Académique Documents

Professionnel Documents

Culture Documents

SELECT GRANULAR BACKFILL

Transféré par

Shankar IyerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SELECT GRANULAR BACKFILL

Transféré par

Shankar IyerDroits d'auteur :

Formats disponibles

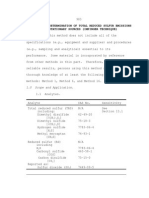

SELECT GRANULAR BACKFILL MATERIAL

All backfill material used shall be reasonably free (maximum of 0.1%) from organic and otherwise deleterious materials, and it shall be approved by the Engineer prior to use. The material shall conform to the following gradation limits: Gradation as determined by AASHTO T 27. SIEVE SIZE 4 inches No. 40 No. 200 PERCENT PASSING 100 0-60 0-15

In addition, the backfill must conform to all of the following requirements: 1. Soundness - The material shall be substantially free from shale or other soft, poor durability particles. The material shall have a magnesium sulfate soundness loss of less than 30 percent after five (5) cycles, measured in accordance with AASHTO T 104, or a sodium sulfate loss of less than 12 percent after five (5) cycles determined in accordance with AASHTO T 104

2. The Plasticity Index (P.I.), as determined by AASHTO T 90, shall not exceed 6. 3. The material shall exhibit an angle of internal friction of not less than 34 degrees as determined by the standard direct shear test AASHTO T 236 on the portion finer than the No. 10 sieve, using a sample of the material compacted to 95 percent of AASHTO T 99, Methods C or D (with oversize correction, as outlined in Note 7 at optimum moisture content). No testing is required for backfills where 80 percent of sizes are greater than 3/4 inch. 4. Shall meet the following electrochemical requirements:

REQUIREMENTS ph= 5-10 Resistivity > 3000 ohm centimeters1 Chlorides < 100 parts per million Sulfates < 200 parts per million

TEST METHOD AASHTO T 289 - 91 AASHTO T 288 - 91 AASHTO T 291 - 91 AASHTO T 290 - 91

Organic Content < 1% AASHTO T 267 - 86 1. If the resistivity is greater or equal to 5000 ohm centimeters the chloride and sulfates requirements may be waived.

Vous aimerez peut-être aussi

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- ASTM A182 Grade F51 Requirement As Per API 6A-60KDocument8 pagesASTM A182 Grade F51 Requirement As Per API 6A-60KPalkesh TrivediPas encore d'évaluation

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- Aashto T99 - T180Document10 pagesAashto T99 - T180julianovmPas encore d'évaluation

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- LPT Spe Level II Exam QBDocument10 pagesLPT Spe Level II Exam QBAruchamy SelvakumarPas encore d'évaluation

- Technical Specifications of Roads - Part3Document19 pagesTechnical Specifications of Roads - Part3citizenkanegPas encore d'évaluation

- ITEM 200 Latest 2004Document12 pagesITEM 200 Latest 2004Marinella AbellaPas encore d'évaluation

- 1.0 SCOPE:: SL - No. Tag No. Area of Exchanger Coating Thickness RemarksDocument5 pages1.0 SCOPE:: SL - No. Tag No. Area of Exchanger Coating Thickness RemarksCorrosion FactoryPas encore d'évaluation

- ITEM 515-517, 520 Latest 2012 (M) Final 4Document20 pagesITEM 515-517, 520 Latest 2012 (M) Final 4Mikhail Tabucal100% (1)

- 15sampling & Testing - Minimum Testing. RequirementsDocument157 pages15sampling & Testing - Minimum Testing. Requirementsm0uth_wash1ngPas encore d'évaluation

- Hot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodDocument6 pagesHot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodAnonymous iinjEi4E2Pas encore d'évaluation

- T ND 00281501000000000000 Dae 02801Document4 pagesT ND 00281501000000000000 Dae 02801asl91Pas encore d'évaluation

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasinghePas encore d'évaluation

- L001E HTM Leaflet enDocument8 pagesL001E HTM Leaflet enMohd HassanudinPas encore d'évaluation

- Chip Seal Specification: Tests On CRS-2R Emulsion Minimum Maximum Test MethodDocument6 pagesChip Seal Specification: Tests On CRS-2R Emulsion Minimum Maximum Test MethodAnonymous iinjEi4E2Pas encore d'évaluation

