Académique Documents

Professionnel Documents

Culture Documents

Building Construction Technology - Assignment 01 (Semester 01)

Transféré par

Anushke HennayakeDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Building Construction Technology - Assignment 01 (Semester 01)

Transféré par

Anushke HennayakeDroits d'auteur :

Formats disponibles

Building construction Technology

1 | P a g e

Table of content

Acknowledgement. 02

Introduction 03

Site selection.. 04 07

Stages in site investigations. 08 11

Soil classification.. 12 13

Available Boring methods. 14 15

Available type of foundations. 16 17

Types of excavation 18

Associated temporary work for the construction of foundation.. 19 20

Construction method of Piled Raft foundation. 21

Formwork arrangements needed for the construction.. 22 23

Reinforce arrangements in structural elements.. 24 29

Brick work. 30

Method for construction of first floor slab 31 33

Wall & floor finishes.. 34 39

Water proofing. 40

Timberwork needed in building construction. 41 42

The ongoing construction site chose to study 43 48

Conclusion 49

References.. 50

Building construction Technology

2 | P a g e

Acknowledgement

Thanking my parents, without whom, I wouldnt survive a single day in my life.

Towards all my teachers at the British College of Applied studies, for teaching me

the first steps of Building Construction Technology & for guiding me.

Thank you.

Building construction Technology

3 | P a g e

Introduction

In Task 01 previews how to select a suitable construction site considering the

borehole logs, the place the site is situated etc. Also in the 1

st

Task it shows

what are the investigation methods should carry on before starting any

construction & how the construction method changes due to different type of

soil types.

2

nd

Task is mainly focused on the foundation. The type of foundations, the

excavation methods to construct the foundation & the method of building a

foundation.

The structure & the partitions of a construction is mainly focused in the 3

rd

Task.

The formwork, Reinforcement & the wet & dry partitions.

I have also attached the structural drawings & the pictures from the site I visited

as a proof to my visit to the site.

Building construction Technology

4 | P a g e

Site Selection

Factors considered in site selection

Design & construction plans

Design & construction plans should be considered before starting the

construction to make sure the construction is suitable, the land has enough area

for the construction & the construction wont conflict with the surroundings.

General site conditions

Before the construction the land has to be observed for general site conditions

such as the slope of the land, whether its on a hill or on a low plain ground etc.

Geological futures

Geological features would be commonly looked at as landforms created through

geologic processes such as erosion, weathering, deposition, and plate tectonics.

The geomorphology

The study of the form and structure of the Earth as the size and shape of the

Earth's surface is known as geomorphology.

Access restrictions for equipment

Access for the heavy machinery, heavy vehicles etc. should be considered

before the construction.

Traffic control requirements during field investigations

Travelling through a construction site can be difficult & confusing for the drivers,

to guarantee the safety of the passing vehicles & people necessary

arrangements should be made.

Location of underground & overhead utilities

Underground pipe lines, Telephone cables etc. & utilities as power lines

overhead the construction site should be considered before the construction.

Type & condition of existing utilities

The condition of the existing utilities should be considered because if the utilities

are in a bad condition it will affect the building later on.

Restriction on working hours

If the site is situated in the middle of a busy town area, handling heavy vehicles &

machinery would cause major traffic problems & if the site is near a hospital or a

court the noise would be affect their activities so when constructing the work

should be done without disturbing the surrounding environment.

Environmental issues

Mainly pollution caused by noise, dust, the disposal of the wasted materials or

the wrappings of the materials .The construction should be done on a

environment friendly way.

Building construction Technology

5 | P a g e

Flood levels

The construction should be done over the flood level & if any construction is

happening below the flood level the necessary actions has to be taken such as

water proofing .If the construction is having a underground car park the flood

level has to be highly considered.

Water traffic & access to water boring sites

Water is majorly used in constructions so access to water should be unlimited or

water has to supplied from tanks without pausing the construction work due to

lack of water supplement also access to underground water sources will give

unlimited supply of water.

Equipment & material storage areas

The storage of materials & equipments also has to considered, if the storage

area is far from the construction site it would waste more time & itll cost more for

transportation, if the storage can be done in the land or near the land it would

save more time & money.

Security

Security of the of Equipments & materials should be considered & necessary anti

theft procedures should be taken to protect the equipments & materials

Building construction Technology

6 | P a g e

Advantages & the disadvantages of the sites

Land on Williamcopallawa road Land on Colombo street

The land can be used to construct a supermarket The land can be used to construct a super market

The land is flat land The land is a slope land but the slope isnt a large

slope to be considered.

The land has limited space so all the heavy

machineries & equipments cannot be kept within

the land, only some can access the land others

have to be kept outside the land.

The land has limited space so all the heavy

machineries & equipments cannot be kept within

the land, only some can access the land others

have to be kept outside the land.

The land is far from the city but the land is on the

main road from Kandy to Colombo there will be

more vehicles passing than on Colombo street so

itll cause traffic problems & safety issues.

The land is in the middle of the city but because

there are alternative routes & because the road

can be blocked from either sides without causing

traffic problems the number of public vehicles can

be controlled. The construction can be carried out

safely.

Williamcopallawa road is a busy road so there can

be some restrictions when moving heavy

machinery & vehicles.

Colombo street is not a busy road mostly its used

for parking & when the road is blocked from either

sides there will be no moving vehicles & there will

be enough space for the heavy vehicles &

machineries.

The water level is 1.8m so access to underground

water source can be gained easily

The water level is 4.8m have to more further deep

for the water source.

