Académique Documents

Professionnel Documents

Culture Documents

415 Reactor

Transféré par

maheshCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

415 Reactor

Transféré par

maheshDroits d'auteur :

Formats disponibles

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

1 ` a c

GENERAL INFORMATION

REGION : SRTS-II b d DATE OF RECEIPT AT SITE : DATE OF ENERGISATION :

17/03/09

DATE OF COMPLETION OF ERECTION & OIL FILLING 21.07.2009 : DETAILS OF EQUIPMENT : i ii iii iv) v) vi vii viii ix x xi xii LOA NO MAKE TYPE RATING SL.NO VOLTAGE CLASS COOLING TYPE YEAR OF : : : : : : : :

C-56301-S919A-3/LOA-II-2129 Dated: 23/08/2006 AREVA : GAPPED CORE 50 MVAR,400 KV B-30225 400 kv ONAN NEUTRAL GROUNDING RESISTER 2007 ( SI.NO : 30230 ) :

TYPE OF NEUTRAL GROUNDING : MANUFACTURE OIL QUANTITY : OIL MAKE & TYPE : FEEDER NAME : 41.8 KL

POWER OIL - PARAFFIN NEYVELI-II

CHECK LIST FOR ELECTRICAL TESTS CARRIED OUT FOR REACTOR

SL. NO. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 NAME OF TEST INSULATION RESISTANCE MEASUREMENT CAPACITANCE & TAN DELTA OF BUSHING CAPACITANCE & TAN DELTA OF WINDING CAPACITANCE & TAN DELTA OF NGR WINDING WINDING RESISTANCE MEASUREMENT WINDING RESISTANCE MEASUREMENT OF NGR MAGNETIZING CURRENT TEST VIBRATION MEASUREMENT INSULATION RESISTANCE MEAS OF BUSHING CT CONTINUITY TEST OF BUSHING CTs SEC WDG RESISTANCE OF BUSHING CTs POLARITY TEST OF BUSHING CTs CONTACT RESISTANCE MEASUREMENT PROTECTION AND ALARM TEST STABILITY TEST OF DIFFERENTIAL & REF PROT. FREQUENCY RESPONSE ANALYSIS PERFORMED YES/ NO YES YES YES YES YES YES YES NO YES YES YES YES YES YES YES YES TEST RESULTS OK/ NOTOK OK OK OK OK OK OK OK NOT OK OK OK OK OK OK OK OK OK

SIGNATURE : NAME : DESIGNATION : ORGANISATION : ( SUPPLIER REPRESENTATIVE ) (WHEREVER APPLICABLE)

SIGNATURE : NAME : DESIGNATION : ORGANISATION : ( ERECTION AGENCY )

SIGNATURE : NAME : DESIGNATION : (POWERGRID SITE I/C)

SIGNATURE : NAME : DESIGNATION : ( POWERGRID COMM TEAM )

PAGE 1 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

3 a

CHECKS AFTER RECEIPT OF REACTOR AT SITE N2 PRESSURE AND DEW POINT RECORD

N2 PRESSURE DURING DISPATCH AT FACTORY AFTER RECEIPT AT SITE DURING STORAGE AT SITE BEFORE COMM. * Please write 'NIL' in case of No Remarks NA 0 2PSI DEW POINT NA NA 0 REMARKS* RECEIVED FROM UDUMALAIPET RECEIVED FROM UDUMALAIPET DRY AIR

NOTE: N2 PRESSURE AND DEW POINT SHOULD BE WITHIN PERMISSIBLE RANGE AS PER GRAPH PROVIDED BY MANUFACTURER AND ALSO GIVEN IN OS DOC NO D-2-03-XX-01-01 REV-01. DURING STORAGE AT SITE, DEW POINT HAS TO BE MEASURED WHENEVER ANY DROP IN N2 PRESSURE IS OBSERVED

IMPACT RECORDER ANALYSIS

RECEIVED IN HEALTHY CONDITION AT SITE ANALYSIS REPORT RECEIVED FROM MANUFACTURER BEFORE CHARGING STATUS YES YES NO REPORT ENCLOSED BRIEF ANALYSIS

Note: Impact Recorder should be detached from the Transformer/ Reactor preferably when the main unit has been placed on its foundation.

CORE INSULATION CHECK

APPLY 1.0 KV DC BETWEEN CL & CC+G INSULATION VALUE >1000 M OHMS >1000 M OHMS >1000MOHMS ( RECOMMENDED VALUE > 10 M Ohms)'

BETWEEN CC-G BETWEEN CL-G BETWEEN CC-CL

Note: SHORTING LINK BETWEEN CC, CL & G TO BE REMOVED AND IR VALUE TO BE TAKEN BETWEEN CC-G, CL-G & CC-CL 4 a b c

CHECKS/ PRECAUTIONS DURING ERECTION

ACTIVE PART OF REACTOR SHOULD MINIMUM EXPOSED TO ATMOSPHERE DURING EXPOSURE OF ACTIVE PART OF REACTOR TO ATMOSPHERE : DRY AIR GENERATOR/ DRY AIR CYLINDERS USED : YES OK NO REMARKS

d e

WHILE ENTERING IN REACTOR TANK, CHECK AVAILABILITY OF PROPER OXYGEN REACTOR KEPT SEALED WITH N2 IN BETWEEN DIFFERENT ERECTION ACTIVITIES - WITH DRY AIR YES OK NO REMARKS

PAGE 2 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

PRE-COMMISSIONING CHECKS: DETAILS :

