Académique Documents

Professionnel Documents

Culture Documents

Standard

Transféré par

raobabar21Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Standard

Transféré par

raobabar21Droits d'auteur :

Formats disponibles

COMPARISON OF

STANDARD-MATERIALS

-2-

TABLE OF CONTENTS

Page

1.

1.1

1.2

1.3

CAST MATERIAL

G-X5 CrNi 13 4

GS 20 Mn 5

GS-45

ASTM A-743, Grade CA 6-NM

ASTM A-148, Grade 80/50

ASTM A-27, Grade 65/35

3

4

5

2.

2.1

2.2

2.3

PLATE MATERIAL

StE 285

StE 355

StE 420

ASTM A-516, Grade 60

ASTM A-537, Class 1

ASTM A-633, Grade E

6

7

8

2.4

2.4.1

2.5

2.6

2.7

Rst 37-2

St 52-3

X5 CrNi 13 4

X10 CrNiNb 189

X10 Cr 13

ASTM A-283, Grade C

ASTM A-537, Class 1

ASTM A-182, Grade F6-NM

ASTM A-240, Type 347

ASTM A-240, Type 410

9

10

11

12

13

3.

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

FORGED MATERIAL

Ck 35

StE 355

St 52-3

34 Cr 4

42 CrMo 4

50 CrMo 4

C22

X 20 Cr 13

X 5 CrNi 13 4

ASTM A-668, Class D

SAE 1522

SAE 1524

AISI 5132

AISI 4140H

AISI 4150H

ASTM A-105

ASTM A-473, Type 420

ASTM A-182, Grade F6-NM

14

15

16

17

18

19

20

21

11

4.

4.1

TUBES

St 35

ASTM A-53, Grade A

22

5.

5.1

HOT BARS

St 37.2

ASTM A-283, Grade C

23

-3-

1.

CAST MATERIAL

1.1

G-X5CrNi 13 4

acc. to DIN 17.445

ASTM A-743

Grade CA-6NM

Chemical Composition

C .............................................. max. 0.060 %

Si................................................max. 1.00 %

Mn.............................................. max. 1.00 %

Cr............................................... 12.0 - 13.5 %

Ni................................................3.5 - 4.5 %

Mo.............................................. 0.40 - 0.70 %

S.................................................max. 0.025 %

P.................................................max. 0.025 %

max. 0.060 %

max. 1.00 %

max. 1.00 %

11.5 - 14.00 %

3.50 - 4.50 %

0.40 - 1.00 %

max. 0.03 %

max. 0.03 %

Mechanical Properties

Tensile strength......................... 760 - 930 N/mm2

Yield point.................................. min. 540 N/mm2

Elongation (L0 = 5d0)..................min. 15 %

min. 755 MPa

min. 550 MPa

min. 15 %

...................................................

Reduction of area......................min. 35%

Impact energy............................ min. 55 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

min. 35 %

not specified

-4-

1.2

GS 20 Mn 5 V

acc. to DIN 17.182

ASTM A-148

Grade 80/50

Chemical Composition

C .............................................. 0.15 - 0.23 %

Mn.............................................. 1.00 - 1.50 %

Mo.............................................. < 0.15 %

Ni................................................< 0.40 %

not specified

not specified

not specified

not specified

P.................................................max. 0.020 %

S.................................................max. 0.015 %

max. 0.05 %

max. 0.06 %

Mechanical Properties

Tensile strength......................... 500 - 650 N/mm2

Yield point.................................. min. 360 N/mm2

Elongation (L0 = 5d0)..................min. 24 %

min. 550 MPa

min. 345 MPa

min. 22 %

...................................................

Reduction of area......................not specified

Impact energy............................ min. 70 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

min. 35 %

not specified

-5-

1.3

GS-45

acc. to DIN 1681

ASTM A-27

Grade

Chemical Composition

65/35

70/40

C .............................................. not specified

Si................................................not specified

Mn.............................................. not specified

P.................................................not specified

S.................................................not specified

max. 0.30 %

max. 0.80 %

max. 0.70 %

max. 0.05 %

max. 0.06 %

0,25 %

0,80 %

1,20 %

0,05 %

0,06 %

Mechanical Properties

Tensile strength......................... 450 N/mm2

min. 450 MPa

Yield point.................................. min. 230 N/mm2 min. 240 MPa

Elongation (L0 = 5d0................... min. 22 %

min. 24 %

...................................................