Because the water level is 1.8m, the basement car

park go below the water level when constructing

so itll require more machinery to dewater & other

equipments, tools & methods to water seal the

basement.

The water level is 4.8m, the basement car park

wouldnt go below the water level so there will be

no need for the extra machinery as on the other

land & itll save time & money.

The storage has to be done outside the land

because the entire land will be used for the

construction. The materials & equipments have to

be brought to the site.

If the client or the contractor can get permission to

keep the certain section of the Colombo street

closed till the construction is over the storage can

be done near the constructing site or else the

storage has to be done outside the land & brought

to the site when needed

The security status of the land can be low because

its away from the city & not much people walking

around & it can be opened to theft.

The land is in the middle of the city so the security

level is high because there are lot o people moving

around & there are other shops, offices etc.

around the construction site.

There is another old supermarket next to the land

so the income will be divided after completing the

construction.

There are no any supermarkets on Colombo street

so itll be wiser to build the supermarket in this

land because the competition is low.

Building construction Technology

7 | P a g e

Recommended site for the construction for a super market

Recommended site considering the general facts

Considering the advantages & the disadvantages of the both sites generally the most

suitable site for the construction is the land in the Colombo street, when considering the

safety, security, storage, the easiness to work & specially the constructions can be

carried out with less disturbance to the surrounding day to day work the most suitable

place is the land in the Colombo street. Even after the construction is over & the super

market is open for the public itll also give more income than the land on

Williamcopallawa road because there the new super market has to compete with Keels

super which is also a super market, but if the super market is built on the Colombo

street there is no any other super markets to compete the new one.

Recommended site - No.110, Colombo street, Kandy.

Recommended site considering the borehole log

Considering the borehole logs given of the two lands the soil is loose on the land in the

Williamcopalla road comparing to the soil on the land in the Colombo street so there

can be a threat of sinking the land also the water level comes at 1.8m which will also

cause more problems when excavating for the foundation & for the basement car park,

even after the construction is done the whole basement has to be water sealed which

will increasing the expenses to construct the building.

The soil in the land on the Colombo street is well compacted so the building is more

firm on this land also another advantage of using the land on Colombo street is the

water level is at 4.8m the basement can be done without water sealing itll save a lot of

money & time so still the most suitable land for the construction is the land on the

Colombo street.

Recommended site - No.110, Colombo street, Kandy.

Considering the general conditions & considering the borehole logs the most suitable land to

construct a 4 storey super market is the land in No.110, Colombo Street, Kandy.

Building construction Technology

8 | P a g e

Stages in site investigation

Site investigation is a process carried out to determine whether the land is suitable for the construction

also the weaknesses in the land, the improvements has to be done & various tests have to done to

ensure the quality of the land to maintain the quality of the building.

Investigating using existing data sources

Reviewing existing data on a site can be helpful to determine boring locations, boring depths &

to provide valuable geological & historical information which will be useful in the geotechnical

report also reviewing existing data sources minimizes the surprises on the field.

Subsurface investigation

Subsurface investigation means, investigating the soil conditions below

& near the ground surface.

Structural performance problems

Various problems as pile length, drivability problems, rock slides,

excessive seepage, unpredicted settlement & other related problems.

Geological survey maps & reports

Geological map is a special map created made to show geological

features using different symbols & colors.

Building construction Technology

9 | P a g e

Flood zone maps

Maps showing areas prone to flooding.

Soil maps

Soil map is a map showing distribution of soil types and/or soil

properties using different colors.

Aerial photographs

Aerial photography is the taking photographs of f the ground from an

elevated position

Site plans

A site plan is an architectural plan, and a detailed engineering drawing

of proposed construction. Usually a site plan shows a building footprint,

travel ways, parking, drainage facilities, sanitary sewer lines, water lines,

trails, lighting, and landscaping.

Building construction Technology

10 | P a g e

Investigation by site visit/plan in hand

By visiting the site, the surveyor can gain knowledge about geotechnical, topographic &

geological features of the site which will allow the surveyor to decide about access, restrictions

& about the working conditions.

A plan in hand visit allows the surveyor to know about the below mentioned features &

situations:

Design & construction plans

General site conditions

Geological features

The geomorphology

Access restriction for equipments

Traffic control requirements

Location of utilities

Type & condition of existing facilities

Adjacent land use

Restriction on working hours

Environmental issues

Outcrops, erosion features & subsurface settlement

Flood levels

Water traffic & access to water boring sites

Benchmarks & other reference points

Equipment storage areas/security

Sub surface exploration planning

Exploration methods on the field. Requirements of sampling & project design, types &

frequency of field test to be performed which can be determined based on the subsurface

information. The availability of equipments & local practice also has to be considered.

Mostly, the investigation program has to be modified after initiating the field work because of

site access constraints or to the variations in subsurface conditions.

Frequency & dept of Borings

The type & the critical nature of the structure, the soil & the rock formation, the known

variability in stratification & the foundation loads decides the location & the frequency of the

borings. Mostly it may require to extend the depths of the borings beyond the minimum dept

due to geological settings, condition or the characteristics of the underlying soil strata, or to

assure that required information is obtained for cases when the structure requirements are not

clearly defined at the time of drilling. When the drilling is done to the bedrock a minimum of

1.5m depth of rock core has to be obtained to verify that the boring has reached the bedrock &

not on the surface of a boulder.

Building construction Technology

11 | P a g e

Boring locations & elevations

Establishing all planned drilling locations & elevations should be carried out by a licensed

surveyor, if a licensed surveyor is unavailable the field inspector is responsible for establishing

the boring locations & the elevations. A G.P.S. device (Global Positioning System) also can be

used to find the accurate locations however the accuracy is m for most projects.

