Académique Documents

Professionnel Documents

Culture Documents

S3 01concretedetails PDF

Transféré par

Amr HalabyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

S3 01concretedetails PDF

Transféré par

Amr HalabyDroits d'auteur :

Formats disponibles

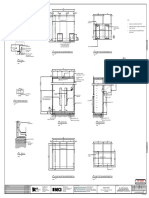

VARIES 50 COVER TO ALL CONCRETE COLUMN REINFORCEMENT CONCRETE COLUMN, REFER TO SECTIONS BELOW FOR COLUMN REINFORCEMENT DROP

PAD FOOTINGS AS REQUIRED FOR DOWNPIPES, TYPICAL LAP 2 ADDITIONAL TIES TO TOP AND BOTTOM OF COLUMN, TYPICAL TAPE 10mm JOINTFLEX STRIP BY PARCHEM OR SIMILAR APPROVED NEATLY AROUND COLUMN BASE TO SLAB INTERFACE, TYPICAL 125 MARK PF1 PF2 PF3 PF4 PF5 SF1 SF2 SF3 SF4 SF5 RW1 RW2 150 MAX. POLYTHENE MEMBRANE, TYPICAL 50 LF1

FOOTING REINFORCEMENT SCHEDULE

SIZE 2300 x 2300 x 550 DEEP PAD 2600 x 2000 x 500 DEEP PAD 1700 x 2400 x 500 DEEP PAD 750 x 750 x 300 DEEP PAD 1200 x 1200 x 300 DEEP PAD 1400 x 350 DEEP STRIP 1650 x 300 DEEP STRIP 850 x 700 DEEP STRIP 450 x 250 DEEP STRIP 400 x 300 DEEP STRIP 1800 x 300 DEEP RETAINING 1200 x 300 DEEP RETAINING REFER TO DETAIL REINFORCEMENT 12-N16 EACH WAY BOTTOM 14-N16 LONGITUDINAL, 11-N16 TRANSVERSE BOTTOM 11-N16 LONGITUDINAL, 17-N16 TRANSVERSE BOTTOM 5-N12 EACH WAY BOTTOM 6-N12 EACH WAY BOTTOM 7-N12 LONGITUDINAL, N12-300 TRANSVERSE BOTTOM N12-200 LONGITUDINAL, N16-200 TRANSVERSE BOTTOM N16-200 EACH WAY BOTTOM 4-L8TM BOTTOM 4-L8TM BOTTOM REFER TO DETAIL REFER TO DETAIL

STUDWORK

VARIES

125

125

150

POUR FIRST SLAB AND PAINT VERTICAL FACE WITH BOND RELEASE. POUR SECOND SLAB HARD AGAINST. JOINT TO BE CLEAN AND STRAIGHT WITH BULLNOSED EDGES, TYPICAL

50

REINFORCEMENT TO BE DISCONTINUOUS AT JOINT LOCATIONS, TYPICAL

POUR FIRST SLAB AND PAINT VERTICAL FACE WITH BOND RELEASE. POUR SECOND SLAB HARD AGAINST. JOINT TO BE CLEAN AND STRAIGHT WITH BULLNOSED EDGES, TYPICAL

50

REFER TO REBATE DETAIL FOR SEALANT REQUIREMENTS

REFER TO REBATE DETAIL FOR SEALANT REQUIREMENTS

50

150mm WIDE SUPERCAST REARGUARD S BY PARCHEM OR SIMILAR APPROVED, TYPICAL

SEALANT TO ARCHITECT'S SPECIFICATIONS

15

BULLNOSED EDGES

REFER TO PLAN FOR SLAB REINFORCEMENT

50 EDGE COVER

200

200

200

30

POLYTHENE MEMBRANE, TYPICAL

150 150

POLYTHENE MEMBRANE, TYPICAL

150 150

10mm COMPRESSIVE FILLER

ENSURE FULL COMPACTION OF CONCRETE UNDERNEATH WATERSTOP, TYPICAL

20 CLOSED CELL POLYETHYLENE BACKING ROD

POLYTHENE MEMBRANE, TYPICAL

150

REFER TO PLAN FOR SLAB REINFORCEMENT 200 MIN.

