Académique Documents

Professionnel Documents

Culture Documents

2343242

Transféré par

Tran Van DaiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2343242

Transféré par

Tran Van DaiDroits d'auteur :

Formats disponibles

CUU LONG JOINT OPERATING COMPANY

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

CONTRACTOR: PTSC M&C

SUB CONTRACTOR: VIETSOVPETRO

BOATLANDINGS OFFSHORE LIFTING ANALYSIS

REPORT

Document No.: 2013-1489-6R-3011

VIETSOVPETRO PTSC M&C CLJOC

REV.

NO.

DATE

PREPARED BY APPROVED BY REVIEWED BY APPROVED BY APPROVED BY

NAME SIGN DATE NAME SIGN DATE NAME SIGN DATE NAME SIGN DATE NAME SIGN DATE

A

07.04.

14

VDC

07.04.

14

PCK

07.04.

14

B

14.05.

14

TVD

14.05.

14

PNV

14.05.

14

0

15.05.

14

TVD

15.05.

14

PNV

15.05.

14

Our Ref: 11-080V-26(R1)/11-1550-26(R1) Braemar Technical Services (Offshore) Vietnam Co. Ltd. Page 1 of 3

from:

Braemar Technical Services (Offshore) VietnamCo. Ltd, Vietnam

an ISO 9001 Certificated Company

DETAILS AND COMMENTS

Project Title: Su Tu Vang South West EPCI Project

Prepared By:

Do Hien

R

dh

C

pta

Doc Title: Boatlanding Offshore Lifting Analysis Report

Date:

14

th

May 2014

Doc No.: 2013-1489-6R-3011; Rev. B

Our Ref:

11-080V-26(R1)/

11-1550-26(R1)

Client: Cuu Long Joint Operating Company

E-mail To :

Mr. Nguyen Ngoc Trung (SVSW, Project Manager) <trungnn@cljoc.com.vn>

Mr. Tran Hoang Viet (SVSW, Engineering Manager) <tran.h.viet@cljoc.com.vn>

Mr. Nguyen Xuan Ngoc (Structural Engineer) nguyen.x.ngoc@cljoc.com.vn

Ms. Cao Thi Dung (Document Controller) cao.t.dung@cljoc.com.vn>

E-mail Cc :

Mr. Le Vu Dung (DEV, Development & Engineering Manager) <le.v.dung@cljoc.com.vn>

Mr. Pham Tuan Anh <tuananh.pham@braemar.com>

Revi ew St at us

Approved

Approved wi th

Comment s

X

Revi ewed wi th

Comment s

Not Approved

Section A Review Comments To be Resolved for Acceptance

Action To

Be Taken

1. All Sections of Document

1.1 We note this document pertains to the structural integrity, lifting points and rigging

strength checks for Boatlanding offshore lifting installation using installation vessel

Truong Sa.

1.2 Review of this document is based on approximately 54.71MT factored lifting weight

of Boatlanding (refer to the enclosed drawing 2013-1489-66-3036; Rev 1).

1.3 We note the following code/specification have been adopted into analysis:-

- AISC-ASD 9

th

Edition

- API RP-2A WSD 21

st

Edition

1.4 Section 3.1. Hook load and Sling Forces; please include the detailed lifting

arrangement drawing for Boatlanding as well as crane lift chart into document in

next revision for verification.

Contractor Response:

Noted, will be updated and incorporated in next revision.

MWS new comment:

Noted.

No Response Required

No Response Required

No Response Required

No Response Required

Our Ref: 11-080V-26(R1)/11-1550-26(R1) Braemar Technical Services (Offshore) Vietnam Co. Ltd. Page 2 of 3

Section A Review Comments To be Resolved for Acceptance (Contd)

Action To

Be Taken

1.5 Appendix H, to include the mentioned valid certificates into report for verification.

Contractor Response:

Noted, will be updated and incorporated in next revision.

MWS new comment:

Noted. No Response Required

Section B On Site/Offshore Issues To Be Addressed

Action To

Be taken

With regard to the actual lifting approval, please be advised that final approval will be

issued by our attending surveyor at site subjected to the following:

1. Our satisfactory review of all the relevant engineering document(s) pertaining to

boatlanding lifting analysis.

2. Our attending surveyors satisfaction with the actual arrangement of the lifting

slings configuration and condition.

3. Our attending surveyors satisfaction with the padeye/trunnion integrity and

welds. In this regards, please note that all padeye/trunnion welds shall be

inspected visually 100% with NDT as follows: -

- 100% UT for all full penetration welds

- 100% MPI for all fillet welds

Please ensure that all material, MPI, UT and valid rigging certificate reports are

made available and presented to our attending surveyor for review.

4. Our attending surveyors satisfaction with valid certificates for all lifting slings,

shackles, crane, etc.

5. Our attending Surveyors satisfaction with the actual mooring patter of crane

vessel, transportation barge/crane vessel stability, all clearances during lift,

weather conditions, etc.

6. Final satisfaction of our attending surveyor at site.

To be closed out by our

attending surveyor on

site

Section C Acceptance Stamp

1. Front-page copy of the above-mentioned document with our acceptance stamp is attached for your

retention and reference.

Comments By: DH Checked By: PTA

For urgent clarification, please contact:-

Review Engineer: Do Hien

Office No.: +84 643 832 178

Mobile No.: +84 983 062 624

Our Ref: 11-080V-26(R1)/11-1550-26(R1) Braemar Technical Services (Offshore) Vietnam Co. Ltd. Page 3 of 3

APPROVED, SUBJECT TO TERMS & CONDITIONS OF THE INSURANCE AND AS

PER OUR COMMENTS,

(IF ANY), IN OUR CORRESPONDENCE.

REF NO.: 11-080V-26(R1)/11-1550-26(R1)

DATE: 14

th

May 2014

Braemar Offshore

BRAEMAR TECHNICAL SERVICES (OFFSHORE) VIETNAM CO. LTD

VIETNAM

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 2 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

REVISION RECORD SHEET

NO. REV. NO. CONTENT OF REVISION DATE OF REVISION

1 A Issued for Review and Comment 18 April 2014

2 B Re-Issued for Review and Comment 14 May 2014

3 0 Approved For Construction 15 May 2014

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 3 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

TABLE OF CONTENT

1.0 INTRODUCTION ........................................................................................................... 4

1.1 DEFINITION .......................................................................................................................... 4

1.2 PURPOSE ............................................................................................................................... 4

1.3 GENERAL INFORMATION ................................................................................................. 4

1.4 SCOPE .................................................................................................................................... 4

1.5 REFERENCE .......................................................................................................................... 4

2.0 BOATLANDING LIFTING ANALYSIS ...................................................................... 5

2.1 COMPUTER MODEL. .......................................................................................................... 5

2.2 DESIGN LOAD ...................................................................................................................... 7

2.3 DYNAMIC LOAD FACTORS .............................................................................................. 9

2.4 LOAD COMBINATION ........................................................................................................ 9

3.0 SUMMARY OF RESULTS ............................................................................................ 9

3.1 HOOK LOAD AND SLING FORCES .................................................................................. 9

3.2 MEMBER AND JOINT UNITY CHECKS ......................................................................... 10

4.0 CONCLUSION .............................................................................................................. 11

APPENDIX

APPENDIX- A : WEIGHT OF BOATLANDING ................................................................ 12

APPENDIX- B : BOATLANDING LIFTING CONFIGURATION ................................. 13

APPENDIX- C : BOATLANDING SACS MODEL PLOT .............................................. 14

APPENDIX D : BOATLANDING SACS MODEL INPUT FILE ................................... 15

APPENDIX E : BOATLANDING SACS OUTPUT FILE .............................................. 16

APPENDIX F : LIFTING RIGGING PADEYE CHECK ................................................... 17

APPENDIX G : BOATLANDING STRUCTURAL DRAWING ........................................ 18

APPENDIX H : SLING AND SHACKLE CERTIFICATE ................................................. 19

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 4 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

1.0 INTRODUCTION

1.1 DEFINITION

CLJOC : Cuu Long Joint Operating Company

VSP : Vietsovpetro Joint Venture

SVSW : Su Tu Vang South West

WHP : Well Head Platform

1.2 PURPOSE

The purpose of this Boatlandings Offshore Lifting Analysis Report is to provide detailed

evaluation of the lifting performance of Drilling Module by crane barge.

The Boatlandings Offshore Lifting Analysis is carried out in this report with C.O.G shift cases.

1.3 GENERAL INFORMATION

Cuu Long Joint Operating has embarked in the development of STV Extension Plan - STV South

West (SVSW) Project located in Block 15-1, offshore Vietnam.

This development consists of an unmanned tripod jacketed platform (SVSW) with minimum

facility which tie-back and operated from the adjacent STV-CPP. The development of this field

will be carried out by utilizing 3 slots consist of one (1) existing well using single Xmas Tree and

two (2) future dual well Xmas Trees. Processing of the SVSW wellstream fluids will be carried

out on the STV-CPP facilities which will also supply gas to SVSW for gas lifting. STV-CPP will

alsocontrol and monitor SVSW.

1.4 SCOPE

This report presents the summary of the results of Boatlandings Offshore Lifting Analysis Report

at installation field, verify all slings to ensure that no damage will occur when offshore

installation.

