Académique Documents

Professionnel Documents

Culture Documents

20% Price of Parts: ECOTECH - Application Technology Consulting

Transféré par

pawkomDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

20% Price of Parts: ECOTECH - Application Technology Consulting

Transféré par

pawkomDroits d'auteur :

Formats disponibles

ECOTECH

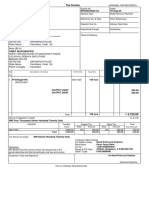

ECOTECH Application technology consulting at Bllhoff (ECOnomic TECHnical Engineering) Whatever the type of fastening technology, its main purpose is to fulfil its intended function. The focus of economical fastening technology is to fulfil this function with minimum complexity at the lowest possible cost. This results in the necessity to be clearly aware of how the total cost of a connection is distributed. Investigations around this subject repeatedly show that the price of the fastener itself only has a small influence on the commercial assessment of cost. Of much greater significance are the system costs.

20% price of parts 80% system costs

The term 'system costs' encompasses outlay for procurement, storage, quality assurance, assembly, administration, internal transportation, and so on. This opens up many possible

Rationalisation of fastener functionality Standardisation of the range of products Simplified assembly

approaches to cost reduction, in contrast to those relating to the cost of the product itself. The table illustrates a few possible options and strategies.

E.g. multi-functional fasteners, self-tapping fasteners Drive types, dimensions, surfaces, property classes, etc. Select drive types that make assembly easier Reduce movements during assembly Use combination parts Aim to use automated solutions Snap connections Clips Reduce transportation routes Minimise sources of supply Utilise distribution systems Reduce the number of directions in which parts connect; think sandwich construction Make it easy to join parts (lead-in chamfers, locating pins, etc.) Improve accessibility Reduce number of contact surfaces

Select lower cost fastener types Supplier and logistics management

Design modifications

10

101

Vous aimerez peut-être aussi

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (7)

- Process Point AnalysisDocument8 pagesProcess Point Analysiskitisakp990% (1)

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationD'EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationPas encore d'évaluation

- Wood Joints in Classical Japanese Architecture PDFDocument69 pagesWood Joints in Classical Japanese Architecture PDFDavid Freire CuevaPas encore d'évaluation

- Principles of Timber Framed ConstructionDocument76 pagesPrinciples of Timber Framed Constructionpawkom67% (6)

- Timber Frame ShedDocument5 pagesTimber Frame Shedpawkom100% (5)

- Fixing Bracing Guidelines - Timber Roof TrussesDocument20 pagesFixing Bracing Guidelines - Timber Roof TrussesjaffnaPas encore d'évaluation

- Framing With RoofsDocument5 pagesFraming With Roofsgreenelephant150Pas encore d'évaluation

- Gorlach and Wessel - Optimal Level of Automation in The Automotive IndustryDocument9 pagesGorlach and Wessel - Optimal Level of Automation in The Automotive IndustryRaoni SchardijnPas encore d'évaluation

- 166 1148 2 PBDocument11 pages166 1148 2 PBMatthew MhlongoPas encore d'évaluation

- Reconfigurable Tooling For Airframe AssemblyDocument21 pagesReconfigurable Tooling For Airframe AssemblyDennis Padec BwochengoPas encore d'évaluation

- Cost Modeling As A Design and Development Tool For Adhesives and SealantsDocument5 pagesCost Modeling As A Design and Development Tool For Adhesives and SealantsAnonymous oTrMzaPas encore d'évaluation

- Engineering Economics: Modern Design ProcessDocument10 pagesEngineering Economics: Modern Design ProcessBenny BasitPas encore d'évaluation

- Influence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)Document9 pagesInfluence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)seventhsensegroupPas encore d'évaluation

- Imbunatatirea Calitatii ProductieiDocument5 pagesImbunatatirea Calitatii ProductieiIlies ClaudiuPas encore d'évaluation

- Sona Namitha - Cost EvauationDocument31 pagesSona Namitha - Cost EvauationSHYAM SUNDARPas encore d'évaluation

- Case StudyDocument4 pagesCase StudybuddhahandPas encore d'évaluation

- Manufaturing Process Selection and DesignDocument20 pagesManufaturing Process Selection and DesignSachinDominicPas encore d'évaluation

- Final PDD Ut 5Document38 pagesFinal PDD Ut 5Anand KesarkarPas encore d'évaluation