Reduction of area......................min. 31 %

Impact energy............................ 27 J

Charpy-V notch

specimen at + 20 C

485 MPa

275 MPa

22 %

(2 inches or 50 mm)

min. 35 %

30 %

-6-

2.

PLATE MATERIAL

2.1

StE 285

acc. to DIN 17.102

ASTM A-516

Grade 60

Chemical Composition

C .............................................. max. 0.18 %

Si................................................max. 0.40 %

Mn.............................................. 0.60 - 1.40 %

P.................................................max. 0.035 %

S.................................................max. 0.030 %

0.21 - 0.27 %

0.13 - 0.45 %

0.55 - 1.30 %

max. 0.035 %

max. 0.035 %

Mechanical Properties

Tensile strength......................... 390 - 510 N/mm2

Yield point.................................. 285 N/mm2

Elongation (L0 = 5d0)..................min. 246 %

415 - 550 MPa

min. 220 MPa

min. 25 %

...................................................

Impact energy............................ min. 55 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

not specified

-7-

2.2

StE 355

acc. to DIN 17.102

ASTM A-537

Class 1

Chemical Composition

C .............................................. max. 0.20 %

Si................................................0.10 - 0.50 %

Mn.............................................. 0.70 - 1.50 %

P.................................................max. 0.035 %

S.................................................max. 0.030 %

max. 0.24 %

0.13 - 0.55 %

0.64 - 1.72 %

max. 0.035 %

max. 0.04 %

Mechanical Properties

Tensile strength......................... 490 - 630 N/mm2

Yield point.................................. 355 N/mm2

Elongation (L0 = 5d0)..................min. 22 %

450 - 620 MPa

310 - 345 MPa

min. 22 %

...................................................

Impact energy............................ min. 55 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

not specified

-8-

2.3

StE 420

acc. to DIN 17.102

ASTM A-633

Grade E

Chemical Composition

C .............................................. max. 0.20 %

Si................................................0.10 - 0.60 %

Mn.............................................. 1.00 - 1.70 %

P.................................................max. 0.035 %

S.................................................max. 0.030 %

max. 0.22 %

0.15 - 0.50 %

1.15 - 1.50 %

max. 0.035 %

max. 0.040 %

Mechanical Properties

Tensile strength......................... 530 - 680 N/mm2

Yield point.................................. 420 N/mm2

Elongation (L0 = 5d0)..................min. 19 %

515 - 690 MPa

380 - 415 MPa

min. 23 %

...................................................

Impact energy............................ min. 55 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

min. 68 J (+25 C)

-9-

2.4

Rst 37-2

ASTM A-283

Grade C

Chemical Composition

C .............................................. max. 0.20 %

P.................................................max. 0.050 %

S.................................................max. 0.050 %

Si................................................-Mn.............................................. --

max. 0.24 %

max. 0.035 %

max. 0.040 %

max. 0.40 %

max. 0.90 %

Mechanical Properties

Tensile strength......................... 360 - 470 N/mm2

Yield point.................................. 215 - 235 N/mm2

Elongation (L0 = 5d0)..................min. 24 %

380 - 485 MPa

min. 205 MPa

min. 22 %

...................................................

Impact energy............................ min. 27 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

not specified

-10-

2.4.1

St 52-3

ASTM A-537

Class 1

Chemical Composition

C .............................................. max. 0.20 %

P.................................................max. 0.04 %

S.................................................max. 0.04 %

Si................................................not specified

Mn.............................................. not specified

max. 0.24 %

max. 0.035 %

max. 0.035 %

0.13 - 0.55 %

0.64 - 1.72 %

Mechanical Properties

Tensile strength......................... 510 - 630 N/mm2

Yield point.................................. 305 - 355 N/mm2

Elongation (L0 = 5d0)..................min. 20 %

450 - 620 MPa

310 - 345 MPa

min. 22 %

...................................................

Impact energy............................ min. 27 J

Charpy-V notch

specimen at + 20 C

(long.)

(2 inches or 50 mm)

not specified

-11-

2.5/3.8

X 5 CrNi 13 4

ASTM A-182

Grade F6-NM

Chemical Composition

C .............................................. max. 0.050 %

Si................................................max. 0.50 %

Mn.............................................. max. 1.0 %

Cr............................................... 12.0 - 13.5 %

Ni................................................3.3 - 4.5 %

Mo.............................................. 0.30 - 0.50 %

S.................................................max. 0.025 %

P.................................................max. 0.030 %

max. 0.05 %

max. 0.60 %

0.050 - 1.00 %

11.5 - 14.0 %

3.5 - 5.5 %

0.5 - 1.0 %

max. 0.030 %

max. 0.030 %

Mechanical Properties

Tensile strength......................... 750 - 950 N/mm2

Yield point.................................. min. 550 N/mm2

Elongation (L0 = 5d0)..................min. 16 %

min. 790 MPa

min. 620 MPa

min. 15 %

...................................................