CONTROL JOINT (C.J.) DETAIL

1 : 20

EXTERNAL CONTROL JOINT (E.C.J.) DETAIL

1 : 20

EXTERNAL CONTROL JOINT 2 (E.C.J.2) DETAIL

1 : 20

REBATE DETAIL

1:2

125 THICK SLAB EDGE DETAIL

1 : 20

N20-200 EACH WAY TOP AND BOTTOM

, VER CO L 45 PICA TY

DEPTH

150

COG

COG SUSPENDED SLAB

275

800

WET AREA SETDOWN

125

150 WAIST.

LENGTH x WIDTH

65 COVER ALL ROUND FOR ALL FOOTING REINFORCEMENT

500 LAP N12-300 DISTRIBUTION BARS, TYPICAL 200 COG, TYPICAL

200 TY WAIS PIC T, AL

N12-450 EACH WAY, TYPICAL

125

TY P.

8-N16 BARS EQUALLY SPACED

200 COG, TYPICAL 8-N16 BARS EQUALLY SPACED

200

CONCRETE COLUMN TO FOOTING DETAIL

1 : 20

WET AREA SETDOWN DETAIL

1 : 20

200

150 MIN.

8-N12 BARS EQUALLY SPACED

LANDING

500 LAP

50

STRIP FOOTING

200

8-N16 BARS EQUALLY SPACED CC1 350 CC2 900 DOWNPIPES SHOWN INDICATIVELY ONLY, TYPICAL 150 MAX. 3-R10-300 LIGS 10-N20 10-N20 STARTER BARS 150 MAX. 350 CC3 600 12-N20 80 MAX. 2-R10-300 LIGS 12-N20 12-N20 STARTER BARS 50 MPa 80 MAX. 100 MIN. 150 MAX. 350 CC4 550 100 MIN.

100

N12-250 DISTRIBUTION BARS TO LANDING

MIN. 150

MIN.

100

R10-300 LIGS 8-N20

350

350

N12-300 CENTRAL 5-N20 CENTRAL 50 MPa

500

'D'

8-N20 STARTER BARS

5-N20 STARTER BARS CENTRAL

'D'

SCABBLE INTERFACE AND WET PRIOR TO POURING STAIRS, TYPICAL

200 COG, TYPICAL 8-N12 BARS EQUALLY SPACED

200

STRIP FOOTING

MIN.

170

500 MAX.

DOWNPIPES SHOWN INDICATIVELY ONLY 2-R10-300 LIGS

CC5 680

LAP 800

STAIR ON GROUND DETAIL

POLYTHENE MEMBRANE, TYPICAL 1 : 20 SERVICES PIPE

LANDING

TAPE 10mm JOINTFLEX STRIP BY PARCHEM OR SIMILAR APPROVED NEATLY AROUND SERVICES PIPE FOR FULL WIDTH OF FOOTING

LOCATE SERVICES OVER FOOTING, TYPICAL

100 MIN. 12-N20 STARTER BARS

8-N16 STARTER BARS PAD FOOTING 'PF3', REFER TO FOOTING REINFORCEMENT SCHEDULE 1700 500

1 PROVIDE HORIZONTAL 'L' BARS 500 LONG. BAR SIZE TO MATCH FOOTING REINFORCEMENT SIZE, TYPICAL (N12 BAR MIN) 500 1 300 MIN. 1 REINFORCEMENT AS SPECIFIED 300 1

REINFORCEMENT AS SPECIFIED

CONCRETE COLUMN SECTIONS

1 : 20

200

250

SUSPENDED STAIR DETAIL

1 : 20

500

SERVICES FOOTING THICKENING

1 : 20

FOOTING STEP DETAIL

1 : 20

F.G.L. SL72 MESH N12-300 N12-200 WATERPROOFING TO ARCHITECT'S DETAILS

1800 MAX. 500

REFER TO FOOTING REINFORCEMENT SCHEDULE FOR SIZE AND REINFORCEMENT

REFER TO FOOTING REINFORCEMENT SCHEDULE FOR SIZE AND REINFORCEMENT

150 PRECAST CONCRETE PANEL N16 REID BAR TO SF1, 800 LONG AT 200 MAXIMUM CENTRES, 60 COVER, TYPICAL

150

INSITU CONCRETE WALL STARTER BARS TO MATCH SLAB REINFORCEMENT SUSPENDED SLAB, REFER TO PLAN FOR REINFORCEMENT REQUIREMENTS

