Académique Documents

Professionnel Documents

Culture Documents

Swaraj Engines LTD PPT 2014 by Satnam Singh

Transféré par

Satnam SinghTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Swaraj Engines LTD PPT 2014 by Satnam Singh

Transféré par

Satnam SinghDroits d'auteur :

Formats disponibles

Six months Industrial

TRAINING

at

SWARAJ ENGINES

LIMITED

SUBMITTED TO:

Er. A.P. Singh

PRESENTED BY

Satnam Singh Sukhjit Singh

UE109066 UE109073

MECHANICAL MECHANICAL

8

th

sem. 8

th

sem.

INTRODUCTION TO SWARAJ GROUP

Swaraj group came into existence with the establishment of Punjab Tractors

Limited. company, Indias first large scale on based totally indigenous design and

technology, was promoted by Punjab State Industrial Development Corporation

PSIDC with the help of govt. of India and Public financial industries.

MAJOR COLLABORATIONS OF SWARAJ GROUPS

Swaraj group has entered into technical and financial collaborations with various

national and international companies. The maximum share holder of swaraj is

now Mahindra and Mahindra. Swaraj Mazda Limited was set with technical and

financial collaborations with Mazda Motors corporation of Japan. Technical

collaboration was entered into Komatsu Forklift Company of Japan for

manufacturing fork lifters at swaraj combine Division. Swaraj

Engines Limited was set up in technical and financial collaboration with kirloskar

Oil Engines Limited, pune for Manufacturing diesel engines.

VARIOUS DIVISIONS OF SWARAJ GROUPS

Swaraj consists of six divisions:

Swaraj Tractors Division.

Swaraj Mazda Limited.

Swaraj Automotive Limited.

Swaraj Engines Limited.

Swaraj Foundry Limited.

Swaraj Combine Division.

SWARAJ TRACTORS DIVISIONS

It is located in phase IV, SAS Nagar. It started with an annual capacity of 5000

tractors with capital of Rs. 37 million. In 1974 it went into commercial production

with swaraj 724 a 26.5 BHP tractor as its first model. During its 22 years of

production it has not only expanded its manufacturing capacity to more than

24000 tractors per annum but also added more products into its manufacturing

range. Its product range includes the following

YEAR OF

MODEL POWER

INTRODUCTION

SWARAJ 724

26.5 BHP

1974

SWARAJ 735

39.0 BHP

1975

SWARAJ 720

19.5 BHP

1978

SWARAJ 855

55.0 BHP

1983

SWARAJ 922

22.0 BHP

1995

SWARAJ 744

44.0 BHP

1999

SWARAJ ENGINE LIMITED

Keeping in view the need to meet various emissions norms SEL

has produce emission measurement equipment and various

standards are stringently followed.

SEL represents fruition of the technology and commercial

relationship of two decades of two Indian companies, both

pioneers in Indian R & D and engineering, KOEL AND PTL. In this

background the factory is quite competitively modernized with

regard to manufacturing technology. It has the unique

distinction of employing the maximum number of CNCs north

of Delhi.

DEPARTMENTS OF S.E.L.

INDUSTRIAL ENGINEERING

MACHINE SHOP

ASSEMBLY AND TESTING SHOP

QUALITY SHOP

MAINTENANCE SHOP

TOOL ROOM

STANDARD ROOM AND TOOL CRIB

STORES

TYPES OF ENGINES

MANUFACTURING IN SEL

The Plant Manufactures five types of engines,

which engines are sent to the swaraj tractor

division, S.A.S. NAGAR. One of these is a single

cylinder engine exclusively designed R&D plant

of Swaraj. Out of rest one is two cylinder and

others three cylinder engines. All the engines are

Euro-3 and SEL is planning for modifications to

be introduced, so that its engines may be Euro-4

compatible. The specifications of these engines

are:

1. S-15, Single Cylinder:

2. RV-2, Two Cylinder:

3.RV-3, Three Cylinder:

4. RB-30, Three Cylinder:

5. RB-33, Three Cylinder:

MACHINE

SHOP

MACHINES USED IN MACHINE

SHOP:

Vertical milling machine

Horizontal milling machine

Radial drilling machine

Gang milling machine

Rough boring machine

Semi-finish boring machine

Finish boring machine

Honing machine

Gun drilling machine

Washing machine

Rotary grinder

Rough milling machine

XLO valve lapping machine

Line boring machine

MACHINES

MILLING MACHINE

DRILLING MACHINE

CNC MACHINES

UPSETTER

ASSEMBLY

SHOP

ASSEMBLY PROCESS.

CRANK SHAFT FITMENT

CAM SHAFT FITMENT

GEAR CASING FITMENT

CRITICAL AREA PISTON ASSEMBLY

CYLINDER BLOCK FITMENT

OIL SUMP FITMENT

CYLINDER HEAD FITMENT

WATER PUMP FITMENT

FIP [FUEL INJECTION PUMP] FITMENT

FUEL TIMING

CRANK SHAFT FITMENT

The crankshaft, sometimes casually abbreviated to

crank, is the part of an engine which translates

reciprocating linear piston motion into rotation.