SL. NO 5.1

DESCRIPTION REACTOR AND ITS AUXILIARIES ARE FREE FROM VISIBLE DEFECTS ON PHYSICAL INSPECTION

STATUS YES YES

NO

REMARK RECORD DEFICIENCIES, IF ANY

5.2

ALL FITTINGS AS PER OUT LINE GENERAL ARRANGEMENT DRAWING . YES

5.3

CHECK MAIN TANK HAS BEEN PROVIDED WITH DOUBLE EARTHING YES YES

5.4

CHECK NEUTRAL IS GROUNDED THROUGH SEPARATE CONNECTIONS. ENSURE METALLIC REQUIREMENTS AS PER SPECIFICATION (e.g. Cu) IN EARTHING STRIPS USED

5.5

CHECK THAT MASHALLING BOX,RADIATOR BANK, PUMP & FAN MOTOR ETC HAS BEEN EARTHED YES

5.6

ALL NUTS AND BOLTS ARE TIGHTENED CORRECTLY AS PER SPECIFIED TORQUE (AS PER MANUFACTURER RECOMMENDATION) YES

5.7 5.8

CHECK TIGHTNESS OF TERMINAL CONNECTORS CHECK LEVELLING OF REACTOR AND ITS ACCESSORIES

YES

YES

5.9

ERECTION COMPLETION CERTIFICATE ALONG WITH LIST OF OUTSTANDING ACTIVITIES REVIEWED YES

5.10

ANY PAINT REMOVED / SCRATCHED IN TRANSIT HAS BEEN TOUCHED UP YES

5.11

BUSHINGS ARE CLEAN AND FREE FROM PHYSICAL DAMAGES YES YES

5.12 5.13

OIL LEVEL IS CORRECT ON ALL BUSHINGS CHECK HERMETICALLLY SEALING IS INTACT IN ALL BUSHINGS

YES

5.14

CHECK OIL LEAKAGE THROUGH ANY JOINTS / VALVES ETC. YES

PAGE 3 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

5.15

CHECK OIL DRAIN VALVES ARE PROPERLY CLOSED AND LOCKED. YES

5.16

CHECK OIL LEVEL IN MAIN TANK AND CONSERVATOR TANK YES

5.17

CHECK OTI AND WTI POCKETS AND REPLENISH THE OIL , IF REQUIRED YES

5.18

CKECK ALL VALVES FOR THEIR OPENING & CLOSING SEQUENCE YES YES

5.19

CHECK THE COLOUR OF BREATHER SILICA GEL ( BLUE WHEN DRY )

5.20

CHECK AVAILABILITY OF OIL IN THE BREATHER CUP YES

5.21

CHECK ALL ROLLERS ARE LOCKED AND TACK WELDED WITH RAILS ( WHEREEVER APPLICABLE ) YES

5.22 5.23

CHECK BUSHING TEST TAP IS GROUNDED CHECK NO DEBRIS , LOOSE T & P AND OIL STRAINS ON AND AROUND THE REACTOR

YES

YES

5.24

CHECK DOOR SEALS OF MARSHALLING BOX IS INTACT AND ALL UNUSED HOLES ARE SEALED YES

5.25

CHECK THAT PRESSURE RELIEF VALVE IS CORRECTLY MOUNTED YES

5.26

ENSURE UNUSED SECONDARY CORES OF BUSHING CT's, IF ANY, HAS BEEN SHORTED YES

5.27

CHECK CT STAR POINT HAS BEEN FORMED PROPERLY AND GROUNDED AT ONE END ONLY AS PER SCHEME YES

5.28

CKECK THAT PERMANENT AND ADEQUATE LIGHITING ARRANGEMENTS ARE READY YES

5.29

CHECK THAT LABELLING AND IDENTIFICATION IS PERMANENT AND SATISFACTORY YES

PAGE 4 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

5.30

CHECK THAT BUCHHOLZ RELAY IS CORRECLY MOUNTED WITH ARROW POINTING TOWARDS CONSERVATOR YES

5.31

CHECK CABLES ARE PROPERLY FIXED AND ENSURE CABLE ENTRY AT THE BOTTOM. YES

5.32

ENSURE ALL POWER AND CONTROL CABLE TERMINALS ARE TIGHTENED YES

5.33

CHECK THAT ALL CABLES ARE CORRECTLY GLANDED YES

5.34

CHECK EXTERNAL CABLING FROM JUNCTIONBOX TO RELAY / CONTROL PANEL COMPLETED YES

5.35

CHECK ALL CABLES AND FERRULS ARE PROVIDED WITH NUMBER AS PER CABLE SCHEDULE (CROSS FERULING TO BE CHECKED) YES

5.36

CHECK THAT AIR HAS BEEN RELEASED FROM THE RADIATORS AND THEIR HEADERS / BUCHHOLZ RELAY / MAIN TANK / BUSHING TURRETS ETC. YES

5.37

CHECK FIRE PROTECTION SYSTEM & EMULSIFIRE SYSTEM IS ADEQUATE & READY YES YES YES

5.38 5.39

CHECK THAT CC, CL & G ARE SHORTED CHECK THAT ALL RADIATOR BANK VALVES ON TOP AND BOTTOM HEADERS ARE OPEN CHANGE OVER OPERATION OF AC SUPPLY FROM SOURCE-1 TO SOURCE-2 CHECKED CHECK VARIOUS INTERLOCKS PROVIDED WITH FIRE FIGHTING AS PER THE SCHEMATIC REF. DRG NO : NAME OF INTERLOCKS NA NA NA CHECKED

5.40

YES

5.41

MASS/405/E2

MEASUREMENT OF EARTH RESISTANCE OF ELECTRODE

LOCATION VALUE (BEFORE CONNECTION TO GRID) VALUE (AFTER CONNECTION TO GRID) NOTE: VALUE OF EARTH RESISTANCE < 1,0 OHM FOR NEU REAC 6.7 0.13 FOR NGR REAC 5.6 0.32