Types of investigation

Remote sensing

The information collected to recognize the condition of the physical futures on the land,

geological information & general soil & rock formations.

Geophysical information

Detecting underground cavities, sudden changes in subsurface etc. is known as

geophysical information which can be collected by doing several tests such as SR(Sound

Resistivity) test, EM(Electro Magnetic conductivity) test & GPR(Ground Penetrating

Radar) test.

Disturbed sampling

A disturbed sample is one in which the structure of the soil has been changed

adequately that tests of structural properties of the soil will not be envoy of in-situ

conditions, the sample is collected from excavated area in a disturbed condition. The

sampling process modifies their natural structure.

In-situ testing

In-situ testing is done in the construction site using raw materials which will give the

results in the same time such as Cone Penetration Test.

Undisturbed sampling

The condition of the soil in the sample is much similar to the conditions of the soil in-situ

to allow tests of structural properties of the soil to be used to approximate the

properties of the soil in-situ. Tests such as place strength, compressibility, plate bearing

& tests for moisture are undisturbed tests.

Building construction Technology

12 | P a g e

Soil classification

Soil is a particular kind of earth or ground consisting of rock & mineral particles mixed with organic

matter or any unconsolidated material that is the product of weathering & mechanical disintegration of

rocks, composed of discrete particles with gases & liquids interspersed between them is known as soil.

Available type of soils

Residual soil

After the soluble elements have been dissolved the remaining is

Residual soil. Residual soils can be formed from igneous, Sedimentary &

Metamorphic rocks. Weathering might be partial; structure may be

meta-stable, exhibiting strength loss on disturbance.

Transported soil

Transported soil is formed in three stages, as in order first stage is

Weathering or breakdown in materials then the second stage is erosion

or the transportation from its original location & the final stage is

deposition.

Alluvial soil

Alluvial soil is a fine grained fertile soil deposited in lakes or in flood

plains by water flowing over them. Alluvial soil contains clay, silt, gravel

& similar materials)

Marine soil

Marine soil is heaped upon the beaches in coastal areas, materials

eroded from the beaches by tidal action of the waves & the materials

carried out to the sea from streams forms Marine soil. These type of soil

have a structure reflecting the saline condition during deposition. In this

soil shell fragments & micro organisms are prevalent.

Building construction Technology

13 | P a g e

Glacial soil

The composition of this type of soil exceedingly non uniform structure

formed by the particles carried out by the Glaciers

Aeolian soils

This kind of soil is so porous its formed from sand & silt particles carried

by wind.

Organic soils

If the soil contains a large percent of organic matter it is known as

organic soil.

Building construction Technology

14 | P a g e

Available boring methods

Bore holes are usually used to classify & to identify the soil purposes or to take samples, also bore holes

are used determine the ground below 6m depth.

Rotary Boring

Most rock formations can be drilled, the drilling can be done above &

below the water table. The drilling depth is over 40m, water & mud

supports unstable formations. A cutting bit attached to the bottom is

used to drill.

Light Percussion Drilling

Simple to operate & maintain comparing to other drilling methods, can

be used on variety of rocks. The drilling dept is considerable but a

relatively slow method.

Auger Boring

A simple & a economical boring method, the method is a dry method &

can be used only on soft soils. Handling should be done carefully when

taking the auger out because it may generate suction in the borehole

which can disturb the soil to be sampled

Hand Auger Boring

This boring method is suitable for soil research & its an inexpensive

method, also its easy to operate & maintain but this method is also a

slow method relatively.

Building construction Technology

15 | P a g e

Wash Boring

In this method soil remains undisturbed, the equipment is light &

inexpensive also an advantage is it can be used for small & large holes.

Water Jetting

This boring method makes the hole by jetting high pressured water to

the soil below the casing. This method is fast, cheap & requires only a

little skill to handle. Disadvantage of using this method is a volume of

soil gets contaminated with water & the soil gets highly disturbed.

Not a suitable method for soil sampling.

Proposed boring method

The chosen site is in the middle of the city so itll cause many problems if heavy machinery is

used during the day time so the most suitable method for the construction in Colombo Street

is Light percussion drilling

In light percussion drilling method, the equipments can be moved easily comparing to like

rotary drilling system other drilling systems also can be used but because its for the soil

exploration & because we dont know the state beneath the ground level this method is much

more suitable.

Proposed boring method Light Percussion Drilling.

Building construction Technology

16 | P a g e

Available types of foundation

Shallow foundations

Spread footing

Spread footing foundations are commonly used in residential

constructions; these are strips or pads of concrete which takes the load

from the walls & columns of the structure.

Pad footing

Pad footing is also known as isolated footing. The footing is provided

under a column, the shape of the footing usually is circular, square &

rectangular.

Strip footing

Usually used to support a line of loads , either due to load from walls or

pad footings are closer. Strip foundations can also be constructed from

unreinforced concrete.

Combined footing

Combined foundations are in rectangular or in trapezoidal shape to

provide a uniform pressure to the ground. Two foundations are

connected using a strap beam.

Building construction Technology

17 | P a g e

Mat or Raft foundation

Raft foundations are used when the load is needed to spread to a large

area, often used in soft soils with a low bearing capacity, Using raft

foundations are more economical & convenient than using number of

excavations.

Deep foundations

Piled foundation

Deep foundations are the ones usually depths go to below 3m, piling is

used to ensure the safety & the required load bearing of the foundation.

The cost is high relatively high comparing to shallow foundation

methods but the safety & the durability is also high comparing to

shallow foundations. Using deep foundations depends on the load of

the structure.