N16-200 STARTER BARS TAPE 10mm JOINTFLEX STRIP BY PARCHEM OR SIMILAR APPROVED NEATLY ALONG SLAB EDGE TO RETAINING WALL INTERFACE, TYPICAL

600 MIN. LAP 125

PLAN VIEW

STRIP FOOTING CORNER DETAILS

1 : 20 TILT UP CONCRETE PANEL

275

SF1 BEYOND LIFT PIT

300 MIN.

400

REFER TO PLAN FOR SLAB REINFORCEMENT

150

N16-400

300

SCABBLE INTERFACE PLACE 2 PLY MALTHOID BETWEEN CONCRETE AND LOADBEARING BRICKWORK, TYPICAL

1500 N12-200 EACH FACE

200

PLACE 2 PLY MALTHOID BETWEEN CONCRETE AND LOADBEARING WALLS, TYPICAL TILT UP CONCRETE PANEL, REFER TO S3.03 FOR PANEL REINFORCEMENT REQUIREMENTS, TYPICAL WATERPROOFING BY OTHERS

CC1 CONCRETE COLUMN, REFER TO DETAIL

600 TYPICAL

2-N10 SHEAR BARS AT 300 CENTRES TO EACH FACE OF GROUT TUBES, ENSURE 25mm MIN. COVER, TYPICAL

800 TYPICAL

N20 IN 50 GROUT TUBE AT CENTRES TO MATCH VERTICAL WALL REINFORCEMENT. GROUT WITH HIGH FLOW NON-SHRINK GROUT AFTER PANEL ALIGNMENT, TYPICAL

TILT UP CONCRETE PANEL, REFER TO DRAWING S3.03 FOR REINFORCEMENT REQUIREMENTS WATERPROOFING TO ARCHITECT'S DETAILS

500

600 RBA16RI FERRULES STAGGERED CENTRAL AT 300 MAXIMUM CENTRES, N12 CONTINUOUS CROSS BAR, TYPICAL N16 REID BAR STAGGERED, 800 LONG. AT 300 MAXIMUM CENTRES, 60 COVER, TYPICAL

200 550

COG

COG

RW1 DETAIL

1 : 20 WATERPROOFING TO ARCHITECT'S DETAILS

175

N12-300 EACH FACE EXISTING BRICKWORK RETAINING WALL N16 REID BAR STAGGERED, 800 LONG AT 250 MAXIMUM CENTRES, 60 COVER, TYPICAL

LIFT CORE FOOTING DETAIL

N20-200 EACH WAY TOP AND BOTTOM

50

PF1 STAIRS 1 RBA16RI FERRULES STAGGERED CENTRAL AT 250 MAXIMUM CENTRES, N12 CONTINUOUS CROSS BAR, TYPICAL 1 200 THICK INSITU SLAB, SL82 MESH TOP AND BOTTOM 750 (x750)

125x125x12.0 EA

250

N12-300, 65 COVER TO RETAINING FACE, TYPICAL N12-300 175 THICK INSITU RETAINING WALL N16-300 STARTER BARS N16 L BARS AT 300 CENTRES, 65 COVER, TYPICAL 50

150 MIN. 2000 MAX.

LOCALLY LOWER PF1 FOOTINGS TO ENSURE TANK WALLS ARE NOT SURCHARGED

300

SECTION

1 : 20

GC

S2.01

4-L8TM, 65 COVER

450 1650

50

SECTION

1 : 20

GB

VARIES 200 MIN.