CALIBRATION OF OTI AND WTI DONE AS PER PROCEDURE

YES

PAGE 5 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

DETAILS OF RELAYS/ CONTACTORS USED: SCHEMATIC DRAWING NO.:

CIRCUIT REFERENCE YN1M300959-CDA MAKE ABB-RET 670 ABB-RET 670 ABB-REL 670 SERIAL NO. T0754174/DIFF T0754170/REF T0754166/B/U TYPE NUMERICAL NUMERICAL NUMERICAL NO+NC CHECKED CHECKED CHECKED

9 9.1

EVACUATING AND OIL FILLING

BEFORE FILLING OIL, EACH DRUM IS PHYSICALLY CHECKED FOR FREE MOISTURE & APPEARANCE YES

9.2 a b c d e f

OIL FILTER MACHINE :

CAPACITY MAKE LUBRICATING OIL OF VACUUM PUMP CHANGED OR NOT FILTER PACKS CLEANED OR NOT WHOLE FILTER MACHINE FLUSHED WITH FRESH OIL OR NOT VACUUM OBTAINED WITHOUT LOAD (milli bar) : : : : 6 KL UDAY FILTERS NEW MACHINE NEW MACHINE FLUSHED 1 MILLI BAR

9.3 a b c d 9.4 a b c d e 9.5 a) b) c) d) e) f) g) 9.6 a) b) c) d)

VACUUM PUMP FOR EVACUATION OF REACTOR :

LUBRICATING OIL CHANGED OR NOT VACUUM OBTAINED WITHOUT LOAD (milli bar) DIAMETER OF VACUUM HOSE (50 mm) DRY ICE CHAMBER EMPLOYED OR NOT : : : : PROVIDED IN FILTER M/C

OIL STORAGE TANK :

INSIDE PAINTED OR NOT SILICA GEL BREATHER PROVIDED OR NOT ANY OPENING LEFT UNCOVERED CAPACITY & QUANTITY CLEANLINESS OF INSIDE OF PIPES/ HOSES TO THE STORAGE TANK : : : : : PAINTED PROVIDED NO 15 KL OK

EXPOSURE DURING ERECTION

First day Second day Third Day N2 pressure applied after each days erection work Ambient Temperature Average Relative Humidity Weather Condition Hrs Hrs Hrs PSI DegC rainy/ stormy/ cloudy/sunny 8 HOURS NIL NIL OF 2 PSI C38 DRY DRY EMPLOYED

N2 SEALING IN CASE OF DELAY IN OIL FILLING

No. of Cylinders used for displacing the air inside the tank N2 admitted from bottom valave Valve at diametriccaly opposite end at top kept open No. of Cylinders used for building up 2 PSI

PAGE 6 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

INSPECTION ACTIONS I. a. TIGHTNESS TEST START EVACUATING ON COMPLETE UNIT AT 0.3 kPa (3 mbar)

DATE 09.07.2009 09.07.2009 3 MILLI BAR 3 MILLI BAR 3 MILLI BAR 3 MILLI BAR 0 35 CU MTR 10.07.2009 1.3 m bar

TIME 09.00 HRS 15.00HRS

CHECKED

REMARKS

b. STOP EVACUATING c. PRESSURE P1 ..... kPa

1 HOUR AFTER STOP EVACUATING d. PRESSURE P2 ..... kPa 0.5 HOUR AFTER READING PREASURE P1 e. LEAKAGE = (P2-P1)xV=.... V=OIL VOL OF REACTOR IN Cu mtr IF LEAKAGE >3.6, CONTINUE EVACUATING 2 b. VACCUM VACUUM IS KEPT FOR

10.00HRS

a. PRESSURE 0.13 kPa (1,3 mbar) REACHED Upto 145 KV , 12 HRS 145 & upto 420 KV, 24 HRS Above 420 KV, 36 HRS 3 a. OIL FILLING oil filling is made oil coservator with air cell 5. DIVERTER SWITCH HOUSING diverter switch housing filled and has an air cushion 6. STANDING TIME Upto 145 KV , 12 HRS 145 & upto 420 KV, 48 HRS Above 420 KV, 120 HRS 9.7

24 hrs

15.07.2009 21.07.2009

9.00HRS 11.00HRS

4. OIL CONSERVATOR

RECORD OF DRYING OUT PROCESS (IF CARRIED OUT)

DRYING OUT STARTED ON AMBIENT TEMP : (HOURLY READING TO BE TAKEN) DATE TIME VAC IN FILT. M/C VAC IN RE. TANK OTI OF MAIN TANK CONDENSATE COLLECTED TOTAL/ RATE REMARKS & SIGN OF MTC ENGINEER DATE : TIME :

NA

RECORD OF FILTRATION AND DRY OUT SHALL BE KEPT IN A REGISTER AND SHALL BE MADE A PART OF THE PRE-COMMISSIONING DOCUMENT

PAGE 7 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

10

a SL.NO A B

INSULATION RESISTANCE MEASUREMENT :

DESCRIPTION CONTROL WIRING COOLING SYSTEM a) MOTOR FAN b) MOTOR PUMP c) CONTROL WIRING STATUS YES

(USING 500 V MEGGER)

REMARK, IF ANY NO

NA

b MAIN WINDING

INSULATION RESISTANCE MEASUREMENT :

IR VALUE TIME IN SECONDS 15 HV - EARTH NGR WINDING 60 600

(USING 5000 V MEGGER)

DIELECTRIC ABSORPT. INDEX (60S/ 15S) TEMPERA TURE IN

C

DETAILS OF TEST KIT: MAKE:KYORITSU , SI.NO :W0165016 , RANGE : 500-5000V , CALI DUE DATE : 29.01.2010 POLARIZATION INDEX (600S/ 60S)