1.5 REFERENCE

The following design code and specification are adopted:

Design Code:

- API RP2A(WSD) 21st Edition-American Petroleum Institute

- AISC Manual of Steel Construction (ASD) 9th Edition-American Institute of Steel

Construction

Other Reference

- Weight Of Boatlanding For Lifting :Refer to Appendix A1

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 5 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

- Boatlanding lifting Configuration; Doc. No. : 2013-1489-66-3036

- SVSW WHP Jacket Weight Control Report; Doc. No. : 2013-3289-6J-0005 Rev 0

2.0 BOATLANDING LIFTING ANALYSIS

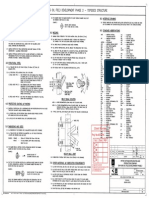

2.1 COMPUTER MODEL.

3-Dimensional (3D) computer model is created to simulate Boatlanding by using SACS

computer program. The computer model for Boatlanding lifting is shown below:

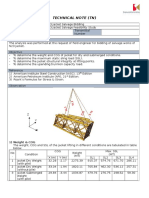

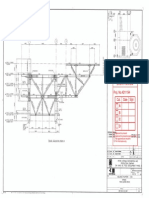

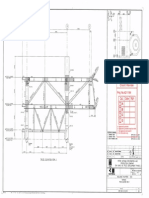

Figure 1: Boatlanding Lifting Analysis Model

A hook point (Joint HOOK) was simulated as fixed point (111111) in all translational and

rotational directions, to be located vertically over the model COG. It is the only vertical load

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 6 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

support in the model and will be connected by sling elements to the lift points. Four (4) lifting

slings were modelled as tubular members with members end fixities release (000011-000111)

such that it were capable of taking only axial tension loads. Two (2) lateral spring elements (Joint

B019 and Joint B020) are modeled and used to maintain structural equilibrium during analyses.

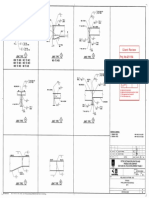

Figure 2: Boundary Condition

The initial model coordinate system is as follow:

Global X-axis : Longitudinal, perpendicular with Boatlanding Grid A,B; X=0 at

Boatlanding Grid 1

Global Y-axis : parallel with Boatlanding Grid A,B; Y=0 at center of distance

with Boatlanding Grid A to with Boatlanding Grid B.

Global Z-axis : Vertical; positive upwards; z=0 at mean seal level (M.S.L=0).

The coordinate system is shown below :

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 7 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

Figure 3: Coordinate System

Coordinate of CoG of Boalanding in SACS coordination system:

X= 0.19 m

Y= 0.77 m

Z= 0.87 m

2.2 DESIGN LOAD

This section presents the summary of manually input and computer-generated loadings. Dead

weight of modelled member is obtained as self-generated by SACS. The lifting will be executed

in calm climate. Hence, it is reasonably assumed that rain and wind effect on Boatlanding

structure is negligible. The Basic Load Description is listed in table below:

Load considerded in the structural analysis are as flow:

Load

condition

Description Load name

Self weight of Subsea Wellhead Template

1 Computer Generated Main subsea model structural self weight DEAD

Appurtenances and miscellaneous steel weights

2

Double plates BL-DOPL

Barge Bumper BL-BUMPE

Fender BL-FENDE

Grating BL-GRATT

Handrail BL-HANDR

Ladder BL-LADDE

Mooring Bit BL-MORIG

Padeye for lifting BL-PADEY

Stair BL-STAIR

3 Couples Force COUPLE

TOTAL

Table 1: LOAD CONDITION

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 8 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

The couple force to match COG is shown in the table below:

Coordinate of CoG follow WCR in sacs mode:

X= -0.2 m

Y= -0.63 m

Coordinate of CoG follow result of SACS

X= -0.19 m

Y= -0.77 m

X(m)= -0.01 m

Y(m)= 0.14 m

Load case X(m) Y(m) POINTS P(KN)

3 -0.01 0.14

B064 12.64

B065 -10.94

B062 13.24

D238 -14.94

Table 2: Couple Force To Match Wcr COG

Description Load Case

Basic Load

(kN)

Load Factor

Factored

Load (kN)

Computer Generated Selfweight 1 370.47 1.13 418.6

Un-modeled weight 2 86.89 1.13 98

Couple force 3 0 1 0

Total Load (Load Combine GRV) 516.6

Table 3 : Basic Load Case

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 9 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

2.3 DYNAMIC LOAD FACTORS

The dynamic load factors for offshore installation lift operation are as per API RP 2A (WSD) :

Members connected to lifting points DLF=2.00

All other members DLF=1.35

2.4 LOAD COMBINATION

Load Com.

Load Combinations & Load Conditions

CB GRV 3

GRV 1.13 1.0

LC1 1.35

LC2 2.0

Table 4 : Load Combine

3.0 SUMMARY OF RESULTS

The Boatlanding members and joint stress obtained from the structural strength analysis for

offshore installation lift were checked against the allowable values in accordance with API RP 2A

and AISC code requirements. Results of analysis are presented in the following sections :

3.1 HOOK LOAD AND SLING FORCES

The hook loads and sling forces are given in the following tables :

Load Case

Hook Loads (kN)

Fx Fy (Fz+Rigging load) x DAF

GRV - - (516.6+20) x 1.3 = 697.58

Table 5: Boatlanding Hook Load

The hook capacity of 150 MT for aux.hook of Truong Sa Crane Barge is greater than the hook

load listed above, hence this crane is satisfactory for the proposed Boatlanding lift.

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 10 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

Sling Members

Sling Forces (kN)

Sling & Shackles

Design(No DAF)

Combine

HOOK-PA01 130.46 GRV

HOOK -PA02 116.18 GRV

HOOK -PA03 144.68 GRV

HOOK -PA04 140.25 GRV

Table 6: Boatlanding Slings Forces

The above slings forces are used for the rigging & pad eye checks.

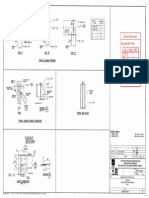

3.2 MEMBER AND JOINT UNITY CHECKS

3.2.1. MEMBER UNITY CHECKS.

Member design code check was performed in accordance with API RP2A (WSD) and AISC-

ASD.

Analysis result indicate that all the member strength and joints unity check ratios for Boatlanding

are less than 0.50 ( ignore all sling members).

Members connected to lifting points with unity check 0.15 are list below :

Member

Member

Section Max.UC Load Case DAF

Group

B036-B064 BL4 40.64x12.7thk. 0.17 LC2 2

B060-B071 BL4 40.64x12.7thk. 0.18 LC2 2

B062-B071 BL4 40.64x12.7thk. 0.20 LC2 2

Table 7: Boatlanding Uc Members Connected To Lifting Point

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 11 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

The maximum unity check of all other members are list below:

Member

Member

Section Max.UC Load Case DAF

Group

B079-B081 BL4 40.64x12.7thk. 0.19 LC1 1.35

Table 8: Boatlanding All Members With Maximum UC

3.2.2. JOINT UNITY CHECKS.

Joints with maximum unity check of all other members are list below :

Joints Max. UC Load Case DAF

B071 0.54 LC2 2

Table 9: Boatlanding Joints With Maximum Uc

4.0 CONCLUSION

The structural integrity of the Boatlanding was analysed for offshore installation lift operation.

Members and joints stressed obtained were checked against the allowable values in accordance

with API RP 2A and AISC code requirements. Results of the analysis and checks indicated that all

stress ratios are less than unity. It is thus concluded that the Boatlanding is structurally adequate

during offshore lift.

The lifting padeye and rigging strength checks also shown that the proposed lifting configuration

is satisfactory for Boatlanding offshore installation lift operation.

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 12 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

APPENDIX- A :

WEIGHT OF BOATLANDING

The weight of BL for

offhore lifting

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 13 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

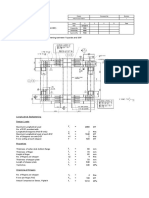

APPENDIX- B :

BOATLANDING LIFTING CONFIGURATION

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 14 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

APPENDIX- C :

