Académique Documents

Professionnel Documents

Culture Documents

Date Tehnice, Cazane Otel 2 Drumuri 'Unical - Ellprex' - in

Transféré par

bsambDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Date Tehnice, Cazane Otel 2 Drumuri 'Unical - Ellprex' - in

Transféré par

bsambDroits d'auteur :

Formats disponibles

1.

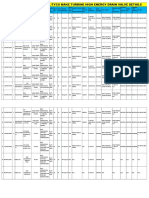

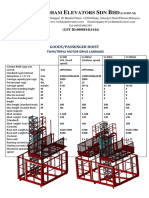

3 - DIMENS IONS AND HY DRAU LIC CONNECT IONS FOR ELLPREX 17 0 6 30

I

F

N T 1 OT 3

B

P T2

T 1-T 3-T 2

T5

T5

4

T6

T4

T4

10 0

1

2

3

4

P

B

S

S

a n e l b o a rd

u rn e r fix in g p la te

m o k e c h a m b e r c le a n in g d o o r

ig h t g la s s

E LLP R E X

N o m in a l

O u tp u t

N o m in a l

In p u t

1

2

3

4

W a te r

c o n te n t

kW

kW

M odel

T

T

T

T

C

C

E

B

.H . flo w

.H . re tu rn

x p a n s io n v e s s e l c o n n e c tio n

o ile r d ra in

W a te r s id e

p re s s u re

lo s s (* * )

S m o k e s id e

p re s s u re

lo s s

M a x im u m

w o rk in g

p re s s u re

W e ig h t

m w .c .

m m w .c .

bar

C O N N E C T IO N S

T 3

T 4

kg

T 1

T 2

U N I2278 P N 16

IS O 7 /1

IS O 7 /1

T 5

i

m m

T 6

m m

ELL 17 0

130170

140186

190

0 ,0 9 0 ,1 5

915

435

D N 65

R p 1

R p

200

180

ELL 240

180240

1 9 5 2 62

2 51

0 ,1 9 0 ,3 3

1528

510

D N 65

R p 1

R p

200

180

ELL 29 0

220290

239317

2 64

0 ,1 2 0 ,2 1

1325

588

D N 80

R p 2

R p

250

210

ELL 340

255340

277371

298

0 ,1 6 0 ,2 8

1734

62 9

D N 80

R p 2

R p

250

210

ELL 420

315420

342459

3 98

0 ,0 9 0 ,1 7

1 6 2 9

796

D N 100

R p 2

R p

250

210

ELL 5 10

385510

418557

4 62

0 ,1 4 0 ,2 5

2443

919

D N 100

R p 2

R p

250

210

ELL 6 30

4 8 0 63 0

5 2 0 68 8

5 65

0 ,2 1 0 ,3 8

3255

1049

D N 100

R p 2

R p

300

210

D IM E N S IO N S

E LLP R E X

M odel

ELL 17 0

A

m m

820

B

m m

885

C

m m

1082

D

m m

190

E

m m

139

F

m m

190

G

m m

64 8

H

m m

380

I

m m

1214

L

m m

130

M*

m m

1210

N

m m

175

O

m m

130

P

m m

185

Q*

m m

7 10

R*

m m

785

10 45

ELL 240

820

1145

1082

190

139

190

64 8

380

1474

130

1210

175

390

185

7 10

ELL 29 0

8 60

1080

1182

190

139

190

708

400

1411

130

1310

215

210

250

750

982

ELL 340

8 60

1210

1182

190

139

190

708

400

1541

130

1310

215

340

250

750

1112

ELL 420

890

1275

1352

190

139

190

748

440

1 60 6

125

148 5

255

285

315

780

117 7

ELL 5 10

890

1470

1352

190

139

190

748

440

1801

125

148 5

255

480

315

780

137 2

ELL 6 30

890

1780

1352

190

139

190

748

440

2113

125

148 5

255

790

315

780

16 8 2

(* ) M in im u m d im e n s io n s fo r b o ile r ro o m a c c e s s re q u ire m e n ts .

(* * ) H y d ra u lic re s is ta n c e fo r d e lta T 1 5 K .