2.52G 25.1G

4.6G 31.9G

12.24G 72.9G

1.83

1.27

2.65

2.26

39 39

11 a

MEASUREMENT OF WINDING RESISTANCE (IN OHM)

WINDING RESISTANCE OF REACTOR WINDING TESTING INSTRUMENT DETAILS TESTING EQUIPMENT CALIBRATION VALID OR NOT AMBIENT TEMPERATURE AT THE TIME OF TEST TEMPERATURE OF OIL WINDING RESISTANCE R-PHASE Y-PHASE B-PHASE 3.843 3.84 3.844 RESISTANCE R 4.469 AT 75 DEG C B 4.377 : Transformer winding resistance meter : Valid upto 05-11-2009 : 38 C : 37 C All Values in ohms FACTORY VALUE R Y B 3.7618 3.7578 3.7604

Y 4.366

WINDING RESISTANCE OF NGR WINDING WINDING RESISTANCE 4.752 RESISTANCE AT 75 DEG C 5.403 All Values in ohms FACTORY VALUE 4.704

12

MAGNETISATION CURRENT TEST

TESTING INSTRUMENT DETAILS TESTING EQUIPMENT CALIBRATION VALID OR NOT AMBIENT TEMPERATURE AT THE TIME OF TEST TEMPERATURE OF OIL VOLTAGE APPLIED R-N Y-N B-N NGR 235.9 CURRENT MEASURED R - PH Y - PH m AMPS 69.5mA m AMPS69.9mA m AMPS69.6mA REMARK :CLAMP METER : VALID UPTO 23-10-2009 :39 C :39 C

236.1

236.3 B - PH 236.1

V

400mA

PAGE 8 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

13

OIL CHARACTERISTICS

(SAMPLE TO BE TAKEN PRIOR TO CHARGING OF REACTOR AND IT SHOULD FULFILL THE RECOMMENDATIONS AS PER IS 1866 ) B.D.V MOISTURE TAN DELTA RESISTIVITY INTERFACIAL OIL ( MIN ) ( MAX ) ( MAX ) ( MIN ) TENSION AT 27 DEG. SAMPLE (KV) (PPM) (90 Deg C) (OHM-CM) ( MIN ) N/m 12 IS-1866 60 10 0.01 6 X 10 O,O35 12 IS-1866 50 15 0.015 6 x 10 O,O35 12 IS-1866 40 20 0.015 6 x 10 O,O35 12 MAIN TANK 72 10 0.001 146 x 10 NA NGR 74 NA NA NA NA The limiting values given in the above table to be revised as per revision in IS 1866 in future REMARKS FOR kV CLASS > 170 Kv < 170 Kv BUT > 72.5 kV < 72.5 kV SAMP. DATE : 21.07.2009 SAMP. DATE :21.07.2009

14

DISSOLVE

DISSOLVED GASES TOTAL GAS (%) H2 CH4 C2H4 C2H6 C2H2 CO CO2 O2 N2

GAS

ANALYSIS

7 DAYS AFTER CHARGING 15 DAYS AFTER CHARGING 01 MONTH AFTER CHARGING 03 MONTH AFTER CHARGING

OIL SAMPLE JUST 24 HRS BEFORE AFTER CHARGING CHARGING

REMARKS IF ANY

NA

NA NA

15

INSULATION RESISTANCE MEASUREMENT OF BUSHING CT's

DETAILS OF TEST KIT: MAKE:KYORITSU , SI.NO :W0165016 , RANGE : 500-5000V , CALI DUE DATE : 29.01.2010 a BETWEEN R -PHASE EARTH - CORE I EARTH - CORE II EARTH - CORE III EARTH - CORE IV b BETWEEN R -PHASE CORE I - CORE II CORE I - CORE III CORE I - CORE IV CORE II - CORE III CORE II - CORE IV CORE III - CORE IV >2000 >2000 >2000 >2000 >2000 >2000 >2000 >2000 >2000 >2000 HV Y -PHASE >2000 >2000 >2000 >2000 HV Y -PHASE >2000 >2000 >2000 >2000 >2000 >2000 NEUTRAL B -PHASE >2000 >2000 >2000 >2000 B -PHASE >2000 >2000 >2000 >2000 >2000 >2000 USING 500 V MEGGER MOHM MOHM MOHM MOHM MOHM MOHM MOHM

( USING 500 V MEGGER)

1000

MOHM MOHM MOHM

PAGE 9 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

16

CONTINUTY TEST OF BUSHING CT's

CORE CORE I CORE II CORE III CORE IV CONTINUTY, CHECK BETWEEN TERMINALS BETWEEN LV TERMINAL R-PHASE Y -PHASE 1S1 - 1S2 2S1 - 2S2 3S1 - 3S2 4S1 - 4S2 : OK / NOT OK NEUTRAL B -PHASE

OK OK OK OK

OK OK OK OK

OK OK OK OK

OK

17 a

SECONDARY WINDING RESISTANCE OF BUSHING CT's (IN OHM)

DETAILS OF TEST : MAKE KIT: :RISH ,RANGE:1000V SI.NO: 001220 HIGH VOLTAGE SIDE CORE BETWEEN R -PHASE TERMINAL FACTORY SITE CORE I CORE II CORE III CORE IV b 1S1 - 1S2 2S1 - 2S2 3S1 - 3S2 4S1 - 4S2 NA NA NA NA 0.8 0.8 0.8 0.4 CALIBRATION DUE DATE: Y -PHASE FACTORY NA NA NA NA 09/03/2010 B -PHASE FACTORY NA NA NA NA