CAM SHAFT FITMENT

A camshaft is a shaft to which a cam is fastened or

of which a cam forms an integral part.

GEAR CASING FITMENT

A gear is a rotating machine part having cut teeth, or cogs, which

mesh with another toothed part in order to transmit torque. Two

or more gears working in tandem are called a transmission and can

produce a mechanical advantage through a gear ratio and thus

may be considered a simple machine.

CRITICAL AREA PISTON

ASSEMBLY

In an engine, its purpose is to transfer force from expanding

gas in the cylinder to the crankshaft via a piston rod and/or

connecting rod.

CYLINDER BLOCK FITMENT

The cylinder block or engine block is a machined casting (or

sometimes an assembly of modules) containing cylindrically

bored holes for the pistons of a multi-cylinder reciprocating

internal combustion engine, or for a similarly constructed

device such as a pump.

OIL SUMP FITMENT

Oil Sump is used to store the lubricating oil which is supplied

oil which is supplied for lubrication to different engine parts

through section tube.

CYLINDER HEAD FITMENT

In an internal combustion engine, the cylinder head (often

informally abbreviated to just head) sits above the cylinders

on top of the cylinder block. It consists of a platform

containing part of the combustion chamber (usually, though

not always), and the location of the poppet valves and spark

plugs.

WATER PUMP FITMENT

Water pump is used to supply water in different parts

of engine for cooling purpose.

FIP FITMENT

Fuel injection pump is used to supply the fuel for combustion.

COMPLETE ENGINE

ENGINE TESTING

ENGINE TESTING

1.Fix engine clutch plate.

2.Clamp the engine.

3.Loosen throttle rod from throttle motor side.

4.Engage throttle with FIP lever at zero position.

5.Tighten throttle at dynamo end.

6.Check power is ON at panel.

7.Keep throttle controller at external at panel.

8.Check & assure switch is at push side.

9.Put switch to set position.

10.Pause for few seconds & press green limit button until it is

ON.

11.Set the knob to run position.

12.Start the engine.

13.Start button on panel should be in ON position.

14.Assure external mode.

15.Open the software.

16.Fill up proper engine no. code, FIP no. etc. & click save button.

17.Click on start button in software.

18.After testing fill up all operator check points.

19.Save the data.

20.For rework click on C hold.

21.After rework click resume if engine is not stopped.

22.Af engine is stopped, click resume & double click on step from

which engine was stopped.

SOP for Engine Testing

S No. RPM Load (in %) Time

(in min)

Check Points

1. Idle NIL 3 Check oil pressure, oil through rocker lever & any

abnormal noise.

2. 1300 20 4 Clean all fuel banjoes &check for any leakage.

3. 1500 40 4 Check for any leakage from water connection

points.

4. 1800 60 4 Check for any lubricant oil leakage, leakage from

banjoes and joints.

5. NLFT NIL 1 Check no load full throttle RPM

6. NLFT Setting

&1800

100 9 Adjust NLFT if required. Check load on engine &

fuel time adjust if required. Spray water on

engine, dry engine using air and check for

leakages using special torch.

7. 1200+/-100 OVER LOAD 2 Check peak torque points.

8. Low Idle NIL 1 Check for un usal noise. Check for hunting at idle

RPM & Oil pressure. Also check for any leakage

from flywheel end side main oil seal.

Check difference in oil pressure at idle and NLFT.

It should be minimum 0.8 kg/cm

2

.

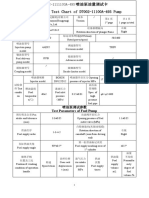

Test Bed Passing Range for XM Engines

S No. Parameters RV2

XM

RV3

XM

RV30

XM

RV2 XM

+3A (AVL)

RV3

XM

+3A

(AVL)

RV30XM

+3A

(AVL)

1. Engine BHP

(Declared)

24 35 31 24 35 31

2. Test bed BHP

passing range

23.3-

25.2

34-

36.8

30.1-32.6 23.3-25.2 34-36.8 30.1-32.6

3. Fuel delivery 46

+/- 2

45

+/- 2

40

+/- 2

46

+/- 2

44

+/-2

40

+/- 2

4. S.F.C. 180

max

175

max

176 max 180 max 175 max 176 max

5. Rated RPM 1800 1800 1800 1800 1800 1800

6. NLFT 1950

+/- 50

1950

+/- 40

1950 +/ -

40

1950 +/-

50

1950+/-

40

1950 +/-

40

7. Idle RPM 650

+/- 50

650

+/- 50

650+/-50 650+/-50 650+/-50 650+/-50

8. % B.U.T MIN.