Proposed foundation for the selected site

The proposed Supermarket is a 4 storey building with a basement car park. A supermarket is a place

where lot of people move around & a considerable amount of load will be on the foundation, also

because of the basement car park the ground has to excavated at least 4m depth. According to the

borehole log provided to the construction site at Colombo Street after excavating for the car park if a

Shallow foundation method is used the foundation has to be done on the Brownish fine sand or on

Fine medium sand which are materials hardly can be relied for a strong foundation so as I think

because of its a commercial building a Deep foundation has to be used to ensure the safety which

means the suitable foundation method is Piled Raft foundation .The piling should go at least 9m

deep till the Blackish grey very highly weathered rock.

Proposed foundation Piled Raft foundation

Building construction Technology

18 | P a g e

Types of excavations

Bulk Excavation

Bulk excavation is the process of excavating the required area & moving

the excavated materials to another place.

Rock Excavation

Breaking rocks using hammers or other machineries widely used in road

construction but if there are rocks disturbing to the construction of the

building rock excavation is used to clear the area.

Trench Excavation

Trench excavation is used for as strip foundations or in raft foundation

to excavate the required trench

Hole/Pit Excavation

Hole excavation is used for piling purposes, pit excavation is to cover a

large area of foundation as in raft foundation. To dig hole there are

various type of drillings as in boring methods for pit excavation there

are certain types of machineries to use.

Building construction Technology

19 | P a g e

Associated temporary works for the construction of foundation

Shoring

Shoring is a method most commonly used to ensure the safety of the workers & to prevent the

excavation from caving in. Shoring is also light weight, portable & easy to install.

Vertical Aluminum Hydraulic Shoring (Spot bracing)

Trench Slide rail system

Trench Lite shield

Extruded Aluminum trench shield

Building construction Technology

20 | P a g e

Hydraulic shields

Trench Waler systems

Man hole shores

Building construction Technology

21 | P a g e

Construction method of Piled Raft foundation

Testing the nature of the soil

The weight resistance of soil & the weight bearing of the soil should be checked before

any type of construction commenced. Types of Soil acts differently due to the load its

bearing soil is classified as Practically incompressible soil, Compressible soil & Soils

which escapes laterally. The type of the foundation depends on which kind of soil the

land has.

Piled foundation

Because of the construction is a commercial building the load will be high during the life

span of the structure, also because of the underground car parks weight & considering

the borehole log the construction requires piling.

There are 3 types of piles; Bored piles, Driven piles & Steel or H piles. Within these three

types the type of piling I choose is bored piling.

To construct the pile first the required depth should be bored using a suitable boring

method, after reaching the required depth the reinforcement for the pile has to be

inserted then finally the bored hole is filled with the special concrete mixture which

dont face aggregation, then let it harden naturally.

Raft foundation (footing)

After completing the piled foundation the construction requires a raft foundation to

distribute the load to the piles.

The method of distributing load is using a Raft foundation.

To construct a Raft foundation first of all the formwork should be arranged after its

done the bottom of the foundation should be water proofed including the pile heads.

After water proofing the reinforcement is done up to standard qualities & with required

spacing, suitable type of bars etc.

Finally the concrete mixture is filled to the required area using vibrates & other

necessary equipments & machineries to maintain the quality

Building construction Technology

22 | P a g e

Formwork arrangements needed for construction

Formwork arrangement needed for the construction of Slab

The Slab formwork previewed in this image is a Aluminum panel

form work with metal beams to support the panels. The

advantage of using this type of form work is it can be reused &

comparing with timber form work this form work method is

cheaper because it doesnt require replacing or buying a new

formwork set for a considerable period.

Formwork arrangement needed for the construction of Beam

To construction of beam form work also steel panels can be

used with metal supports. Using Metal supports & steel panels

can increase the speed of the construction & it also helps to

maintain the quality because of its adjustable heights.

Formwork arrangement needed for the construction of Column

Steel form work is also available for column formwork; its also

re usable & can construct any column with any height.

Building construction Technology

23 | P a g e

Formwork arrangement needed for the construction of Staircase

For the formwork of staircase the materials

used is timber, metal bars & to support the

structure & ply wood as showed in the image.

Building construction Technology

24 | P a g e

Reinforce arrangement in structural elements

Reinforce arrangement for Beam

Method of construction Beam reinforcement

Before placing reinforcement in beam footings you need to make a cage out of rods and stirrups as they

form a cage. Place the reinforcement cage in the trench, making sure it does not touch the trench sides

& has the required cover. Support the bottom bars or rods on bar chairs, or hang them from a timber

support across the top of the trench also when one beam meets another beam, overlap the rods by the

full width of the cage.

Building construction Technology

25 | P a g e

Beam reinforced arrangement of the visited site

Building construction Technology

26 | P a g e

Building construction Technology

27 | P a g e

Reinforce arrangement for Column

Method of construction Column reinforcement

As same as Beam reinforcement steel cages are made with steel & usually columns are made with the

slab reinforcement so the slab reinforcement & the column reinforcements are connected. Unlike Beam

reinforcement column reinforcement doesnt require a trench because its built vertical form work is

required only when concreting when preparing the reinforcement no formwork is needed. As in beam

reinforcement when the reinforcement of one column connects to another column reinforcement the

two reinforcement should overlap for at least for 1m. The links, number of bars the space between them

has to be up to standards to maintain the quality.