BOATLANDING SACS MODEL PLOT

EL(-)5200

EL(-)2200

EL(+)1062

EL(+)2262

EL(+)7000

B

A

HOOK

POINT

SLING 02

SLING 04

SLING 01

SLING 03

KING POST WITH 1500MM OVER LENGHT

REFER NOTE 6-DRW: 2013-3289-63-0017

ISOMETRIC

110000 110000

111111

X

Y

Z

HOOK POINT

JOINT HOOK

LIFTING POINT

JOINT PA01

LIFTING POINT

JOINT PA04

LIFTING POINT

JOINT PA02

LIFTING POINT

JOINT PA01

SPRING

JOINT B020

SPRING

JOINT B019

PLAN VIEW AT Y = -1.300

B029 B033 B034 B035 B036 B037

B045 B046 B047 B048 B049 B050 B051

B052

B060

B061 B062 B063 B064

B071 B081

PA03

PA04

X

Z

PLAN VIEW AT X = -5.333

B001

B003

B009

B011

B012

B015

B017

B019

B024

B027

B079

PA01

Y

Z

PLAN VIEW AT X = -2.999

B033

B046

B058

B060

B061 B068

B069 B072

Y

Z

PLAN VIEW AT X = 0.001

B035

B048

B056

B063 B066 B083

Y

Z

PLAN VIEW AT X = 3.001

B037

B050

B054 B085

Y

Z

PLAN VIEW AT X = 5.333

B002

B004

B010

B013

B014

B016

B018

B020

B025

B028

PA02

Y

Z

PLAN VIEW AT Z = -2.200

B024 B025

B045 B046 B047 B048 B049 B050 B051

X

Y

PLAN VIEW AT Z = 0.808

B027 B028

B029 B033 B034 B035 B036 B037 B052

B053 B054 B055 B056 B057 B058 B059

B085 B102

X

Y

PLAN VIEW AT Z = 2.059

B061 B062 B063 B064

B065 B066 B067 B068

B083 B084 B100

X

Y

PLAN VIEW AT Z = 3.259

B060

B069 B070

B071

B072 B073

B079 B080

B081

B082

X

Y

PLAN VIEW AT Y = -1.300

LABEL=GROUP

BL3 BL3 BL3 BL3 BL3 BL3

BL3 BL3 BL3 BL3 BL3 BL3

B

L

4

B

L

4

B

L

4

B

L

4

B

L

4

B

L

4

B

L

4

B

L

4

B

L

4

BL4

B

L

4

BL4 BL4

B

L

4

BL4

BL4

P

A

P

A

X

Z

PLAN VIEW AT X = -5.333

B

L

1

LABEL=GROUP

B

L

1

B

L

1

B

L

2

B

L

2

B

L

2

B

L

2

B

L

2

B

L

2

BL5

BL5

P

A

Y

Z

PLAN VIEW AT X = -2.999

LABEL=GROUP

B

L

4

B

L

4

B

L

4

BL7

BL8

B

L

8

B

L

8

BL8

B

L

8

BL8

Y

Z

PLAN VIEW AT X = -1.499

LABEL=GROUP

B

L

4

B

L

4

B

L

4

BL7 BL7 BL7

BL8

B

L

8

B

L

8

BL8

B

L

8

BL8

P

A

Y

Z

PLAN VIEW AT X = 0.001

LABEL=GROUP

B

L

4

B

L

4

BL8

B

L

8

B

L

8

BL8 BL8

Y

Z

PLAN VIEW AT X = 1.501

LABEL=GROUP

B

L

4

B

L

4

BL7 BL7

BL8

B

L

8

B

L

8

BL8

P

A

Y

Z

PLAN VIEW AT X = 3.001

LABEL=GROUP

B

L

4

BL8

B

L

8

BL8

Y

Z

PLAN VIEW AT X = 5.333

LABEL=GROUP

B

L

1

B

L

1

B

L

1

B

L

2

B

L

2

B

L

2

B

L

2

B

L

2

BL5

BL5

P

A

Y

Z

PLAN VIEW AT Z = -2.200

LABEL=GROUP

B

L

3

BL3 BL3 BL3 BL3 BL3 BL3

B

L

3

X

Y

PLAN VIEW AT Z = 0.808

LABEL=GROUP

B

L

3

BL3 BL3 BL3 BL3 BL3 BL3

B

L

3

B

L

6

B

L

6

BL6 BL6 BL6 BL6 BL6 BL6

B

L

8

B

L

8

B

L

8

B

L

8

B

L

8

B

L

8

B

L

8

BL9

X

Y

PLAN VIEW AT Z = 2.059

LABEL=GROUP

BL4 BL4 BL4

B

L

7

B

L

7

BL7 BL7 BL7

B

L

7

B

L

8

B

L

8

B

L

8

B

L

8

BL9 BL9

X

Y

PLAN VIEW AT Z = 3.259

LABEL=GROUP

BL4

B

L

4

BL4

BL7

B

L

7

B

L

7

B

L

7

B

L

7

BL7

B

L

8

B

L

8

BL8

X

Y

PLAN VIEW AT Y = -1.300

LABEL=SECTION

50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54

50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

40.64X1.27

4

0

.

6

4

X

1

.

2

7

40.64X1.27 40.64X1.27

4

0

.

6

4

X

1

.

2

7

40.64X1.27

40.64X1.27

2

1

.

9

X

1

.

2

7

2

1

.

9

X

1

.

2

7

X

Z

PLAN VIEW AT X = -5.333

7

6

.

2

X

2

.

5

4

LABEL=SECTION

7

6

.

2

X

2

.

5

4

7

6

.

2

X

2

.

5

4

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

45.7X2.54

45.7X2.54

2

1

.

9

X

1

.

2

7

Y

Z

PLAN VIEW AT X = -2.999

LABEL=SECTION

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

27.31X1.27

21.91X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

21.91X1.27

2

1

.

9

1

X

1

.

2

7

21.91X1.27

Y

Z

PLAN VIEW AT X = -1.499

LABEL=SECTION

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

27.31X1.27 27.31X1.27 27.31X1.27

21.91X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

21.91X1.27

2

1

.

9

1

X

1

.

2

7

21.91X1.27

2

1

.

9

X

1

.

2

7

Y

Z

PLAN VIEW AT X = 0.001

LABEL=SECTION

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

21.91X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

21.91X1.27 21.91X1.27

Y

Z

PLAN VIEW AT X = 1.501

LABEL=SECTION

4

0

.

6

4

X

1

.

2

7

4

0

.

6

4

X

1

.

2

7

27.31X1.27 27.31X1.27

21.91X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

21.91X1.27

2

1

.

9

X

1

.

2

7

Y

Z

PLAN VIEW AT X = 3.001

LABEL=SECTION

4

0

.

6

4

X

1

.

2

7

21.91X1.27

2

1

.

9

1

X

1

.

2

7

21.91X1.27

Y

Z

PLAN VIEW AT X = 5.333

LABEL=SECTION

7

6

.

2

X

2

.

5

4

7

6

.

2

X

2

.

5

4

7

6

.

2

X

2

.

5

4

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

6

1

X

3

.

1

8

45.7X2.54

45.7X2.54

2

1

.

9

X

1

.

2

7

Y

Z

PLAN VIEW AT Z = -2.200

LABEL=SECTION

5

0

.

8

X

2

.

5

4

50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 5

0

.

8

X

2

.

5

4

X

Y

PLAN VIEW AT Z = 0.808

LABEL=SECTION

5

0

.

8

X

2

.

5

4

50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 50.8X2.54 5

0

.

8

X

2

.

5

4

3

2

.

3

9

X

1

.

2

7

3

2

.

3

9

X

1

.

2

7

32.39X1.27 32.39X1.27 32.39X1.27 32.39X1.27 32.39X1.27 32.39X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7 2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

16.83X0.952

X

Y

PLAN VIEW AT Z = 2.059

LABEL=SECTION

40.64X1.27 40.64X1.27 40.64X1.27

2

7

.

3

1

X

1

.

2

7

2

7

.

3

1

X

1

.

2

7

27.31X1.27 27.31X1.27 27.31X1.27

2

7

.

3

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

16.83X0.952 16.83X0.952

X

Y

PLAN VIEW AT Z = 3.259

LABEL=SECTION

40.64X1.27

4

0

.

6

4

X

1

.

2

7

40.64X1.27

27.31X1.27

2

7

.

3

1

X

1

.

2

7

2

7

.

3

1

X

1

.

2

7

2

7

.

3

1

X

1

.

2

7

2

7

.

3

1

X

1

.

2

7

27.31X1.27

2

1

.

9

1

X

1

.

2

7

2

1

.

9

1

X

1

.

2

7

21.91X1.27

X

Y

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 15 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

APPENDIX D :

BOATLANDING SACS MODEL INPUT FILE

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

LDOPT NF+Z1.0250007.850000 GLOBMN HYDFLD MPP

**************************** SV-SW JACKET*****************************

* T&I ENGINEERING FOR SV-SW PROJECT *

* VIETSOVPETRO *

* Vung Tau, Vietnam. *

* Project No. : .... *

* Commenced modelling : APR 2014 *

* File name : sacinp.Boatlanding *

* Client : Cuu Long JOC *

* Description : boatlanding lifting ANALYSIS *

* REVISION : A *

* PREPARE by : VDC *

* REVIEWED BY : PCK *

* APPROVED BY : NDT *

* *

*****************************************************************************

OPTIONS MN SDUCJT 8 8 DC C PTPTPTPTPT PTPT

LCSEL CB GRV LC1 LC2

UCPART 0.5000.5001.0001.000

GRUP

GRUP BL1 76.200 2.540 21.0080.0034.50 1 1.001.00 0.500 7.8500

GRUP BL2 61.000 3.180 21.0080.0034.50 1 1.001.00 0.500 7.8500

GRUP BL3 50.800 2.540 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP BL4 40.640 1.270 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP BL5 45.700 2.540 21.0080.0034.50 1 1.001.00 0.500 7.8500

GRUP BL6 32.390 1.270 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP BL7 27.310 1.270 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP BL8 21.910 1.270 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP BL9 16.830 0.952 21.0080.0024.00 1 1.001.00 0.500 7.8500