Reduction of area......................min. 25 %

Impact energy............................ min. 45 J

Charpy-V notch

specimen at + 20 C

(long.)

(2 inches or 50 mm)

min. 45 %

not specified

-12-

2.6

X 10 CrNiNb 18 9

ASTM A-240

acc. to NORM M 3121

Chemical Composition

Type 347

Type

304L

C .............................................. max. 0.10 %

Si................................................max. 1.0 %

Mn.............................................. max. 2.0 %

Cr............................................... 17.0 to 19.0 %

Ni................................................9.0 - 11.5 %

S.................................................max. 0.030 %

P.................................................max. 0.045 %

max. 0.08 %

max. 0.75 %

max. 2.00 %

17.0 - 19.0 %

9.0 - 13.0 %

max. 0.030 %

max. 0.045 %

0,03 %

0,75 %

2,00 %

18-20 %

8 - 12 %

0,030 %

0,045 %

Tensile strength......................... 500 - 700 N/mm2 min. 515 MPa

Yield point.................................. min. 205 N/mm2 min. 205 MPa

Elongation (L0 = 5d0................... min. 35 %

min. 40 %

485 MPa

170 MPa

40 %

Mechanical Properties

...................................................

(2 inches or 50 mm)

-13-

2.7

X 10 Cr 13

acc. to DIN 17.440

ASTM A-240

Type 410

Chemical Composition

C .............................................. 0.08 - 0.12 %

P.................................................max. 0.045 %

S.................................................max. 0.030 %

Si................................................max. 1.0 %

Mn.............................................. max. 1.0 %

Cr............................................... 12.0 - 14.0 %

Ni................................................--

max. 0.15 %

max. 0.040 %

max. 0.030 %

max. 1.00 %

max. 1.0 %

11.5 - 13.5 %

max. 0.75 %

Mechanical Properties

Tensile strength......................... 600 - 800 N/mm2

Yield point.................................. min. 420 N/mm2

Elongation (L0 = 5d0)..................min. 18 %

min. 450 MPa

min. 205 MPa

min. 20 %

...................................................

(2 inches or 50 mm)

-14-

3.

FORGED MATERIAL

3.1

CK 35

acc. to DIN 17.200

ASTM A-668

Class D

Chemical Composition

C .............................................. 0.32 - 0.39 %

Si................................................max. 0.40 %

Mn.............................................. 0.50 - 0.80 %

S.................................................max. 0.030 %

P.................................................max. 0.035 %

not specified

not specified

max. 1.35 %

max. 0.05 %

max. 0.05 %

Mechanical Properties

Tensile strength

= 250...................................... 490 - 640 N/mm2

min. 515 MPa

250 = 500...................................490 - 640 N/mm2

Yield point

= 250...................................... min. 295 N/mm2

min. 515 MPa

250 = 500...................................min. 275 N/mm2

Elongation (L0 = 5d0)

min. 260 MPa

= 250...................................... min. 22 % long.

min. 22 %

250 = 500...................................min. 21 % long.

= 250...................................... min. 19 % tang.

min. 19 %

min. 22 %

250 = 500...................................min. 18 % tang.

Reduction of area...................... ..........................

Impact energy............................ min. 31 J long.

Impact energy............................ min. 27 J tang.

Charpy-V notch

specimen at + 20 C

min. 19 %

min. 30 %

not specified

not specified

min. 260 MPa

-15-

3.2

StE 355

acc. to DIN 17.103

SAE 1522

Chemical Composition

C .............................................. max. 0.20 %

Si................................................0.10 - 0.50 %

Mn.............................................. 0.90 - 1.65 %

P.................................................max. 0.035 %

S.................................................max. 0.030 %

0.18 - 0.24 %

not specified

1.10 - 1.40 %

max. 0.04 %

max. 0.05 %

Mechanical Properties

Tensile strength......................... 490 - 630 N/mm2

Yield point.................................. 355 N/mm2

Elongation (L0 = 5d0)..................min. 23 %

not specified

not specified

not specified

Impact energy............................ min. 55 J

Charpy-V notch

specimen at + 20 C

(long.)