SITE 0.9 0.9 0.9 0.4

SITE 0.8 0.8 0.8 0.4

NEUTRAL SIDE CORE BETWEEN TERMINAL CORE I 1S1 - 1S2

NEUTRAL FACTORY NA

SITE 0.55 WITH 1.5 V DC SUPPLY (CONNECT +VE AT P1 AND - VE AT P2 ) HV R -PHASE Y -PHASE B -PHASE

18

POLARITY TEST OF BUSHING CT's

CORE CORE I CORE II CORE III CORE IV BETWEEN 1S1 (+VE) 2S1 (+VE) 3S1 (+VE) 4S1 (+VE) 1S2 (-VE) 2S2 (-VE) 3S2(-VE) 4S2 (-VE)

NEUTRAL

OK OK OK OK

OK OK OK OK

OK OK OK OK

OK

19

CURRENT RATIO TEST

PRIMARY INJECTION THROUGH PRIMARY INJECTION KIT AT PRIMARY TERMINAL P1 - P2 MEASURE CURRENT ON THE SECONDARY TERMINALS a HIGH VOLTAGE CORE PRIMARY S1 - S2 % CORE I (1S1 - 1S2) CORE II (2S1 - 2S2) CORE III (3S1 - 3S2) CORE IV (4S1 - 4S2) 50% 100% 50% 100% 50% 100% 50% 100% R - PHASE CURRENT ACTUAL 100 200 100 200 100 200 100 200

SECONDARY CURRENT 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1

THEORETICAL RATIO 0.5 1 0.5 1 0.5 1 0.5 1

ACTUAL RATIO 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1

% OF ERROR 2 2 2 2 2 2 0 0

PAGE 10 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

Y - PHASE CORE I (1S1 - 1S2) CORE II (2S1 - 2S2) CORE III (3S1 - 3S2) CORE IV (4S1 - 4S2) 50% 100% 50% 100% 50% 100% 50% 100% 100 200 100 200 100 200 100 200 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1 2 2 2 2 2 2 0 0

B - PHASE CORE I (1S1 - 1S2) CORE II (2S1 - 2S2) CORE III (3S1 - 3S2) CORE IV (4S1 - 4S2) 50% 100% 50% 100% 50% 100% 50% 100% 100 200 100 200 100 200 100 200 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1.02 0.5 1 0.5 1 0.5 1 0.5 1 0.49 0.98 0.49 0.98 0.49 0.98 0.5 1.02 2 2 2 2 2 2 0 -2

20

MAGNETISING

CURVES

PERFORMANCE

CALIBRATION DUE DATE: 19/02/2010

DETAILS OF TEST MAKE:LUTRON KIT: SL.NO:E 69550 (NOT TO BE DONE FOR METERING CORE) KNEE POINT VOLTAGE (KVp) = 200 VOLT a R - PHASE VOLTAGE TO BE APPLIED O.50 X KVp O.75 X KVp 1.O0 X KVp ACTUAL VALUE 100 150 200 CORE - I 1S1-1S2 49.5 66 83 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 48.3 60.2 78.2 CORE - III 3S1 - 3S2 50.2 66.8 81

HV SIDE CORE - IV 4S1 - 4S2 NA NA NA mA mA mA

PAGE 11 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

Y - PHASE VOLTAGE TO BE APPLIED O.50 X KVp O.75 X KVp 1.O0 X KVp ACTUAL VALUE 100 150 200 CORE - I 1S1-1S2 53.9 70.1 84.9 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 55.1 73 88.1 CORE - III 3S1 - 3S2 55.7 72.9 88.6 CORE - IV 4S1 - 4S2 NA NA NA mA mA mA NEUTRAL BUSHING 48.3 66.6 88.7

B - PHASE VOLTAGE TO BE APPLIED O.50 X KVp O.75 X KVp 1.O0 X KVp ACTUAL VALUE 100 150 200 CORE - I 1S1-1S2 53.1 68.4 83.5 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 52.4 68.6 83.1 CORE - III 3S1 - 3S2 53.7 69.5 84.8 CORE - IV 4S1 - 4S2 NA NA NA mA mA mA

NOTE : 1.0 CT SHOULD NOT SATURATE AT 110 % OF KNEEPOINT VOLTAGE ( KVp ) 2.0 IF KNEEPOINT VOLTAGE IS NOT MENTIONED THEN KNEE POINT CURRENT MAY BE TAKEN INTO CONSIDERATION 21

CONTACT RESISTANCE MEASUREMENT

CONTACT RESISTANCE ACROSS HV BUSHING TERMINAL JOINT ACROSS NEUTRAL BUSHING TERMINAL JOINT NGR TERMINAL CONNECTOR R-PHASE 4.25

AT 100 AMPS Y-PHASE 10.03 9.36 8.89 B-PHASE 6.62 MICRO OHM MICRO OHM

NOTE: THE VALUE OF CONTACT RESISTANCE SHOULD NOT BE MORE THAN 10 MICRO OHMS PER JOINT/ CONNECTOR 22

BUSHING DETAILS

DETAILS MAKE TYPE SL.NO R-PHASE AREVA NA 807358 Y-PHASE AREVA NA 807357 B-PHASE AREVA NA 805253 NEUTRAL AREVA NA 802233

PAGE 12 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

23

MAGNETISING CURVES NEUTRAL SIDE

PERFORMANCE

CALIBRATION DUE DATE: 19/02/2010

DETAILS OF TEST MAKE:LUTRON KIT: SL.NO:E 69550 (NOT TO BE DONE FOR METERING CORE) KNEE POINT VOLTAGE (KVp) = 200 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp R - PHASE ACTUAL VALUE 50 100 150 200 220 CORE - I 1S1-1S2 28.9 47.6 62.5 79.8 86.6 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 28.3 46.7 62 77.1 83.6 CORE - III 3S1 - 3S2 29.6 48.3 64.3 80.5 87.3