S2.01

FULLY SITE WELD COLUMN TO CAST-IN PLATE 2-N16 BARS, 600 LONG, WELDED 100mm EACH SIDE, TYPICAL

REFER TO STAIR ON GROUND DETAIL FOR REINFORCEMENT REQUIREMENTS NON-TRAFFICABLE SLAB, REFER TO PLAN FOR REINFORCEMENT

CONSTRUCTION SET

1

2 1 0

REV

300

250x250x12 PLATE

50 TY PIC AL

7/08/13 27/05/13

DATE

ISSUED FOR CONSTRUCTION ISSUED FOR TENDER

DESCRIPTION

300

N12-300

300

1200 (x1000)

STRIP FOOTING SF2, REFER TO FOOTING REINFORCEMENT SCHEDULE

200 MIN. 4-N16 LUGS C.P.B.W TO CAST-IN PLATE, TYPICAL

50

RW2 DETAIL

1 : 20 1 CONNECTION PANEL 3 TO PANEL 1 AT THE BACK FACE VIA 10 PLATE, 1+1-M12 MECHANICAL ANCHORS, TYPICAL

NOTE: CAST-IN PLATES TO BE HOT DIPPED GALVANISED

SECTION

1 : 20 1

GA

S2.01

85

C5 TO CAST-IN PLATE ISOMETRIC DETAIL

1 : 20

SECTION

1 : 20

GD

S2.01

N10-200 EACH WAY

N10-200 EACH WAY

75x75x6.0 EA WITH 1+1-M12 MECHANICAL ANCHORS, TYPICAL

3 N10-200 LIGS N10-200 N10-200 LIGS N10-200 LIGS 3 1

JOHN CURTIN COLLEGE OF THE ARTS

YEAR 7 TEACHING FACILITIES CONCRETE DETAILS

DRAWN

5-N10 BARS

3-N10 BARS

5-N10 BARS

3-N10 BARS

N10-200

5-N10 BARS

3-N10 BARS

N10-200

N10-200 EACH WAY

TYPICAL CONCRETE SEAT LAYOUT

SECTION X-X

REFER TO ARCHITECTURAL DETAILS FOR LOCATIONS AND PANEL DIMENSIONS NOTE: PLATES AND ANCHORS TO BE GALVANISED

TYPICAL SEAT PANEL 1 TO SEAT PANEL 3 CONNECTION DETAIL

BA AE -

DESIGNED PRINCIPAL

600

RCB

REDUCTION 0 25

CHECKED APPROVED SCALE

DATE

DRAWING No.

As indicated

JAN '13

BMW FILE No.

TYPICAL PRECAST CONCRETE SEAT DETAIL

1 : 20

BMW PROJ No.

BMW 0362713

THIS IS A REVIT DRAWING DO NOT AMEND MANUALLY

2013/03627

S3.01

C:\Users\Bradley\Documents\REVIT LOCAL\STRU_JCCOTA_BUILD_CENTRAL_2013_Bradley.rvt

Vous aimerez peut-être aussi

- Opd Office Civil C 001Document1 pageOpd Office Civil C 001Justin BeiterPas encore d'évaluation

- Benefits From The Use of Standard Prefabricated Building Components IncludeDocument3 pagesBenefits From The Use of Standard Prefabricated Building Components Includeप्रणव कडूPas encore d'évaluation

- Concrete LintelsDocument24 pagesConcrete LintelsAmber ChristensenPas encore d'évaluation

- Hollowcore Plant Design ManualDocument59 pagesHollowcore Plant Design Manualnfaayed100% (1)

- Clotan Steel - Purlin Span LengthsDocument3 pagesClotan Steel - Purlin Span LengthsColin SillmanPas encore d'évaluation

- Purlins & GirtsDocument105 pagesPurlins & Girtsrajkumar_chinniahPas encore d'évaluation

- Hilti Rebar 2Document69 pagesHilti Rebar 2Jeevan ShendrePas encore d'évaluation

- Member Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZBDocument2 pagesMember Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZByusuf abdinasirPas encore d'évaluation

- Presentation On Reinforcing Detailing of R.CDocument16 pagesPresentation On Reinforcing Detailing of R.CbertazcorpPas encore d'évaluation

- Lysaght Smartdek - Jan 2019Document2 pagesLysaght Smartdek - Jan 2019Chai Weng KuakPas encore d'évaluation

- C8-Seismic Assessment of Unreinforced Masonry Buildings PDFDocument189 pagesC8-Seismic Assessment of Unreinforced Masonry Buildings PDFMaria Luisa RGPas encore d'évaluation

