Académique Documents

Professionnel Documents

Culture Documents

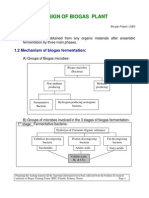

2the Complete Biogas Handbook

Transféré par

Jhe InibamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2the Complete Biogas Handbook

Transféré par

Jhe InibamDroits d'auteur :

Formats disponibles

The Complete Biogas

Handbook

How To Build a Small Biogas Digester

Main

Contents

Build a digester

Workshops

Contact

Need a consultant?

55-gallon digester

ARTI digester

Underground digester

Plastic ag digester

How to Build an Underground Masonry Digester

If reports are to be believed, some 14 million digesters have been built in

China, and many millions have been built in India and other countries as well.

Depending primarily on the size of the digester and local prices for bricks

etc.!, such a unit may cost from "#$%&' to "#$&'' and up, which is a great

deal of money for a village family in most of the world. Consider that in the

year (''')

about 59 percent of the Indian population

(495 million people) had an annual household

income of less than [$280!

*orld +esources Institute, Resource consumption

patterns and implications: India, ('',

-herefore the great ma.ority of these millions of digesters have been built with

government and international /01 subsidies. Is that 2sustainable34!

#peaking generally, virtually all of these digesters are either 2fi5ed dome3 or

2floating dome3 also known by some as 2Chinese6style3 and 72Indian6style3

digesters, respectively!, such as these two8

-he process for building either type of digester in any of their many

variations! is roughly similar. 1ne digs a large pit, and most often using brick!

builds up the main structure of the digester. 9inishing touches are put on and in,

and the digester is covered over with earth.

-hat:s a simple description of a process that can re;uire significant work. <nd

that implies that in the transition from a digester made from, say, a single &&6

gallon drum to a digester made from two water tanks, to the point where one is

considering an underground masonry digester, the game changes.

Consider long6term use, for e5ample. =ased on what we have seen, almost all

&&6gallon drum digesters are fairly ;uickly abandoned> owners do not

continue to feed and care for them> because, as mentioned above, they can be

difficult to deal with and they do not provide truly practical amounts of biogas.

=esides, most folks who build a &&6gallon drum digester are almost always

trying to scratch an itch rather than meet a need. -hey want to know, but they

don:t really need the biogas being produced. "se it, don:t use it8 no biggie.

If we assume that a typical <+-I6style digester is ,ft?(m in diameter, and ,ft?(m high,

then it will have a volume of 1@'ft

%

?4.Am

%

?B1,%'' gallons. *ith a 4'6&' day C+-

retention time!, then to maintain full output, one must feed such a unit (&gal?1'' liters of

slurry every day. -hink about it8 every day you:d have to fill up three6to6five &6gallon

containers with a mi5 of water, food scraps and other organic matter from around your

neighborhood. Dvery day.

1f course, if you don:t want or need full output from the digester, you can feed it less.

Eut it on a diet.!

*hile data known to us anyway! are not available, it would not be surprising

if far fewer <+-I6style digesters were abandoned, because they can provide a

good supply of cooking fuel, most folks who have them need that fuel, they

would have a hard time paying to replace it, and the units re;uire a fairly

significant financial investment. #ome, of course, will be abandoned, and if so

our wager would be that a survey would find that owners primarily in urban

settings! found it difficult to continue to gather the amount of organic matter

needed to keep the digester properly fed.

*hat has been found with studies of underground masonry digesters is that as

long as the owners?users were properly selected Fmeaning, for e5ample, a)they

have an on6going source of organic matter to feed the digester, b) realistic

e5pectations, and c) sufficient knowledge about G d) a committment to

properly maintaining the digesterH, and if they continue to get good support

from the program that built the digesters, most of those digesters will continue

to be used, perhaps for (' years or longer. <nd again, those who have the

digesters would actually need the biogas for cooking and lightingI they could

only replace those functions with considerable labor gathering wood daily!, or

paying very scarce cash for kerosene or similar fuels.