HV SIDE CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA

KNEE POINT VOLTAGE (KVp) = 250 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp Y - PHASE KNEE POINT VOLTAGE (KVp) = 250 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp B - PHASE KNEE POINT VOLTAGE (KVp) = 250 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp ACTUAL VALUE 62.5 125 187.5 250 275 CORE - I 1S1-1S2 13.7 23.6 34.1 47.1 51.7 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 14.5 24.8 40.3 47.8 49 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 62.5 125 187.5 250 275 CORE - I 1S1-1S2 14.6 24.9 33.5 46.8 54.9 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 22.7 35.4 46.7 64.1 80.5 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 62.5 125 187.5 250 275 CORE - I 1S1-1S2 19.5 30.5 41.5 52.6 63.5 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 17.6 27.6 36.1 45.7 54.5 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA

PAGE 13 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

R - PHASE KNEE POINT VOLTAGE (KVp) = 500 VOLTS VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp Y - PHASE KNEE POINT VOLTAGE (KVp) = 500 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp B - PHASE KNEE POINT VOLTAGE (KVp) =500 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp R - PHASE KNEE POINT VOLTAGE (KVp) =1000 VOLTS VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp Y - PHASE KNEE POINT VOLTAGE (KVp) = 1000 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp B - PHASE KNEE POINT VOLTAGE (KVp) = 1000 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp ACTUAL VALUE 250 500 750 1000 1100 CORE - I 1S1-1S2 3.7 6.4 9.4 12.2 14.7 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 3.7 6.1 8.5 10.9 13.9 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 250 500 750 1000 1100 CORE - I 1S1-1S2 3.5 5.8 8.2 11.5 14.5 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 6 8.9 12 16.9 20.9 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 250 500 750 1000 1100 CORE - I 1S1-1S2 4.5 7 9.4 13.1 16 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 4 6.2 8.3 11.2 13.2 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 125 250 375 500 550 CORE - I 1S1-1S2 7.1 11.5 16.6 22.2 26.1 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 8 12.9 16.9 21.7 25.7 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 125 250 375 500 550 CORE - I 1S1-1S2 6.9 12 16.4 22.8 28.3 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 11.4 17.3 22.5 29.7 36.8 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA ACTUAL VALUE 125 250 375 500 550 CORE - I 1S1-1S2 9 14 19.5 25.6 31 CURRENT MEASUREMENT CORE - II 2S1 - 2S2 8 12.5 16.5 22.1 25.6 CORE - III 3S1 - 3S2 NA NA NA NA NA CORE - IV 4S1 - 4S2 NA NA NA NA NA mA mA mA mA mA

PAGE 14 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

SECONDARY WINDING RESISTANCE OF NEUTRAL SIDE CT's (IN OHM)

a DETAILS OF TEST : MAKE KIT: :RISH SI.NO: 001220 HIGH VOLTAGE SIDE CORE BETWEEN R -PHASE TERMINAL FACTORY SITE CORE I CORE II CORE III 1S1 - 1S2 2S1 - 2S2 3S1 - 3S2 3S1 - 3S3 3S1 - 3S4 CORE IV 4S1 - 4S2 4S1 - 4S3 4S1 - 4S4 NA NA NA NA NA NA NA NA 1.1 NA 1.9 3.5 6.8 1.9 3.7 7.2 CALIBRATION DUE DATE: Y -PHASE FACTORY NA NA NA NA NA NA NA NA 09/03/2010 B -PHASE FACTORY 1.1 NA NA NA NA NA NA NA

SITE 1.1 0.5 2 3.6 7.2 1.9 3.5 7.5

SITE 0.88 NA 2.1 3.6 7.3 1.9 3.8 7 OHM OHM OHM OHM OHM OHM OHM OHM

INSULATION RESISTANCE MEASUREMENT OF NEUTRAL SIDE CT's

BETWEEN R -PHASE EARTH - CORE I EARTH - CORE II EARTH - CORE III EARTH - CORE IV CORE I - CORE II CORE I - CORE III CORE I - CORE IV CORE II - CORE III CORE II - CORE IV CORE III - CORE IV HV Y -PHASE B -PHASE

( USING 500 V MEGGER)

1000 NA 1000 1000 1000 1000 1000 NA NA 1000

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

1000 NA 1000 1000 1000 1000 1000 NA NA 1000

MOHM MOHM MOHM MOHM MOHM MOHM MOHM MOHM MOHM MOHM ( USING 500 V MEGGER)

INSULATION RESISTANCE MEASUREMENT OFNGR CT'S

BETWEEN EARTH - CORE I HS1 TO HS2 EARTH - CORE II GS1 TO GS2 NEUTRAL

1000

MOHM

1000

MOHM

WINDING RESISTANCE MEASUREMENT OFNGR CT'S

BETWEEN EARTH - CORE I HS1 TO HS2 EARTH - CORE II GS1 TO GS2 NEUTRAL

0.7

OHM

0.65

OHM

CURRENT RATIO TEST -NGR

MEASURE CURRENT ON THE SECONDARY TERMINALS HIGH VOLTAGE CORE PRIMARY S1 - S2 CORE I HS1 TO HS2 % 20 % 40 % 80 % R - PHASE CURRENT ACTUAL 40 80 160

SECONDARY CURRENT 0.204 0.402 0.801

THEORETICAL RATIO 0.2 0.4 0.8

ACTUAL RATIO 0.204 0.402 0.801

% OF ERROR -2 -0.5 -0.125

MAGNETISING NGR SIDE

CURVES

PERFORMANCE

KNEE POINT VOLTAGE (KVp) = 200 VOLT VOLTAGE TO BE APPLIED O.25 X KVp O.50 X KVp O.75 X KVp 1.O0 X KVp 1.10 X KVp ACTUAL VALUE 50 100 150 200 220 CURRENT MEASUREMENT CORE - I HS1-HS2 28.9 48.2 67.8 87.6 132.7 CORE - II GS1-GS2 18.1 33.5 53.5 79.1 91.4 mA mA mA mA mA