DET AIL FOR DOOR DRILLING

ELL 17 0 240

Blin d bu rn er p la te 25 0 x 25 0

DET AIL FOR DOOR DRILLING

ELL 29 0 6 30

Blin d bu rn er p la te 28 0 x 28 0

Bu rn er p la te in s u la tion g a s k et 25 0 x 25 0

Fiber wool

Bu rn er p la te in s u la tion g a s k et 28 0 x 28 0

Fiber wool

95

fig . 3

210

210

Cera m ic fiber

18 0

18 0

Cera m ic fiber

fig . 2

T 5 F lu e s o c k e t

T 6 M a x . b u r n e r b la s t tu b e d ia .

95

fig . 4

DIMENSIONS AND HYDRAULIC CONNECTIONS FOR ELLPREX 760970

I

F

B

T1

T3

T1-T3-T2

T2

T5

T5

4

2

T6

T4

L

T4

200

fig. 5

1

2

3

4

Panel board

Burner fixing plate

Smoke chamber cleaning door

Sight glass

ELLPREX

Nominal

Input

Nominal

Output

T1

T2

T3

T4

Water

content

C.H. flow

C.H. return

Expansion vessel connection

Boiler drain

T5 Flue socket

T6 Max. burner blast tube dia.

Water side

pressure

loss(**)

Smoke side

pressure

loss

Maximum

working

pressure

Weight

CONNECTIONS

T3

T4

UNI 2278 PN16

T6

mm

Model

kW

kW

m w. c.

mm w. c.

bar

kg

T1

T2

UNI 2278 PN16

ISO 7/1

T5

i

mm

ELL 760

580760

630830

671

0,150,26

2951

1341

DN 125

DN 65

Rp 1

350

270

ELL 870

660870

715950

753

0,190,33

3357

1447

DN 125

DN 65

Rp 1

350

270

ELL 970

750970

8151060

836

0,240,41

2949

1553

DN 125

DN 65

Rp 1

350

270

DIMENSIONS

ELLPREX

A

mm

Model

ELL 760

1122

ELL 870

1122

ELL 970

1122

O

mm

435

P

mm

440

125

1540

298

630

440

1020

1699

125

1540

298

825

440

1020

1894

480

2184

480

2379

E

mm

195

F

mm

190

G

mm

765

H

mm

480

1800

1432

190

195

190

765

1995

1432

190

195

190

765

R*

mm

1504

N

mm

298

L

mm

125

D

mm

190

Q*

mm

1020

M*

mm

1540

I

mm

1989

C

mm

1432

B

mm

1605

(*) Minimum dimensions for boiler room access requirements.

(**) Hydraulic resistance for delta T 15K.

DETAIL FOR DOOR DRILLING

ELL 760970

Blind burner plate 330x330

Burner plate insulation gasket 330x330

Refractory cement

270

270

Ceramic fiber

150

fig. 6

DIMENSIONS AND HYDRAULIC CONNECTIONS FOR ELLPREX 11002650

I

F

B

N

T3

T1

E

P

T1-T3-T2

T2

T8

T5

T5

T6

T7

T4

1

2

3

4

Panel board

Burner fixing plate

Smoke chamber cleaning door

Sight glass

Model

C.H. flow

C.H. return

Expansion vessel connection

Boiler drain

T5

T6

T7

T8

Water side

pressure

loss(**)

Smoke side

pressure

loss

Maximum

working

pressure

Weight

m w. c.

mm w. c.

bar

kg

Water

content

kW

kW

200

T1

T2

T3

T4

Nominal

Input

Nominal

Output

ELLPREX

T4

fig. 7

Flue socket

Max. burner blast tube dia.

