Académique Documents

Professionnel Documents

Culture Documents

CFBC Datasheets

Transféré par

animesh907Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CFBC Datasheets

Transféré par

animesh907Droits d'auteur :

Formats disponibles

passion to excel

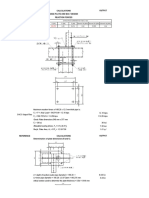

LOW CEMENT CASTABLES FOR CFBC BOILER

PARTICULARS

REFCAST LC 45

REFCAST LC 50

REFCAST LC 60

REFCAST LC 80

REFCAST LC 90

SERVICE TEMP OC (MAX)

GRAIN SIZE,MM (MAX)

1550

1550

1600

1700

1700

WATER REQUIRED TO MIX (%)

4 to 5

4 to 5

4.5 to 5.0

4 to 5

4 to 5

0.5

0.5

0.6

0.75

0.85

2.3

2.3

2.6

2.9

200

200

200

250

250

GENERAL PROPERTIES

REVERSIBLE THERMAL EXPANSION

PHYSICAL PROPERTIES

BULK DENSITY (GM/CC) (DRIED AT 110 OC)(MIN)

2

COLD CRUSHING STRENGTH (KGF/CM )

1 DAY

O

110 C

750

750

800

870

1000

950

950

950

1100

1150

1100

1100

1100

1300

1300

110 OC

100

100

120

130

140

1100 OC

125

125

150

180

200

165

165

170

250

270

1717

1717

1804

1820

1820

1100 C

1500 C

MOR, KG/CM2

1500 C

THERMAL PROPERTIES

REFRACTORIES OC

PERMENANENT LINEAR CHANGE(%)(MAX)

800 OC

0.20

0.20

0.20

0.20

0.20

1100 OC

0.30

0.30

0.30

0.30

0.30

1.00

1.00

0.50

0.80

0.80

400O F/3 HRS

0.84

0.84

0.95

1.65

2.2

600O F/3 HRS

1.05

1.05

1.1

1.75

2.3

1.16

1.16

1.2

1.8

2.35

45

50

60

80

90

1.5

1.5

1.8

1.8

1500 OC

THERMAL CONDUCTIVITY(KCAL/HR/M/OC

800O F/3 HRS

CHEMICAL PROPERTIES (%)

AL2O3 (MIN)

FE2O3(MAX)

APPLICATION GUIDELINES

MIXER

PLACEMENT

20+5

20+5

20+5

20+5

20+5

2/5.

2/5.

2/5.

2/5.

2/5.

WATER/MIX TEMPERATURE OC

MIXING TIME (MIN):DRY/WET

PLASTIC REFRACTORIES FOR CFBC BOILER

PARTICULARS

PLASCRETE 60 D

PLASCRETE 80 D

PLASCRETE 90 D

1500

1600

1700

2.4

2.6

2.7

@ 110OC / 24 HRS

300

400

400

@ 1100C / 3 HRS

500

700

900

@ 110OC / 24 HRS

50

80

80

@ 1100C / 3 HRS

80

120

160

@ 110OC / 24 HRS

0.5

0.5

0.5

@ 1100C / 3 HRS

1.0

1.0

1.0

AL2O2 (MIN)

60

80

90

FE2O3 (MAX)

1.5

1.5

10 - 11

9 - 10

8-9

SERVICE TEMPERATURE (OC) (MAX)

BULK DENSITY AT 110OC (GM/CC) (MIN)

2

COLD CRUSHING STRENGHT (KGF/CM ) (MIN)

MOR (KG/CM ) (MIN)

PERMANENT LINEAR CHANGE (%)

HOT ABRASION AT 1100OC (CC) (MAX)

CHEMICAL ANALYSIS (%)

MAXIMUM GRAIN SIZE (MM)

RECOMMENDED BINDER ADDITION BY LITER (%)

Note:

1. We shall supply in two components namely in powder form and liquid form. The two components are to be mixed in the recommended proportion in a sand

mixer and rammed by pneumatic tools.

