Training - WRC 107 INPUTDocument5 pagesCAESAR II Training - WRC 107 INPUTSeungmin Paek100% (1)

- (CAT) 유니슨 - Pipe Hangers & SupportsDocument174 pages(CAT) 유니슨 - Pipe Hangers & SupportsSeungmin PaekPas encore d'évaluation

- Velocity of Flow and Water Hammer: by Michael B. Haener, C.I.DDocument2 pagesVelocity of Flow and Water Hammer: by Michael B. Haener, C.I.DSeungmin PaekPas encore d'évaluation

- Steel Line Blanks & Spacer Dimension TableDocument5 pagesSteel Line Blanks & Spacer Dimension TableSeungmin PaekPas encore d'évaluation

- Pressure Balanced Expansion JointsDocument1 pagePressure Balanced Expansion JointsSeungmin PaekPas encore d'évaluation

- PRV Flex ConnectorsDocument1 pagePRV Flex ConnectorsSeungmin PaekPas encore d'évaluation

- 12 Allowable Pipe Span Formulas and TablesDocument10 pages12 Allowable Pipe Span Formulas and TablesSeungmin Paek91% (11)

- Bellows Pressure Thrust The Good and Dark Side of The ForceDocument1 pageBellows Pressure Thrust The Good and Dark Side of The ForceSeungmin PaekPas encore d'évaluation

- Riser Lug: 150A and Smaller 175A and LargerDocument1 pageRiser Lug: 150A and Smaller 175A and LargerSeungmin PaekPas encore d'évaluation

- Van Stone BellowsDocument1 pageVan Stone BellowsSeungmin PaekPas encore d'évaluation

- Inspecting Bellows DamageDocument1 pageInspecting Bellows DamageSeungmin PaekPas encore d'évaluation

- Multiple Ply BellowsDocument1 pageMultiple Ply BellowsSeungmin PaekPas encore d'évaluation

- Externally Pressurized Expansion JointsDocument1 pageExternally Pressurized Expansion JointsSeungmin PaekPas encore d'évaluation

- Going Laterally in An Axial WorldDocument1 pageGoing Laterally in An Axial WorldSeungmin PaekPas encore d'évaluation

- Maintaining 2 Ply Testable BellowsDocument1 pageMaintaining 2 Ply Testable BellowsSeungmin PaekPas encore d'évaluation

- Insider Secrets of Bellows RepairDocument1 pageInsider Secrets of Bellows RepairSeungmin PaekPas encore d'évaluation

- Cryogenic Properties of Stainless Steel BellowsDocument1 pageCryogenic Properties of Stainless Steel BellowsSeungmin PaekPas encore d'évaluation

- Alloy 625 Vs 625 LCF BellowsDocument1 pageAlloy 625 Vs 625 LCF BellowsSeungmin PaekPas encore d'évaluation

- Fillet Welding On Gussets and LugsDocument1 pageFillet Welding On Gussets and LugsSeungmin PaekPas encore d'évaluation

- Piping Tie-Rod Design Made SimpleDocument3 pagesPiping Tie-Rod Design Made SimpleSeungmin PaekPas encore d'évaluation

- Allowable Pump Piping LoadsDocument4 pagesAllowable Pump Piping LoadsSeungmin Paek100% (2)

- Pump Baseplate Design and InstallationDocument4 pagesPump Baseplate Design and InstallationSeungmin Paek100% (1)

- Select Expansion Joints ProperlyDocument4 pagesSelect Expansion Joints ProperlySeungmin Paek100% (2)