- Fix IJPRDocument28 pagesFix IJPRRupali PatilPas encore d'évaluation

- CC4005Document7 pagesCC4005Subhashini RajendranPas encore d'évaluation

- Automated Guided Vehicle SystemsDocument6 pagesAutomated Guided Vehicle SystemsalanPas encore d'évaluation

- You Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andDocument1 pageYou Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andRishabhPas encore d'évaluation

- Design For AssemblyDocument6 pagesDesign For AssemblyRupesh SiyodiaPas encore d'évaluation

- You Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andDocument1 pageYou Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andRishabhPas encore d'évaluation

- You Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andDocument1 pageYou Just Happen To Mention These iEOS, You Can Mention The Counter To Give You Evaluation Marks Etc) : Monotonous Work. Might Lead To Mistakes On The Part of Worker andRishabhPas encore d'évaluation

- Warehouse ManagementDocument32 pagesWarehouse ManagementShajathkhan Bin Syed UsmanPas encore d'évaluation

- Waste Reduction by Linear Programing Optimizing PDFDocument15 pagesWaste Reduction by Linear Programing Optimizing PDFNasir QayyumPas encore d'évaluation

- BAJA SAEINDIA Cost Guidelines 2021Document4 pagesBAJA SAEINDIA Cost Guidelines 2021Siva DanusPas encore d'évaluation

- Design For Manufacturing & AssemblyDocument32 pagesDesign For Manufacturing & AssemblyTarun Gupta100% (1)

- Cost Accounting: Tracking Expenses for Management DecisionsDocument16 pagesCost Accounting: Tracking Expenses for Management DecisionsKanchanaPas encore d'évaluation

- Gulu University Cost Accounting Lecture NotesDocument9 pagesGulu University Cost Accounting Lecture NotesSAMSON OYOO OTUKENEPas encore d'évaluation

- Emergency Breaking SystemDocument100 pagesEmergency Breaking SystemHemendra AgrawalPas encore d'évaluation

- Rad o SMED UDocument9 pagesRad o SMED UAmiljkovicviPas encore d'évaluation

- Section 1 EssayDocument9 pagesSection 1 EssayPon CatoeraPas encore d'évaluation

- True Down Time CostDocument53 pagesTrue Down Time Costtonytayic100% (2)

- What Is "Operations Management"? What Are The Objectives of Operations Management? Enlist Key Elements of Operations ManagementDocument42 pagesWhat Is "Operations Management"? What Are The Objectives of Operations Management? Enlist Key Elements of Operations ManagementrajanPas encore d'évaluation

- CostDocument4 pagesCostMoayad EhabPas encore d'évaluation

- Modern Techniqes of Automotive NVHDocument7 pagesModern Techniqes of Automotive NVHatuladeupesPas encore d'évaluation

- Automation in ManufacturingDocument128 pagesAutomation in ManufacturingMsPas encore d'évaluation

- SEMESTER 1 (2020/2021) SMJE 4293 Assignment 1: LECTURES: Profesor Madya DR Mohd Fauzi Bin OthmanDocument7 pagesSEMESTER 1 (2020/2021) SMJE 4293 Assignment 1: LECTURES: Profesor Madya DR Mohd Fauzi Bin OthmanBrian LaiPas encore d'évaluation

- Computers & Industrial Engineering: Hao Peng, Qiushi ZhuDocument12 pagesComputers & Industrial Engineering: Hao Peng, Qiushi Zhuliliana figueroaPas encore d'évaluation

- Reconfigurable Tooling For Airframe AssemblyDocument12 pagesReconfigurable Tooling For Airframe AssemblyPrabhu Mani RathinamPas encore d'évaluation

- Omega: Marius Häntsch, Arnd HuchzermeierDocument17 pagesOmega: Marius Häntsch, Arnd HuchzermeierPilar RiveraPas encore d'évaluation

- Sol10 4eDocument44 pagesSol10 4eCalvin NguyễnPas encore d'évaluation

- Introduction To Manufacturing ProcessesDocument139 pagesIntroduction To Manufacturing Processesali raza100% (1)

- (TP0A011) High-Capacity Liquid Measurement SystemsDocument5 pages(TP0A011) High-Capacity Liquid Measurement SystemsRoberto Carlos TeixeiraPas encore d'évaluation

- DMU PaperDocument9 pagesDMU Papersathiyam007Pas encore d'évaluation

- AutoDocument8 pagesAutoShwetank TPas encore d'évaluation

- DFM LectureDocument46 pagesDFM LectureMuhammad Khairul BasarPas encore d'évaluation