2. Above are average test data subject to reasonable variation.

3. Tested as per BIS: 10570-1983 & ASTM Standards.

VELCRETE FOR CFBC BOILER

PARTICULARS

VELCRETE 80 SPL

VELCRETE 002

VELCRETE 005

1750

1650

1650

10

4.5 - 5.0

4 to 5

4.5 - 5.0

2.7 - 2.8

2.7

2.6

GENERAL PROPERTIES

SERVICE TEMP OC (MAX)

GRAIN SIZE,MM (MAX)

WATER REQUIRED TO MIX (%)

PHYSICAL PROPERTIES

BULK DENSITY (GM/CC) (DRIED AT 110 OC)(MIN)

COLD CRUSHING STRENGTH (Mpa)

110 OC

87

90

100

110

100

110

120

120

120

1100 C

1400 C

COLD MOR, (Mpa)

110 OC

13

18

20

18

20

22

1100 C

1500 OC

25

24

24

34

36

25

1820

1650

1800

PERMENANENT LINEAR CHANGE(%)(MAX) @ 1600 C

0.8

0.5

0.2

THERMAL CONDUCTIVITY(KCAL/HR/M/ oC) @ 600O F/3 HRS

1.75

NA

HOT MOR, (Mpa) @ 1100 C

THERMAL PROPERTIES

REFRACTORIES OC

O

1.5

POROSITY @ 1300oC

CHEMICAL PROPERTIES (%)

AL2O3 (MIN)

16

12

16

75 - 80

50

60

FE2O3(MAX)

1.0 - 2.0

0.5

0.9

THERMAL EXPANSION (%) @ 1100 C

APPLICATION GUIDELINES

MIXER

PLACEMENT

20+5

20+5

20+5

2/5.

2/5.

2/5.

WATER/MIX TEMPERATURE OC

MIXING TIME (MIN):DRY/WET

INSULATING CASTABLES FOR CFBC BOILER

PARTICULARS

HOT FACE TEMPO C

RAW MATERIAL BASE

BULK DENSITY (GM/CC)

(DRIED AT 110O C)

REFINSUL 7

REFINSUL 8S

REFINSUL 13LI

REFINSUL 15LI

1100

1300

1350

1350

EXPANDED

INSULATION

INSULATION

INSULATION

VERMICULITE

NODULES/

GROG/

GROG/

EX.PERLITE

CAL.CLAY

CAL.CLAY

0.9

1.45

1.6

0.85

1.6

1.0

0.7

0.9

(1100O C)

(1300O C)

(1300O C)

(1300O C)

12

4

6

--

25

20

20

30

85

40

40

45

130

75

75

90

0.14

0.2

0.4

0.44

CHEMICAL ANALYSIS

Fe2O3 (%)

8.5

1.5

1.5

GRAIN SIZE (MM)

0 -6

0-6

0-6

0-6

R/V/T

R/V/T

R/V/T

R/V/T

20 5

20 5

20 5

20 5

2/5

2/5

2/5

2/5

PERMANENT LINEAR CHANGE (%)

(TEMP X 3 HRS)

COLD CRUSHING STRENGHT (KGF/CM2)

110OC

800C

1100C

1300C

THERMAL CONDUCTIVITY

(K CAL / M2 / HR / O C)

MIXER

PLACEMENT

O

WATER / MIX TEMP C

MIXING TIME (MIN) : DRY / WET

Vous aimerez peut-être aussi

- Introduction to the simulation of power plants for EBSILON®Professional Version 15D'EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Pas encore d'évaluation

- CFBC Boiler Bed MaterialDocument2 pagesCFBC Boiler Bed MaterialmkoelrealPas encore d'évaluation

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshD'EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshPas encore d'évaluation

- Technical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Document12 pagesTechnical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Bijaya Kumar MohantyPas encore d'évaluation

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasD'EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasPas encore d'évaluation

- 57-62 1m809 - Eng72dpiDocument6 pages57-62 1m809 - Eng72dpiAbhinav TewariPas encore d'évaluation