GRUP PA 21.900 1.270 20.007.72424.80 9 1.001.00 0.500 1.00-5

GRUP SLI 5.000 2.400 20.007.72424.80 9 1.001.00 0.500 1.00-5

MEMBER

MEMBER B011B015 BL1 L 1.801.80

MEMBER B012B011 BL1

MEMBER B013B016 BL1 L 1.801.80

MEMBER B014B013 BL1

MEMBER B017B012 BL1 L 1.801.80

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

MEMBER B018B014 BL1 L 1.801.80

MEMBER B001B003 BL2 L 11.111.1

MEMBER B002B004 BL2 L 11.111.1

MEMBER B009B024 BL2 L 11.111.1

MEMBER B010B025 BL2 L 11.111.1

MEMBER B019B009 BL2 L 11.111.1

MEMBER B020B010 BL2 L 11.111.1

MEMBER B024B027 BL2 L 11.111.1

MEMBER B025B028 BL2 L 11.111.1

MEMBER B027B079 BL2 L 11.111.1

MEMBER B028B002 BL2 L 11.111.1

MEMBER B079B001 BL2 L 11.111.1

MEMBER1B024B045 BL3 L 10.61.72

MEMBER OFFSETS 20.047-22.99

MEMBER1B027B029 BL3 L 10.61.65

MEMBER OFFSETS 20.047-22.99

MEMBER B029B033 BL3 L 10.61.20

MEMBER B033B034 BL3 L 10.61.50

MEMBER B034B035 BL3 L 10.61.50

MEMBER B035B036 BL3 L 10.61.50

MEMBER B036B037 BL3 L 10.61.50

MEMBER B037B052 BL3 L 10.61.20

MEMBER B045B046 BL3 L 8.401.20

MEMBER B046B047 BL3 L 8.401.50

MEMBER B047B048 BL3 L 8.401.50

MEMBER B048B049 BL3 L 8.401.50

MEMBER B049B050 BL3 L 8.401.50

MEMBER B050B051 BL3 L 8.401.20

MEMBER1B051B025 BL3 L 10.61.72

MEMBER OFFSETS -20.04-22.99

MEMBER1B052B028 BL3 L 10.61.65

MEMBER OFFSETS -20.04-22.99

MEMBER B033B061 BL4 L 2.401.20

MEMBER B034B062 BL4 L 2.401.20

MEMBER B035B063 BL4 L 1.201.20

MEMBER1B036B064 BL4 L 1.201.20

MEMBER OFFSETS -20.32

MEMBER B046B033 BL4 L 3.263.26

MEMBER B047B034 BL4 L 3.263.26

MEMBER B048B035 BL4 L 3.263.26

MEMBER B049B036 BL4 L 3.263.26

MEMBER B050B037 BL4 L 3.263.26

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

MEMBER1B060B071 BL4 L 3.831.50

MEMBER OFFSETS 28.000

MEMBER B061B060 BL4 L 2.401.20

MEMBER1B061B062 BL4 L 4.501.50

MEMBER OFFSETS -28.00

MEMBER B062B063 BL4 L 4.501.50

MEMBER B062B071 BL4 L 2.401.20

MEMBER1B063B064 BL4 L 4.501.50

MEMBER OFFSETS 28.000

MEMBER1B079B081 BL4 L 3.831.65

MEMBER OFFSETS 20.047-22.99

MEMBER B081B060 BL4 L 3.831.20

MEMBER1B011B001 BL5 L 1.901.90

MEMBER OFFSETS 38.100 -30.50

MEMBER1B012B009 BL5 L 1.901.90

MEMBER OFFSETS 38.100 -30.50

MEMBER1B013B002 BL5

MEMBER OFFSETS 38.100 -30.50

MEMBER1B014B010 BL5

MEMBER OFFSETS 38.100 -30.50

MEMBER1B027B059 BL6 L 10.61.65

MEMBER OFFSETS 20.94522.171

MEMBER1B053B028 BL6 L 10.61.65

MEMBER OFFSETS -20.9422.177

MEMBER B054B053 BL6 L 10.61.20

MEMBER B055B054 BL6 L 10.61.50

MEMBER B056B055 BL6 L 10.61.50

MEMBER B057B056 BL6 L 10.61.50

MEMBER B058B057 BL6 L 10.61.50

MEMBER B059B058 BL6 L 10.61.20

MEMBER1B061B068 BL7 L 2.502.50

MEMBER OFFSETS 20.320 15.000

MEMBER1B064B084 BL7 L 2.501.30

MEMBER OFFSETS 20.320

MEMBER1B066B065 BL7 L 4.501.50

MEMBER OFFSETS -13.65

MEMBER B067B066 BL7 L 4.501.50

MEMBER1B068B067 BL7 L 4.501.50

MEMBER OFFSETS 13.655

MEMBER B069B070 BL7 L 3.831.50

MEMBER1B070B073 BL7 L 4.101.60

MEMBER OFFSETS 22.000

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

MEMBER1B071B080 BL7 L 4.102.50

MEMBER OFFSETS 20.320

MEMBER1B079B082 BL7 L 3.831.65

MEMBER OFFSETS 20.94522.171

MEMBER B080B070 BL7 L 4.102.50

MEMBER B082B069 BL7 L 3.831.20

MEMBER B084B065 BL7 L 2.501.30

MEMBER1B033B058 BL8 L 2.502.50

MEMBER OFFSETS 25.400 -16.19

MEMBER1B034B057 BL8 L 2.502.50

MEMBER OFFSETS 25.400 -16.19

MEMBER1B035B056 BL8 L 2.502.50

MEMBER OFFSETS 25.400 -16.19

MEMBER1B036B102 BL8 L 2.502.50

MEMBER OFFSETS 25.400

MEMBER1B037B085 BL8 L 2.502.50

MEMBER OFFSETS 25.400

MEMBER1B046B058 BL8 L 4.114.11

MEMBER OFFSETS 15.45120.160 -9.851-12.85

MEMBER1B047B057 BL8 L 4.114.11

MEMBER OFFSETS 15.45120.160 -9.851-12.85

MEMBER1B048B056 BL8 L 4.114.11

MEMBER OFFSETS 15.45120.160 -9.851-12.85

MEMBER1B049B055 BL8 L 4.114.11

MEMBER OFFSETS 15.45120.160 -9.851-12.85

MEMBER1B050B054 BL8 L 4.114.11

MEMBER OFFSETS 15.45120.160 -9.851-12.85

MEMBER1B054B065 BL8 L 1.921.92

MEMBER OFFSETS -20.24 16.19517.069 -13.65

MEMBER1B055B065 BL8 L 1.201.20

MEMBER OFFSETS 16.195 -13.65

MEMBER1B056B066 BL8 L 1.201.20

MEMBER OFFSETS 16.195 -13.65

MEMBER1B057B067 BL8 L 2.401.20

MEMBER OFFSETS 16.195 -13.65

MEMBER1B058B068 BL8 L 2.401.20

MEMBER OFFSETS 16.195 -13.65

MEMBER1B060B069 BL8 L 4.102.50

MEMBER OFFSETS 20.320 -13.65

MEMBER1B062B100 BL8 L 2.501.30

MEMBER OFFSETS 20.320

MEMBER1B063B083 BL8 L 2.501.30

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

MEMBER OFFSETS 20.320

MEMBER1B066B070 BL8 L 1.921.92

MEMBER OFFSETS -17.07 13.65517.069 -13.65

MEMBER1B067B070 BL8 L 2.401.20

MEMBER OFFSETS 13.655 -13.65

MEMBER1B068B069 BL8 L 2.401.20

MEMBER OFFSETS 13.655 -13.65

MEMBER B069B072 BL8 L 4.101.60

MEMBER B072B073 BL8 L 1.50

MEMBER1B083B066 BL8 L 2.501.30

MEMBER OFFSETS -13.65

MEMBER1B083B080 BL8 L 1.921.92

MEMBER OFFSETS -8.554 6.84410.663 -8.530

MEMBER1B085B054 BL8 L 2.502.50

MEMBER OFFSETS -16.19

MEMBER1B085B084 BL8 L 1.921.92

MEMBER OFFSETS -8.554 6.84410.663 -8.530

MEMBER1B100B067 BL8 L 2.501.30

MEMBER OFFSETS -13.65

MEMBER1B102B055 BL8 L 2.502.50

MEMBER OFFSETS -16.19

MEMBER1B083B084 BL9 L 3.001.50

MEMBER OFFSETS 10.955 -13.65

MEMBER1B100B083 BL9 L 3.001.50

MEMBER OFFSETS 10.955 -10.96

MEMBER1B102B085 BL9 L 1.501.50

MEMBER OFFSETS 10.955 -10.96

MEMBER B003PA01 PA

MEMBER B004PA02 PA

MEMBER1B064PA04 PA

MEMBER OFFSETS 20.300

MEMBER1B071PA03 PA

MEMBER OFFSETS 20.300

MEMBER PA01HOOK SLI 000011000111

MEMBER PA02HOOK SLI 000011000111

MEMBER PA03HOOK SLI 000011000111

MEMBER PA04HOOK SLI 000011000111

JOINT

JOINT B001 -5. 0. 5.-33.350

JOINT B002 5. 0. 5. 33.350 0.004

JOINT B003 -5. 0. 7.-33.350

JOINT B004 5. 0. 7. 33.350 0.004

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

JOINT B009 -5. 0. -2.-33.350 -85.000

JOINT B010 5. 0. -2. 33.350 0.004-85.000

JOINT B011 -5. -1. 5.-33.350-90.000

JOINT B012 -5. -1. -2.-33.350-90.000-85.000

JOINT B013 5. -1. 5. 33.350-90.000

JOINT B014 5. -1. -2. 33.350-90.000-85.000

JOINT B015 -5. -1. 5.-33.350-90.000 90.000

JOINT B016 5. -1. 5. 33.350-90.000 90.000

JOINT B017 -5. -1. -3.-33.350-90.000-70.000

JOINT B018 5. -1. -3. 33.350-90.000-70.000

JOINT B019 -5. 0. -5.-33.350 -22.000 110000

JOINT B019 10.000 10.000 ELASTI

JOINT B020 5. 0. -5. 33.350 -22.000 110000

JOINT B020 10.000 10.000 ELASTI

JOINT B024 -5. 0. -2.-33.350 -20.000

JOINT B025 5. 0. -2. 33.350 0.004-20.000

JOINT B027 -5. 0. 0.-33.350 80.800

JOINT B028 5. 0. 0. 33.350 0.004 80.800

JOINT B029 -4. -1. 0.-19.947-29.996 80.800

JOINT B033 -2. -1. 0.-99.947-29.996 80.800

JOINT B034 -1. -1. 0.-49.947-29.996 80.800

JOINT B035 0. -1. 0. 0.053-29.996 80.800

JOINT B036 1. -1. 0. 50.053-29.996 80.800

JOINT B037 3. -1. 0. 0.053-29.996 80.800

JOINT B045 -4. -1. -2.-19.947-29.996-20.000

JOINT B046 -2. -1. -2.-99.947-29.996-20.000

JOINT B047 -1. -1. -2.-49.947-29.996-20.000

JOINT B048 0. -1. -2. 0.053-29.996-20.000

JOINT B049 1. -1. -2. 50.053-29.996-20.000

JOINT B050 3. -1. -2. 0.053-29.996-20.000

JOINT B051 4. -1. -2. 20.053-29.996-20.000

JOINT B052 4. -1. 0. 20.053-29.996 80.800

JOINT B053 4. 1. 0. 20.053 20.004 80.800

JOINT B054 3. 1. 0. 0.053 20.004 80.800

JOINT B055 1. 1. 0. 50.053 20.004 80.800

JOINT B056 0. 1. 0. 0.053 20.004 80.800

JOINT B057 -1. 1. 0.-49.947 20.004 80.800

JOINT B058 -2. 1. 0.-99.947 20.004 80.800

JOINT B059 -4. 1. 0.-19.947 20.004 80.800

JOINT B060 -2. -1. 3.-99.947-29.996 25.880

JOINT B061 -2. -1. 2.-99.947-29.996 5.880

JOINT B062 -1. -1. 2.-49.947-29.996 5.880

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

JOINT B063 0. -1. 2. 0.053-29.996 5.880

JOINT B064 1. -1. 2. 50.053-29.996 5.880

JOINT B065 1. 1. 2. 50.053 20.004 5.880

JOINT B066 0. 1. 2. 0.053 20.004 5.880

JOINT B067 -1. 1. 2.-49.947 20.004 5.880

JOINT B068 -2. 1. 2.-99.947 20.004 5.880

JOINT B069 -2. 1. 3.-99.947 20.004 25.880

JOINT B070 -1. 1. 3.-49.947 20.004 25.880

JOINT B071 -1. -1. 3.-49.947-29.996 25.880

