Académique Documents

Professionnel Documents

Culture Documents

19 Tunnel-Form Construction PDF

Transféré par

taz_taz3Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

19 Tunnel-Form Construction PDF

Transféré par

taz_taz3Droits d'auteur :

Formats disponibles

Tunnel-form construction

Page 1 of 1

Tunnel-form construction

Tunnel form systems are used for the construction of units for hotels, flats, houses and similar structures. The traditional approach would be to construct walls and floors separately. With tunnel form systems, storey-height inverted L-shaped units are locked together to make inverted U-shaped wall, floor and ceiling forms, which are cast as a single unit. Doorways and corridors are boxed out, conduits are installed for lighting etc, and reinforcement fixed. The concrete is then cast. Heaters are generally installed inside the forms and the ends of the tunnels sealed. The raised temperature accelerates the strength gain of the concrete and the forms can be stripped and repositioned the next day. The forms are steel-faced; the resulting cast surfaces can be decorated with a minimum of preparation. Although the system is best suited to a regular arrangement of identical rooms, variations in width and height can be accommodated by the use of infill panels. It has been suggested that tunnel form can reduce the cost of the frame of a typical hotel or similar building by about 15% when compared with traditional construction, chiefly due to the increased speed of construction. Savings in construction time of up to 25% over traditional frame construction methods can be achieved; for low-rise construction, which would traditionally be in brick or block, savings of 45% on the construction time have been achieved. Acknowledgement: The Concrete Society Books available from our Concrete Bookshop

Tunnel form being craned into position Courtesy of Ischebeck Titan

The information contained in this nugget has been provided by The Concrete Society technical staff.

http://www.concrete.org.uk/services/print_fingertips.asp?docid=534

4/6/2011

Vous aimerez peut-être aussi

- Tilt Up Construction PDFDocument32 pagesTilt Up Construction PDFLauren Grant100% (2)

- Cladding Fixation MethodDocument106 pagesCladding Fixation MethodUnited Construction Est. TechnicalPas encore d'évaluation

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocument20 pagesRatliperl: The Modern Solution For Energy Efficient BuildingChris BothaPas encore d'évaluation

- Anchor Bolt FAZ IIDocument4 pagesAnchor Bolt FAZ IImmaleniPas encore d'évaluation

- Seismic Analysis of BuildingsDocument35 pagesSeismic Analysis of Buildingssidk1984Pas encore d'évaluation

- High Performance Buildings: Using Tunnel Form Concrete ConstructionDocument8 pagesHigh Performance Buildings: Using Tunnel Form Concrete ConstructionDawit SolomonPas encore d'évaluation

- Design of RC Shear Wall Per Ibc 2000Document6 pagesDesign of RC Shear Wall Per Ibc 2000avdhoowheePas encore d'évaluation

- Masonry Design PDFDocument28 pagesMasonry Design PDFnanaamoakoPas encore d'évaluation

- Revised BOQ 24.02.2020 Unique RehabDocument25 pagesRevised BOQ 24.02.2020 Unique RehabSandeep MauryaPas encore d'évaluation

- Roofing Fact Sheet-2 Column Format052820final PDFDocument6 pagesRoofing Fact Sheet-2 Column Format052820final PDFDiego Quiroga CruzPas encore d'évaluation

- Misfa 2Document28 pagesMisfa 2Delwar HossainPas encore d'évaluation

- Cfsei 2015 Award Winners - CemcoDocument3 pagesCfsei 2015 Award Winners - CemcokrlosPas encore d'évaluation

- FootingDocument121 pagesFootingAras H.MPas encore d'évaluation

- 07a BoQDocument15 pages07a BoQDean KoortzenPas encore d'évaluation

- Stuctures PortfolioDocument77 pagesStuctures PortfolioIndraja RmPas encore d'évaluation

- Steel Vs Concrete StructureDocument2 pagesSteel Vs Concrete StructureDedy KristiantoPas encore d'évaluation

- Crack Stitching PDFDocument2 pagesCrack Stitching PDFPaul Lawless0% (1)

- BoQ For A 3-Classroom Block 2021-22Document78 pagesBoQ For A 3-Classroom Block 2021-22mukiibiPas encore d'évaluation

- IESL EstimateDocument14 pagesIESL EstimateAnuranga SahampathPas encore d'évaluation