not specified

-16-

St 52-3

acc. to DIN 17.100

SAE 1524

Chemical Composition

C .............................................. max. 0.22 %

Si................................................max. 0.60 %

Mn.............................................. max. 1.70 %

P.................................................max. 0.04 %

S.................................................max. 0.04 %

0.19 - 0.25 %

not specified

1.35 - 1.65 %

max. 0.04 %

max. 0.05 %

Mechanical Properties

Tensile strength......................... 490 - 630 N/mm2

Yield point.................................. 315 - 355 N/mm2

Elongation (L0 = 5d0)..................min. 20 %

not specified

not specified

not specified

Impact energy............................ min. 23 J

Charpy-V notch

specimen at + 20 C

(long.)

not specified

-17-

3.3

34 Cr 4

acc. to DIN

17.200

AISI 5132

(ASTM A304)

Chemical Composition

A304

C .............................................. 0.30 - 0.37 %

0.30 - 0.35 %

0,29-0,35 %

Si................................................max. 0.40 %

Mn.............................................. 0.60 - 0.90 %

Cr............................................... 0.90 - 1.20 %

P.................................................max. 0.035 %

S.................................................max. 0.030 %

0.15 - 35 %

0.60 - 0.80 %

0.75 - 1.00 %

max. 0.035 %

max. 0.040 %

0,29-0,35 %

0,50-0,90 %

0,65-1,10 %

not specified

not specified

Mechanical Properties

Tensile strength......................... 700 - 850 N/mm2 not specified

Yield point.................................. min. 510 N/mm2 not specified

Elongation (L0 = 5d0................... min. 14 %

not specified

Reduction of area .....................min. 40 %

Impact energy............................ min. 40 J

Charpy-V notch

specimen at + 20 C

not specified

not specified

-18-

3.4

42 CrMo 4

acc. to DIN

17.200

AISI 4140 H

(ASTM A304)

Chemical Composition

A304

C .............................................. 0.38 - 0.42 %

0.38 - 0.43 %

0,37-0,44 %

Si................................................max. 0.40 %

Mn.............................................. 0.60 - 0.90 %

Cr............................................... 0.90 - 1.20 %

Mo.............................................. 0.015 - 0.30 %

S.................................................max. 0.03 %

P.................................................max. 0.035 %

0.15 - 0.35 %

0.75 - 1.00 %

0.80 - 1.10 %

0.15 - 0.25 %

max. 0.040 %

max. 0.035 %

0,15-0,35 %

0,65-1,10 %

0,75-1,20 %

0,15-0,25 %

not specified

not specified

Mechanical Properties

Tensile strength......................... 780 - 930 N/mm2 not specified

Yield point.................................. min. 560 N/mm2 not specified

Elongation (L0 = 5d0................... min. 13 %

not specified

Reduction of area .....................min. 50 %

Impact energy............................ min. 46J

Charpy-V notch

specimen at + 20 C

not specified

not specified

-19-

3.5

50 CrMo 4

acc. to DIN

17.200

AISI 4150 H

(ASTM A304)

Chemical Composition

A304

C .............................................. 0.46 - 0.54 %

Si................................................max. 0.40 %

0.48 - 0.53 %

0.15 - 0.35 %

0,42-0,49 %

0,15-0,35 %

Mn.............................................. 0.50 - 0.80 %

Cr............................................... 0.90 - 1.20 %

Mo.............................................. 0.15 - 0.30 %

S.................................................max. 0.03 %

P.................................................max. 0.035 %

0.75 - 1.00 %

0.80 - 1.10 %

0.15 - 0.25 %

max. 0.40 %

max. 0.35 %

0,65-1,10 %

0,75-1,20 %

0,15-1,20 %

not specified

not specified

Mechanical Properties

Tensile strength......................... 780 - 930 N/mm2 not specified

Yield point.................................. min. 635 N/mm2 not specified

Elongation (L0 = 5d0................... min. 13 %

not specified

Reduction of area .....................min. 50 %

Impact energy............................ min. 39J

Charpy-V notch

specimen at + 20 C

not specified

not specified

-20-

3.6

C22

acc. to DIN 17.200

ASTM A-105

Chemical Composition

C .............................................. 0.17 - 0.24 %

Si................................................max. 0.40 %

Mn.............................................. 0.30 - 0.60 %

P.................................................max. 0.045 %

S.................................................max. 0.045 %

max. 0.35 %

max. 0.35 %

0.60 - 1.05 %

max. 0.04 %

max. 0.05 %

Mechanical Properties

Tensile strength......................... 410 - 520 N/mm2

Yield point.................................. min. 225 N/mm2

Elongation (L0 = 5d0)..................min. 22 %

max. 485 MPa

max. 250 MPa

min. 22 %

...................................................