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsD'EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilPas encore d'évaluation

- History of Thermal Power PlantsDocument9 pagesHistory of Thermal Power PlantsAnonymous gr5Pr9AVPas encore d'évaluation

- 13 MW Steam Turbine 50 HZ NewDocument6 pages13 MW Steam Turbine 50 HZ Newteewee_cutePas encore d'évaluation

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajPas encore d'évaluation

- Proveness CriteriaDocument366 pagesProveness CriteriaHimadri SPas encore d'évaluation

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajPas encore d'évaluation

- NPTI Publications PDFDocument3 pagesNPTI Publications PDFBalraj SinghPas encore d'évaluation

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniPas encore d'évaluation

- Generator Capability CurveDocument18 pagesGenerator Capability Curvenamgyel30Pas encore d'évaluation

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- APGENCO FlyashDocument37 pagesAPGENCO Flyashlokesh0144Pas encore d'évaluation

- Boiler Types and ClassificationsDocument26 pagesBoiler Types and ClassificationshardikPas encore d'évaluation

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDocument2 pagesWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerPas encore d'évaluation

- Steam TurbinesDocument45 pagesSteam TurbinesHaseeb Bokhari100% (1)

- C&I in CFBC-1Document25 pagesC&I in CFBC-1Prudhvi RajPas encore d'évaluation

- Ash Build-Up in Boiler Bottom Ash HoppersDocument6 pagesAsh Build-Up in Boiler Bottom Ash HoppersSara LopezPas encore d'évaluation

- SERIES 22.2: Heavy Duty Gear ReducersDocument2 pagesSERIES 22.2: Heavy Duty Gear ReducersAmir KhanPas encore d'évaluation

- BOE Viva Exam PreparationDocument43 pagesBOE Viva Exam PreparationMV AmohanAKarthicKPas encore d'évaluation

- APH Seal LeakagesDocument17 pagesAPH Seal LeakagesBhargav ChaudhariPas encore d'évaluation

- Power Plant Combustion TheoreyDocument6 pagesPower Plant Combustion TheoreySaiVenkat0% (1)

- Furnace Explosion in CFBC BoilersDocument6 pagesFurnace Explosion in CFBC BoilersHardik Kumar MendparaPas encore d'évaluation

- StartupDocument28 pagesStartupAjay Chauhan100% (1)

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthPas encore d'évaluation

- Quality - Concept of CombustionDocument3 pagesQuality - Concept of CombustionNoviandryPas encore d'évaluation

- Mill Reject SystemDocument22 pagesMill Reject SystemgangatharanPas encore d'évaluation

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDocument4 pagesRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargPas encore d'évaluation

- Data SheetDocument5 pagesData SheetPaolo S. ContrerasPas encore d'évaluation

- CFCB Bed Ash CoolerDocument11 pagesCFCB Bed Ash CoolerUdhayakumar VenkataramanPas encore d'évaluation

- Pump Manual - Single Plunger AmbicaDocument24 pagesPump Manual - Single Plunger AmbicaHimTex /JaswinderPas encore d'évaluation

- Coal FeedDocument8 pagesCoal FeedaakashtrivediPas encore d'évaluation

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaPas encore d'évaluation

- Fuel & CombustionDocument22 pagesFuel & CombustionMohammed GamalPas encore d'évaluation

- Electrostatic PrecipitorsDocument2 pagesElectrostatic PrecipitorsTeererai KaguraPas encore d'évaluation

- Smart Soot Blower SystemDocument8 pagesSmart Soot Blower SystemidigitiPas encore d'évaluation

- Ir-Cfbc Boiler Drive Start/Stop LogicDocument6 pagesIr-Cfbc Boiler Drive Start/Stop Logicsambhu100% (1)

- High Efficiency ESP PDFDocument221 pagesHigh Efficiency ESP PDFraju100% (1)

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaPas encore d'évaluation

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshPas encore d'évaluation

- 02 FSSS Logic SystemDocument51 pages02 FSSS Logic SystemSam100% (3)