15% @

1100+

/- 100

rpm

MI%

12-20

%

@

1100+

/- 100

rpm

Min.

15%@

1100+/ -

100 rpm

Min15%@

1100+/-

100 rpm

Min12-

20%@11

00+/-

100 rpm.

Min

15%@11

00+/- 100

rpm

9. Smoke FL/OL 2/3.5 2/3.5 2/3.5 2/3.5 2/3.5 2/3.5

Test Bed Passing Range for Green Engines

S No. Parameters RB30 TR+ RB33 TR+ S-15 TR+

1. Engine BHP

(Declared)

45 50 21.2

2. Test bed BHP

passing range

41.6- 46.5 46.5 - 52.0 20.3-20.7

3. Fuel delivery 54

max

62

max

84.5

max

4. S.F.C. 182

max

182

max

194

max

5. Rated RPM 2000 2000 1900

6. NLFT 2150

+/-

50

2150

+/-

40

2020

+/-

40

7. Idle RPM 650

+/-

50

650

+/-

50

650

+/-

50

8. % B.U.T 12

Min.

@

1200

rpm

12

Min.

@

1200

rpm

10 to 15

%

9. Smoke FL/OL 2.0/3.8 2.0/3.8 3.2/4.0

PROJECTS

UNDERTAKEN

ASSEMBLY SHOP

1. Time study of RB cylinder block leak test.

ACTIVITY

Pick up the Component from Conveyor using tackle

Load the component on fixture of Leak testing unit

Remove the tackle from component & move hoist side

Locate the component from 2 locating pins

Put 3 clamps in position & ensure the location of rubber washer

in push rod holes

Switch on the clamping lever upward to clamp the component

hydro-pneumatically.

Ensure the drain pipe in vertical position & fill the tank with

coolant up to level marked

Observe the unit for 30 seconds for any air bubbles occurrence

After 30 seconds drain the coolant by operating the lever

downward

Close the air inlet valve

Down the lever to declamp the component

Pick up the component from unit by inserting tackle & lifting up

from unit

Move the hoist to conveyors & unload the component on

conveyor & draw back the tackle & move towards starting

position

2. BUMPING:

It is a process in which T.D.C. of engine cylinder or clearance

between piston and cylinder head is set by placing shims

between liner and cylinder head.

Detailed Study of Bumping

Clearance volume or bumping clearance is the space between the

top of the piston and the cylinder head of an air compressor. This

clearance is an important aspect of the compressors and should be

as less as practically possible to improve the volumetric efficiency

of the compressor. The clearance volume should not be too less or

too more. Moreover, it affects the efficiency of the machinery and

thus should be checked at regular intervals of time.

Significance and Effects of Bumping Clearance

In an air compressor, when the discharge valve closes in the end of

the compression cycle, a small amount of high pressure air is

trapped in the clearance volume.

Before again taking suction, the air trapped in the clearance

volume must expand below the suction pressure i.e. below the

atmospheric pressure.

The expansion of this trapped air in the clearance volume causes

effective loss of stroke due to which the volumetric efficiency of

compressor drops. Therefore, the clearance volume has a

significant effect on the efficiency of the compressor.

Marking T.D.C:

When the first piston from flywheel side is at its T.D.C. then a point is marked

below the pointer on pulley.

Shim

Shims are the spacer of big size which are inserted between liners and cylinder

head in order to lift the cylinder head to avoid head noise.

Bumping shim and CV shim

The shim which is bigger in size and placed at outer surface of liner is known as

bumping shim. This shim is used to support the cylinder head.

The shim which is smaller in size as compared to bumping shim and placed at

inner surface of liner is known as CV shim. This shim is used to provide clearance

between piston and cylinder head.

Effects Due to Less Clearance

Small clearance volume may result in piston banging or

colliding to the cylinder head.

This is dangerous when the compressor when is running in

unloaded condition without any resistance to the movement of

the piston.

Effects Due to Large Clearance

Large bumping clearance retards the formation of vacuum on

the suction stroke and thus less air is drawn inside for

compression and accordingly the weight of the air delivered is

reduced proportional to the clearance volume.

Compressor has to run for a longer period to provide the

necessary compression pressure.

Reasons for Change in Clearance Volume

During overhauls of the air compressor, if the gasket fitted

between the cylinder head joints is of the wrong type, then the

bumping clearance will increase, resulting in wear down of

bottom bearings or wrong bearings are put in place.

How Bumping Clearance is checked?

Bumping clearance is checked by putting a lead ball or plastic

gauges over the piston and then turning the compressor one

revolution by hand.

By doing this the lead ball will compress and the thickness obtained

is the clearance volume.

This thickness is measured with venire caliper or micrometer and is

then compared with the manufacturers value. Adjustments are

made in case there is an offset in the value.

Adjustment of bumping clearance

Bumping clearance can be adjusted with the help of inserting shims

(thin metallic plates) in the bottom bearings. Inserting shims will

move the connecting rod and the piston which will change the

clearance.