- Elements Re51420 2010-10Document14 pagesElements Re51420 2010-10Admir TalicPas encore d'évaluation

- SAE J189-1998 Power Steering Return Hose - Low PressureDocument5 pagesSAE J189-1998 Power Steering Return Hose - Low Pressurekhhose100% (1)

- Inspection of ElectrodesDocument62 pagesInspection of ElectrodesARAVINDAN DPas encore d'évaluation

- SA Standard NotesDocument22 pagesSA Standard Notesatiq0592Pas encore d'évaluation

- Tracerase: Operating and Instruction ManualDocument16 pagesTracerase: Operating and Instruction ManualKrishnaPas encore d'évaluation

- SIKA Sikadur 42 MP Normal HCDocument5 pagesSIKA Sikadur 42 MP Normal HCKang Mas WiralodraPas encore d'évaluation

- Sec 1038Document4 pagesSec 1038Lauren BowenPas encore d'évaluation

- Filters - EPE PDFDocument8 pagesFilters - EPE PDFSyed Mujtaba Ali BukhariPas encore d'évaluation

- Rust Protection by Metal Preservatives in The Humidity CabinetDocument9 pagesRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxPas encore d'évaluation

- Scope: Bursting Strength of A Material Is Defined As The Maximum Hydrostatic Pressure Required To Produce Rupture ofDocument6 pagesScope: Bursting Strength of A Material Is Defined As The Maximum Hydrostatic Pressure Required To Produce Rupture ofKeka SomaiahPas encore d'évaluation

- Gu01 2009 Testing MethodDocument40 pagesGu01 2009 Testing MethodFrancis BoeyPas encore d'évaluation

- Double Chip Specification 2Document6 pagesDouble Chip Specification 2Anonymous iinjEi4E2Pas encore d'évaluation

- Storage Tank API 650Document20 pagesStorage Tank API 650jalison07xPas encore d'évaluation

- Method 16A - Determination of Total Reduced Sulfur Emissions From Stationary Sources (Impinger Technique)Document38 pagesMethod 16A - Determination of Total Reduced Sulfur Emissions From Stationary Sources (Impinger Technique)Mardo Mardomardo Mardo MardomardoPas encore d'évaluation

- 04 AASHTO Online PDFDocument306 pages04 AASHTO Online PDFragunas tatyaPas encore d'évaluation

- Irs T 47-2006Document24 pagesIrs T 47-2006vpmohammedPas encore d'évaluation

- Pipeline Wrapping Specification GuideDocument9 pagesPipeline Wrapping Specification GuideMahdiPas encore d'évaluation

- T Proc Notices Notices 040 K Notice Doc 35762 449071606Document5 pagesT Proc Notices Notices 040 K Notice Doc 35762 449071606jaafar abdullahPas encore d'évaluation

- Plate Material Data Sheet FOR P335NL2 (1.1106) : Rev. DescriptionDocument6 pagesPlate Material Data Sheet FOR P335NL2 (1.1106) : Rev. DescriptionHosseinPas encore d'évaluation

- Florida Department of Transportation: 605 Suwannee Street Tallahassee, FL 32399-0450Document17 pagesFlorida Department of Transportation: 605 Suwannee Street Tallahassee, FL 32399-0450murdicksPas encore d'évaluation

- Hse Approved SpecificationDocument16 pagesHse Approved SpecificationPrasit MeeboonPas encore d'évaluation

- Use of PB Is Required For PE and PVC Pipe BackfillDocument4 pagesUse of PB Is Required For PE and PVC Pipe BackfillYimer MesheshaPas encore d'évaluation

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001Pas encore d'évaluation

- Asphalt: Testing EquipmentsDocument14 pagesAsphalt: Testing EquipmentsMorched TounsiPas encore d'évaluation

- Ti e Protegol 32-55 RRM Nov 07Document4 pagesTi e Protegol 32-55 RRM Nov 07A MahmoodPas encore d'évaluation

- Standard Test Method For: Normal Consistency of Hydraulic Cement1Document4 pagesStandard Test Method For: Normal Consistency of Hydraulic Cement1Soto LopezPas encore d'évaluation