- Notes On Hy-RibDocument20 pagesNotes On Hy-RibMohd Faizal100% (1)

- Design and Calculation of Fixing GRC Elements: Rev. No: 1 Date: 26-SEP-15Document10 pagesDesign and Calculation of Fixing GRC Elements: Rev. No: 1 Date: 26-SEP-15Deepum HalloomanPas encore d'évaluation

- Adapt PT Tutorial Beam FrameDocument22 pagesAdapt PT Tutorial Beam FrameHai NguyenPas encore d'évaluation

- Cost For Each Pile CapDocument4 pagesCost For Each Pile CapGeetashree PaulPas encore d'évaluation

- Material & Method Statement: Concrete Repair SystemsDocument3 pagesMaterial & Method Statement: Concrete Repair SystemsJuris DixonPas encore d'évaluation

- Bison Hollow Core FloorsDocument16 pagesBison Hollow Core FloorsJohn WoodsPas encore d'évaluation

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Reinstatement of Trenches Along Local Asphalt Roads A101.01Document2 pagesReinstatement of Trenches Along Local Asphalt Roads A101.01Nicholas VineyPas encore d'évaluation

- Reinforced Concrete DWGDocument11 pagesReinforced Concrete DWGAnonymous CPEha1db7UPas encore d'évaluation

- Slipway BEMEDocument4 pagesSlipway BEMEebed_meleckPas encore d'évaluation

- Synkoflex WaterstopDocument6 pagesSynkoflex WaterstopscshekarPas encore d'évaluation

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 pagesModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioPas encore d'évaluation

- Lok Set Resin CapsuleDocument4 pagesLok Set Resin CapsuleDaniel Alcides Arias RafaelPas encore d'évaluation

- Weighcom Company ProfileDocument11 pagesWeighcom Company ProfileWeighcom Electrical in Kampala 0750614536Pas encore d'évaluation

- Hanson Omnia Brochure FLOORING SystemDocument16 pagesHanson Omnia Brochure FLOORING SystemDC1234100% (3)

- Bondeck 600 PDFDocument9 pagesBondeck 600 PDFcivilPas encore d'évaluation

- Box CulvertDocument4 pagesBox CulvertDen OghangsombanPas encore d'évaluation

- Contoh BetonDocument29 pagesContoh Betonnaffian2Pas encore d'évaluation

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingPas encore d'évaluation

- A5-01 - Precast-Proposal Abu Dhabi Presidential Power Stat.Document6 pagesA5-01 - Precast-Proposal Abu Dhabi Presidential Power Stat.ninoak1962Pas encore d'évaluation

- Workshop 3Document4 pagesWorkshop 3Ajiri IvoviPas encore d'évaluation

- General NotesDocument1 pageGeneral NotesalayshahPas encore d'évaluation

- Precast: Stairs and LandingsDocument17 pagesPrecast: Stairs and LandingsFaizah SophiPas encore d'évaluation

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonPas encore d'évaluation

- Square PileDocument2 pagesSquare Piledepi_rachman100% (1)

- Reinforcing Steel in Post-Tensioned FloorDocument19 pagesReinforcing Steel in Post-Tensioned FloorAmnart KhampanitPas encore d'évaluation

- IWK Guide On FeeDocument1 pageIWK Guide On FeeJohnyReubenPas encore d'évaluation

- RC Simple Notions of Moment DistributionDocument136 pagesRC Simple Notions of Moment Distributionامين الزريقيPas encore d'évaluation

- Precast HandbookDocument179 pagesPrecast HandbookFernando LopezPas encore d'évaluation

- FoundOcean Fabric Formwork Grout Bag CatalogueDocument20 pagesFoundOcean Fabric Formwork Grout Bag Cataloguejptl6477Pas encore d'évaluation

- API - A Specialist in Precast Concrete ProductsDocument3 pagesAPI - A Specialist in Precast Concrete Productsalgebra1975100% (1)

- Supreme Beam and Block FloorDocument8 pagesSupreme Beam and Block FloorDoralba V NolanPas encore d'évaluation

- Fischer THB INT 110640 082013Document445 pagesFischer THB INT 110640 082013arunks4uPas encore d'évaluation