Sludge drain

Inspection door

CONNECTIONS

T1

T2

UNI 2278 PN16

T3

T4

UNI 2278 PN16

ISO 7/1

T5

i

mm

T6

mm

ELL 1100

8601100

9351200

1040

0,180,30

3252

1821

DN 150

DN 80

Rp 1

400

320

ELL 1320

10001320

10871442

1242

0,200,35

3867

2030

DN 150

DN 80

Rp 1

400

320

ELL 1570

12001570

13041715

1418

0,190,33

3560

2780

DN 175

DN 100

Rp 1

450

320

ELL 1850

14001850

15202020

1617

0,260,45

4273

3280

DN 175

DN 100

Rp 1

450

320

ELL 2200

17002200

18452400

2086

0,210,34

3965

4145

DN 200

DN 125

Rp 1

520

380

ELL 2650

20002650

21702890

2324

0,280,48

4376

4465

DN 200

DN 125

Rp 1

520

380

Q*

mm

1250

R*

mm

1846

DIMENSIONS

ELLPREX

A

mm

1352

Model

ELL 1100

B

mm

1952

C

mm

1432

D

mm

190

E

mm

207

F

mm

187

G

mm

810

H

mm

595

I

mm

2346

L

mm

180

M*

mm

1540

N

mm

461

O

mm

330

P

mm

500

ELL 1320

1352

2292

1432

190

207

187

810

595

2686

180

1540

461

670

500

1250

2186

ELL 1570

1462

2282

1542

190

227

272

880

640

2781

75

1650

561

510

550

1360

2176

ELL 1850

1462

2652

1542

190

227

272

880

640

3151

75

1650

561

880

550

1360

2546

ELL 2200

1622

2692

1702

190

259

274

950

690

3225

75

1810

661

670

700

1520

2590

ELL 2650

1622

3014

1702

190

258

273

950

690

3545

75

1810

662

990

700

1520

2910

(*) Minimum dimensions for boiler room access requirements.

(**) Hydraulic resistance for delta T 15K.

Blind burner plate 380x380

160

fig. 8

180

DETAIL FOR DOOR DRILLING

ELL 22002650

Blind burner plate 450x450

Burner plate insulation gasket 450x450

Refractory cement

380

Burner plate insulation gasket 380x380

Refractory cement

320

320

320

Burner plate insulation gasket 380x380

Refractory cement

320

Blind burner plate 380x380

DETAIL FOR DOOR DRILLING

ELL 15701850

fig. 9

380

DETAIL FOR DOOR DRILLING

ELL 11001320

190

fig. 10

DIMENSIONS AND HYDRAULIC CONNECTIONS FOR ELLPREX 30003500

I

F

T1

T3

T2

T8

T5

T6

T7

T4

1

2

3

4

Panel board

Burner fixing plate

Smoke chamber cleaning door

Sight glass

ELLPREX

145

Nominal

Output

Nominal

Input

T1

T2

T3

T4

Water

content

C.H. flow

C.H. return

Expansion vessel connection

Boiler drain

T5

T6

T7

T8

Water side

pressure

loss(**)

Smoke side

pressure

loss

Maximum

working

pressure

Weight

m w. c.

mm w. c.

bar

kg

fig. 11

Flue socket

Max. burner blast tube dia.

Sludge drain

Inspection door

CONNECTIONS

T1

T2

UNI 2278 PN16

T3

T4

UNI 2278 PN16

ISO 7/1

T5

i

mm

T6

mm

Model

kW

kW

ELL 3000

23003000

24923280

2667

0,360,62

3560

5110

DN 200

DN 125

Rp 1

570

380

ELL 3500

27003500

29303825

4142

0,540,84

4778

6700

DN 200

DN 125

Rp 1

620

380

DIMENSIONS

ELLPREX

Model

ELL 3000

ELL 3500

1720

B

mm

3230

C

mm

1830

D

mm

190

E

mm

295

F

mm

340

G

mm

1315

H

mm

772

I

mm

3835

L

mm

115

M*

mm

1990

N

mm

325

O

mm

1100

P

mm

1330

Q*

mm

1620

R*

mm

3200

1970

3194

2090

190

325

390

1535

915

3879

144

2271

377

1060

1280

1870

3164

A

mm

((*) Minimum dimensions for boiler room access requirements.

(**) Hydraulic resistance for delta T 15K.