<begin lecture>

#imilar points will apply to you, if you are considering building a small

digester. -hat is, as the size increases, the e5pense likewise increases, and as

well, the time and money re;uired to maintain and feed the digester increases.

-o make it all work, you likewise would need to have a certain situation and

outlook. -hus, again, as we asyou! transition from those smaller digesters to

larger digesters, doing it because 2it would be cool3 or simply to learn more

about biogas becomes less and less tenable as a primary motivation. 0reat

place to start, but that can:t be all you:ve got, or it won:t be sustainable.

In other words, it would only make sense to build a larger digester where

you have enough time, money, knowledge TCBH4! and skill to do so,

where there is enough organic matter on6site or conveniently nearby to

keep it fed, and

where the e5pected outcome has sufficient value, as you see it, to offset

the e5pense, time, and hassle.

1J4 -hat:s the lecture.

</end lecture>

/ow as far as how that translates, first consider a partial materials list for a

typical underground masonry digester a 2fi5ed dome 00C ('4@ model3!

adapted from the =iogas #ector Eartnership /epal site

www.bspnepal.org.np!. [Note 2/26/12: We had a link to the proper page on

BSP Nepal but !ost o" the entire site has disappeared as o" late #eb 2$12%

&'en their o(n !ain !enu links gi'e )$)s% * good alternati'e re"erence is

+,eal -ost o" -onstruction Sur'ey o" a .ypical Bio/gas Plant0

"ound here1 -he materials list is not complete, and so the totals shown do

not reflect the complete cost. /evertheless, based on casual visits to a few

hardware sales websites, we assume the listed materials, purchased at retail in

the US, would cost

$A.(& for B1'' lb. bag of cement &' kg K 11' lbs.!,

%'L per brick although as compared with /epal, the size of our bricks

may be different!,

both M%4 2gravel3 161?(7 to (7 rock fragments! and sand cost $%& per

ton where a m

%

of small rocks, sand, or gravel is about %,A'' lbs.!, and

smaller gravel costs $(A per ton.

*e will not show the cost of each item in the table below, but based on the

above information, if you are really interested, you can find out how we got the

total costs we show by making your own spreadsheet, or you can contact us and

we will send you what we have. #ince =#E indicates one can use either rocks

or bricks, we calculated based on which was cheaper.

*e do not figure or include the cost of paint last column below!, because

frankly it makes no sense to me that anyone could do very much that is

practical with a single liter of paint when using it on a several cubic meter

underground masonry digester. #ee further below for some suggestions for

waterproofing the inside of such digesters.

Plant

Size

m

3

Cost of partial list of materials

needed, on desri!ed !asis

Cement

!ags

"o# $or%

Bri#s

&ra'el

$(% Sand Paint

)*+

#g,!ag m

3

!ri#s

- of ement

!ags liters

4 $,,% 1161( %.& 1,('' %' ,' 1.'

, $@@& 1%614 4.& 1,4'' %& @' 1.'

A $N1@ 1&61, ,.& 1,@'' 4' A' 1.&

1' $1,111 1N6(1 A.' (,''' &' N' (.'

9or more on materials with which to coat the inside of the digester> after all

it:s made from brick or cement, and if it:s not coated it will not be gasOtight>

see Elasters and Coats for Digesters and 0as6Colders, pg. ,1, in 0-P:s now

0IP! publication. <ll four reports in this series are available from this page,

down toward the bottom.!