JOINT B072 -2. 2. 3.-99.947 80.004 25.880

JOINT B073 -1. 2. 3.-49.947 80.004 25.880

JOINT B079 -5. 0. 3.-33.350 25.880

JOINT B080 -1. 0. 3.-49.947 0.004 25.880

JOINT B081 -4. -1. 3.-19.947-29.996 25.880

JOINT B082 -4. 1. 3.-19.947 20.004 25.880

JOINT B083 0. 0. 2. 0.053 0.004 5.880

JOINT B084 1. 0. 2. 50.053 0.004 5.880

JOINT B085 3. 0. 0. 0.053 0.004 80.800

JOINT B100 -1. 0. 2.-49.947 0.004 5.880

JOINT B102 1. 0. 0. 50.053 0.004 80.800

JOINT HOOK 0. 0. 22.-20.116-62.850 54.600 111111

JOINT PA01 -5. 0. 7.-33.350 17.000

JOINT PA02 5. 0. 7. 33.350 0.004 17.000

JOINT PA03 -1. -1. 3.-49.947-29.996 63.180

JOINT PA04 1. -1. 2. 50.053-29.996 43.180

LOAD

LOADCN 2

LOAD Z B046B033 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B033B061 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B061B060 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B047B034 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B034B062 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B062B071 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B048B035 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B035B063 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B049B036 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B036B064 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B050B037 -0.6100 -0.6100 GLOB UNIF BL-FENDE

LOAD Z B079B082 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B082B069 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B069B072 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B072B073 -0.3100 -0.3100 GLOB UNIF BL-HANDR

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

LOAD Z B066B070 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B066B065 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B054B065 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B083B080 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B085B084 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B054B053 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B053B028 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B062B100 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B100B083 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B102B085 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B036B102 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B064B084 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B071B080 -0.3100 -0.3100 GLOB UNIF BL-HANDR

LOAD Z B079B081 0.80000-0.6000 GLOB CONC BL-LADDE

LOAD Z B027B029 0.80000-0.3000 GLOB CONC BL-LADDE

LOAD Z B024B045 0.80000-0.3000 GLOB CONC BL-LADDE

LOAD Z B079B081 1.30000-0.6000 GLOB CONC BL-LADDE

LOAD Z B027B029 1.30000-0.3000 GLOB CONC BL-LADDE

LOAD Z B024B045 1.30000-0.3000 GLOB CONC BL-LADDE

LOAD B003 -1.2000 GLOB JOIN BL-PADEY

LOAD B004 -1.2000 GLOB JOIN BL-PADEY

LOAD B071 -0.6000 GLOB JOIN BL-PADEY

LOAD B064 -0.6000 GLOB JOIN BL-PADEY

LOAD Z B079B082 0.70000-0.7500 GLOB CONC BL-MORIG

LOAD Z B053B028 0.70000-0.7500 GLOB CONC BL-MORIG

LOAD Z B070B073 0.10000-0.6000 GLOB CONC BL-STAIR

LOAD Z B070B073 1.40000-0.6000 GLOB CONC BL-STAIR

*

***LDS1** -5.334-4.70206-4 3.462 -4.200 -1.299 3.462 -4.200

***LDS2** 1.201 3.462 -4.200 1.201 3.462 -0.551 -0.551

***LDS3** 0.340 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B079B081 -0.5499 -0.5499 GLOB UNIF BL-GRATT

*

***LDS1** -3.000 1.201 3.462 -3.000 2.801 3.462 -3.000

***LDS2** 1.201 3.462 -3.000 2.801 3.462 -0.551 -0.551

***LDS3** 0.340 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B069B072 -0.4133 -0.4133 GLOB UNIF BL-GRATT

LOAD Z B070B073 -0.41331.60000-0.4133 GLOB UNIF BL-GRATT

*

***LDS1** -4.200 -1.299 3.462 -3.000 -1.299 3.462 -4.200

***LDS2** 1.201 3.462 -3.000 1.201 3.462 -0.551 -0.551

***LDS3** 0.305 50 3 3 0 12 -2EQUPPRESBL-GRATT

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

LOAD Z B081B060 -0.6887 -0.6887 GLOB UNIF BL-GRATT

LOAD Z B082B069 -0.6888 -0.6888 GLOB UNIF BL-GRATT

*

***LDS1** -3.000 -1.299 3.462 -3.000 1.201 3.462 -3.000

***LDS2** -1.299 3.462 -3.000 1.201 3.462 -0.551 -0.551

***LDS3** 0.305 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B060B069 -0.4782 -0.4782 GLOB UNIF BL-GRATT

LOAD Z B071B080 -0.4898 -0.4898 GLOB UNIF BL-GRATT

LOAD Z B080B070 -0.4133 -0.4133 GLOB UNIF BL-GRATT

*

***LDS1** -3.000 -1.299 2.262 -3.000 1.201 2.262 -3.000

***LDS2** -1.299 2.262 -3.000 1.201 2.262 -0.551 -0.551

***LDS3** 0.500 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B064B084 -0.4898 -0.4898 GLOB UNIF BL-GRATT

LOAD Z B084B065 -0.4133 -0.4133 GLOB UNIF BL-GRATT

LOAD Z B062B100 -0.9796 -0.9796 GLOB UNIF BL-GRATT

LOAD Z B063B083 -0.9796 -0.9796 GLOB UNIF BL-GRATT

LOAD Z B083B066 -0.9326 -0.9326 GLOB UNIF BL-GRATT

*

***LDS1** -3.000 -1.299 1.062 -3.000 1.201 1.062 -3.000

***LDS2** -1.299 1.062 -3.000 1.201 1.062 -0.551 -0.551

***LDS3** 0.500 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B037B085 -0.5136 -0.5136 GLOB UNIF BL-GRATT

LOAD Z B085B054 -0.4777 -0.4777 GLOB UNIF BL-GRATT

*

***LDS1** 3.000 -1.299 1.062 4.200 -1.299 1.062 3.000

***LDS2** 1.201 1.062 4.200 1.201 1.062 -0.551 -0.551

***LDS3** 0.500 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B037B052 -0.6887 -0.6887 GLOB UNIF BL-GRATT

LOAD Z B054B053 -0.6888 -0.6888 GLOB UNIF BL-GRATT

*

***LDS1** 4.200 1.201 1.062 5.334 0.001 1.062 4.200

***LDS2** -1.299 1.062 4.200 -1.299 1.062 -0.551 -0.551

***LDS3** 0.500 50 3 3 0 12 -2EQUPPRESBL-GRATT

LOAD Z B053B028 -0.4728 -0.4728 GLOB UNIF BL-GRATT

LOAD Z B083B080 -0.3850 -0.3850 GLOB UNIF BL-GRATT

LOAD Z B066B070 -0.3850 -0.3850 GLOB UNIF BL-GRATT

LOAD Z B085B084 -0.3850 -0.3850 GLOB UNIF BL-GRATT

LOAD Z B054B065 -0.3850 -0.3850 GLOB UNIF BL-GRATT

LOAD B001 -0.7400 GLOB JOIN BL-_DOPL

LOAD B009 -0.7400 GLOB JOIN BL-_DOPL

LOAD B010 -0.7400 GLOB JOIN BL-_DOPL

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX D : SACS INPUT

Page: 1 of 10

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

LOAD B002 -0.7400 GLOB JOIN BL-_DOPL

LOAD B054 -0.1800 GLOB JOIN BL-_DOPL

LOAD B085 -0.1800 GLOB JOIN BL-_DOPL

LOAD B066 -0.1800 GLOB JOIN BL-_DOPL

LOAD B083 -0.1800 GLOB JOIN BL-_DOPL

LOAD B073 -0.1800 GLOB JOIN BL-_DOPL

LOAD B070 -0.1800 GLOB JOIN BL-_DOPL

LOAD Z B012B011 -2.4051 -2.4051 GLOB UNIF BL-BUMPE

LOAD Z B014B013 -2.4051 -2.4051 GLOB UNIF BL-BUMPE

LOADCN 1

DEAD

DEAD -Z M

LOADCN 3

LOAD B065 -10.940 GLOB JOIN COUPLE

LOAD B064 12.6400 GLOB JOIN COUPLE

LOAD B067 -14.940 GLOB JOIN COUPLE

LOAD B062 13.2400 GLOB JOIN COUPLE

LCOMB

LCOMB CB 1 1.00002 1.0000

LCOMB GRV CB 1.13003 1.0000

LCOMB LC1 GRV 1.3500

LCOMB LC2 GRV 2.0000

END

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

Page: 16 of 19

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

APPENDIX E :

BOATLANDING SACS OUTPUT FILE

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

1. SEASTATE LOAD CASE CENTER REPORT

**************************** SV-SW JACKET ************************************* DATE 01-APR-2014 TIME 15:36:04 PST PAGE

5

SACS-IV SYSTEM FIXED JOINTS REACTION FORCES AND MOMENTS SUMMARY

*** MOMENTS SUMMED ABOUT ORIGIN ***

********************* KN ******************** ******************** KN-M *******************

LOAD FORCE(X) FORCE(Y) FORCE(Z) MOMENT(X) MOMENT(Y) MOMENT(Z)

CASE

CB -0.127 2.296 457.363 -339.207 89.130 -0.542

GRV 0.040 0.264 516.820 -330.768 104.859 -0.028

LC1 0.054 0.356 697.707 -446.536 141.559 -0.038

LC2 0.079 0.528 1033.640 -661.535 209.717 -0.056

*********** EDI/SACS IV SEASTATE PROGRAM *********** DATE 01-APR-2014 TIME 15:36:04 SEA PAGE 21

************* SEASTATE LOAD CASE CENTER REPORT *************

RELATIVE TO STRUCTURAL ORIGIN

LOAD LOAD ********* X - DIRECTION ********* ********* Y - DIRECTION ********* ********* Z - DIRECTION *********

CASE LABEL FORCE X Y Z FORCE X Y Z FORCE X Y Z

(KN) (M) (M) (M) (KN) (M) (M) (M) (KN) (M) (M) (M)