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioPas encore d'évaluation

- BOQ Restaurant: Urban OakDocument5 pagesBOQ Restaurant: Urban OakManohar RobertPas encore d'évaluation

- Plans TIF 1Document37 pagesPlans TIF 1sharilyn6156Pas encore d'évaluation

- ENGI6705 StructuralAnalysis ClassNotes1Document15 pagesENGI6705 StructuralAnalysis ClassNotes1Shakeel WaseemPas encore d'évaluation

- Tunnel FormworkDocument14 pagesTunnel FormworkMohammed HajaraPas encore d'évaluation

- Folk Architecture in The PhilippinesDocument15 pagesFolk Architecture in The PhilippinesEldrine BalberonaPas encore d'évaluation

- "Precast Concrete Construction" (A Case Study)Document25 pages"Precast Concrete Construction" (A Case Study)honin alshaeerPas encore d'évaluation

- Bison Hollow Core FloorsDocument16 pagesBison Hollow Core FloorsJohn WoodsPas encore d'évaluation

- Method Statement For Water Proofing Self Adhesive Membrane PDFDocument3 pagesMethod Statement For Water Proofing Self Adhesive Membrane PDFNonie NPas encore d'évaluation

- Cross Laminated Timber (CLT) As A New Archetype Per FEMA p695Document9 pagesCross Laminated Timber (CLT) As A New Archetype Per FEMA p695LJD211Pas encore d'évaluation

- Standard Conditions of Engagement For Consultancy Services (Technical)Document14 pagesStandard Conditions of Engagement For Consultancy Services (Technical)Sagheer Ahmed100% (1)

- Construction and Design of MultistoreyDocument37 pagesConstruction and Design of MultistoreyFawadPas encore d'évaluation

- TN 395 Civil Boq AVVNLDocument18 pagesTN 395 Civil Boq AVVNLMukesh Jangid100% (1)

- Tunnel Form DocumentDocument15 pagesTunnel Form DocumentZineNBAPas encore d'évaluation

- What Is CYPEDocument17 pagesWhat Is CYPEChoffo YannickPas encore d'évaluation

- Cast Walls and Slab at The Same Time With Tunnel Forms - tcm45-341116Document3 pagesCast Walls and Slab at The Same Time With Tunnel Forms - tcm45-341116akbar102Pas encore d'évaluation

- Tunnel FormDocument11 pagesTunnel Formscriptd_ozd3nPas encore d'évaluation

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument12 pagesFM Global Property Loss Prevention Data Sheets: List of FigureshhPas encore d'évaluation

- Construction Technology For High-Rise BuildingDocument33 pagesConstruction Technology For High-Rise BuildingMageshwarPas encore d'évaluation

- Barrier Cable System PDFDocument8 pagesBarrier Cable System PDFsdutta2591Pas encore d'évaluation

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument24 pagesFM Global Property Loss Prevention Data Sheets: List of FigureshhPas encore d'évaluation

- Technical Data Sheet For Hilti HIT HY 200Document39 pagesTechnical Data Sheet For Hilti HIT HY 200ValeriuPas encore d'évaluation

- Raphael Structural Integrity ReportDocument22 pagesRaphael Structural Integrity ReportAnthony MugoPas encore d'évaluation

- ASCE 7-22 CH 18 - For PC - SouDocument57 pagesASCE 7-22 CH 18 - For PC - SousharethefilesPas encore d'évaluation

- Sub GradeDocument6 pagesSub GradeIra AgcaoiliPas encore d'évaluation

- Diaphragm WallDocument4 pagesDiaphragm Wallリムスィギャン瑞娴Pas encore d'évaluation

- Ac I DiaphragmDocument10 pagesAc I DiaphragmBintaZoelviaPas encore d'évaluation

- Comparative Study Between Different Types of FormworkDocument3 pagesComparative Study Between Different Types of FormworkLPas encore d'évaluation

- Instalación de Tendones en Post-TensadoDocument80 pagesInstalación de Tendones en Post-TensadoJorge Fernando Loaiza VergaraPas encore d'évaluation

- Neru Kalip İngi̇li̇zce SunumDocument22 pagesNeru Kalip İngi̇li̇zce SunumsuvraPas encore d'évaluation

- General Design AssumptionsDocument2 pagesGeneral Design AssumptionsRiadh TrabelsiPas encore d'évaluation