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuPas encore d'évaluation

- Mill - Fire ProtectionDocument3 pagesMill - Fire ProtectionANAND PANDEYPas encore d'évaluation

- Fluidized Bed Combustion System (FBC)Document41 pagesFluidized Bed Combustion System (FBC)ashishmathew0% (1)

- Online Monitoring of Bottom Ash Hopper TemperatureDocument6 pagesOnline Monitoring of Bottom Ash Hopper Temperaturerama jenaPas encore d'évaluation

- Thermal Power PlantDocument33 pagesThermal Power PlantManoj KumarPas encore d'évaluation

- NK Bansal BHEL Experience Sharing On Spring Loaded PaperDocument4 pagesNK Bansal BHEL Experience Sharing On Spring Loaded PaperelrajilPas encore d'évaluation

- CFBC Boiler Scale UpDocument14 pagesCFBC Boiler Scale UpBijoy B MenonPas encore d'évaluation

- Boiler Afbc PDFDocument101 pagesBoiler Afbc PDFdika wahyuPas encore d'évaluation

- Sizing Generators For Leading Power FactorDocument9 pagesSizing Generators For Leading Power Factor최형식Pas encore d'évaluation

- Xviii. Soot Blowers and Furnace Temperature ProbeDocument18 pagesXviii. Soot Blowers and Furnace Temperature Probeupt vadodaraPas encore d'évaluation

- Electrostatic PrecipitatorDocument1 pageElectrostatic PrecipitatormsraiPas encore d'évaluation

- Product Catalogue - NewDocument35 pagesProduct Catalogue - NewSiddhartha BogawatPas encore d'évaluation

- 10 Basic Fact About ClinkerDocument52 pages10 Basic Fact About ClinkermngyooPas encore d'évaluation

- Zamil 250Document13 pagesZamil 250Zaid Samha100% (1)

- Cem PDFDocument3 pagesCem PDFsrinivas gillalaPas encore d'évaluation

- English I Upsc Mains PaperDocument3 pagesEnglish I Upsc Mains Paperanimesh907Pas encore d'évaluation

- CFBC DatasheetsDocument5 pagesCFBC Datasheetsanimesh907100% (1)

- Application Process For Trainee Engineers - Automotive and Farm SectorDocument9 pagesApplication Process For Trainee Engineers - Automotive and Farm SectorkrishnamanikandanPas encore d'évaluation

- Sample Cover Letter: Service EngineerDocument1 pageSample Cover Letter: Service Engineeranimesh907Pas encore d'évaluation

- How Alternator WorksDocument10 pagesHow Alternator Worksanimesh907100% (1)

- (To Be On Company Letterhead) : Ref - No. DateDocument1 page(To Be On Company Letterhead) : Ref - No. Dateanimesh907Pas encore d'évaluation

- Complete Info On List of PSU's Recruiting Through GATE 2013 ScoresDocument1 pageComplete Info On List of PSU's Recruiting Through GATE 2013 Scoresanimesh907Pas encore d'évaluation

- Delhi College of Technology & Management: Computer Aided Design (Cad) Practical FileDocument1 pageDelhi College of Technology & Management: Computer Aided Design (Cad) Practical Fileanimesh907Pas encore d'évaluation

- Delhi College of Technology & Management: Computer Aided Design (Cad) Practical FileDocument1 pageDelhi College of Technology & Management: Computer Aided Design (Cad) Practical Fileanimesh907Pas encore d'évaluation

- Result MakerDocument5 pagesResult Makeranimesh907Pas encore d'évaluation

- Dyeing OverviewDocument38 pagesDyeing OverviewAmdeworkPas encore d'évaluation

- Factors Affecting Mechanical Design of Overhead LinesDocument3 pagesFactors Affecting Mechanical Design of Overhead LinesNuraddeen MagajiPas encore d'évaluation

- Unit 4 QB Chemistry AktuDocument35 pagesUnit 4 QB Chemistry AktuVAISHNAVI SINGHPas encore d'évaluation