1 2 0.00 0.00 -86.89 -0.24 -0.93 1.47

2 1 0.00 0.00 -370.47 -0.18 -0.73 0.73

3 3 0.00 0.00 0.00

4 CB 0.00 0.00 -457.37 -0.19 -0.77 0.87

5 GRV 0.00 0.00 -516.82 -0.20 -0.64 0.87

6 LC1 0.00 0.00 -697.71 -0.20 -0.64 0.87

7 LC2 0.00 0.00 -1033.65 -0.20 -0.64 0.87

2. SUPPORT REACTION

**************************** SV-SW JACKET ************************************* DATE 01-APR-2014 TIME 15:36:04 PST

PAGE 5

SACS-IV SYSTEM FIXED JOINTS REACTION FORCES AND MOMENTS SUMMARY

*** MOMENTS SUMMED ABOUT ORIGIN ***

********************* KN ******************** ******************** KN-M *******************

LOAD FORCE(X) FORCE(Y) FORCE(Z) MOMENT(X) MOMENT(Y) MOMENT(Z)

CASE

CB -0.127 2.296 457.363 -339.207 89.130 -0.542

GRV 0.040 0.264 516.820 -330.768 104.859 -0.028

LC1 0.054 0.356 697.707 -446.536 141.559 -0.038

LC2 0.079 0.528 1033.640 -661.535 209.717 -0.056

3. SLING FORCES

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

MEMBER FORCES AND MOMENTS

******************** kN ********************* ******************* kN-m ********************

MEMBER MEMBER GROUP LOAD FORCE(X) FORCE(Y) FORCE(Z) MOMENT(X) MOMENT(Y) MOMENT(Z)

NUMBER END ID COND

PA01-HOOK PA01 SLI GRV 130.4610 0.0000 0.0000 0.0000 0.0000 0.0000

HOOK GRV 130.4610 0.0000 0.0000 0.0000 0.0000 0.0000

PA02-HOOK PA02 SLI GRV 116.1842 0.0000 0.0000 0.0000 0.0000 0.0000

HOOK GRV 116.1842 0.0000 0.0000 0.0000 0.0000 0.0000

PA03-HOOK PA03 SLI GRV 144.6812 0.0000 0.0000 0.0000 0.0000 0.0000

HOOK GRV 144.6812 0.0000 0.0000 0.0000 0.0000 0.0000

PA04-HOOK PA04 SLI GRV 140.2521 0.0000 0.0000 0.0000 0.0000 0.0000

HOOK GRV 140.2521 0.0000 0.0000 0.0000 0.0000 0.0000

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

4. MEMBERS UNITY CHECK PLOT

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP I - UNITY CHECKS GREATER THAN 0.00 AND LESS THAN 0.50

MAXIMUM LOAD DIST AXIAL BENDING STRESS SHEAR FORCE SECOND-HIGHEST THIRD-HIGHEST

MEMBER GROUP COMBINED COND FROM STRESS Y Z FY FZ KLY/RY KLZ/RZ UNITY LOAD UNITY LOAD

ID UNITY CK NO. END N/mm2 N/mm2 N/mm2 kN kN CHECK COND CHECK COND

B011-B015 BL1 0.001 LC1 0.0 -0.11 0.00 0.00 0.00 0.00 6.9 6.9 0.000 0.000

B012-B011 BL1 0.045 LC1 7.8 0.52 -5.36 9.79 0.01 -0.01 30.1 30.1 0.000 0.000

B013-B016 BL1 0.001 LC1 0.0 -0.11 0.00 0.00 0.00 0.00 6.9 6.9 0.000 0.000

B014-B013 BL1 0.056 LC1 7.8 0.23 -4.67 -13.40 -0.01 -0.01 30.1 30.1 0.000 0.000

B017-B012 BL1 0.000 LC1 0.8 0.10 0.00 0.00 0.00 0.00 6.9 6.9 0.000 0.000

B018-B014 BL1 0.000 LC1 0.8 0.10 0.00 0.00 0.00 0.00 6.9 6.9 0.000 0.000

B001-B003 BL2 0.072 LC1 0.0 2.62 -1.87 15.23 -0.06 0.01 54.2 54.2 0.000 0.000

B002-B004 BL2 0.067 LC1 0.0 2.29 -1.65 -14.51 0.05 0.01 54.2 54.2 0.000 0.000

B009-B024 BL2 0.039 LC1 0.6 1.46 8.17 -1.59 -0.01 0.01 54.2 54.2 0.000 0.000

B010-B025 BL2 0.062 LC1 0.6 1.76 11.69 7.40 0.01 0.01 54.2 54.2 0.000 0.000

B019-B009 BL2 0.002 LC1 2.4 0.28 -0.05 -0.01 0.00 0.00 54.2 54.2 0.000 0.000

B020-B010 BL2 0.002 LC1 2.4 0.28 -0.05 -0.01 0.00 0.00 54.2 54.2 0.000 0.000

B024-B027 BL2 0.028 LC1 0.0 1.45 5.35 -1.23 0.01 -0.01 54.2 54.2 0.000 0.000

B025-B028 BL2 0.072 LC1 3.0 2.05 -4.54 -15.31 -0.05 -0.03 54.2 54.2 0.000 0.000

B027-B079 BL2 0.053 LC1 2.5 2.16 -5.45 9.57 0.02 -0.01 54.2 54.2 0.000 0.000

B028-B002 BL2 0.134 LC1 0.0 1.35 -11.53 -30.84 0.06 0.02 54.2 54.2 0.000 0.000

B079-B001 BL2 0.083 LC1 0.0 1.67 -8.93 17.28 -0.07 0.02 54.2 54.2 0.000 0.000

B024-B045 BL3 0.034 LC1 0.0 1.01 4.21 -2.52 0.00 0.00 62.0 10.1 0.000 0.000

B027-B029 BL3 0.023 LC1 0.0 0.01 3.48 2.09 0.00 0.00 62.0 9.7 0.000 0.000

B029-B033 BL3 0.018 LC1 1.2 0.08 -1.28 0.22 0.00 -0.01 62.0 7.0 0.000 0.000

B033-B034 BL3 0.056 LC1 1.5 -0.50 -9.18 -1.13 0.00 -0.05 62.0 8.8 0.000 0.000

B034-B035 BL3 0.037 LC1 0.0 -1.20 -4.81 -0.61 0.00 0.02 62.0 8.8 0.000

0.000

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP I - UNITY CHECKS GREATER THAN 0.00 AND LESS THAN 0.50

MAXIMUM LOAD DIST AXIAL BENDING STRESS SHEAR FORCE SECOND-HIGHEST

THIRD-HIGHEST

MEMBER GROUP COMBINED COND FROM STRESS Y Z FY FZ KLY/RY KLZ/RZ UNITY LOAD UNITY LOAD

ID UNITY CK NO. END N/mm2 N/mm2 N/mm2 kN kN CHECK COND CHECK COND

B035-B036 BL3 0.059 LC1 1.5 -1.71 -8.01 0.40 0.01 -0.03 62.0 8.8 0.000 0.000

B036-B037 BL3 0.098 LC1 0.0 -2.09 -13.84 -4.20 0.02 0.07 62.0 8.8 0.000 0.000

B037-B052 BL3 0.112 LC1 1.2 -2.47 13.77 8.73 0.06 0.05 62.0 7.0 0.000 0.000

B045-B046 BL3 0.038 LC1 1.2 0.70 -3.08 4.70 0.03 -0.01 49.2 7.0 0.000 0.000

B046-B047 BL3 0.036 LC1 1.5 0.60 -3.62 4.32 0.01 -0.01 49.2 8.8 0.000 0.000

B047-B048 BL3 0.027 LC1 0.0 0.63 -3.71 1.85 0.00 0.01 49.2 8.8 0.000 0.000

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

B048-B049 BL3 0.033 LC1 0.0 0.79 -3.51 3.42 -0.01 0.00 49.2 8.8 0.000 0.000

B049-B050 BL3 0.063 LC1 0.0 1.17 -8.44 5.17 -0.02 0.05 49.2 8.8 0.000 0.000

B050-B051 BL3 0.056 LC1 0.0 1.68 -0.60 6.22 -0.05 0.02 49.2 7.0 0.000 0.000

B051-B025 BL3 0.063 LC1 0.0 2.00 6.19 -6.21 0.02 0.01 62.0 10.1 0.000 0.000

B052-B028 BL3 0.141 LC1 1.4 -2.74 21.03 -2.32 -0.03 0.04 62.0 9.7 0.000 0.000

B033-B061 BL4 0.105 LC1 0.0 0.85 -6.48 16.38 -0.03 0.01 17.2 8.6 0.000 0.000

B034-B062 BL4 0.128 LC1 0.0 7.92 -1.66 13.07 -0.03 0.00 17.2 8.6 0.000 0.000

B035-B063 BL4 0.039 LC1 0.0 -0.31 -0.58 6.51 -0.01 0.00 8.6 8.6 0.000 0.000

B036-B064 BL4 0.113 LC1 1.0 11.78 2.60 -4.90 0.00 0.00 8.6 8.6 0.000 0.000

B046-B033 BL4 0.074 LC1 0.0 2.02 3.30 4.25 0.00 0.00 23.4 23.4 0.000 0.000

B047-B034 BL4 0.058 LC1 0.0 2.81 6.81 -0.66 0.00 -0.01 23.4 23.4 0.000 0.000

B048-B035 BL4 0.063 LC1 0.0 1.40 7.45 -5.96 0.01 -0.01 23.4 23.4 0.000 0.000

B049-B036 BL4 0.113 LC1 0.0 4.48 4.94 -13.84 0.01 0.00 23.4 23.4 0.000 0.000

B050-B037 BL4 0.137 LC1 0.0 0.33 -1.44 -18.04 0.02 0.00 23.4 23.4 0.000 0.000

B060-B071 BL4 0.119 LC1 1.8 -1.07 -19.50 -4.67 0.00 -0.03 27.5 10.8 0.000 0.000

B061-B060 BL4 0.161 LC1 1.2 -0.70 12.38 -25.28 -0.05 0.02 17.2 8.6 0.000 0.000

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP I - UNITY CHECKS GREATER THAN 0.00 AND LESS THAN 0.50