DETAIL FOR DOOR DRILLING

ELL 30003500

Blind burner plate 450x450

380

380

Burner plate insulation gasket 450x450

Refractory cement

210

fig. 12

Vous aimerez peut-être aussi

- Abb Price ListDocument12 pagesAbb Price ListShamim Ahsan Parvez47% (15)

- Valiant Water Heater ManualDocument8 pagesValiant Water Heater Manualjoe900050% (2)

- D4ga - Euro4 Engine - EGRDocument59 pagesD4ga - Euro4 Engine - EGRBigfair HD78100% (15)

- Gas ValveDocument9 pagesGas ValveJJPas encore d'évaluation

- Gt250 PartsDocument353 pagesGt250 PartsLandynut100% (1)

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamPas encore d'évaluation

- Compressiong SpringsDocument68 pagesCompressiong SpringsponcatoeraPas encore d'évaluation

- Gas Turbine Functional DescriptionDocument20 pagesGas Turbine Functional Descriptioncbmanaus100% (1)

- ABC COSTING With Answers PDFDocument13 pagesABC COSTING With Answers PDFShaira Rehj Rivera100% (1)

- ASTM B 69 Rolled ZN - 1998Document4 pagesASTM B 69 Rolled ZN - 1998ecsuperalPas encore d'évaluation

- RTAC Customer PackageDocument15 pagesRTAC Customer PackageAldo MartinezPas encore d'évaluation

- Sams 605-7 Fisher Model X-101-bDocument8 pagesSams 605-7 Fisher Model X-101-balutamyn100% (1)

- Catalogue LRC TS NewDocument16 pagesCatalogue LRC TS Newliang_thailandPas encore d'évaluation

- Manual Electrico NCENTURY 2008aDocument112 pagesManual Electrico NCENTURY 2008aOvidio RiosPas encore d'évaluation

- RC 1979 12Document64 pagesRC 1979 12Jan PranPas encore d'évaluation

- List PompaDocument10 pagesList PompamarthtjuluPas encore d'évaluation

- Hydromek Electric BachoDocument18 pagesHydromek Electric Bachowtn2013Pas encore d'évaluation

- Drawing - PinoutDocument1 pageDrawing - PinoutJohn JonesPas encore d'évaluation

- E74099 Talea Giro-Ing - Sup032or Rev.07 GruppoDocument6 pagesE74099 Talea Giro-Ing - Sup032or Rev.07 GruppotimmboPas encore d'évaluation

- Strainer Air Eliminator EC 31-EC 32 - EC 39: Description - Installation ServicingDocument10 pagesStrainer Air Eliminator EC 31-EC 32 - EC 39: Description - Installation ServicingFredwash RichardPas encore d'évaluation

- Alumunium For BodyplaneDocument7 pagesAlumunium For Bodyplaneikhsan alfinusPas encore d'évaluation

- MX Ind 071394 vt2 132 SsDocument2 pagesMX Ind 071394 vt2 132 SseveraroniekPas encore d'évaluation

- 4 Hi Mill Temp Scanner PanelDocument2 pages4 Hi Mill Temp Scanner PanelsumitbahlPas encore d'évaluation

- Sempell Valve PDFDocument2 pagesSempell Valve PDFAnand K. MouryaPas encore d'évaluation

- GE Lighting Systems Price Book - Outdoor Designers Guide 4-79 - 9-79Document80 pagesGE Lighting Systems Price Book - Outdoor Designers Guide 4-79 - 9-79Alan MastersPas encore d'évaluation

- r1Document3 pagesr1naseema1Pas encore d'évaluation

- Generai ($eiectric: (All Values K Min Max Are in L Nun Inches) L Max Min Min Min NomDocument1 pageGenerai ($eiectric: (All Values K Min Max Are in L Nun Inches) L Max Min Min Min NomMohamed HamedPas encore d'évaluation

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- Opthamology FDNSDocument1 pageOpthamology FDNSMasaba SolomonPas encore d'évaluation

- Electro Valves ElectrovalvulasDocument22 pagesElectro Valves ElectrovalvulasbloggusbloggusPas encore d'évaluation

- Vitomax 200HSDocument14 pagesVitomax 200HSDamir ĆavarPas encore d'évaluation

- Project: Client: Engineer: Remarks:: Your Company Name HereDocument5 pagesProject: Client: Engineer: Remarks:: Your Company Name HerevPas encore d'évaluation

- Ust Drawing Typical EN12285-1Document1 pageUst Drawing Typical EN12285-1vonipkoPas encore d'évaluation