Reduction of area......................min. 45 %

Impact energy............................ min. 50 J

Charpy-V notch

specimen at + 20 C

(2 inches or 50 mm)

min. 30 %

not specified

-21-

3.7

X20 Cr 13

acc. to DIN 17.440

ASTM A-473

Type 420

Chemical Composition

C .............................................. 0.17 - 0.25 %

P.................................................max. 0.045 %

S.................................................max. 0.030 %

Si................................................max. 1.00 %

Mn.............................................. max. 1.0 %

Cr............................................... 12.0 - 14.0 %

min. 0.15 %

max. 0.040 %

max. 0.030 %

max. 1.00 %

max. 1.0 %

12.0 - 14.0 %

Mechanical Properties

Tensile strength......................... 650 - 800 N/mm2

Yield point.................................. 450 N/mm2

Elongation (L0 = 5d0)..................min. 14 %

not specified

not specified

not specified

Reduction of area......................min. 25 %

Impact energy............................ min. 46 J

Charpy-V notch

specimen at + 20 C

not specified

not specified

-22-

4.

TUBES

4.1

St35

acc. to DIN 1629 T3

ASTM A-53

Grade A

Chemical Composition

C .............................................. max. 0.17 %

Si................................................0.10 to 0.35 %

Mn.............................................. max. 0.40 %

P.................................................max. 0.05 %

S.................................................max. 0.05 %

max. 0.25 %

not specified

max. 0.95 %

max. 0.05 %

max. 0.06 %

Mechanical Properties

Tensile strength......................... 340 - 440 N/mm2

Yield point.................................. min. 235 N/mm2

Elongation (L0 = 5d0)..................min. 25 %

min. 330 MPa

min. 205 MPa

see table 3 of

...................................................

cited standard

-23-

5.

HOT BARS

5.1

St 37.2

acc. to DIN 17.100

ASTM A-283

Grade C

Chemical Composition

C .............................................. max. 0.17 %

P.................................................max. 0.050 %

S.................................................max. 0.050 %

Si................................................-Mn.............................................. --

max. 0.24 %

max. 0.035 %

max. 0.04 %

max. 0.40 %

max. 0.90 %

Mechanical Properties

Tensile strength......................... 340 - 470 N/mm2

Yield point.................................. min. 235 N/mm2

Elongation (L0 = 5d0)..................min. 26 %

380 - 485 MPa

min. 205 MPa

min. 22 %

...................................................

(2 inches or 50 mm)

Vous aimerez peut-être aussi

- Compressor ChecklistDocument5 pagesCompressor ChecklistJuanPabloAlvarezPas encore d'évaluation

- Asme B16.1-2020Document49 pagesAsme B16.1-2020Toni71% (7)

- OTIS-GECB Service Tool ManualDocument38 pagesOTIS-GECB Service Tool ManualRoyal Akash50% (2)

- Structural MembersDocument33 pagesStructural MembersALZHAMMER MANUPACPas encore d'évaluation

- Annex F Design of Tanks For Small Internal PressuresDocument9 pagesAnnex F Design of Tanks For Small Internal PressuresJamir Diaz MechanPas encore d'évaluation

- PLP-E01a-Centrifugal Compressors (Part 1 of 2)Document65 pagesPLP-E01a-Centrifugal Compressors (Part 1 of 2)SuhendraPas encore d'évaluation

- Bored Pile CalculationDocument226 pagesBored Pile CalculationK H V V MADUSHANKA100% (1)

- W.B.M & O.B.M Testing PDFDocument67 pagesW.B.M & O.B.M Testing PDFKarim Wasi100% (1)

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1Document5 pagesASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1David VegaPas encore d'évaluation

- USS PlateDocument78 pagesUSS Platepipedown456Pas encore d'évaluation

- LUBRICACIONDocument6 pagesLUBRICACIONOrlando LaraPas encore d'évaluation

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLPas encore d'évaluation

- Turbines and Generators Specifications and Drawings March 2016Document606 pagesTurbines and Generators Specifications and Drawings March 2016jing qiangPas encore d'évaluation

- Chemical Compatibility ManualDocument18 pagesChemical Compatibility ManualGustavoPas encore d'évaluation