- Post Tensioning in Building StructuresDocument25 pagesPost Tensioning in Building StructuresBaranitharan APas encore d'évaluation

- 20170709-Boq-Proposed Apartments-R0 PDFDocument7 pages20170709-Boq-Proposed Apartments-R0 PDFAtul Shrivastava100% (1)

- Concrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionDocument2 pagesConcrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionPhara LuckyPas encore d'évaluation

- 8M-Digest VOL 6 PDFDocument52 pages8M-Digest VOL 6 PDFSamuel AcidriPas encore d'évaluation

- Superstructure of High Rise Residential BuildingDocument13 pagesSuperstructure of High Rise Residential BuildingshekharPas encore d'évaluation

- Reinforced Concrete DesignDocument10 pagesReinforced Concrete Designmuhammed sabir v aPas encore d'évaluation

- Method Statement For Pile Breaking PDFDocument3 pagesMethod Statement For Pile Breaking PDFSoe PaingPas encore d'évaluation

- Braced Wall PanelsDocument10 pagesBraced Wall PanelsMike LojoPas encore d'évaluation

- Piles DesignDocument12 pagesPiles Designn_sasanPas encore d'évaluation

- W 36Document12 pagesW 36matsiasPas encore d'évaluation

- Concrete&baseplate PDFDocument18 pagesConcrete&baseplate PDFmitimas2003Pas encore d'évaluation

- Natsteel BRCDocument8 pagesNatsteel BRClwin_oo2435Pas encore d'évaluation

- Hebel MC v09.11Document12 pagesHebel MC v09.11subhaschandraPas encore d'évaluation

- Exposed TBZ UAE - Tahnoun Bin Zayed UAE Syriya Sanction - WSJ ExclusiveDocument4 pagesExposed TBZ UAE - Tahnoun Bin Zayed UAE Syriya Sanction - WSJ ExclusiveArabLeaksPas encore d'évaluation

- MMC TechniquesDocument20 pagesMMC TechniquesTRIUMPH50000Pas encore d'évaluation

- TunneForms by OutinordDocument7 pagesTunneForms by Outinordaandueza_1Pas encore d'évaluation

- Open Prefabrication SystemsDocument17 pagesOpen Prefabrication SystemsRemya R. Kumar100% (2)

- PB SectionDocument1 pagePB Sectiontaz_taz3Pas encore d'évaluation

- ER Slab GeoDocument1 pageER Slab Geotaz_taz3Pas encore d'évaluation

- PM RatioDocument1 pagePM Ratiotaz_taz3Pas encore d'évaluation

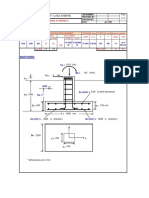

- Design Summary:: Isolated Foundation (F-1) (ACI 318M-95)Document1 pageDesign Summary:: Isolated Foundation (F-1) (ACI 318M-95)taz_taz3Pas encore d'évaluation

- S4 PDFDocument1 pageS4 PDFtaz_taz3Pas encore d'évaluation

- DL LL W M: Structural Al-Nakheel 6 Two Way SlabDocument1 pageDL LL W M: Structural Al-Nakheel 6 Two Way Slabtaz_taz3Pas encore d'évaluation

- 3d ViewDocument1 page3d Viewtaz_taz3Pas encore d'évaluation

- Structural Design BriefDocument5 pagesStructural Design Brieftaz_taz3Pas encore d'évaluation

- Structural Design Calc Slide 5Document1 pageStructural Design Calc Slide 5taz_taz3Pas encore d'évaluation

- Input Data:: Isolated Foundation (F-1) (ACI 318M-95)Document1 pageInput Data:: Isolated Foundation (F-1) (ACI 318M-95)taz_taz3Pas encore d'évaluation

- Checking:: Isolated Foundation (F-1) (ACI 318M-95)Document1 pageChecking:: Isolated Foundation (F-1) (ACI 318M-95)taz_taz3Pas encore d'évaluation

- School Name Remarks Generic/Non GenericDocument1 pageSchool Name Remarks Generic/Non Generictaz_taz3Pas encore d'évaluation

- Handout No. 7 Employee InvolvementDocument12 pagesHandout No. 7 Employee Involvementtaz_taz3Pas encore d'évaluation