- Zhang L 2016 Removal of Heavy Metal Ions Using Chitosan and Modified Chitosan A ReviewDocument17 pagesZhang L 2016 Removal of Heavy Metal Ions Using Chitosan and Modified Chitosan A ReviewWulan HumairahPas encore d'évaluation

- PSMA General Chemistry Part 1Document10 pagesPSMA General Chemistry Part 1Lady RicaPas encore d'évaluation

- The Cell PotentialDocument6 pagesThe Cell PotentialGuruprasad [4113-20]Pas encore d'évaluation

- Multiphase Systems PDFDocument11 pagesMultiphase Systems PDFDicky HartantoPas encore d'évaluation

- Scaffco CatalogDocument38 pagesScaffco Catalogmark joseph robentaPas encore d'évaluation

- BF Alkali ProblemDocument6 pagesBF Alkali ProblemSuresh BabuPas encore d'évaluation

- Floating and Trunnion Mounted Ball ValvesDocument24 pagesFloating and Trunnion Mounted Ball ValvesEHT pipePas encore d'évaluation

- Inorganic Chemistry Chem-318 Lec 3Document24 pagesInorganic Chemistry Chem-318 Lec 3Mahnoor ShakeelPas encore d'évaluation

- ACT Crack Chemistry AnswersDocument76 pagesACT Crack Chemistry AnswersMahmoud EbaidPas encore d'évaluation

- Er. Elmady Chs KP 20181023Document21 pagesEr. Elmady Chs KP 20181023susan87Pas encore d'évaluation

- Mark Scheme (Results) January 2007: GCE Chemistry (6244/01)Document23 pagesMark Scheme (Results) January 2007: GCE Chemistry (6244/01)Ajmaeen Mahtab GalibPas encore d'évaluation

- Chapter 1 ThermochemistryDocument78 pagesChapter 1 Thermochemistrymikki11Pas encore d'évaluation

- CHB Wall & Slab EstimateDocument13 pagesCHB Wall & Slab EstimateNuel LacionPas encore d'évaluation

- Tianjin Soright Technology Product CatalogueDocument7 pagesTianjin Soright Technology Product Cataloguecacalot93Pas encore d'évaluation

- Base Plate & Bolt DesignDocument2 pagesBase Plate & Bolt DesigndovermanPas encore d'évaluation

- Steam and Cooling Water Saving in Sugar Factory by The Use of Phase Change MaterialsBDocument8 pagesSteam and Cooling Water Saving in Sugar Factory by The Use of Phase Change MaterialsBParthosarothy K MukherjiPas encore d'évaluation

- SECTION 01010 Summary of WorkDocument14 pagesSECTION 01010 Summary of Workabdullah amanullahPas encore d'évaluation

- Zinc Ribbon Anode: ApplicationDocument2 pagesZinc Ribbon Anode: ApplicationSoltani AliPas encore d'évaluation

- WRC 570 Studies H2 Attack in C-0.5Mo+Weldments Abstract Liu Lundin Prager $225Document9 pagesWRC 570 Studies H2 Attack in C-0.5Mo+Weldments Abstract Liu Lundin Prager $225Anonymous nw5AXJqjdPas encore d'évaluation

- CH 4-Gating System and RiseringDocument63 pagesCH 4-Gating System and RiseringGosaye Desalegn100% (1)

- Biogas PDFDocument12 pagesBiogas PDFKhang TrầnPas encore d'évaluation

- g11 Electrical Installation and Maintenance Test Bank 1st SemesterDocument12 pagesg11 Electrical Installation and Maintenance Test Bank 1st SemesterMelvin Metra100% (1)

- Well Logging Methods MSCDocument147 pagesWell Logging Methods MSCmack_eaus100% (3)

- Final MNGL HarshalDocument96 pagesFinal MNGL Harshalakhil mohanPas encore d'évaluation

- Guarantee Certificate FormatDocument2 pagesGuarantee Certificate Formatjsp160% (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)