PAGE 15 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

24

TAN DELTA AND CAPACITANCE MEASUREMENT OF BUSHING

CAPACITANCE VOLTAGE SITE 2 KV 10 KV 404.7pf 404.7pf R PHASE FACTORY NA NA SITE 400.3pf 400.2pf Y PHASE FACTORY NA NA SITE 406.7pf 406.7pf ( MEASURED VALUE ) B PHASE FACTORY NA NA NEUTRAL SITE 283.2pf 283.2pf

REMARKS : FIT FOR COMMISSIONING

TAN DELTA VOLTAGE SITE 2 KV 10 KV 0.00391 0.00381 R PHASE FACTORY NA NA SITE 0.0039 0.00383 Y PHASE FACTORY NA NA

( MEASURED VALUE ) B SITE 0.00377 0.00369 PHASE FACTORY NA NA NEUTRAL SITE 0.00411 0.00405

MEASUREMENT OF C1 TAN DELTA

REMARKS : FIT FOR COMMISSIONING

FACTORY TEST REPORT REF NO : 25

TAN DELTA AND CAPACITANCE MEASUREMENT OF WINDING

HIGH VOLTAGE SIDE VOLTAGE 2 KV 10 KV REMARKS : FIT FOR COMMISSIONING BETWEEN HV / TANK+E CAPACITANCE SITE 8.732 8.72 FACTORY NA NA TAN DELTA SITE 0.00393 0.00376 FACTORY NA NA REMARK

FACTORY TEST REPORT REF NO :

PAGE 16 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

25 A

TAN DELTA AND CAPACITANCE MEASUREMENT OF NGR WINDING

HIGH VOLTAGE SIDE VOLTAGE 2 KV 10 KV REMARKS : BETWEEN HV / TANK+E CAPACITANCE SITE 956.1 956 TAN DELTA SITE 0.00375 0.00344 REMARK FACTORY NA NA

FACTORY NA NA

FACTORY TEST REPORT REF NO :

NA

26

TAN DELTA AND CAPACITANCE MEASUREMENT OF NGR BUSHING

VOLTAGE 2 KV 10 KV VOLTAGE 2 KV 10 KV TAN DELTA (MEASURED VALUE) SITE FACTORY 0.00322 NA 0.00314 NA CAPACITANCE (MEASURED VALUE) SITE FACTORY 243.8 NA 243.8 NA FACTORY TEST REPORT REF NO :

27

VIBRATION MEASUREMENT TEST

VIBRATION MEASUREMENTS ARE TO BE CARRIED OUT AFTER ENERGIZATION OF THE REACTOR. THIS WILL BE A REFERENCE DATA FOR FUTURE MEASUREMENTS. VARIOUS LOCATIONS ARE TO BE SHOWN IN THE DIAGRAM WITH X,Y CO-ORDINATES FOR EASY IDENTIFICATION. SIDE PLAN SIDE

HIGH VOLTAGE SIDE

C

NEUTRAL SIDE SIDE

B D

HIGH VOLTAGE SIDE

SIDE

NEUTRAL SIDE

SIDE

PAGE 17 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

SL. NO

DATE OF MEASUREMENT

LOCATION

VALUE

REMARKS

28

PROTECTION

SL NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 NOTE :

AND

ALARMS

SET FOR ALARM 90 85 NA NA YES YES NA YES YES NA YES YES YES NA NA NA NA NA NA TRIP 105 95 YES YES YES YES NA NA NA NA YES YES YES YES YES YES YES NA NA PROVED ALARM 90 85 NA NA YES YES NA YES YES NA YES YES YES NA NA NA NA NA NA YES OK

DEVICE EXCESSIVE WINDING TEMPERATURE. EXCESSIVE OIL TEMPERATURE. PRESSURE PRESSURE RELIEF RELIEF VALVE (MAIN TANK ) VALVE ( NGR )

MAIN TANK BUCHHOLZ RELAY NGR BUCHHOLZ RELAY FAN FAILURE LOW OIL LEVEL ( MAIN TANK ) LOW OIL LEVEL ( NGR ) HIGH OIL LEVEL ( MAIN TANK ) OTI ( MAIN TANK ) OTI ( NGR ) WTI ( MAIN TANK ) DIFFERENTIAL BACKUP IMPEDENCE RELAY EARTH FAULT RELAY ( REF ) INTER TRIP , IF ANY TRIP FREE CHECK TEED PROTECTION PROTECTION SETTINGS APPLIED AS PER ENGG. APPROVED SETTINGS STABILITY TEST OF DIFFERENTIAL & REF PROTECTION

PROVE THE TRIPPING OF ASSOCIATED BREAKERS BY ACTUAL OPERATION OF THE VARIOUS DEVICES AND RELAYS AS PER THE SCHEMES.