Building construction Technology

28 | P a g e

Column Reinforce arrangement of the visited site

Building construction Technology

29 | P a g e

Reinforce arrangement for Slab

Method of construction Slab reinforcement

First the formwork should be arranged after completing the formwork the reinforced has to be laid with

the required steel bars. After laying the reinforcement concrete cover blocks should be kept under the

reinforcement to lift the reinforcement for the required cover to obtain the fire resistance & the

moisture resistance as structure requires. Overlapping also should be done when joining the

reinforcement.

Building construction Technology

30 | P a g e

Brick work

Brick walls are known as wet partition its because it requires a mortar mixed with water to construct

using this material. Bricks are made by molding good clay into a block & let it dry then burnt. Hand

molding & drying out in the sun was the first method use to make bricks but now with the technological

development machineries are used to cut & burn the bricks.

Uses of brick work in construction

As building blocks

Before bricks are used in construction work first it has

to be tested for its quality, there can be cracks,

deformations , not in standard shape etc. after testing

bricks are laid using a mortar as a bonding agent. When

bricks are used to build walls there is a special

arrangement of laying bricks its known as English

bond (shown in the image). In bricklaying, an

arrangement of bricks such that one course has the

short sides of the bricks (headers) facing outwards, and

the next course has the long sides of the bricks

(stretchers) facing outwards is known as English bond.

Building brick walls as to English bond gives the wall its

required strength & characteristics of a wall.

Fire protection

Bricks have a good fire resistance capability. Using this

advantage of bricks when a building needs extra fire

protection (as emergency fire exits) a layer of brick is

added to cover the structure. Which will give the

construction extra protection against fire. Construction

method is same as brick walls

Foot paths/Pavements

Because of bricks appearance & strength its also used

in foot paths & pavements.

Building construction Technology

31 | P a g e

Method for construction of first floor concrete slab

Formwork arrangement

The formwork of slabs should be started after completing the columns up to the bottom level of slab

beams. Plywood sheets can be arranged for the form work & it has to be water proofed by applying

grease or covering it from a polythene layer. GI pipes, Acro(T) jack and 2"x4" timber arrangements are

used to supports the formwork.

Slab formwork arrangements

Building construction Technology

32 | P a g e

Plywood sheets used for formwork.

Arrangements to support the form work.

Reinforce arrangement

The Reinforcement is arranged according to the design provided & the arrangement depends on the

load the slab will be carrying. The bars, spacing everything will be decided by the structural engineer

& the reinforcement has to be laid according to him. After laying the reinforcement concrete cover

blocks are kept under the reinforcement to protect the reinforcement from moisture & for the fire

resistance required by the building.

Rein force arrangement Concrete cover block

Building construction Technology

33 | P a g e

Concreting

After the formwork & reinforcement arrangements are done the final step is to fill it with the concrete

mixture. While filling the concrete a vibrator is used to allow concrete to touch every surface & to make

sure there will be no cavities after hardened. After concreting the surface is smoothed before getting

hardened.

Using the vibrator smoothing the surface

Curing

After concreting a good care has to be taken of the concrete to ensure that the concrete will gain its full

strength after hardening. The concrete starts to harden from outside after around 2, 3 days. If there is

no sufficient water the slab will start to crack & the slab will be a failure. To avoid this from happening

the surface of the concrete should always be in a wet condition. To keep the surface wet a brick wall can

be made around the concrete from cement or clay, then fill water to the surface. It has to be checked

from time to time until the concrete gains its full strength & when the surface looks dry it has to be filled

again. Also the concrete can be covered by polythene to stop water evaporating from the surface

A brick wall made around the concrete Covered from polythene

Building construction Technology

34 | P a g e

Wall & Floor finishes

The site I selected for the exploration is a General hospital so wall & floor finishes are considered for

The front reception, Bathrooms & for the hospital wards.

Available materials for the floor finishing

Material for the floor finishing of the showrooms should provide a pleasant look to the customer

& also it should give a luxurious look to the showroom. Because of lot of people are moving so

the material should be easy to clean & in the same time the material shouldnt require often

cleaning.

Laminated wood flooring

Laminate flooring is a multi layer synthetic flooring product

fused together using a lamination process. Laminated floor is

attractive as same as natural floor materials but it costs less

than natural floor materials & also much durable than using

carpet

Hardwood flooring

Hardwood flooring is a material rich in its appearance also it

gives more strength and overall long life. using hardwood

flooring costs more but its a durable material for flooring.

Building construction Technology

35 | P a g e

Lime stone tile

Limestone is a sedimentary rock composed largely of the

minerals calcite and/or aragonite. Limestone flooring is durable

& gives a luxurious appearance but using limestone tiles are

highly expensive.

Terrazzo

Terrazzo is made up of small marble chips or stone chips that

are set hard in a binding material and then ground over until

completely level. Using terrazzo is less expensive & durable also

the appearance of the floor increases as the usage of the floor

increases.

Ceramic tile

Ceramic tiles are made with clay base & glazed ceramic material

top. Ceramic tiles are relatively cheap & only the top surface

can be exposed, if the top ceramic layer is chipped off the tile

cannot be used. Advantage of using this type of tile is wide

range of colors & textures are available.

Building construction Technology

36 | P a g e

Granite tile

Granite is made by cutting & polishing the granite stone.

Granite doesnt under go any manufacturing process, variety of

textures is available & the appearance can be improved into a

glossy, grand look by polishing. The cost for granite is high as

same as marble & granite doesnt have to be polished

continuously.

Glass tiles & Mosaics

Glass tiles are pieces of glass formed into consistent shapes&

artistic figures. Because of glass tiles are more rigid it can break

easily & glass tiles are highly expensive.

Homogeneous tiles

Homogeneous tiles are made with the same material unlike

ceramic or porcelain tiles any side of the tile can be exposed.