What should be the Bumping Clearance?

Generally bumping clearance depends on the manufacturer but as a

thumb rule it should be between 0.5% to 1% of the bore of the

cylinder.

Shims used of various thickness according to various reading:

READING THICKNESS OF SHIM

For positive reading 1.2mm

0 to -0.10 1.2mm

-0.10 to-0.20 1.2mm

-0.20 to-0.30 1.3mm

-0.30 to-0.40 1.4mm

-0.40 to-0.5 0 1.5mm

These are the readings for Bombay engine.

PROJECT WORK :

Before shims are inserted on liners, oil is applied on shims in order

to prevent rusting. Then these shims are placed on a inclined rod.

In this arrangement shims get stick to each other. When they are

inserted on liners then sometimes worker put two shims instead of

one. This results in rejection of engine during testing. The naming

of positions of different shims on stand was also not done properly.

1. We have made a new arrangement of shims in which stand is not

inclined, it becomes vertical and rods becomes long and horizontal and a

stopper is fixed at the free end of rod. The naming of positions of different

shims on stand is done properly.

2. We have used a pressure gun in order to apply air pressure on shims

arrangement on horizontal stand so that their stickiness should not take

place. By using these methods in arrangement of shims, the rejection of

engine can be decreased up to a great extent.

Air pressure applied on

shims.

ENGINE TESTING SHOP

3. Engine Test Report (RV Model)

Date 28/03/2014

Shift B

Test Bed No.9

Tester E.No.2570

Inspector E.No.2596

Engine No. STD004874

Engine Model RV3 XM +3A (AVL)

Engine Code 39.1354

FIP No. 41821305

Test Started @ 9:14:02

Test Stopped @ 9:43:48

Total Run 00:29:46

S No. Check points Specif- ications Actual Remarks

Min. Max.

Ok/ not ok

1. Engine idle

speed

600 700 683 Ok

2. Engine fly up

speed

1900 2000 1943 Ok

3. Max power

(BHP)@rate

d speed

33.33 36.8 34.4 ok

4. SFC value@

rate speed

100 175 172.2 ok

5. Fuel delivery 42 46 43.9 0k

S

No.

Speed

rpm

Torque Engine

Power

Fuel

Delivery

Flow

Rate

Fuel

Time

Fuel

Wt.

SFC

1. 1299 3.8 5.1 0 0 0 0 0

2. 1499 8.34 12.5 0 0 0 0 0

3. 1799 12.72 22.9 0 0 0 0 0

4. 1943 0.19 0.4 0 0 0 0 0

5. 1799 18.82 33.9 42.7 5.78 62.3 100 170.7

6. 1801 18.79 33.8 42.3 5.72 63.01 100.1 169

7. 1802 19.09 34.4 43.9 5.93 60.84 100.3 172.7

8. 1100 22.32 24.6 0 0 0 0

9. 1965 0.23 0.5 0 0 0 0

10. 683 0.12 0.1 0 0 0 0

S No. Ext

Temp

Water

outlet

temp

Lub. Oil

Temp

Lub.

Oil Pr.

Pr. 2 Atm

Pr.