<nother report is from Biogas plants in animal husbandry8

"ome tried and pro#en seal coats$

multilayer bitumen [asphalt% applied cold (hot

application poses the&dan'er of in(ur) b) burns

and smo*e nuisance)+ sol#ents cause

dan'erous,e-plosi#e #apors. /0o to four thic*

coats re1uired.

bitumen with aluminum foil$ thin sheets of

o#erlappin' aluminum foil applied to the still&

stic*) bitumen% follo0ed b) the ne-t coat of

bitumen.

plastics% as a rule epo-) resin or acr)lic paint+

#er) 'ood but e-pensi#e.

paraffin [0a-% diluted 0ith 2253 *erosene

heated to 40056 and applied to the preheated

masonr). /he paraffin penetrates deep into the

masonr)% thus pro#idin' an effecti#e (deep)

seal. 7se *erosene,'as torch to heat masonr).

8erner% "t9hr% :

;ees% Biogas plants in

animal husbandry% 4989

[emphasis added

=iogas digesters actually either above or below ground! can also be made from

ferrocement. -he =ig Difference between a water tank and a digester is that for

the latter, the entire tank should be gas6tight, instead of .ust having the bottom

and sides be waterOtight, but that may be less of a difference than it might

sound. In any case, a fair to ;uite good resource on ferrocement tanks for

water storage, not for biogas, but hey! is -echnical Eresentation of Qarious

-ypes of Cisterns =uilt in the +ural Communities of the #emiarid +egion of

=razil. Rou may also wish to look at some of the publications on this page.

Eu5in, a Chinese company, makes a number of biogas6related products such as

stoves, including portable concrete forms to produce digesters more ;uickly.

#ee the video on this page for essentially all the information you need to

understand how these portable forms work. It would be interesting to know if

these forms would work if they were made from fiberglass)!

-he third edition of the =iogas?=iofertilizer Candbook has some good

information on ferrocement digesters as an appendi5 not the info in chapter ,!.

Rou may wish to note that rather more than half of the te5t of chapter 1 in this

book is directly 2adapted3 from -C=C.!

<s with any of these sub.ects, a good deal more can be said, but based on what

we have seen e5tant on the lovely e5plosionOinOaOlibrary known as the *orld

*ide *eb do you need the acronym4!, this page likely offers more resources

than you will find elsewhere) 9inally, we end with a picture from =#E, the

=iogas #upport Erogram of /epal8

#ee much larger original image here.

Vous aimerez peut-être aussi

- Complete Biogas HandbookDocument4 pagesComplete Biogas HandbookBelega Mihail100% (1)

- Ferrocement Biogas DigesterDocument38 pagesFerrocement Biogas DigesterBotár CsabaPas encore d'évaluation

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationD'EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationPas encore d'évaluation

- 1 Biodigester DesignDocument9 pages1 Biodigester DesignJhe Inibam100% (2)

- Biogas Revolution Secrets Biogas PlansDocument16 pagesBiogas Revolution Secrets Biogas PlanslimlerianPas encore d'évaluation

- Perennial Grasses for Bioenergy and Bioproducts: Production, Uses, Sustainability and Markets for Giant Reed, Miscanthus, Switchgrass, Reed Canary Grass and BambooD'EverandPerennial Grasses for Bioenergy and Bioproducts: Production, Uses, Sustainability and Markets for Giant Reed, Miscanthus, Switchgrass, Reed Canary Grass and BambooEfthymia AlexopoulouPas encore d'évaluation

- Home BiogasDocument10 pagesHome Biogas直播高清Pas encore d'évaluation

- The Complete Guide to Water Storage: How to Use Gray Water and Rainwater Systems, Rain Barrels, Tanks, and Other Water Storage Techniques for Household and Emergency UseD'EverandThe Complete Guide to Water Storage: How to Use Gray Water and Rainwater Systems, Rain Barrels, Tanks, and Other Water Storage Techniques for Household and Emergency UseÉvaluation : 4 sur 5 étoiles4/5 (3)

- A Practical Handbook For The Trainer of Trainers of Biogas Construction EnterprisesDocument44 pagesA Practical Handbook For The Trainer of Trainers of Biogas Construction EnterprisesTaimur AkhtarPas encore d'évaluation