- (M. Levitt, Levitt, Mauri Levitt DR) Concrete Mate PDFDocument121 pages(M. Levitt, Levitt, Mauri Levitt DR) Concrete Mate PDFامين الزريقيPas encore d'évaluation

- Muro Wall FormworkDocument10 pagesMuro Wall FormworkDaliform GroupPas encore d'évaluation

- 2018 19 LOKRITE Ironmongery CatalogueDocument98 pages2018 19 LOKRITE Ironmongery CatalogueKho Song YuanPas encore d'évaluation

- Geoweb Material SpecificationDocument15 pagesGeoweb Material Specificationriki187Pas encore d'évaluation

- Prestress Concrete DPDocument20 pagesPrestress Concrete DPdanielPas encore d'évaluation

- Pile Foundation Design Example - US Units - Design Step 9Document103 pagesPile Foundation Design Example - US Units - Design Step 9Gere Lu100% (1)

- Port Conceptual Development Cost EstimatesDocument6 pagesPort Conceptual Development Cost EstimatesklynchellePas encore d'évaluation

- FootingDocument121 pagesFootingAras H.MPas encore d'évaluation

- StripDocument8 pagesStripnawidrasoolyPas encore d'évaluation

- Water Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01Document7 pagesWater Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01hmaisano1100% (1)

- WRN STD 002aDocument1 pageWRN STD 002ahenryLYDPas encore d'évaluation

- Cast-In-situ CC Lining (13!12!2006) 2Document1 pageCast-In-situ CC Lining (13!12!2006) 2Santhosh Kumar BaswaPas encore d'évaluation

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750Pas encore d'évaluation

- DR 2GL Se 4206Document1 pageDR 2GL Se 4206bobmarley20161934Pas encore d'évaluation

- Scientific American Supplement, No. 470, January 3, 1885D'EverandScientific American Supplement, No. 470, January 3, 1885Pas encore d'évaluation

- Project 1 Quality Control ChecklistDocument1 pageProject 1 Quality Control ChecklistAmr HalabyPas encore d'évaluation

- StructEngII Connections 276-327Document52 pagesStructEngII Connections 276-327Saad Al HelyPas encore d'évaluation

- عرب اوروباDocument188 pagesعرب اوروباZsaxc Shawkey0% (1)

- Technical Lamination SDocument4 pagesTechnical Lamination SAlexander RichardsonPas encore d'évaluation

- Transport HandbookDocument937 pagesTransport HandbookUmesh Rai100% (9)

- AS1710 12 Datasheet EN v4Document20 pagesAS1710 12 Datasheet EN v4Amr HalabyPas encore d'évaluation

- Formwork DesignDocument17 pagesFormwork DesignEajaz Buzruk100% (3)

- Formwork PDFDocument27 pagesFormwork PDFKandarp Rajyaguru100% (1)

- Ohse Subbypack Section Two OHSE Management Plan: Word Format VersionDocument43 pagesOhse Subbypack Section Two OHSE Management Plan: Word Format VersionAmr HalabyPas encore d'évaluation

- Children of RuinDocument164 pagesChildren of RuinAmr HalabyPas encore d'évaluation

- Jcca102p6 Rev 1 PDFDocument1 pageJcca102p6 Rev 1 PDFAmr HalabyPas encore d'évaluation

- B. Spuida - Technical Writing Made EasierDocument17 pagesB. Spuida - Technical Writing Made EasieraeloysPas encore d'évaluation

- A Tale of Two CitiesDocument537 pagesA Tale of Two Citiessilver999Pas encore d'évaluation

- Learn SpanishDocument96 pagesLearn Spanishv155r100% (64)

- English Basics PDFDocument287 pagesEnglish Basics PDFmetnak.menbanatPas encore d'évaluation

- With Us You Will Get Safe Food: We Follow These 10 Golden RulesDocument2 pagesWith Us You Will Get Safe Food: We Follow These 10 Golden RulesAkshay DeshmukhPas encore d'évaluation

- Portales Etapas 2022 - MonicaDocument141 pagesPortales Etapas 2022 - Monicadenis_c341Pas encore d'évaluation

- Contoh Background Thesis Bahasa InggrisDocument6 pagesContoh Background Thesis Bahasa InggrisLisa Riley100% (2)