Pr.4 CF DIN Smoke Step Time

1. 709 44.3 30.3 5.39 .006 .965 0 1.06281 0 9:21:66

2. 702 45.8 30.2 5.47 .007 .965 0 1.06281 0 9:25:07

3. 686 47 30.3 5.66 .007 .965 0 1.06281 0 9:29:05

4. 680 46.7 30.3 5.77 .008 .965 0 1.06281 0 9:30:04

5. 690 46.5 30.4 5.58 .008 .965 0 1.06281 0 9:31:58

6. 677 47.5 30.4 5.54 .008 .8 0 1.06281 0 9:33:37

7. 694 48.4 30.5 5.48 .008 .965 0 1.06281 0 9:35:37

8. 685 48.5 30.7 4.78 .008 .965 0 1.06281 0 9:42:45

9. 682 48.2 30.6 5.54 .007 .965 0 1.06281 0 9:43:14

10. 686 48.2 30.6 4.49 .006 .965 0 1.06281 0 9:4:.41

4. ENGINE TEST REPORT ( RB Model)

Date 3/3/2014

Shift A

Test Bed No.8

Tester E No.3274

Inspector E No.2596

Engine No. STB04393

Engine Model RB33 TR+

Engine Code 47.1409

FIP No. 41769823

Test started @ 6:26:31

Test stopped @ 6:54:08

Total Run 0:27:37

S No. Check points Specifications Actual Reading Remarks

Min Max

1. Engine Idle Speed 600 700 669 Ok

2. Engine Fly up

speed

2100 200 2156 Ok

3. Max. power

(BHP) @ rated

speed

47.5 52.5 52.5 Ok

4. SFC value @

rated speed

170 175 167.6 Not Ok

5. Fuel Delivery 1 62 58.4 Ok

S NO. Measured Values

Speed Torque Engine

Power

Fuel

delivery

Flow

Rate

Fuel

Time

Fuel wt. SFC

1. 665 0.19 0.1 0 0 0 0 0

2. 1302 5.43 7.1 0 0 0 0 0

3. 1502 10.35 15.5 0 0 0 0 0

4. 2156 0.17 0.4 0 0 0 0 0

5. 2000 27.62 55.3 63.9 9.6 37.56 100.2 173.8

6. 2001 26.19 52.4 58.4 8.78 41.01 100 167.6

7. 2002 26.21 52.4 58.4 8.78 41.17 100.4 167.6

8. 2000 26.27 52.5 58.4 8.78 41.17 100.4 167.6

9. 1202 31.19 37.5 0 0 0 0 0

10. 2160 0.16 0.4 0 0 0 0 0

S No. Temperature Pressure CF

DIN

S

m

o

ke

Step

Time

Ext Wtr

out

Lub.

oil

Lub.

oil

Pr. 1 Pr. 2 Atm Pr. 4

1 30 11 19.5 4.53 0 1.994 .965 0 1.0628

1

0 6:29:18

2. 30 11.4 19.6 5.07 0 1.994 .965 0 1.0628

1

0 6:33:09

3. 30 11.4 19.8 5.11 0 1.995 .965 0 1.0628

1

0 6:37:03

4. 30 10.8 20.2 5.48 0 1.994 .965 0 1.0628

1

0 6:41:57

5. 30 13.8 20.6 5.14 0 1.994 .965 0 1.0628

1

0 6:45:24

6. 30 12.3 21.2 5.01 0 1.994 .965 0 1.0628

1

0 6:48:21

7. 30 12 21.4 4.95 0 1.994 .965 0 1.0628

1

0 6:49:50

8. 30 11.6 21.5 4.91 0 1.995 .965 0 1.0628

1

0 6:51:03

9. 30 11.7 22 4.28 0 1.994 .965 0 1.0628

1

0 6:55:03

10. 30 11.7 22 5.04 0 1.995 .965 0 1.0628

1

0 6:55:33

CHECK POINTS

FIP Model

FIP Hunting

Engine No. & Code

Lub. Oil level

Compressor Leakage

Valve Leakage

Tappet Noise

Gear Noise

Valve Touch

Humming Noise

FD Noise at overload

Water Mixing with Lubricating Oil

Diesel Mixing with Lubricating Oil

Engine Overheating

Unusual Vibrations

Seating Rubber Bush Bottom

Lub Oil Leakage

Fuel Leakage

Blow by

Engine washing

MACHINE SHOP

5. Valve leakage in RB cylinder head.

The main reason for leakage in cylinder head valves is wrong seat generation.

The PROBABLE CAUSES were proposed for this problem were :-

Pallet station Interference between outer dia. of seat & internal dia. of

exhaust valve.

Improper clamping

Faulty casting design

ANALYSIS OF ALL THE CAUSES:-

Pallet station :

It would have been possible that the leakage in the heads was

specific to a particular pallet and station in the machines.

The Makino machine a51 comprises of 2 pallets with 3 stations

each. These were known as top , left & right pallet station and for

analysis of this cause the components were coded when they

were machined so as to determine if this problem was specific to

a pallet station. The coding was done as follows according to

PALLET (1 or 2) _STATION (T, L or R)

For e.g. The top station of pallet 1 was written as 1T

The right station of pallet 2 was written as 2R and so on.

TABLE- PALLET STATION ANALYSIS

CONCLUSION-

It was found out that the leakage problem was

independent of the pallet and station at which the

component was machined. Therefore this was justified that

the problem is not in any particular pallet but in the

process on the whole.

Improper clamping

The clamping system is responsible to hold the component

in its place while machining operations take place on it. The

clamps used were flat surface therefore they could not

incorporate for any irregularities in the casting of head. To

minimize this effect, ROLLER clamps by TESA are used so

that even if there is any variation in flatness of the casting,

the clamps will hold the component in position.

BEFORE

AFTER

FLAT CLAMPS

ROLLER CLAMPS BY TISA

ANALYSIS:

0

10

20

30

40

50

60

70

80

FLAT CLAMP ROLLER CLAMP

% of leaked components

% of leaked components

CONCLUSION-

The bar graph describes that the percentage of failed or

rejected components fell steeply in general after changing

the clamps of pallet 2 in machine 499.01 . This justified that

the clamping of components was not proper earlier and that

this issue needed to be addressed and changing the clamps

was a positive move.

Faulty casting design

On further exploring the scenario it was found out that the

casting design was not adequate according to the

requirement for the clamps and needed modification.

CASTING MODIFICATION

CONCLUSION-

The modifications in casting to increase the surface

uniformity lead to better clamping of the component in the

pallet station. The clamps were able to hold the

component completely under all vibrations.