- Farm drainage The Principles, Processes, and Effects of Draining Land with Stones, Wood, Plows, and Open Ditches, and Especially with TilesD'EverandFarm drainage The Principles, Processes, and Effects of Draining Land with Stones, Wood, Plows, and Open Ditches, and Especially with TilesPas encore d'évaluation

- Design, Construction and Maintenance of A Biogas GeneratorDocument23 pagesDesign, Construction and Maintenance of A Biogas GeneratorOxfam100% (4)

- Gasifiers Wood Gasification & Off Grid PowerD'EverandGasifiers Wood Gasification & Off Grid PowerÉvaluation : 5 sur 5 étoiles5/5 (1)

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Document17 pagesBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- Nitrification and Denitrification in the Activated Sludge ProcessD'EverandNitrification and Denitrification in the Activated Sludge ProcessPas encore d'évaluation

- The Purification of BiogasDocument29 pagesThe Purification of Biogasaldipdg100% (1)

- Home Biogas System (Philippine BioDigesters) - Appropedia - The Sustainability Wiki PDFDocument9 pagesHome Biogas System (Philippine BioDigesters) - Appropedia - The Sustainability Wiki PDFel jeoPas encore d'évaluation

- Last Chance To Donate To Wikipedia in 2009: Anaerobic DigestionDocument24 pagesLast Chance To Donate To Wikipedia in 2009: Anaerobic DigestionVincent Ekhator100% (1)

- Anaerobic Digester DesignDocument85 pagesAnaerobic Digester Designprannoy100% (1)

- Biogas HandbookDocument124 pagesBiogas HandbookDaniel Gonzalo Herrera Peña100% (6)

- A Small-Scale Bio Dig Ester Designed and Built in The Philippines by Gerry BaronDocument8 pagesA Small-Scale Bio Dig Ester Designed and Built in The Philippines by Gerry BaronVortex79Pas encore d'évaluation

- Anaerobic Digestion PDFDocument19 pagesAnaerobic Digestion PDFbekkuPas encore d'évaluation

- BIOGASDocument61 pagesBIOGASlivre i natural67% (3)

- Anaerobic Digesters: Frequently Asked Questions: What Is The Anaerobic Digestion Process?Document4 pagesAnaerobic Digesters: Frequently Asked Questions: What Is The Anaerobic Digestion Process?Kate MayerPas encore d'évaluation

- Handbook On Biogas UtilizationDocument148 pagesHandbook On Biogas UtilizationRusty MacCharles100% (3)

- Anaerobic DigestionDocument109 pagesAnaerobic DigestionAjaysingh BayasPas encore d'évaluation

- Passive Solar Building Design SasDocument26 pagesPassive Solar Building Design Sassanu222Pas encore d'évaluation

- Basic Biogas DigesterDocument7 pagesBasic Biogas DigesterOpen Knowledge and Education Book ProgramsPas encore d'évaluation

- Earth BatteryDocument55 pagesEarth BatteryHaris AvPas encore d'évaluation

- Biogas NotesDocument28 pagesBiogas NotesPaul HarrisPas encore d'évaluation

- Rocket Stove Design GuideDocument9 pagesRocket Stove Design Guidefrola5100% (2)

- Anaerobic Digestion - Collins GavinDocument152 pagesAnaerobic Digestion - Collins Gavinivmc1985100% (1)

- Biogas Technology: Construction, Utilization and Operation ManualDocument52 pagesBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoPas encore d'évaluation

- Anaerobic Digesters and Biogas SafetyDocument4 pagesAnaerobic Digesters and Biogas SafetyadhavanrkPas encore d'évaluation

- Turnning Waste: Into EnergyDocument23 pagesTurnning Waste: Into EnergyGreen MyanmarPas encore d'évaluation

- Extraction of Methane From Biogas - FinalDocument23 pagesExtraction of Methane From Biogas - FinaldhanushPas encore d'évaluation

- ANAEROBIC DIGESTION, Gasification, Pyrolysis of WasteDocument22 pagesANAEROBIC DIGESTION, Gasification, Pyrolysis of WasteJoao Minho100% (1)