- Agma 9002-A86 Inch Bore and Ansi b17.1Document6 pagesAgma 9002-A86 Inch Bore and Ansi b17.1k21p81100% (2)

- All About Albumin: Biochemistry, Genetics, and Medical ApplicationsD'EverandAll About Albumin: Biochemistry, Genetics, and Medical ApplicationsPas encore d'évaluation

- Material Compatibility GuideDocument18 pagesMaterial Compatibility GuidearrancatetasPas encore d'évaluation

- Blue Creek Premium - MV HCC: Technical InformationDocument2 pagesBlue Creek Premium - MV HCC: Technical Informationnaresh adusumilliPas encore d'évaluation

- Instruction Manual PDFDocument38 pagesInstruction Manual PDFLuis MartinezPas encore d'évaluation

- Metal Chemical CompositionDocument18 pagesMetal Chemical CompositionnaeandPas encore d'évaluation

- HIGH LEADED TIN BRONZE (83-7-7-3) C93200: Mechanical and Physical Properties NominalcompositionDocument1 pageHIGH LEADED TIN BRONZE (83-7-7-3) C93200: Mechanical and Physical Properties Nominalcompositionjose.figueroa@foseco.comPas encore d'évaluation

- EP FE ME SPC 011 01 E - Specification - Piping - Classes - ASME - B31.3Document451 pagesEP FE ME SPC 011 01 E - Specification - Piping - Classes - ASME - B31.3Lumy NastasePas encore d'évaluation

- QualityManual& Welding Training ManualDocument68 pagesQualityManual& Welding Training ManualAbid MujtabaPas encore d'évaluation

- 74 032409 00 - CDocument7 pages74 032409 00 - CGlory Hilman0% (1)

- Materialise Manufacturing - Datasheets (03-2019)Document46 pagesMaterialise Manufacturing - Datasheets (03-2019)WilliamPas encore d'évaluation

- Report ChenDocument105 pagesReport ChenMarcelo GuerraPas encore d'évaluation

- Af4000e Processing ConditionsDocument121 pagesAf4000e Processing ConditionssunhuynhPas encore d'évaluation

- Econolite CastableDocument1 pageEconolite CastableJosue MorenoPas encore d'évaluation

- SMM Ca001 0805NDocument28 pagesSMM Ca001 0805NcarlosorizabaPas encore d'évaluation

- Sandwich ManifoldsDocument817 pagesSandwich ManifoldsvictorPas encore d'évaluation

- Sae Spec For Steel Shot & GritDocument3 pagesSae Spec For Steel Shot & Gritsanoopvk100% (1)

- O-Ring FRDocument157 pagesO-Ring FRNano MaxPas encore d'évaluation

- Determination of Yield Strength For NonpDocument103 pagesDetermination of Yield Strength For NonpRani HendrikusPas encore d'évaluation

- FINAL Report CPF RGA 04 13 Yield Determination PDFDocument103 pagesFINAL Report CPF RGA 04 13 Yield Determination PDFAung Hlaing HtutPas encore d'évaluation

- Material CladeadoDocument13 pagesMaterial Cladeadowilian_coelho3309Pas encore d'évaluation

- ST 350Document50 pagesST 350davidPas encore d'évaluation

- 100 Questions OMR SheetDocument1 page100 Questions OMR SheetJubin Kumar33% (3)

- Previews ASME CSD-1 2012 W CPRT PreDocument10 pagesPreviews ASME CSD-1 2012 W CPRT PreHimanshu PatelPas encore d'évaluation

- A .Nuclear Cross Section Hand Book PDFDocument292 pagesA .Nuclear Cross Section Hand Book PDFeric_rr_1985Pas encore d'évaluation

- Texas Metal Flange CatalogueDocument73 pagesTexas Metal Flange CatalogueeASMEPas encore d'évaluation

- Materialise Datasheets 19-07-2022Document48 pagesMaterialise Datasheets 19-07-2022Nicola MerzagoraPas encore d'évaluation

- Ipr Open PDFDocument128 pagesIpr Open PDFkhetaramPas encore d'évaluation

- Stepan C SeriesDocument2 pagesStepan C Seriesachwan febriantoPas encore d'évaluation

- Samarpan Steel Final EIA PDFDocument326 pagesSamarpan Steel Final EIA PDFGanesh N KPas encore d'évaluation

- Signa 4923 Trailer Part CatalougeDocument218 pagesSigna 4923 Trailer Part CatalougeAman DeepPas encore d'évaluation