RESULT AND FUTURE SCOPE

The 2 major causes for cylinder head leakage were

Improper clamping

Faulty casting design

After addressing to these problems, there has been a drastic change in a positive

direction in the no. of rejected cylinder heads.

As on 28/04/2014 morning A shift, only 3 components out of 96 pieces were

found to be leaking.

FUTURE SCOPE:

Efforts are still on to further minimize the rejection due to leakage of cylinder

heads to < 1%.

BIBLIOGRAPHY

Daily dairy.

Operators.

www.swarajenterprise.com

THANKS.

Vous aimerez peut-être aussi

- SwarajDocument24 pagesSwarajÁjáý RáñáPas encore d'évaluation

- R 45 F17 10 Introduction of New Mahindra YUVODocument13 pagesR 45 F17 10 Introduction of New Mahindra YUVODipen patraPas encore d'évaluation

- Swaraj 834 735 724Document5 pagesSwaraj 834 735 724Dadasaheb MorePas encore d'évaluation

- Swaraj 735 Fe Tractor - T - 768-1276-2011Document13 pagesSwaraj 735 Fe Tractor - T - 768-1276-2011Amit Chopra Amit0% (1)

- Compare Mahindra Arjun Tractors 57HP vs 50HP ModelsDocument2 pagesCompare Mahindra Arjun Tractors 57HP vs 50HP ModelsPrashant PatilPas encore d'évaluation

- Potrait 1 Clutch Catalogue After Market 2022Document29 pagesPotrait 1 Clutch Catalogue After Market 2022Rishabh GuptaPas encore d'évaluation

- MetalcoDocument39 pagesMetalcokumaryoPas encore d'évaluation

- Escorts Agri Machinery PPT on Growth and ProductsDocument37 pagesEscorts Agri Machinery PPT on Growth and ProductsASHPas encore d'évaluation

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument94 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamPas encore d'évaluation

- Internship ReportDocument16 pagesInternship ReportGurushant B100% (1)

- Bosch Automotive Aftermarket Braking Parts and Accessories MRP ListDocument37 pagesBosch Automotive Aftermarket Braking Parts and Accessories MRP ListNirav SoniPas encore d'évaluation

- New Price List JCB 22Document1 pageNew Price List JCB 22MM SparesPas encore d'évaluation

- Illustrated Part List FOR: Kirloskar Oil Engines LimitedDocument84 pagesIllustrated Part List FOR: Kirloskar Oil Engines LimitedBraian HuertasPas encore d'évaluation

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument88 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamPas encore d'évaluation

- Amw MRP 04.10.2013Document131 pagesAmw MRP 04.10.2013Niten Gupta33% (3)

- India's First Smart Truck Guarantees Higher MileageDocument22 pagesIndia's First Smart Truck Guarantees Higher MileageabcPas encore d'évaluation

- Parts Catalog 475 TotalDocument60 pagesParts Catalog 475 TotalIndian Empire50% (2)

- Regular Parts Catalogue Inclusive 235DI 245DI 12MAY09Document268 pagesRegular Parts Catalogue Inclusive 235DI 245DI 12MAY09PSChatrathPas encore d'évaluation

- 30 Series PC Low Resolution PDFDocument226 pages30 Series PC Low Resolution PDFJose Luis Correa ArangoPas encore d'évaluation

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument61 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDarshan MakwanaPas encore d'évaluation

- Dynaco p31 p51 p76 Bearing Pump PDFDocument7 pagesDynaco p31 p51 p76 Bearing Pump PDFnbgearsPas encore d'évaluation

- AIP Abilities India Piston & Rings LTDDocument21 pagesAIP Abilities India Piston & Rings LTDSushant_Sagar_9240100% (1)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument99 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamPas encore d'évaluation

- STL Catalogue PDFDocument33 pagesSTL Catalogue PDFpreetPas encore d'évaluation

- Sonalika-MR-Harihar Nayak-PDocument70 pagesSonalika-MR-Harihar Nayak-PBimal Kumar Dash0% (1)

- Lavjya Parts Catalogue-744fe - 742fe - 855fe-Sept 1713Document199 pagesLavjya Parts Catalogue-744fe - 742fe - 855fe-Sept 1713Nil PhadtarePas encore d'évaluation

- Gyrovator SeriesDocument62 pagesGyrovator SeriesPreet NagpalPas encore d'évaluation

- TML HCV FinalDocument208 pagesTML HCV FinalVenkat CmrlPas encore d'évaluation

- 2016 Dealer PriceDocument13 pages2016 Dealer Priceadetejubello100% (3)

- Range List For Swaraj Tractor PDFDocument9 pagesRange List For Swaraj Tractor PDFpuneet chadhaPas encore d'évaluation