- 10.portable BiodigesterDocument12 pages10.portable BiodigesterTimothy NdelevaPas encore d'évaluation

- Biogas TecDocument131 pagesBiogas TecHabimana Fabien100% (1)

- Biogas From Human Waste HandbookDocument164 pagesBiogas From Human Waste Handbookazim_niaziPas encore d'évaluation

- Raising Healthier Poultry in NigeriaDocument7 pagesRaising Healthier Poultry in NigeriaPearl Igboegwu UzokwePas encore d'évaluation

- BIOGAS-Technology For IndiaDocument43 pagesBIOGAS-Technology For IndiaH.J.Prabhu100% (3)

- Physical Conversion TechnologiesDocument89 pagesPhysical Conversion TechnologiesIttihad KhanPas encore d'évaluation

- Anaerobic Methane Biodigester (Tulum Limpio EN)Document10 pagesAnaerobic Methane Biodigester (Tulum Limpio EN)Antonio Found100% (1)

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalPas encore d'évaluation

- Fabricating A Heavy Duty Rocket StoveDocument10 pagesFabricating A Heavy Duty Rocket Stoveboon1961Pas encore d'évaluation

- Calculations Biogas ProductionDocument4 pagesCalculations Biogas ProductionTony Deligiorgis100% (5)

- 5 Steps To Making Homemade BiogasDocument5 pages5 Steps To Making Homemade BiogasJan Aguilar EstefaniPas encore d'évaluation

- Project ReportDocument25 pagesProject ReportROHITPas encore d'évaluation

- Biogas Digester - Shaun's Backyard - What Is Permaculture - PDFDocument26 pagesBiogas Digester - Shaun's Backyard - What Is Permaculture - PDFel jeo100% (1)

- DIY Methane GeneratorDocument5 pagesDIY Methane GeneratorGermanHundPas encore d'évaluation

- Biodiesel From Micro AlgaeDocument3 pagesBiodiesel From Micro Algaeraanja2Pas encore d'évaluation

- PyrolysisDocument3 pagesPyrolysisYashwant Kumar0% (1)

- Handbook On Bio Gas and Its ApplicationsDocument10 pagesHandbook On Bio Gas and Its Applicationsawhk2006Pas encore d'évaluation

- Small-Scale Biomass GasifierDocument88 pagesSmall-Scale Biomass Gasifierkylden100% (6)

- Design of Biogas DigestersDocument22 pagesDesign of Biogas DigestersSharath Chandra100% (5)

- Publications - Design Biogas PlantDocument12 pagesPublications - Design Biogas Planttssa100% (15)

- GSM No Power. No Sun. No Problem!: What Is This Technology?Document3 pagesGSM No Power. No Sun. No Problem!: What Is This Technology?Fred SauerPas encore d'évaluation

- Fixed Fire Suppression Systems Testing ScheduleDocument10 pagesFixed Fire Suppression Systems Testing ScheduleJhe InibamPas encore d'évaluation

- Sprinkler System ChecklistDocument2 pagesSprinkler System ChecklistJhe Inibam100% (3)

- Converting Pump Head To Pressure and Vice VersaDocument2 pagesConverting Pump Head To Pressure and Vice VersaJhe InibamPas encore d'évaluation

- Pump Basic RulesDocument5 pagesPump Basic RulesMaria Precious Paula LapizarPas encore d'évaluation

- PE Pipes and Pressure GradesDocument1 pagePE Pipes and Pressure GradesJeronePas encore d'évaluation

- Dpwh-Cost Estimate GuidelinesDocument20 pagesDpwh-Cost Estimate Guidelinesnagtipunan85% (94)

- Fire Pump Checklist PDFDocument2 pagesFire Pump Checklist PDFJhe InibamPas encore d'évaluation