- NO Jenis Mesin Spesfikasi Sat: Pengajuan PeralatanDocument6 pagesNO Jenis Mesin Spesfikasi Sat: Pengajuan PeralatanKamal Kamal KamalPas encore d'évaluation

- Chap 03Document65 pagesChap 03hassan haddadiPas encore d'évaluation

- Chap - 03 TESTINGDocument65 pagesChap - 03 TESTINGNeal LahkarPas encore d'évaluation

- Material Compatibility TableDocument18 pagesMaterial Compatibility TableADITYA_PATHAKPas encore d'évaluation

- ትግራይ_ብመንፅር_ታሪኽን_ባህሊን፤_ቀዳማይ_ረቂቕDocument118 pagesትግራይ_ብመንፅር_ታሪኽን_ባህሊን፤_ቀዳማይ_ረቂቕBereket BahtaPas encore d'évaluation

- 20 June 2002Document37 pages20 June 2002MEHDI FARROKHIPas encore d'évaluation

- ReportsDocument2 pagesReportsseharhussain110Pas encore d'évaluation

- Controls and Safety Devices For Automatically Fired Boilers: ASME CSD-1-2015Document12 pagesControls and Safety Devices For Automatically Fired Boilers: ASME CSD-1-2015Himanshu PatelPas encore d'évaluation

- Peace Thesis Final PDFDocument171 pagesPeace Thesis Final PDFKimberly Cyreene CantosPas encore d'évaluation

- Instruction Manual: E1M40, E1M80, E2M40 and E2M80 E2M40S and E2M80S Rotary Vacuum PumpsDocument64 pagesInstruction Manual: E1M40, E1M80, E2M40 and E2M80 E2M40S and E2M80S Rotary Vacuum PumpsDilson Barbosa RamosPas encore d'évaluation

- Testing, Standards & FacilitiesDocument19 pagesTesting, Standards & FacilitiesFlavio BadaroPas encore d'évaluation

- Bio-Pharm Fittings: Asme BpeDocument56 pagesBio-Pharm Fittings: Asme BpeTonyPas encore d'évaluation

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Document54 pagesIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- Blackrod Baseline Discipline Reports SecureDocument1 364 pagesBlackrod Baseline Discipline Reports SecureMuhammad NaeemPas encore d'évaluation

- DIN EN 809:2012-10 (E) : Pumps and Pump Units For Liquids - Common Safety RequirementsDocument2 pagesDIN EN 809:2012-10 (E) : Pumps and Pump Units For Liquids - Common Safety RequirementsBvitalizePas encore d'évaluation

- Boilers, Pressure Vessels, Thermal-Oil Installations and IncineratorsDocument51 pagesBoilers, Pressure Vessels, Thermal-Oil Installations and Incineratorsagniva dattaPas encore d'évaluation

- Temperley-Lieb Recoupling Theory and Invariants of 3-Manifolds (AM-134), Volume 134D'EverandTemperley-Lieb Recoupling Theory and Invariants of 3-Manifolds (AM-134), Volume 134Pas encore d'évaluation

- Nilpotence and Periodicity in Stable Homotopy Theory. (AM-128), Volume 128D'EverandNilpotence and Periodicity in Stable Homotopy Theory. (AM-128), Volume 128Pas encore d'évaluation

- China Coreless IntermediateDocument21 pagesChina Coreless Intermediateraobabar21Pas encore d'évaluation

- Financial AnalysisDocument16 pagesFinancial Analysisraobabar21Pas encore d'évaluation

- Refractory Solution FDocument5 pagesRefractory Solution Fraobabar21Pas encore d'évaluation

- Bangla Steel Mill RollDocument29 pagesBangla Steel Mill Rollraobabar21Pas encore d'évaluation

- Geart Failure LubricationDocument17 pagesGeart Failure Lubricationraobabar21Pas encore d'évaluation

- Usrcontrol3 Plant Svcs Tcm9 12753Document8 pagesUsrcontrol3 Plant Svcs Tcm9 12753raobabar21Pas encore d'évaluation

- Pavingexpert - Formwork and ShutteringDocument6 pagesPavingexpert - Formwork and Shutteringraobabar21Pas encore d'évaluation

- Texas Commission On Environmental Quality Table 11 InstructionsDocument2 pagesTexas Commission On Environmental Quality Table 11 Instructionsraobabar21Pas encore d'évaluation

- MSS SP-115 (1999)Document11 pagesMSS SP-115 (1999)raobabar21Pas encore d'évaluation