- Draw ADM For The Following Activity Predecessor A - B A, B C A, B D D E G, E F D G D H DDocument7 pagesDraw ADM For The Following Activity Predecessor A - B A, B C A, B D D E G, E F D G D H Dtaz_taz3Pas encore d'évaluation

- 3 Course StudiesDocument16 pages3 Course Studiestaz_taz3Pas encore d'évaluation

- Timescaled Logic DiagramsDocument4 pagesTimescaled Logic Diagramstaz_taz3Pas encore d'évaluation

- Project Planning & Control-IDocument3 pagesProject Planning & Control-Itaz_taz3Pas encore d'évaluation

- TQM QuestionnaireDocument12 pagesTQM Questionnairetaz_taz30% (1)

- 20126161164245453FBR Quarterly Jan-March 2012 (Final 12-6-12)Document44 pages20126161164245453FBR Quarterly Jan-March 2012 (Final 12-6-12)taz_taz3Pas encore d'évaluation

- TQM Course Plan-ApplicableDocument2 pagesTQM Course Plan-Applicabletaz_taz3Pas encore d'évaluation

- Handout No. 5 EthicsDocument5 pagesHandout No. 5 Ethicstaz_taz3Pas encore d'évaluation

- Indian Standard Heavy I SectionDocument1 pageIndian Standard Heavy I SectionCIVILPas encore d'évaluation

- Design of Slabculverts PDF 5Document17 pagesDesign of Slabculverts PDF 5Raj Kumar GargPas encore d'évaluation

- Tugas Bahasa InggrisDocument5 pagesTugas Bahasa InggrisBintang RamadhanPas encore d'évaluation

- Pour Compact and Finish Concrete ConstructionDocument23 pagesPour Compact and Finish Concrete ConstructionReggie DuranPas encore d'évaluation

- Syllabus of LDCE For Promotion To Group B in Civil Engineering Cadre PDFDocument6 pagesSyllabus of LDCE For Promotion To Group B in Civil Engineering Cadre PDFVinay Kumar SinghPas encore d'évaluation

- Struktur Baja II Part 03-Lentur 02Document31 pagesStruktur Baja II Part 03-Lentur 02RatihPas encore d'évaluation

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98Pas encore d'évaluation

- Traffic Light Cable: Typical Section of Rigid Pavement at JunctionDocument1 pageTraffic Light Cable: Typical Section of Rigid Pavement at JunctiongeobyunPas encore d'évaluation

- Assignment #1.1Document23 pagesAssignment #1.1teweldePas encore d'évaluation

- Evolution of High RiseDocument10 pagesEvolution of High RiseAstha GoyalPas encore d'évaluation

- Parametric Study On Underpass RCC BridgeDocument7 pagesParametric Study On Underpass RCC BridgePramod SinghPas encore d'évaluation

- MD V60 PDFDocument18 pagesMD V60 PDFhemendraengPas encore d'évaluation

- 42 ND Div - Yoga School BillDocument123 pages42 ND Div - Yoga School Billsasidharkatari91572Pas encore d'évaluation

- A Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderDocument4 pagesA Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderAnuraagPas encore d'évaluation

- 1 Building Const 3Document99 pages1 Building Const 3ashleyane garlanPas encore d'évaluation

- Brickwork PDFDocument114 pagesBrickwork PDFfluretPas encore d'évaluation

- LT1061 Catalogue of RebarDocument2 pagesLT1061 Catalogue of Rebarengage4u2020Pas encore d'évaluation

- Chapter 01-IntroductionDocument41 pagesChapter 01-Introductionyolo louoPas encore d'évaluation

- CTM ReportDocument238 pagesCTM ReportChristian ReyesPas encore d'évaluation

- M.Tech Curriculum ReferenceDocument32 pagesM.Tech Curriculum ReferenceMunaganti KiranPas encore d'évaluation

- Chapter 9. Design of ColumnDocument14 pagesChapter 9. Design of ColumnDelina TedrosPas encore d'évaluation

- Universiti Teknologi Mara Final Examination: Confidential EC/OCT 2009/ECS308/KJC324Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EC/OCT 2009/ECS308/KJC324Faiz NajidPas encore d'évaluation

- Chapter 5Document382 pagesChapter 5Engr Aizaz AhmadPas encore d'évaluation