- 5 Steps To Calculate Total Roof Drains NeededDocument2 pages5 Steps To Calculate Total Roof Drains NeededJhe InibamPas encore d'évaluation

- Site Sampling and Testing of Concrete: A Practical Guide For Site PersonnelDocument12 pagesSite Sampling and Testing of Concrete: A Practical Guide For Site PersonnelJhe InibamPas encore d'évaluation

- What Is What Is Annualized Withholding Tax (AlphalistAnnualized Withholding Tax (Alphalist)Document5 pagesWhat Is What Is Annualized Withholding Tax (AlphalistAnnualized Withholding Tax (Alphalist)Jhe InibamPas encore d'évaluation

- Concrete TestingDocument22 pagesConcrete TestingAdnan JadoonPas encore d'évaluation

- Peerless Pump Company PJPC Jockey Pump Controllers: Installation and Operation InstructionsDocument8 pagesPeerless Pump Company PJPC Jockey Pump Controllers: Installation and Operation InstructionsJhe InibamPas encore d'évaluation

- Fire Pump Pressure SettingsDocument2 pagesFire Pump Pressure SettingsJhe Inibam100% (1)

- Seismic Design and Retrofit of Piping Systems 7 02Document120 pagesSeismic Design and Retrofit of Piping Systems 7 02Jhe InibamPas encore d'évaluation

- Victaulic - Design Data For Seismic Application PDFDocument12 pagesVictaulic - Design Data For Seismic Application PDFpodariuPas encore d'évaluation

- High Density Polyethylene (HDPE) Pipe and FittingsDocument8 pagesHigh Density Polyethylene (HDPE) Pipe and FittingsJhe InibamPas encore d'évaluation

- The Basics of SignageDocument7 pagesThe Basics of SignageRobVajko100% (1)

- Togaf Open Group Business ScenarioDocument40 pagesTogaf Open Group Business Scenariohmh97Pas encore d'évaluation

- Panera Bread Company: Case AnalysisDocument9 pagesPanera Bread Company: Case AnalysisJaclyn Novak FreemanPas encore d'évaluation

- Project Report On ICICI BankDocument106 pagesProject Report On ICICI BankRohan MishraPas encore d'évaluation

- Alcatraz Analysis (With Explanations)Document16 pagesAlcatraz Analysis (With Explanations)Raul Dolo Quinones100% (1)

- Government by Algorithm - Artificial Intelligence in Federal Administrative AgenciesDocument122 pagesGovernment by Algorithm - Artificial Intelligence in Federal Administrative AgenciesRone Eleandro dos SantosPas encore d'évaluation

- Entrenamiento 3412HTDocument1 092 pagesEntrenamiento 3412HTWuagner Montoya100% (5)

- On The Linguistic Turn in Philosophy - Stenlund2002 PDFDocument40 pagesOn The Linguistic Turn in Philosophy - Stenlund2002 PDFPablo BarbosaPas encore d'évaluation

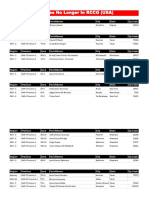

- Churches That Have Left RCCG 0722 PDFDocument2 pagesChurches That Have Left RCCG 0722 PDFKadiri JohnPas encore d'évaluation

- Project TitleDocument15 pagesProject TitleadvikaPas encore d'évaluation

- Medicidefamilie 2011Document6 pagesMedicidefamilie 2011Mesaros AlexandruPas encore d'évaluation

- Political and Institutional Challenges of ReforminDocument28 pagesPolitical and Institutional Challenges of ReforminferreiraccarolinaPas encore d'évaluation

- TEsis Doctoral en SuecoDocument312 pagesTEsis Doctoral en SuecoPruebaPas encore d'évaluation

- List of Vocabulary C2Document43 pagesList of Vocabulary C2Lina LilyPas encore d'évaluation

- Information Security Policies & Procedures: Slide 4Document33 pagesInformation Security Policies & Procedures: Slide 4jeypopPas encore d'évaluation