- 703 Aggregate PDFDocument5 pages703 Aggregate PDFdrPas encore d'évaluation

- A12370 PerformanceDocument2 pagesA12370 PerformanceClef GonadanPas encore d'évaluation

- t99-t180-MOISTURE-DENSITY RELATIONS OF SOILSDocument10 pagest99-t180-MOISTURE-DENSITY RELATIONS OF SOILSpmendonça_18Pas encore d'évaluation

- Corrosion Astm D 1838-07Document5 pagesCorrosion Astm D 1838-07Cecilia Cruz Toribio100% (1)

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiPas encore d'évaluation

- Material ControlDocument3 pagesMaterial ControlChe EllePas encore d'évaluation

- Summary of Evidence Report: - Hydraulic Brake Hoses (FMVSS 106)Document13 pagesSummary of Evidence Report: - Hydraulic Brake Hoses (FMVSS 106)MarsellusProbstPas encore d'évaluation

- MP 0 2600 26 Sept 09Document8 pagesMP 0 2600 26 Sept 09Sreenath S KallaaraPas encore d'évaluation

- Astm A572 - 04Document1 pageAstm A572 - 04Hai TranPas encore d'évaluation

- Surface Prep & Application of MI-DTI Insulating CoatingDocument2 pagesSurface Prep & Application of MI-DTI Insulating CoatingYing Kei ChanPas encore d'évaluation

- Atz 300Document2 pagesAtz 300Rahul KumarPas encore d'évaluation

- Pollution Control Handbook for Oil and Gas EngineeringD'EverandPollution Control Handbook for Oil and Gas EngineeringPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesD'EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesPas encore d'évaluation

- General License Exam Cliff Note Manual 2015-2019D'EverandGeneral License Exam Cliff Note Manual 2015-2019Évaluation : 1 sur 5 étoiles1/5 (1)

- PVC Structural Pile Work Steel Approval - OctoberDocument2 pagesPVC Structural Pile Work Steel Approval - OctoberShankar IyerPas encore d'évaluation

- Ar-2006 (6 3 07)Document271 pagesAr-2006 (6 3 07)gsr_svsPas encore d'évaluation

- 2911 4 PDFDocument21 pages2911 4 PDFKalipada SenPas encore d'évaluation

- SPT Capability To Estimate Undrained Shear Strength of Fine Grained SoilsDocument10 pagesSPT Capability To Estimate Undrained Shear Strength of Fine Grained SoilsPatrick VunPas encore d'évaluation

- Load CalculationsDocument4 pagesLoad CalculationsShankar IyerPas encore d'évaluation

- CR MethodDocument32 pagesCR MethodShankar IyerPas encore d'évaluation

- Aashto T 193-81 CBRDocument6 pagesAashto T 193-81 CBRJoRge BaRrios100% (2)

- Ron-01 and Ron-02 MBR Bore Hole-Layout1Document1 pageRon-01 and Ron-02 MBR Bore Hole-Layout1Shankar IyerPas encore d'évaluation

- Bearing Capacity All MethodsDocument2 pagesBearing Capacity All MethodsJayChristian QuimsonPas encore d'évaluation

- Correlation Between Physical Properties and California Bearing Ratio-LibreDocument10 pagesCorrelation Between Physical Properties and California Bearing Ratio-LibreShankar IyerPas encore d'évaluation

- Deterministic shallow foundation design using SPT dataDocument4 pagesDeterministic shallow foundation design using SPT dataZahira HeloPas encore d'évaluation

- Is 9143 1979Document11 pagesIs 9143 1979rajenkoleyPas encore d'évaluation

- List of Equip. in LabDocument4 pagesList of Equip. in LabShankar IyerPas encore d'évaluation

- Cross Sections 2Document1 pageCross Sections 2Shankar IyerPas encore d'évaluation

- Identifying Swelling SoilsDocument5 pagesIdentifying Swelling SoilsShankar IyerPas encore d'évaluation

- Mica in SoilDocument1 pageMica in SoilShankar IyerPas encore d'évaluation

- Vesic SPTDocument5 pagesVesic SPTSiddharam Ishwarkatti0% (1)