Homogeneous tiles are more expensive than ceramic tiles but it

is durable & if the tile gets damaged the visibility of the damage

is low with this type of tiles.

Building construction Technology

37 | P a g e

Carpet tiles

Carpet tiles are square sections of carpeting that are sometimes

used in place of rolled carpeting, user can choose the carpet

from a wide range of colors. Installation of carpet tiles is much

easier than any other flooring material & another advantage of

using carpet tiles is if a carpet gets stained only the particular

section has to be replaced. The cost for carpet tiles is expensive

than a normal carpet.

Carpet

Common types available are fabric & wool loops carpets

because carpets are synthetic materials a wide range of colors

are available & wide range of textures are available. The cost is

low comparing to other materials, the durability of a carpet is

also low comparatively.

Vinyl plank flooring

Vinyl is easy to install quickly & it also gives a looking surface

.Because of its an artificial material a wide range of textures &

colors are available also vinyl flooring is relatively cheap but the

price may differ from the vinyl chosen. The durability is same as

carpets, advantage of using this material is its hygienic.

Building construction Technology

38 | P a g e

Floor finishing material for the front reception

The front of a hospital should be attractive & it should give the patient a pleasant feeling that this

hospital is hygienic & it certainly can cure the illness he has, so it has to be a material easy to clean,

Hygienic & with some luxury look so between these materials the most suitable material for the front

reception is Granite flooring.

Floor finishing recommended for the front reception Granite tiles.

Floor finishing material for the bathrooms

The bathroom is a place that used by lot of people, so it has to be a material so easy to clean, less

slippery, easy to clean & a material doesnt absorb water. So considering the above materials the most

suitable material for the bathroom floor finish is Ceramic tiles.

Floor finishing recommended for bathroom Ceramic tiles.

Floor finishing material for the Hospital wards

The hospital ward also has to be hygienic & clean as any other place in a hospital. Also patients can

vomit or drop liquids or blood can drop on the wards floor so again it has to be a material doesnt

absorb water, easy to clean & not stains so again the suitable material for flooring of the hospital ward is

Ceramic tiles.

Floor finishing recommended for the hospital ward Ceramic tiles.

Building construction Technology

39 | P a g e

Available materials for the wall finishes

Material chose for the outer wall finish is as much as important as any other finishing because its the

first thing the customer sees & from the outer finish people decides how inside of the shopping

complex is. If the shopping complex has a poor outer wall finish people wouldnt even care much to take

a look inside but if it has a rich outer wall finish people would come in even its an empty shopping

complex. An outer wall increases the income of a commercial building so it has to be luxurious,

attractive & something unique to grab peoples attention.

Plastering & paint

Plastering is commonly used in brick & block walls, Gypsum plastering,

Lime plastering & Cement plastering are the available plastering

methods. The surface remains smooth & soft after plastering. Usually

after plastering paint is applied on the wall to improve the appearance.

PVC Cladding

Covering one material from another material is called cladding.

Aluminum sheet, stone, brick, granite, wood etc. can be used for

cladding. The appearance of any kind of partition can be improved using

cladding.

Wall finishing material for the front reception, Hospital wards &

bathrooms.

For all three places the most suitable material is PVC cladding because it is water proof, hygienic & its

easy to keep clean. Also it has a good luxury look.

Wall finishing recommended for the hospital ward, Front reception & bathrooms PVC cladding.

Building construction Technology

40 | P a g e

Water proofing

Elements to be water proofed in a building

Basement

Foundation

Roof

Bathroom floors/walls

Method of water proofing the bathroom

Fiber flex

Fiber flex is a material can be applied on top of joints & places possible of having a leakage. When it is

applied it seals the place & water proof the place this product can be applied on bathroom walls & floors

for water proofing.

Poly cloth reinforcing fabric

This is product can be pated on top for water proofing for bathroom floors this material can be pasted

from the bottom & then tile the surface from the top. Also can be used in the same way on walls, the

plastering or the painting can be done top of this product.

Building construction Technology

41 | P a g e

Timberwork used in building construction

Formwork

Timber is used in formwork because of its a easy material to

find & a material with a reasonable durability. Timber is used in

form work for slabs, beams, columns, foundation Almost in

every concrete work mostly timber is used as a material for the

form work.

Doors

Timber doors are mostly used in residential construction

because of its durability & for the strength.

Windows

Timber is used in windows to increase the appearance of a

house or a building. Mostly timber windows are also used in

residential construction because of its expensiveness timber

dont get used usually in large scales

Building construction Technology

42 | P a g e

Timber joints

Mortise & Tenon joints

This is the most commonly used type of joints this joint is much

stronger & the joint is less likely to crack. A mortise is basically a

slot cut in a piece of stock & a Tenon is a reduced tongue.

Mortise & Tenon joints with pin

This is the most common of all conventional joints, The pining

offers the opportunity to accent the corners.

Haunch Mortise & Tenon joints

The haunch piece should extend beyond no more than one

quarter along the tenon

Haunched Mortise & Tenon

This is built into the tenon to fill the grooves in the stiles

Building construction Technology

43 | P a g e

The ongoing construction site chose to study

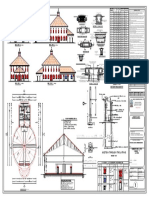

Elevations of the proposed construction

Building construction Technology

44 | P a g e

Slab & Beam layout of the proposed construction

Building construction Technology

45 | P a g e

Wall foundation & retaining wall detail of the proposed construction

Building construction Technology

46 | P a g e

Column foundation detail of the proposed construction

Building construction Technology

47 | P a g e

Foundation & tie beam layout of the proposed construction

Building construction Technology

48 | P a g e

Pictures of the visited site

Building construction Technology

49 | P a g e

Conclusion

This is the final page of the assignment & it was really difficult to find

information on some topics even on the internet so I referred the

tutorials I was given regarding this subject. Most of my conclusions on

the topics are mentioned in the assignment.