- Errata Notes: For Principles of HVAC (Howell Et Al. 2001) and Solutions ManualDocument2 pagesErrata Notes: For Principles of HVAC (Howell Et Al. 2001) and Solutions ManualPrabakar MahesanPas encore d'évaluation

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarPas encore d'évaluation

- DT9 9 (83-85)Document36 pagesDT9 9 (83-85)Stefano SinigagliesiPas encore d'évaluation

- Ow-En AirpelDocument4 pagesOw-En AirpelmuppetscrapPas encore d'évaluation

- 10.1016@0032 39507590172 0Document7 pages10.1016@0032 39507590172 0JaancaarloDiiazPas encore d'évaluation

- Odular YPE A F S AF: IR Ilter EriesDocument9 pagesOdular YPE A F S AF: IR Ilter ErieshadePas encore d'évaluation

- E Ductulator09Document9 pagesE Ductulator09Abhyuday GhoshPas encore d'évaluation

- KV GB PPR GreyDocument28 pagesKV GB PPR GreyIvaszuk SzabyPas encore d'évaluation

- Gas Pipework Installations For Residential Properties - Guidelines For Desingers Builders and Heatinstallers Booklet 2Document40 pagesGas Pipework Installations For Residential Properties - Guidelines For Desingers Builders and Heatinstallers Booklet 2kasandra01Pas encore d'évaluation

- MLX90247 Family: Discrete Infrared Thermopile Detectors Features and BenefitsDocument9 pagesMLX90247 Family: Discrete Infrared Thermopile Detectors Features and BenefitsRomulo IlvayPas encore d'évaluation

- SCR, Omron, Envio 2Document23 pagesSCR, Omron, Envio 2viejas buenasPas encore d'évaluation

- I7V Overload Loz,: DrawnDocument4 pagesI7V Overload Loz,: Drawnjohnahearne8639Pas encore d'évaluation

- Parafusos PT SemblexDocument10 pagesParafusos PT SemblexSBonderPas encore d'évaluation

- KS Se3Document6 pagesKS Se3Jefferson Damian PradaPas encore d'évaluation

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuPas encore d'évaluation

- Cs3035 PM ListDocument15 pagesCs3035 PM ListSunny SinghPas encore d'évaluation

- AW 885 - EnuDocument164 pagesAW 885 - EnutantmeuxPas encore d'évaluation

- Fiitjee: Answers, Hints & SolutionsDocument15 pagesFiitjee: Answers, Hints & SolutionsChanderpal BarupalPas encore d'évaluation

- Valves CatalogueDocument30 pagesValves CatalogueRuth Sarai YañezPas encore d'évaluation

- Enfriador UltracoolDocument3 pagesEnfriador Ultracoolmmaldonado10Pas encore d'évaluation

- Dimensionarea Conductelor de Distributie A Apei Reci, Pentru Conducte Din OlznDocument16 pagesDimensionarea Conductelor de Distributie A Apei Reci, Pentru Conducte Din OlznStratulat Lucian-IonutPas encore d'évaluation

- GeneratorDocument55 pagesGeneratorVlad Iulian100% (3)

- PEL Distribution TransformersDocument17 pagesPEL Distribution TransformersLaeeq Ahmad FaizPas encore d'évaluation

- Psychrometric Properties of Humid Air Calculation ProceduresDocument18 pagesPsychrometric Properties of Humid Air Calculation ProceduresArturoPas encore d'évaluation

- Washer Gentle Annie GW51 52Document19 pagesWasher Gentle Annie GW51 52telzPas encore d'évaluation

- 110 Semiconductor Projects for the Home ConstructorD'Everand110 Semiconductor Projects for the Home ConstructorÉvaluation : 4 sur 5 étoiles4/5 (1)

- Electronic Circuit Design Ideas: Edn Series for Design EngineersD'EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersÉvaluation : 5 sur 5 étoiles5/5 (2)

- Test Gear and Measurements: A Collection of Useful and Tested Circuit Design Ideas'D'EverandTest Gear and Measurements: A Collection of Useful and Tested Circuit Design Ideas'Pas encore d'évaluation

- Medical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesD'EverandMedical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesPas encore d'évaluation