- 4-String Cigar Box Guitar Chord Book (Brent Robitaille) (Z-Library)Document172 pages4-String Cigar Box Guitar Chord Book (Brent Robitaille) (Z-Library)gregory berlemontPas encore d'évaluation

- Bulk Materail International March April 2011 20110300 - 36598714Document20 pagesBulk Materail International March April 2011 20110300 - 36598714ookyilwin3795Pas encore d'évaluation

- Marimba ReferenceDocument320 pagesMarimba Referenceapi-3752991Pas encore d'évaluation

- Member, National Gender Resource Pool Philippine Commission On WomenDocument66 pagesMember, National Gender Resource Pool Philippine Commission On WomenMonika LangngagPas encore d'évaluation

- Bennett Et Al 2019 Towards A Sustainable and Equitable Blue EconomyDocument3 pagesBennett Et Al 2019 Towards A Sustainable and Equitable Blue Economynaomi 23Pas encore d'évaluation

- Solution pdf-51Document68 pagesSolution pdf-51Tanmay GoyalPas encore d'évaluation

- Fmi Unit 2Document86 pagesFmi Unit 2Pranav vigneshPas encore d'évaluation

- Food Security: Its Components and ChallengesDocument9 pagesFood Security: Its Components and ChallengesSimlindile NgobelaPas encore d'évaluation

- Interpretive Dance RubricDocument1 pageInterpretive Dance RubricWarren Sumile67% (3)

- Chapter 2 - Practice QuestionsDocument2 pagesChapter 2 - Practice QuestionsSiddhant AggarwalPas encore d'évaluation

- Ethereum WorldDocument41 pagesEthereum WorldHarihara Gopalan SPas encore d'évaluation

- Addendum PDFDocument2 pagesAddendum PDFIbaiMitxelenaSanchezPas encore d'évaluation

- CFJ Seminars TrainingGuide L1EnglishDocument136 pagesCFJ Seminars TrainingGuide L1EnglishAttila AygininPas encore d'évaluation

- RPMDocument35 pagesRPMnisfyPas encore d'évaluation

- Dergiler Ingilizce Okuma Gramer NotlariDocument753 pagesDergiler Ingilizce Okuma Gramer NotlarierdemPas encore d'évaluation

- CT, PT, IVT, Current Transformer, Potential Transformer, Distribution Boxes, LT Distribution BoxesDocument2 pagesCT, PT, IVT, Current Transformer, Potential Transformer, Distribution Boxes, LT Distribution BoxesSharafatPas encore d'évaluation

- Corporation True or FalseDocument2 pagesCorporation True or FalseAllyza Magtibay50% (2)

- Philsa International Placement and Services Corporation vs. Secretary of Labor and Employment PDFDocument20 pagesPhilsa International Placement and Services Corporation vs. Secretary of Labor and Employment PDFKrissaPas encore d'évaluation

- Cone Penetration Test (CPT) Interpretation: InputDocument5 pagesCone Penetration Test (CPT) Interpretation: Inputstephanie andriamanalinaPas encore d'évaluation

- Max3080 Max3089Document21 pagesMax3080 Max3089Peter BirdPas encore d'évaluation

- Chapter 2 System Architecture: HapterDocument34 pagesChapter 2 System Architecture: HapterMohamed AminePas encore d'évaluation

- Test Bank For Biology 7th Edition Neil A CampbellDocument36 pagesTest Bank For Biology 7th Edition Neil A Campbellpoupetonlerneanoiv0ob100% (31)

- The List of Official United States National SymbolsDocument3 pagesThe List of Official United States National SymbolsВікторія АтаманюкPas encore d'évaluation

- Guide To Tanzania Taxation SystemDocument3 pagesGuide To Tanzania Taxation Systemhima100% (1)

- AWS PowerPoint PresentationDocument129 pagesAWS PowerPoint PresentationZack Abrahms56% (9)

- ATM BrochuresDocument5 pagesATM Brochuresगुंजन सिन्हाPas encore d'évaluation

- Security Information and Event Management (SIEM) - 2021Document4 pagesSecurity Information and Event Management (SIEM) - 2021HarumPas encore d'évaluation