I hope Ive done the assignment according to the proper criteria & I

Thank you for spending your valuable time to take a look at this

assignment

Building construction Technology

50 | P a g e

Reference

http://www.itc.nl/~rossiter/Docs/FM5-410/FM5-410_Ch5.pdf

http://www.realmagick.com/alluvial-soil/

http://www.tpub.com/content/engineering/14069/css/14069_516.htm

http://www.scribd.com/doc/38415788/Boring-Methods-Presentation

http://jamesmkc.blogspot.com/2006_08_01_archive.html

http://environment.uwe.ac.uk/geocal/foundations/Fountype.htm

http://www.gme-shields.com/products

Vous aimerez peut-être aussi

- Topic 8 EXTERNAL WORKS, NotesDocument15 pagesTopic 8 EXTERNAL WORKS, NotesCaroline MugurePas encore d'évaluation

- BLD 204 Building Construction III Combined PDFDocument49 pagesBLD 204 Building Construction III Combined PDFdkaviti83% (30)

- QUS 104 Building ScienceDocument70 pagesQUS 104 Building ScienceOlagoke Habeeb Ademola100% (3)

- BLD 204 PDFDocument20 pagesBLD 204 PDFOluwaseyi Toheeb Arc.Azeez50% (2)

- Cost Implications of Architectural Design Variables PDFDocument241 pagesCost Implications of Architectural Design Variables PDFsoleb80% (5)

- The Functions and Classification of RoofsDocument6 pagesThe Functions and Classification of RoofsKevin De Silva86% (7)

- Building TechnologyDocument55 pagesBuilding TechnologyJames Muriithi GichukiPas encore d'évaluation

- Step To Construct The BuildingDocument41 pagesStep To Construct The Buildingliza100% (12)

- ATGB3612 Building Maintenance Technology - Chapter 1Document61 pagesATGB3612 Building Maintenance Technology - Chapter 1IAN CHEW E PING100% (2)

- Ce 223 Notes 2010.2011 PDFDocument128 pagesCe 223 Notes 2010.2011 PDFAthiyo MartinPas encore d'évaluation

- Role of Qs During BriefingDocument3 pagesRole of Qs During Briefingkhairul hazwan100% (3)

- Floor FinishesDocument17 pagesFloor Finishesvikina34100% (1)

- QUS 201 - Building Measurement & Specification (Theory-Practical)Document122 pagesQUS 201 - Building Measurement & Specification (Theory-Practical)VietHungCao93% (14)

- Meas - Lecture Note Substructure Note 3Document14 pagesMeas - Lecture Note Substructure Note 3LokuliyanaNPas encore d'évaluation

- BLD 207 Building Services Final CombinedDocument169 pagesBLD 207 Building Services Final CombinedVietHungCao100% (7)

- Building ElementsDocument57 pagesBuilding ElementsjahnvighoghariPas encore d'évaluation

- BLD 104 Building Construction CombinedDocument59 pagesBLD 104 Building Construction Combineddkaviti83% (6)

- QUS 101 - Intro To Measurement PDFDocument107 pagesQUS 101 - Intro To Measurement PDFariff.arifin75% (4)

- Design VariablesDocument12 pagesDesign VariablesWalter Buyela100% (3)

- BLD 112 Lecture NoteDocument42 pagesBLD 112 Lecture NoteUmar Bello Nuhu100% (1)

- QUS 102 Measurement of Building WorksDocument120 pagesQUS 102 Measurement of Building Worksyes i can86% (7)

- BLD 102 PracticalBookDocument29 pagesBLD 102 PracticalBookdkaviti50% (2)

- QUS 207 - Principles of Const. Econs IDocument93 pagesQUS 207 - Principles of Const. Econs IVietHungCao100% (11)

- BLD 103 Building Construction I CombinedDocument56 pagesBLD 103 Building Construction I Combinedshaybaby1657% (7)

- Building Economics, Quantity Surveying, and Cost Estimation - 2017Document57 pagesBuilding Economics, Quantity Surveying, and Cost Estimation - 2017Hamza NayefPas encore d'évaluation

- Advanced Construction TechnologyDocument41 pagesAdvanced Construction TechnologyBCAS HND QS Assignment100% (1)

- SubstructureDocument35 pagesSubstructureMeghna AshokPas encore d'évaluation

- Estimating and Costing I Notes Done by Vincent Momanyi, Kevin Khisa and Nelson NyabwariDocument36 pagesEstimating and Costing I Notes Done by Vincent Momanyi, Kevin Khisa and Nelson NyabwariIan Kirika100% (1)

- Building MeasurementDocument22 pagesBuilding MeasurementBCAS HND QS Assignment100% (2)

- Building ConstructionDocument120 pagesBuilding Constructionइंजि कौस्तुभ पवारPas encore d'évaluation

- COMPLET BLD 103.... SamuelDocument39 pagesCOMPLET BLD 103.... SamuelFadare SamuelPas encore d'évaluation

- BLD 202Document2 pagesBLD 202ibiwumiPas encore d'évaluation

- Transportation of ConcreteDocument12 pagesTransportation of Concretesagar devidas khot100% (3)