- Grila TVDocument17 pagesGrila TVbsamb100% (2)

- Reduction of Emissions by Optimal Use of Gas Turbines: by Terence G. Hazel Senior Member IEEEDocument24 pagesReduction of Emissions by Optimal Use of Gas Turbines: by Terence G. Hazel Senior Member IEEEbsambPas encore d'évaluation

- Coping With Difficult Participants in A TrainingDocument9 pagesCoping With Difficult Participants in A Trainingbsamb100% (1)

- Denon AVR-1906Document70 pagesDenon AVR-1906bsambPas encore d'évaluation

- Info - N 2.07 New Version of SANICALDocument1 pageInfo - N 2.07 New Version of SANICALbsambPas encore d'évaluation

- Instructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)Document32 pagesInstructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)bsambPas encore d'évaluation

- ELLPREX, Pagina Catalog 2011 Unical Engleza (En)Document1 pageELLPREX, Pagina Catalog 2011 Unical Engleza (En)bsambPas encore d'évaluation

- Engineering Properties of Quartz Mica SchistDocument15 pagesEngineering Properties of Quartz Mica Schistkrainaoz2011100% (1)

- GT4 Strategy GuideDocument120 pagesGT4 Strategy GuideGiovanni BassiPas encore d'évaluation

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- 811 Brochure GrisgoldDocument20 pages811 Brochure GrisgoldEmerson RuizPas encore d'évaluation

- P357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFDocument35 pagesP357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFParvezPas encore d'évaluation

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 pagesPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Pas encore d'évaluation

- Cross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFDocument22 pagesCross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFSiva KumarPas encore d'évaluation

- Technical Sheet of EI2 60 Handed DoorDocument1 pageTechnical Sheet of EI2 60 Handed DoorTaoufikAzarkanPas encore d'évaluation

- Allpile ManualDocument103 pagesAllpile ManualKang Mas WiralodraPas encore d'évaluation

- P091 067 UmDocument208 pagesP091 067 UmBojan MarkovićPas encore d'évaluation

- AD5934Document31 pagesAD5934PRADEEPKUMAR CHOUDHARYPas encore d'évaluation

- Wake Up and Roar Satsang With H.W.L. PoonjaDocument1 pageWake Up and Roar Satsang With H.W.L. PoonjaIrina MTrPas encore d'évaluation

- Case Study 5 - Enhanced ERDDocument4 pagesCase Study 5 - Enhanced ERDMarcos Jeremy0% (1)

- Solutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageDocument3 pagesSolutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageMazen A. TaherPas encore d'évaluation

- Installation Instructions RISE CableDocument14 pagesInstallation Instructions RISE CableABDUL GHAFOORPas encore d'évaluation

- M04 - L01 - Student GuideDocument9 pagesM04 - L01 - Student GuideShreyasPas encore d'évaluation

- IBM Tape in Unix SystemsDocument300 pagesIBM Tape in Unix SystemsChanchal MukherjeePas encore d'évaluation

- CVV CableDocument7 pagesCVV CableNopPas encore d'évaluation

- Operators Manual: TEC-B-0002 REV0 1/09Document117 pagesOperators Manual: TEC-B-0002 REV0 1/09Clay MorrisPas encore d'évaluation

- Alternative Binder Systems For Lower Carbon Concrete Code of PracticeDocument8 pagesAlternative Binder Systems For Lower Carbon Concrete Code of Practicezaidiamna9Pas encore d'évaluation

- The Space Shuttle DecisionDocument488 pagesThe Space Shuttle DecisionNate YlitaloPas encore d'évaluation

- SC200 RevDocument2 pagesSC200 RevAshraf MuhtarPas encore d'évaluation

- Ariston Shape 10l Also Elhelyezesu Villanybojler Robbantott AbraDocument4 pagesAriston Shape 10l Also Elhelyezesu Villanybojler Robbantott AbraSinkó AttilaPas encore d'évaluation

- 7 Longest Bridges in The WorldDocument15 pages7 Longest Bridges in The WorldWai Lana ButlerPas encore d'évaluation

- Gas Cutting EquipmentDocument92 pagesGas Cutting EquipmentFord KatimPas encore d'évaluation