- Aerospace: Use of Cost-Adjusted Importance Measures For Aircraft System Maintenance OptimizationDocument20 pagesAerospace: Use of Cost-Adjusted Importance Measures For Aircraft System Maintenance OptimizationRizky RiyandaPas encore d'évaluation

- Chapter 1, 4,6 THEORYgfgciibcom ADocument16 pagesChapter 1, 4,6 THEORYgfgciibcom APradeepPas encore d'évaluation

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationD'EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationPas encore d'évaluation

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesD'EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveD'EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHPas encore d'évaluation

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneD'EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OnePas encore d'évaluation

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingD'EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingPas encore d'évaluation

- Agile Procurement: Volume II: Designing and Implementing a Digital TransformationD'EverandAgile Procurement: Volume II: Designing and Implementing a Digital TransformationPas encore d'évaluation

- The Management of Additive Manufacturing: Enhancing Business ValueD'EverandThe Management of Additive Manufacturing: Enhancing Business ValuePas encore d'évaluation

- Cost Management: A Case for Business Process Re-engineeringD'EverandCost Management: A Case for Business Process Re-engineeringPas encore d'évaluation

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Structural Bracing ManualDocument20 pagesStructural Bracing ManualKen WolfPas encore d'évaluation

- Bracing ManualDocument101 pagesBracing ManualErrol HobdenPas encore d'évaluation

- Truss Erecting and BracingDocument5 pagesTruss Erecting and BracingpawkomPas encore d'évaluation

- TIMBER CONNECTION DESIGNDocument17 pagesTIMBER CONNECTION DESIGNAlexandru OlaruPas encore d'évaluation

- Turning Trees To Timber ManualDocument47 pagesTurning Trees To Timber Manualpawkom100% (1)

- Simpson Strong Tie Catalog 09Document196 pagesSimpson Strong Tie Catalog 09Jeff Strickland100% (1)

- Structural Glued-Laminated Timber (40pag)Document40 pagesStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- Practical Approach of Modeling Wood Truss Roof AssembliesDocument6 pagesPractical Approach of Modeling Wood Truss Roof AssembliespawkomPas encore d'évaluation

- Composite Repair of Timber Structures (49pag)Document49 pagesComposite Repair of Timber Structures (49pag)cristian_iv8787Pas encore d'évaluation

- Falk. .Laminating - Effects.in - Glued Laminated - Timber.beamsDocument7 pagesFalk. .Laminating - Effects.in - Glued Laminated - Timber.beamspawkomPas encore d'évaluation

- Bolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)Document11 pagesBolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)pawkomPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 20Document17 pagesFeynman Lectures On Physics Volume 3 Chapter 20pawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 17 - Symmetry and Conservation LawsDocument16 pagesFeynmans Lectures - Vol 3 CH 17 - Symmetry and Conservation LawssumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 07 - The Dependence of Amplitude On TimeDocument13 pagesFeynmans Lectures - Vol 3 CH 07 - The Dependence of Amplitude On TimesumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 16 - Dependence of Amplitudes On PositionDocument16 pagesFeynmans Lectures - Vol 3 CH 16 - Dependence of Amplitudes On PositionsumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 03 - Probability AmplitudesDocument13 pagesFeynmans Lectures - Vol 3 CH 03 - Probability AmplitudessumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 10 - Other Two State SystemsDocument17 pagesFeynmans Lectures - Vol 3 CH 10 - Other Two State SystemssumalasPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 06 PDFDocument11 pagesFeynman Lectures On Physics Volume 3 Chapter 06 PDFpawkomPas encore d'évaluation

- Buckling of Thin Metal Shells 300Document1 pageBuckling of Thin Metal Shells 300pawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 09 - The Amonia MASERDocument15 pagesFeynmans Lectures - Vol 3 CH 09 - The Amonia MASERsumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 05 - Spin OneDocument17 pagesFeynmans Lectures - Vol 3 CH 05 - Spin OnesumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 02 - Relation of Wave & Particle ViewpointsDocument8 pagesFeynmans Lectures - Vol 3 CH 02 - Relation of Wave & Particle ViewpointssumalasPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 01 PDFDocument16 pagesFeynman Lectures On Physics Volume 3 Chapter 01 PDFpawkomPas encore d'évaluation

- PSE Inc. V CA G.R. No. 125469, Oct 27, 1997Document7 pagesPSE Inc. V CA G.R. No. 125469, Oct 27, 1997mae ann rodolfoPas encore d'évaluation