- HMT Tractor Oil SealsDocument17 pagesHMT Tractor Oil SealsAmit Chopra Amit100% (2)

- Kobelco Engine OilDocument2 pagesKobelco Engine OildnoaisapsPas encore d'évaluation

- 245 DI Orchard Part Catalogue103 PDFDocument93 pages245 DI Orchard Part Catalogue103 PDFSamsher Ali100% (1)

- LuK Tractor Price List 2020Document6 pagesLuK Tractor Price List 2020Amit Chopra AmitPas encore d'évaluation

- Illustrated Spare Parts List for 2R1040 Engine Power GenerationDocument122 pagesIllustrated Spare Parts List for 2R1040 Engine Power Generationyudi handoko0% (1)

- Falcon BUS CatalogueDocument4 pagesFalcon BUS CatalogueVikky Mehta50% (2)

- Mekoauto India Price List Water Pumps 2022Document34 pagesMekoauto India Price List Water Pumps 2022MM SparesPas encore d'évaluation

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument91 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya Anam100% (1)

- Compact Air Intake System Parts ListDocument90 pagesCompact Air Intake System Parts ListRAFEEQ PASHA100% (1)

- Rev - A - Asp 10011 - SPC - 07-08-2020Document134 pagesRev - A - Asp 10011 - SPC - 07-08-2020Cuong Nguyen100% (1)

- Chota ChilliDocument1 pageChota ChilliRishu ranaPas encore d'évaluation

- Launch Notes BS6 Apr'22 CV SACDocument5 pagesLaunch Notes BS6 Apr'22 CV SACShambhu Kumar100% (1)

- Hero Honda GlamourDocument7 pagesHero Honda Glamourrudey18Pas encore d'évaluation

- Boschkbx Price 2013 PDFDocument40 pagesBoschkbx Price 2013 PDFvivek0630Pas encore d'évaluation

- Parts 44a 44b 12.5-9.4 BTDB 15.0 - 12.0 BTDCDocument102 pagesParts 44a 44b 12.5-9.4 BTDB 15.0 - 12.0 BTDCnyaungzinPas encore d'évaluation

- Spare Parts Catalogue 100kvaDocument72 pagesSpare Parts Catalogue 100kvanaseefPas encore d'évaluation

- Safari 22l Dicor LHD Tata Motor 22l Dicor LHD Tata Motors Limited Safari Ex 4x2 22l PDFDocument422 pagesSafari 22l Dicor LHD Tata Motor 22l Dicor LHD Tata Motors Limited Safari Ex 4x2 22l PDFAlex Antonio Silva AcevedoPas encore d'évaluation

- Price List Application WiseDocument1 pagePrice List Application Wisemanojkhare7620Pas encore d'évaluation

- HOW TO USE PARTS CATALOGUEDocument139 pagesHOW TO USE PARTS CATALOGUEKanhaiya AgrawalPas encore d'évaluation

- ABR Price List - (Wef 10th April'21) - Updated (24102021)Document3 pagesABR Price List - (Wef 10th April'21) - Updated (24102021)MM SparesPas encore d'évaluation

- Mahindra TharDocument4 pagesMahindra Tharapi-27077834100% (1)

- Luk Tractors Price List Jan 2022Document8 pagesLuk Tractors Price List Jan 2022ANURAGPas encore d'évaluation

- Escort Compactor Ec 5250Document2 pagesEscort Compactor Ec 5250Felix Sanders100% (3)

- Doosan DP Engine series 77-828kW for generatorsDocument2 pagesDoosan DP Engine series 77-828kW for generatorsRizka PsPas encore d'évaluation

- Kirloskar 6R1080TA 41-50Document10 pagesKirloskar 6R1080TA 41-50Niten GuptaPas encore d'évaluation

- Commercial Vehicle Business Unit: Product Spare Parts CatalogueDocument125 pagesCommercial Vehicle Business Unit: Product Spare Parts CatalogueAngu ChamyPas encore d'évaluation

- SWARAJ ENGINEDocument30 pagesSWARAJ ENGINEKaran SinghPas encore d'évaluation

- Yamaha BR250 Bravo Snowmobile Service ManualDocument191 pagesYamaha BR250 Bravo Snowmobile Service ManualSmedlowPas encore d'évaluation

- Generador Chino PDFDocument73 pagesGenerador Chino PDFOmar TaréPas encore d'évaluation

- On SaonalikaDocument14 pagesOn SaonalikaAmanda MatthewsPas encore d'évaluation

- Swaraj Engines Ltd. Training Report by Satnam SinghDocument58 pagesSwaraj Engines Ltd. Training Report by Satnam SinghSatnam Singh100% (4)

- Improvement of Evaporative Cooling SystemDocument7 pagesImprovement of Evaporative Cooling SystemSatnam SinghPas encore d'évaluation

- 2013-14 Be MechDocument94 pages2013-14 Be MechNikhil GargPas encore d'évaluation