- My Parenting DnaDocument4 pagesMy Parenting Dnaapi-468161460Pas encore d'évaluation

- Maule M7 ChecklistDocument2 pagesMaule M7 ChecklistRameez33Pas encore d'évaluation

- Vce Smart Task 1 (Project Finance)Document7 pagesVce Smart Task 1 (Project Finance)Ronak Jain100% (5)

- Dummies Guide To Writing A SonnetDocument1 pageDummies Guide To Writing A Sonnetritafstone2387100% (2)

- Borer (2013) Advanced Exercise Endocrinology PDFDocument272 pagesBorer (2013) Advanced Exercise Endocrinology PDFNicolás Bastarrica100% (1)

- BP TB A2PlusDocument209 pagesBP TB A2PlusTAMER KIRKAYA100% (1)

- Harbin Institute of TechnologyDocument7 pagesHarbin Institute of TechnologyWei LeePas encore d'évaluation

- Ignorance Is The Curse of God. Knowledge Is The Wing Wherewith We Fly To Heaven."Document3 pagesIgnorance Is The Curse of God. Knowledge Is The Wing Wherewith We Fly To Heaven."Flori025Pas encore d'évaluation

- A Professional Ethical Analysis - Mumleyr 022817 0344cst 1Document40 pagesA Professional Ethical Analysis - Mumleyr 022817 0344cst 1Syed Aquib AbbasPas encore d'évaluation

- Wwe SVR 2006 07 08 09 10 11 IdsDocument10 pagesWwe SVR 2006 07 08 09 10 11 IdsAXELL ENRIQUE CLAUDIO MENDIETAPas encore d'évaluation

- Deseret First Credit Union Statement.Document6 pagesDeseret First Credit Union Statement.cathy clarkPas encore d'évaluation

- Laboratory Methodsin ImmnunologyDocument58 pagesLaboratory Methodsin Immnunologyadi pPas encore d'évaluation

- Learner's Material: ScienceDocument27 pagesLearner's Material: ScienceCarlz BrianPas encore d'évaluation

- Visual Images of America in The Sixteenth Century: Elaine BrennanDocument24 pagesVisual Images of America in The Sixteenth Century: Elaine Brennanjoerg_spickerPas encore d'évaluation

- Wetlands Denote Perennial Water Bodies That Originate From Underground Sources of Water or RainsDocument3 pagesWetlands Denote Perennial Water Bodies That Originate From Underground Sources of Water or RainsManish thapaPas encore d'évaluation

- DHBVNDocument13 pagesDHBVNnitishPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- Cable Supported Bridges: Concept and DesignD'EverandCable Supported Bridges: Concept and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeD'EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (59)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetD'EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Summary of Neil Postman's Amusing Ourselves to DeathD'EverandSummary of Neil Postman's Amusing Ourselves to DeathÉvaluation : 4 sur 5 étoiles4/5 (2)

- Troubleshooting and Repair of Diesel EnginesD'EverandTroubleshooting and Repair of Diesel EnginesÉvaluation : 1.5 sur 5 étoiles1.5/5 (2)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Construction Innovation and Process ImprovementD'EverandConstruction Innovation and Process ImprovementAkintola AkintoyePas encore d'évaluation

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisD'EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisÉvaluation : 5 sur 5 étoiles5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingD'EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesPas encore d'évaluation

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyD'EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Up and Running with AutoCAD 2020: 2D Drafting and DesignD'EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignPas encore d'évaluation

- The Diesel That Did It: General Motors' FT LocomotiveD'EverandThe Diesel That Did It: General Motors' FT LocomotivePas encore d'évaluation

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementD'EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementPas encore d'évaluation

- Compendium of Best Practices in Road Asset ManagementD'EverandCompendium of Best Practices in Road Asset ManagementPas encore d'évaluation

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesD'EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesÉvaluation : 4 sur 5 étoiles4/5 (5)