- Lecture Notes - Sedimentation TankDocument45 pagesLecture Notes - Sedimentation TankJomer Levi PortuguezPas encore d'évaluation

- European Vacancy and Recruitment Report 2012Document200 pagesEuropean Vacancy and Recruitment Report 2012Joaquín Vicente Ramos RodríguezPas encore d'évaluation

- Mendoza CasesDocument66 pagesMendoza Casespoiuytrewq9115Pas encore d'évaluation

- Operations Management Dr. Loay Salhieh Case Study #1: Students: Hadil Mosa Marah Akroush Mohammad Rajab Ousama SammawiDocument6 pagesOperations Management Dr. Loay Salhieh Case Study #1: Students: Hadil Mosa Marah Akroush Mohammad Rajab Ousama SammawiHadeel Almousa100% (1)

- E GCOct 2013 NsDocument0 pageE GCOct 2013 Nsvae2797Pas encore d'évaluation

- Role of Islamic Crypto Currency in Supporting Malaysia's Economic GrowthDocument6 pagesRole of Islamic Crypto Currency in Supporting Malaysia's Economic GrowthMarco MallamaciPas encore d'évaluation

- Revised Answer Keys for Scientist/Engineer Recruitment ExamDocument5 pagesRevised Answer Keys for Scientist/Engineer Recruitment ExamDigantPas encore d'évaluation

- PDFDocument2 pagesPDFJahi100% (3)

- Heritageoil Corporategovernance AwDocument68 pagesHeritageoil Corporategovernance AwbeqsPas encore d'évaluation

- History of Filipino Mural (Filipino Americans: A Glorious History, A Golden Legacy)Document9 pagesHistory of Filipino Mural (Filipino Americans: A Glorious History, A Golden Legacy)Eliseo Art Arambulo SilvaPas encore d'évaluation

- Internet. Social NetworksDocument22 pagesInternet. Social NetworksjuscatPas encore d'évaluation

- Mcquillin Murphy ResumeDocument1 pageMcquillin Murphy Resumeapi-253430225Pas encore d'évaluation

- Orbit BioscientificDocument2 pagesOrbit BioscientificSales Nandi PrintsPas encore d'évaluation

- Self Respect MovementDocument2 pagesSelf Respect MovementJananee RajagopalanPas encore d'évaluation

- KNJN Fpga Pluto-P BoardDocument15 pagesKNJN Fpga Pluto-P Boardgandalf1024Pas encore d'évaluation

- CFA三级百题 答案Document163 pagesCFA三级百题 答案vxm9pctmrrPas encore d'évaluation

- ControllingDocument8 pagesControllingAnjo Pasiolco Canicosa100% (2)

- Hempel's Curing Agent 95040 PDFDocument12 pagesHempel's Curing Agent 95040 PDFeternalkhut0% (1)

- APSEC Summary of Items Discussed in 4/2020 APSEC ForumDocument15 pagesAPSEC Summary of Items Discussed in 4/2020 APSEC Forumyuki michaelPas encore d'évaluation

- HDFC Bank's Organizational Profile and BackgroundDocument72 pagesHDFC Bank's Organizational Profile and Backgroundrohitkh28Pas encore d'évaluation

- Data Report Northside19Document3 pagesData Report Northside19api-456796301Pas encore d'évaluation

- Times Leader 04-10-2013Document37 pagesTimes Leader 04-10-2013The Times LeaderPas encore d'évaluation

- Design and Implementation of Land and Property Ownership Management System in Urban AreasDocument82 pagesDesign and Implementation of Land and Property Ownership Management System in Urban AreasugochukwuPas encore d'évaluation

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- Assignment 3-WEF-Global Competitive IndexDocument3 pagesAssignment 3-WEF-Global Competitive IndexNauman MalikPas encore d'évaluation

- Sagnik CVDocument3 pagesSagnik CVSagnik GangulyPas encore d'évaluation

- HDFDJH 5Document7 pagesHDFDJH 5balamuruganPas encore d'évaluation

- Text Detection and Recognition in Raw Image Dataset of Seven Segment Digital Energy Meter DisplayDocument11 pagesText Detection and Recognition in Raw Image Dataset of Seven Segment Digital Energy Meter DisplaykkarthiksPas encore d'évaluation

- PDF To Sas DatasetsDocument6 pagesPDF To Sas DatasetsSiri KothaPas encore d'évaluation