MAXIMUM LOAD DIST AXIAL BENDING STRESS SHEAR FORCE SECOND-HIGHEST

THIRD-HIGHEST

MEMBER GROUP COMBINED COND FROM STRESS Y Z FY FZ KLY/RY KLZ/RZ UNITY LOAD UNITY LOAD

ID UNITY CK NO. END N/mm2 N/mm2 N/mm2 kN kN CHECK COND CHECK COND

B061-B062 BL4 0.136 LC1 0.0 -1.53 22.37 0.70 0.00 -0.03 32.3 10.8 0.000 0.000

B062-B063 BL4 0.030 LC1 1.5 -1.92 -0.22 -1.80 0.00 0.00 32.3 10.8 0.000 0.000

B062-B071 BL4 0.138 LC1 0.0 9.84 1.20 12.54 -0.03 0.00 17.2 8.6 0.000 0.000

B063-B064 BL4 0.034 LC1 1.8 -1.20 -3.78 -1.07 0.00 -0.01 32.3 10.8 0.000 0.000

B079-B081 BL4 0.187 LC1 0.0 -4.44 26.89 -6.49 0.02 -0.03 27.5 11.8 0.000 0.000

B081-B060 BL4 0.144 LC1 1.2 -4.02 -14.06 -14.85 -0.04 -0.03 27.5 8.6 0.000 0.000

B011-B001 BL5 0.124 LC1 1.2 0.43 -1.67 -1.92 -0.01 -0.04 12.4 12.4 0.000 0.000

B012-B009 BL5 0.044 LC1 0.0 -0.43 10.45 -2.39 0.01 -0.06 12.4 12.4 0.000 0.000

B013-B002 BL5 0.156 LC1 1.2 0.42 4.07 1.89 0.01 -0.02 7.9 7.9 0.000 0.000

B014-B010 BL5 0.087 LC1 1.2 -0.42 -16.92 -1.89 -0.01 -0.08 7.9 7.9 0.000 0.000

B027-B059 BL6 0.025 LC1 0.0 -0.11 -3.34 2.67 0.00 0.00 96.3 15.0 0.000 0.000

B053-B028 BL6 0.126 LC1 0.0 -1.52 -3.36 -5.59 0.01 0.01 96.3 15.0 0.000 0.000

B054-B053 BL6 0.101 LC1 0.0 -1.81 1.51 0.65 0.00 0.01 96.3 10.9 0.000 0.000

B055-B054 BL6 0.060 LC1 1.5 -0.96 -2.37 2.87 0.00 0.00 96.3 13.6 0.000 0.000

B056-B055 BL6 0.029 LC1 1.5 -0.81 -3.57 0.16 0.00 0.00 96.3 13.6 0.000 0.000

B057-B056 BL6 0.009 LC1 0.0 -0.47 0.01 -0.79 0.00 0.00 96.3 13.6 0.000 0.000

B058-B057 BL6 0.019 LC1 0.0 -0.24 -2.01 0.91 0.00 0.00 96.3 13.6 0.000 0.000

B059-B058 BL6 0.008 LC1 1.0 -0.18 1.06 -0.36 0.00 0.00 96.3 10.9 0.000 0.000

B061-B068 BL7 0.035 LC1 0.0 0.64 -4.10 -3.57 0.00 0.00 27.1 27.1 0.000 0.000

B064-B084 BL7 0.061 LC1 0.0 -0.81 -9.81 -0.49 0.00 0.01 27.1 14.1 0.000 0.000

B066-B065 BL7 0.022 LC1 1.4 -0.69 -2.77 -0.91 0.00 0.00 48.8 16.3 0.000 0.000

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

B067-B066 BL7 0.011 LC1 1.5 0.34 -1.55 -0.13 0.00 0.00 48.8 16.3 0.000 0.000

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP I - UNITY CHECKS GREATER THAN 0.00 AND LESS THAN 0.50

MAXIMUM LOAD DIST AXIAL BENDING STRESS SHEAR FORCE SECOND-HIGHEST

THIRD-HIGHEST

MEMBER GROUP COMBINED COND FROM STRESS Y Z FY FZ KLY/RY KLZ/RZ UNITY LOAD UNITY LOAD

ID UNITY CK NO. END N/mm2 N/mm2 N/mm2 kN kN CHECK COND CHECK COND

B068-B067 BL7 0.030 LC1 1.4 0.00 -3.47 -2.46 0.00 0.00 48.8 16.3 0.000 0.000

B069-B070 BL7 0.070 LC1 1.5 -1.54 -1.76 -5.47 0.00 0.00 41.6 16.3 0.000 0.000

B070-B073 BL7 0.053 LC1 0.0 -0.04 -9.48 0.63 0.00 0.01 44.5 17.4 0.000 0.000

B071-B080 BL7 0.043 LC1 0.0 -0.47 -7.03 0.31 0.00 0.01 44.5 27.1 0.000 0.000

B079-B082 BL7 0.135 LC1 1.3 -1.66 -5.38 -7.39 -0.01 -0.01 41.6 17.9 0.000 0.000

B080-B070 BL7 0.027 LC1 1.2 -0.63 3.76 1.12 0.00 0.00 44.5 27.1 0.000 0.000

B082-B069 BL7 0.117 LC1 1.2 -1.94 -3.56 1.47 0.00 -0.01 41.6 13.0 0.000 0.000

B084-B065 BL7 0.046 LC1 0.0 -0.76 5.25 5.02 -0.01 0.00 27.1 14.1 0.000 0.000

B033-B058 BL8 0.033 LC1 0.0 1.52 -2.87 -1.94 0.00 0.00 34.2 34.2 0.000 0.000

B034-B057 BL8 0.048 LC1 0.0 1.68 -6.38 -1.59 0.00 0.00 34.2 34.2 0.000 0.000

B035-B056 BL8 0.045 LC1 0.0 1.84 -5.84 -0.35 0.00 0.00 34.2 34.2 0.000 0.000

B036-B102 BL8 0.056 LC1 0.0 1.96 -6.46 4.03 0.00 0.00 34.2 34.2 0.000 0.000

B037-B085 BL8 0.086 LC1 0.0 4.46 7.22 6.68 0.00 0.00 34.2 34.2 0.000 0.000

B046-B058 BL8 0.053 LC1 0.0 -3.34 -4.43 0.60 0.00 0.00 56.2 56.2 0.000 0.000

B047-B057 BL8 0.065 LC1 0.0 -3.46 -6.31 1.22 0.00 0.00 56.2 56.2 0.000 0.000

B048-B056 BL8 0.065 LC1 0.0 -3.14 -6.74 1.79 0.00 0.00 56.2 56.2 0.000 0.000

B049-B055 BL8 0.064 LC1 0.0 -3.19 -5.81 3.26 0.00 0.00 56.2 56.2 0.000 0.000

B050-B054 BL8 0.066 LC1 0.0 -4.54 -3.83 3.22 0.00 0.00 56.2 56.2 0.000 0.000

B054-B065 BL8 0.060 LC1 0.0 -1.97 -1.83 -7.63 0.00 0.00 26.3 26.3 0.000 0.000

B055-B065 BL8 0.051 LC1 0.0 -1.88 6.51 1.60 0.00 0.00 16.4 16.4 0.000 0.000

B056-B066 BL8 0.046 LC1 0.0 -2.37 1.70 4.83 0.00 0.00 16.4 16.4 0.000 0.000

B057-B067 BL8 0.042 LC1 0.0 -2.55 -0.87 4.08 0.00 0.00 32.8 16.4 0.000 0.000

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP I - UNITY CHECKS GREATER THAN 0.00 AND LESS THAN 0.50