- Capital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter HDocument14 pagesCapital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter Hraobabar21Pas encore d'évaluation

- Trainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099Document2 pagesTrainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099raobabar21Pas encore d'évaluation

- 95000401Document1 page95000401raobabar21Pas encore d'évaluation

- Rad 1/2 D: 001 C/D M88 DB-950006 00Document1 pageRad 1/2 D: 001 C/D M88 DB-950006 00raobabar21Pas encore d'évaluation

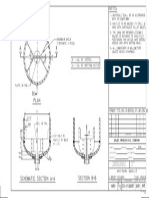

- Notes:: D I.D. of Vessel D I.D. of Bottom OutletDocument1 pageNotes:: D I.D. of Vessel D I.D. of Bottom Outletraobabar21Pas encore d'évaluation

- Exceed 3518PA Cast PDFDocument2 pagesExceed 3518PA Cast PDFchinchotarngPas encore d'évaluation

- Manoair600: Micropressure Manometer Volume Flowmetering in StacksDocument2 pagesManoair600: Micropressure Manometer Volume Flowmetering in StacksWilson SantosPas encore d'évaluation

- Differential Pressure SwitchDocument2 pagesDifferential Pressure Switchmithilesh5103Pas encore d'évaluation

- Ftejerez Assessment: Guidance MaterialDocument31 pagesFtejerez Assessment: Guidance MaterialPilotsaicharan AirbusPas encore d'évaluation

- 4500S VW Standard PiezometersDocument4 pages4500S VW Standard PiezometersShiwas JorgePas encore d'évaluation

- To Convert From Do ThisDocument18 pagesTo Convert From Do ThisSidgi BadjriPas encore d'évaluation

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaPas encore d'évaluation

- HM1 Tutorial Examples Module-5 Drilling Blasting-MIN2001Document46 pagesHM1 Tutorial Examples Module-5 Drilling Blasting-MIN2001shahidPas encore d'évaluation

- Cycom PR520 RTM 031912Document6 pagesCycom PR520 RTM 031912Angel LagrañaPas encore d'évaluation

- Datasheets E FDMDocument5 pagesDatasheets E FDMAlireza YaghoubiPas encore d'évaluation

- Construction and Building Materials: Decebal Michaud, Amir Fam, Marc-André DagenaisDocument14 pagesConstruction and Building Materials: Decebal Michaud, Amir Fam, Marc-André Dagenaiskareem abdullahPas encore d'évaluation

- Hdpe Pipe Specifications PDFDocument5 pagesHdpe Pipe Specifications PDFawanarifPas encore d'évaluation

- KNS2163 Assignment 4 (SI In-Situ Testing) - FS (Q)Document2 pagesKNS2163 Assignment 4 (SI In-Situ Testing) - FS (Q)Mohd Afiq AminPas encore d'évaluation

- 1) DE4101 SI Units Vectors and ForcesDocument5 pages1) DE4101 SI Units Vectors and ForcesbernardPas encore d'évaluation

- Ahmed, Mostafa, Therese (2020) Bruied Pipes Using GeogridDocument19 pagesAhmed, Mostafa, Therese (2020) Bruied Pipes Using GeogridCarlos Arturo Gomez JimenezPas encore d'évaluation

- Iso 4267-2Document38 pagesIso 4267-2Haytham DiaaPas encore d'évaluation

- Rubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForDocument5 pagesRubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForPyone Ei ZinPas encore d'évaluation

- Imperial College TensiometerDocument4 pagesImperial College TensiometerMichael ZonshainPas encore d'évaluation

- Chapter 1 MatterDocument27 pagesChapter 1 MatterNatalie GracePas encore d'évaluation

- Pyrofil MR60H 24K: Tow TensileDocument2 pagesPyrofil MR60H 24K: Tow TensileyigitilgazPas encore d'évaluation

- Narrow Face Flange - Slip On Hub Type For External PressureDocument23 pagesNarrow Face Flange - Slip On Hub Type For External PressureEng-CalculationsPas encore d'évaluation

- TECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENDocument2 pagesTECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENKarima ABOUALIPas encore d'évaluation

- Tabel 1.3 Satuan Panjang Lain Berdasarkan MeterDocument5 pagesTabel 1.3 Satuan Panjang Lain Berdasarkan MeterGita MustikaPas encore d'évaluation

- Datasheet Cawiton PR13610 - 002Document1 pageDatasheet Cawiton PR13610 - 002Fred HahnPas encore d'évaluation