PAGE 18 OF 16

SHUNT REACTOR

POWER GRID CORPORATION OF INDIA LIMITED CORPORATE OPERATION SERVICES

PRE-COMMISSIONING OF REACTOR COMMISSIONING FORMATS

DOC NO. : SUB STATION :

MR/CF/SR/07/R-2 DATED : 31/12/07 KARUR SS

BAY NO : 415R EQUIPMENT IDENTIFICATION NO : DATE OF TESTING 23/07/09 :

29 a b c d

FREQUENCY RESPONSE ANALYSIS (FRA)

CARRIED OUT AFTER COMPLETION OF ALL COMMISSIONING ACTIVITIES INTERPRETATION OF TEST RESULTS CARRIED OUT TEST RESULTS MATCHING WITH THE FACTORY RESULTS FACTORY & SITE FRA TEST REPORT AVAILABLE AT SITE YES YES YES YES

30

ALL ELECTRICAL TEST RESULTS COMPARED WITH FACTORY TEST RESULTS AND FOUND TO BE IN ORDER

YES

31

CHECKS AFTER CHARGING OF REACTOR

RECORD THE FOLLOWING AFTER CHARGING a b ANY ABNORMAL SOUND EMANATING FROM THE REACTOR: REACTOR CURENT AT RELAY TERMINAL R PHASE Y PHASE B PHASE c 0.345A 0.345A 0.345A YES

CT RATIO:200/1

TEMPERATURE (AT THE TIME OF CHARGING) OTI WTI AMBIENT

34C 34C 34C C

YES

d e

MAXIMUM TEMPERATURE AFTER 24 HOURS THERMOVISION SCANNING DONE ATLEAST AFTER 24 HOURS OF LOADING AND REPEATED AFTER ONE WEEK

32 a b

FINAL DOCUMENTATION REVIEW

FACTORY TEST RESULTS ARE AVAILABLE FINAL DOCUMENT OF PRE-COMMISSIONING CHECKS REVIEWED AND APPROVED DOCUMENTS REGARDING SPARES, EQUIPMENT, O & M MANNUALS ETC AVAILABLE AT SITE FOR O & M PURPOSE AFTER MODIFICATION, IF ANY, "AS BUILT DRAWINGS" ARE AVAILABLE AT SITE YES

YES

YES

YES

SIGNATURE : NAME : DESIGNATION : ORGANISATION : ( SUPPLIER REPRESENTATIVE ) (WHEREVER APPLICABLE)

SIGNATURE : NAME : DESIGNATION : ORGANISATION : ( ERECTION AGENCY )

SIGNATURE : NAME : DESIGNATION : (POWERGRID SITE I/C)

SIGNATURE : NAME : DESIGNATION : ( POWERGRID COMM TEAM )

PAGE 19 OF 16

SHUNT REACTOR

Vous aimerez peut-être aussi

- Request Letter: Sub:Requesting Experience Certificate For Applying BOE ExamDocument3 pagesRequest Letter: Sub:Requesting Experience Certificate For Applying BOE ExammaheshPas encore d'évaluation

- Tsi Sap FormatDocument6 pagesTsi Sap FormatmaheshPas encore d'évaluation

- Turbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylinderDocument5 pagesTurbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylindermaheshPas encore d'évaluation

- 415 V Bus ChargingDocument3 pages415 V Bus ChargingmaheshPas encore d'évaluation

- Rack Interface Module 3500 20SDocument71 pagesRack Interface Module 3500 20SmaheshPas encore d'évaluation

- Elect. Drag - GA132 DolDocument5 pagesElect. Drag - GA132 DolmaheshPas encore d'évaluation

- RCS-974AG UHV Tranfomrer Protection Communication Protocol: Nari-Relays 通信规规规明Document10 pagesRCS-974AG UHV Tranfomrer Protection Communication Protocol: Nari-Relays 通信规规规明maheshPas encore d'évaluation

- 7ut613 DiffDocument2 pages7ut613 DiffmaheshPas encore d'évaluation

- Voltage Regulation CalculationDocument135 pagesVoltage Regulation Calculationmahesh75% (12)

- Sagardighi WBPDCL Extn Interlocks NRDocument1 pageSagardighi WBPDCL Extn Interlocks NRmaheshPas encore d'évaluation

- Trans Diff TestlDocument3 pagesTrans Diff TestlmaheshPas encore d'évaluation

- RetDocument12 pagesRetmahesh100% (1)

- 16a - Protection in Breaker and Half SystemDocument37 pages16a - Protection in Breaker and Half SystemmaheshPas encore d'évaluation

- Relay Setting Chart - CRP Panel - Shambhu - REVBDocument21 pagesRelay Setting Chart - CRP Panel - Shambhu - REVBmahesh100% (1)

- 08 Distance Calculation SheetDocument6 pages08 Distance Calculation Sheetmahesh100% (2)

- Time Curve CalculationDocument1 pageTime Curve CalculationmaheshPas encore d'évaluation

- TFR Cal DiffDocument5 pagesTFR Cal Diffbusstation100% (1)

- REF Stabilizing Resistor CalculationsDocument8 pagesREF Stabilizing Resistor CalculationsmaheshPas encore d'évaluation

- Setting Calculation For Distance Protection SchemeDocument6 pagesSetting Calculation For Distance Protection SchememaheshPas encore d'évaluation

- Max Efficiency % Loss 1.06 0.0106 Loss in MVA 0.424 Loss in MW 1 0.424 Loss in KWDocument1 pageMax Efficiency % Loss 1.06 0.0106 Loss in MVA 0.424 Loss in MW 1 0.424 Loss in KWmaheshPas encore d'évaluation

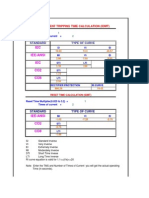

- Over Current Tripping Time Calculation (Idmt) : Type of Curve StandardDocument2 pagesOver Current Tripping Time Calculation (Idmt) : Type of Curve StandardmaheshPas encore d'évaluation

- Summation of L1 + L2 + L3: Complex Summation of 3 Vectors V1.0 - M.E. ABBDocument3 pagesSummation of L1 + L2 + L3: Complex Summation of 3 Vectors V1.0 - M.E. ABBmaheshPas encore d'évaluation

- Biased Differential Relay Operation: Average Current As % of Rated CurrentDocument2 pagesBiased Differential Relay Operation: Average Current As % of Rated CurrentmaheshPas encore d'évaluation

- ZFB CalculationDocument13 pagesZFB CalculationmaheshPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)