- Industrial TrainingDocument59 pagesIndustrial TrainingSatnam SinghPas encore d'évaluation

- Industrial Training of PTL REPORTDocument42 pagesIndustrial Training of PTL REPORTHimanshu SagarPas encore d'évaluation

- L-39 Flight ManualDocument290 pagesL-39 Flight ManualCory Lovell100% (3)

- Nissan Mr20deDocument11 pagesNissan Mr20dework.the.diagnosticsPas encore d'évaluation

- Series Parts CatalogDocument24 pagesSeries Parts Catalogcochran04Pas encore d'évaluation

- Audi Volkswagen - 2.0L Chain Drive - P0016 Cam - Crank Correlation Check - Ross-Tech ForumsDocument6 pagesAudi Volkswagen - 2.0L Chain Drive - P0016 Cam - Crank Correlation Check - Ross-Tech ForumsMatias Meinero100% (1)

- Driver's Handbook: Volvo Enhanced Cruise (VEC) VN, VTDocument38 pagesDriver's Handbook: Volvo Enhanced Cruise (VEC) VN, VTErnesto TurpoPas encore d'évaluation

- Brochure G4D31TDocument1 pageBrochure G4D31TElton FloresPas encore d'évaluation

- Catalogo Apache Rtr180 PDF 2012Document48 pagesCatalogo Apache Rtr180 PDF 2012Edgar Sorto63% (8)

- Service Manual Trucks: Circuit and Wiring Numbers VN, VHDDocument34 pagesService Manual Trucks: Circuit and Wiring Numbers VN, VHDАндрейPas encore d'évaluation

- YC4108 Fuel Injection PumpDocument3 pagesYC4108 Fuel Injection PumpCarlos GuajardoPas encore d'évaluation

- 2014 Chevrolet Cruze maintenance schedule guideDocument2 pages2014 Chevrolet Cruze maintenance schedule guidericardo rodriguezPas encore d'évaluation

- Manual Motor Hyundai Elantra - Unlocked PDFDocument164 pagesManual Motor Hyundai Elantra - Unlocked PDFloky13100% (1)

- Aprilia SR 150 ManualDocument98 pagesAprilia SR 150 Manualmujohaso12350% (2)

- Mercury Service Manual 40-50-55-60-90Document566 pagesMercury Service Manual 40-50-55-60-90Will Gates86% (208)

- Service Manual: EQ1030T47D-820 Light Commercial TruckDocument175 pagesService Manual: EQ1030T47D-820 Light Commercial TruckYonny ColquePas encore d'évaluation

- 5L40EDocument177 pages5L40EValentinDudkin100% (3)

- 78 Olds CSMCHPT 0Document25 pages78 Olds CSMCHPT 0vixentdPas encore d'évaluation

- Course 4 Engine CyclesDocument53 pagesCourse 4 Engine CyclesLuca PenesPas encore d'évaluation

- UO Submission FormDocument1 pageUO Submission FormDee JoshiPas encore d'évaluation

- D883002BX03Document2 pagesD883002BX03Juan Diego SarangoPas encore d'évaluation

- Engine Overhauling AssignmentDocument11 pagesEngine Overhauling AssignmentSabeeh Safdar100% (1)

- FZ 21CGDocument55 pagesFZ 21CGlahiruPas encore d'évaluation

- CUBE Acid 2x Darkgrey N Flashyellow 2017Document8 pagesCUBE Acid 2x Darkgrey N Flashyellow 2017Wong TerbiumPas encore d'évaluation

- Presentation On History of CarsDocument19 pagesPresentation On History of CarsDigvijay SinghPas encore d'évaluation

- Honda CRF 450 R 2007r. Service Manual SerwisówkaDocument169 pagesHonda CRF 450 R 2007r. Service Manual SerwisówkaNight Street WarriorsPas encore d'évaluation

- Part Unit PDFDocument8 pagesPart Unit PDFOgy Tirta PerdanaPas encore d'évaluation

- Dodge Twin Turbo Kit Installation InstructionsDocument24 pagesDodge Twin Turbo Kit Installation InstructionsctdmnPas encore d'évaluation

- Ic05 Display Unit: Training Document Without UpdatesDocument24 pagesIc05 Display Unit: Training Document Without UpdatesAris NurrochmanPas encore d'évaluation

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistNeethPas encore d'évaluation

- Hyosung Motors Cylinder Head Parts ListDocument124 pagesHyosung Motors Cylinder Head Parts ListJason CumbiePas encore d'évaluation

- Makalah DASAR-DASAR Mesin: Untuk Memenuhi Salah Satu Tugas Mata Pelajaran Teknik Dasar OtomotifDocument14 pagesMakalah DASAR-DASAR Mesin: Untuk Memenuhi Salah Satu Tugas Mata Pelajaran Teknik Dasar OtomotifAevunx CthmPas encore d'évaluation