MAXIMUM LOAD DIST AXIAL BENDING STRESS SHEAR FORCE SECOND-HIGHEST

THIRD-HIGHEST

MEMBER GROUP COMBINED COND FROM STRESS Y Z FY FZ KLY/RY KLZ/RZ UNITY LOAD UNITY LOAD

ID UNITY CK NO. END N/mm2 N/mm2 N/mm2 kN kN CHECK COND CHECK COND

B058-B068 BL8 0.048 LC1 0.0 -1.88 -5.11 3.18 0.00 0.00 32.8 16.4 0.000 0.000

B060-B069 BL8 0.032 LC1 0.0 1.25 -0.95 -4.06 0.00 0.00 56.1 34.2 0.000 0.000

B062-B100 BL8 0.055 LC1 0.0 -0.03 -9.28 -3.13 0.00 0.01 34.2 17.8 0.000 0.000

B063-B083 BL8 0.044 LC1 0.0 -0.25 -7.13 -2.60 0.00 0.00 34.2 17.8 0.000 0.000

B066-B070 BL8 0.034 LC1 0.0 -2.50 -1.71 -0.84 0.00 0.00 26.3 26.3 0.000 0.000

B067-B070 BL8 0.018 LC1 0.0 0.46 1.80 0.37 0.00 0.00 32.8 16.4 0.000 0.000

B068-B069 BL8 0.046 LC1 0.9 -2.03 -0.11 -5.45 0.00 0.00 32.8 16.4 0.000 0.000

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

B069-B072 BL8 0.064 LC1 0.0 0.05 -11.50 0.53 0.00 0.00 56.1 21.9 0.000 0.000

B072-B073 BL8 0.010 LC1 0.0 0.00 -1.72 0.66 0.00 0.00 20.5 20.5 0.000 0.000

B083-B066 BL8 0.021 LC1 0.0 0.05 3.63 -0.66 0.00 0.00 34.2 17.8 0.000 0.000

B083-B080 BL8 0.025 LC1 1.7 -0.02 -1.99 -3.59 0.00 0.00 26.3 26.3 0.000 0.000

B085-B054 BL8 0.057 LC1 1.0 4.19 0.98 1.73 0.00 0.00 34.2 34.2 0.000 0.000

B085-B084 BL8 0.039 LC1 1.7 1.71 -4.45 1.21 0.00 0.00 26.3 26.3 0.000 0.000

B100-B067 BL8 0.026 LC1 1.1 -0.06 4.34 1.32 0.00 0.00 34.2 17.8 0.000 0.000

B102-B055 BL8 0.040 LC1 1.0 2.11 4.48 0.52 0.00 0.00 34.2 34.2 0.000 0.000

B083-B084 BL9 0.017 LC1 0.0 0.47 0.83 -2.25 0.00 0.00 53.3 26.7 0.000 0.000

B100-B083 BL9 0.021 LC1 0.0 0.30 -1.24 1.42 0.00 0.00 53.3 26.7 0.000 0.000

B102-B085 BL9 0.045 LC1 0.0 -0.74 -2.20 -4.27 0.00 0.00 26.7 26.7 0.000 0.000

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP II - UNITY CHECKS GREATER THAN 0.50 AND LESS THAN 1.00

** NO UNITY CHECKS IN THIS GROUP **

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV MEMBER UNITY CHECK RANGE SUMMARY

GROUP III - UNITY CHECKS GREATER THAN 1.00

** NO UNITY CHECKS IN THIS GROUP **

MEMBER CONNECT LIFTING POINT

DATE 1-APR-2014 TIME 15:39:44

**************************** SV-SW JACKET *************************************

SACS-IV SYSTEM ELEMENT UNITY CHECK REPORT

MAX. CRIT. LOAD DIST * * * * U N I T Y C H E C K C O M P O N E N T S * * * * EFFECTIVE

MEMBER GRP UNITY COND COND FROM EULER *** SHEAR *** * COMBINED BENDING AND AXIAL * * CM VALUES * SLENDERNESS

CHECK NO. END BUCKLING Y Z AXIAL BEND-Y BEND-Z TOTAL Y Z Y-Y Z-Z

m

B001-B003 BL2 0.11 TN+BN LC2 0.0 0.000 0.021 0.000 0.019 0.001 0.087 0.107 0.850 0.850 54.22 54.22

B002-B004 BL2 0.10 TN+BN LC2 0.0 0.000 0.020 0.000 0.016 0.001 0.083 0.100 0.850 0.850 54.22 54.22

B036-B064 BL4 0.17 TN+BN LC2 1.0 0.000 0.014 0.000 0.121 0.010 0.036 0.167 0.850 0.850 8.62 8.62

B060-B071 BL4 0.18 C<.15 LC2 1.8 0.002 0.075 0.000 0.012 0.156 0.009 0.177 0.850 0.850 27.50 10.77

B062-B071 BL4 0.20 TN+BN LC2 0.0 0.000 0.090 0.000 0.101 0.001 0.103 0.205 0.850 0.850 17.23 8.62

B063-B064 BL4 0.05 C<.15 LC2 1.8 0.003 0.050 0.000 0.013 0.030 0.002 0.050 0.850 0.850 32.31 10.77

B064-B084 BL7 0.09 C<.15 LC2 0.0 0.001 0.047 0.000 0.009 0.081 0.000 0.090 0.850 0.850 27.12 14.10

B071-B080 BL7 0.06 C<.15 LC2 0.0 0.002 0.032 0.000 0.005 0.058 0.000 0.063 0.850 0.850 44.48 27.12

STV EXTENSION STV SOUTH WEST PROJECT

EPCI FOR WHP-SVSW, PIPELINES

AND CPP MODIFICATIONS

Document No.:

2013-1489-6R-3011

BOATLANDINGS OFFSHORE LIFTING

ANALYSIS REPORT

APPENDIX E : SACS OUTPUT

Page: 1 of 6

Revision No: 0 Date: 15 May 2014

SuTuVangSouthWest

5. JOINT CAN SUMMARY UNITY CHECK

**************************** SV-SW JACKET ************************************* DATE 01-APR-2014 TIME 15:36:04 JCN

PAGE 16

* * J O I N T C A N S U M M A R Y * *

(UNITY CHECK ORDER)

**************** ORIGINAL ************* ***************** DESIGN **************

JOINT DIAMETER THICKNESS YLD STRS UC DIAMETER THICKNESS YLD STRS UC

(CM) (CM) (N/MM2) (CM) (CM) (N/MM2)

B071 40.640 1.270 240.000 0.540 40.640 1.270 240.000 0.540

B061 40.640 1.270 240.000 0.265 40.640 1.270 240.000 0.265

B060 40.640 1.270 240.000 0.224 40.640 1.270 240.000 0.224

B081 40.640 1.270 240.000 0.215 40.640 1.270 240.000 0.215

B062 40.640 1.270 240.000 0.187 40.640 1.270 240.000 0.187

B036 50.800 2.540 240.000 0.168 50.800 2.540 240.000 0.168

B054 32.390 1.270 240.000 0.167 32.390 1.270 240.000 0.167

B055 32.390 1.270 240.000 0.146 32.390 1.270 240.000 0.146

B057 32.390 1.270 240.000 0.134 32.390 1.270 240.000 0.134

B034 50.800 2.540 240.000 0.132 50.800 2.540 240.000 0.132

B058 32.390 1.270 240.000 0.131 32.390 1.270 240.000 0.131

B056 32.390 1.270 240.000 0.129 32.390 1.270 240.000 0.129

B052 50.800 2.540 240.000 0.118 50.800 2.540 240.000 0.118

B063 40.640 1.270 240.000 0.115 40.640 1.270 240.000 0.115

B053 32.390 1.270 240.000 0.114 32.390 1.270 240.000 0.114

B064 40.640 1.270 240.000 0.113 40.640 1.270 240.000 0.113

B069 27.310 1.270 240.000 0.103 27.310 1.270 240.000 0.103

B067 27.310 1.270 240.000 0.102 27.310 1.270 240.000 0.102

B028 61.000 3.180 345.000 0.101 61.000 3.180 345.000 0.101

B066 27.310 1.270 240.000 0.101 27.310 1.270 240.000 0.101

B049 50.800 2.540 240.000 0.098 50.800 2.540 240.000 0.098

B082 27.310 1.270 240.000 0.098 27.310 1.270 240.000 0.098

B068 27.310 1.270 240.000 0.097 27.310 1.270 240.000 0.097

B084 27.310 1.270 240.000 0.096 27.310 1.270 240.000 0.096

B065 27.310 1.270 240.000 0.093 27.310 1.270 240.000 0.093

B037 50.800 2.540 240.000 0.086 50.800 2.540 240.000 0.086

B051 50.800 2.540 240.000 0.082 50.800 2.540 240.000 0.082

B070 27.310 1.270 240.000 0.079 27.310 1.270 240.000 0.079

B011 76.200 2.540 345.000 0.077 76.200 2.540 345.000 0.077

B013 76.200 2.540 345.000 0.074 76.200 2.540 345.000 0.074

B079 61.000 3.180 345.000 0.071 61.000 3.180 345.000 0.071

B050 50.800 2.540 240.000 0.071 50.800 2.540 240.000 0.071

B012 76.200 2.540 345.000 0.070 76.200 2.540 345.000 0.070

B047 50.800 2.540 240.000 0.067 50.800 2.540 240.000 0.067

B014 76.200 2.540 345.000 0.065 76.200 2.540 345.000 0.065

B048 50.800 2.540 240.000 0.065 50.800 2.540 240.000 0.065

B046 50.800 2.540 240.000 0.058 50.800 2.540 240.000 0.058

B010 61.000 3.180 345.000 0.053 61.000 3.180 345.000 0.053

B025 61.000 3.180 345.000 0.053 61.000 3.180 345.000 0.053

B085 21.910 1.270 240.000 0.049 21.910 1.270 240.000 0.049

B033 50.800 2.540 240.000 0.049 50.800 2.540 240.000 0.049

B035 50.800 2.540 240.000 0.046 50.800 2.540 240.000 0.046

B009 61.000 3.180 345.000 0.036 61.000 3.180 345.000 0.036

B102 21.910 1.270 240.000 0.033 21.910 1.270 240.000 0.033

B024 61.000 3.180 345.000 0.032 61.000 3.180 345.000 0.032

B080 27.310 1.270 240.000 0.029 27.310 1.270 240.000 0.029

B083 21.910 1.270 240.000 0.024 21.910 1.270 240.000 0.024

B002 61.000 3.180 345.000 0.021 61.000 3.180 345.000 0.021

B045 50.800 2.540 240.000 0.020 50.800 2.540 240.000 0.020

B001 61.000 3.180 345.000 0.017 61.000 3.180 345.000 0.017

**************************** SV-SW JACKET ************************************* DATE 01-APR-2014 TIME 15:36:04 JCN

PAGE 17

* * J O I N T C A N S U M M A R Y * *

(UNITY CHECK ORDER)

**************** ORIGINAL ************* ***************** DESIGN **************

JOINT DIAMETER THICKNESS YLD STRS UC DIAMETER THICKNESS YLD STRS UC

(CM) (CM) (N/MM2) (CM) (CM) (N/MM2)

B100 21.910 1.270 240.000 0.014 21.910 1.270 240.000 0.014

B027 61.000 3.180 345.000 0.014 61.000 3.180 345.000 0.014

B059 32.390 1.270 240.000 0.009 32.390 1.270 240.000 0.009

B072 21.910 1.270 240.000 0.008 21.910 1.270 240.000 0.008

B073 27.310 1.270 240.000 0.007 27.310 1.270 240.000 0.007

B029 50.800 2.540 240.000 0.006 50.800 2.540 240.000 0.006