- Construction Plant and EquipmentDocument10 pagesConstruction Plant and Equipmentpaul machariaPas encore d'évaluation

- Building Maintenance Lecture NotesDocument56 pagesBuilding Maintenance Lecture NotesRichard Simon Kisitu86% (14)

- BLD 206 MergedDocument54 pagesBLD 206 MergedVietHungCao100% (1)

- Advanced Building MeasurementsDocument3 pagesAdvanced Building MeasurementsSundar Ramasamy50% (2)

- Building Construction IDocument57 pagesBuilding Construction IChinedu Godfrey100% (1)

- Building ConstructionDocument26 pagesBuilding ConstructionThrishala DharanikotaPas encore d'évaluation

- HND Building TechDocument191 pagesHND Building TechOlusesi oluwatobaPas encore d'évaluation

- Construction Technology Assaignment-1Document40 pagesConstruction Technology Assaignment-1JayaniPas encore d'évaluation

- BLD 203 Building Construction III Combined PDFDocument54 pagesBLD 203 Building Construction III Combined PDFdkaviti85% (39)

- Method of Payment For PreliminariesDocument2 pagesMethod of Payment For PreliminariesAnonymous zsBCtskz80% (5)

- Building Construction PDFDocument7 pagesBuilding Construction PDFrenuvenkat00778% (9)

- Construction Economics ND 2 QS-1 PDFDocument5 pagesConstruction Economics ND 2 QS-1 PDFMuhammad Ibrahim SugunPas encore d'évaluation

- Building Economics Lecture NotesDocument17 pagesBuilding Economics Lecture NotesJackson60% (5)

- FLOOR CONSTRUCTION CYCLE IN PROJECTS With LinkDocument14 pagesFLOOR CONSTRUCTION CYCLE IN PROJECTS With LinkJayasri ArunachalamPas encore d'évaluation

- Site SelectionDocument5 pagesSite SelectionMonty KushwahaPas encore d'évaluation

- Summer Training Report of DLFDocument40 pagesSummer Training Report of DLFarunscribd20100% (2)

- Road Divider ReportLDocument88 pagesRoad Divider ReportLKrina Parekh100% (1)

- Construction Challenges For Bridges in Hilly Are ADocument23 pagesConstruction Challenges For Bridges in Hilly Are Apraveenpv750% (4)

- Construction Practice 1 For TechnicianDocument24 pagesConstruction Practice 1 For TechnicianMichael_Mensah_2238Pas encore d'évaluation

- Site VisitDocument17 pagesSite VisitShantanuShahPas encore d'évaluation

- Imran Ahmad SheikhDocument17 pagesImran Ahmad Sheikhwadhwacommunisation0001Pas encore d'évaluation

- Construction Technology On SKYPARKDocument17 pagesConstruction Technology On SKYPARKDarrenTofuPas encore d'évaluation

- Mohd Irfan KhanDocument23 pagesMohd Irfan Khanwadhwacommunisation0001Pas encore d'évaluation

- Construction Challenges For Bridges in Hilly AreaDocument24 pagesConstruction Challenges For Bridges in Hilly AreaVarnanaPas encore d'évaluation

- Wku Group-Mara Proposal For ThesisDocument16 pagesWku Group-Mara Proposal For Thesismerga abdeta100% (1)

- Internship Report On 120 Mens Hostel ConstructionDocument47 pagesInternship Report On 120 Mens Hostel ConstructionApollyon A100% (3)

- Construction InnovationDocument18 pagesConstruction InnovationAnushke HennayakePas encore d'évaluation

- Hydrology ReportDocument26 pagesHydrology ReportAnushke HennayakePas encore d'évaluation

- Ictad SBD 01Document119 pagesIctad SBD 01Anushke HennayakePas encore d'évaluation

- SUPERMAN CHORDS by Five For Fighting at Ultimate-GuitarDocument1 pageSUPERMAN CHORDS by Five For Fighting at Ultimate-GuitarAnushke HennayakePas encore d'évaluation

- Proposal For Camera SystemDocument3 pagesProposal For Camera SystemAnushke HennayakePas encore d'évaluation

- Project Management MethodsDocument37 pagesProject Management MethodsAnushke HennayakePas encore d'évaluation

- Bcu Id - 17107599Document30 pagesBcu Id - 17107599Anushke HennayakePas encore d'évaluation

- Progress & MaintenanceDocument4 pagesProgress & MaintenanceAnushke HennayakePas encore d'évaluation

- First - AidDocument50 pagesFirst - AidAnushke HennayakePas encore d'évaluation

- Living and Working in IcelandDocument44 pagesLiving and Working in IcelandRamazan İslamogluPas encore d'évaluation

- Cash ImprestDocument3 pagesCash ImprestAnushke HennayakePas encore d'évaluation

- Cash ImprestDocument3 pagesCash ImprestAnushke HennayakePas encore d'évaluation

- OT InstructionsDocument2 pagesOT InstructionsAnushke HennayakePas encore d'évaluation

- InvoiceDocument1 pageInvoiceAnushke HennayakePas encore d'évaluation

- Weekly Progress ReportDocument6 pagesWeekly Progress ReportAnushke HennayakePas encore d'évaluation

- Master Program For Hydro PowerDocument1 pageMaster Program For Hydro PowerAnushke HennayakePas encore d'évaluation

- Meter Hours / Meter Lengths (KM) / Machine Present (1 or 0Document2 pagesMeter Hours / Meter Lengths (KM) / Machine Present (1 or 0Anushke HennayakePas encore d'évaluation

- Gantt Chart SampleDocument2 pagesGantt Chart SampleAnushke HennayakePas encore d'évaluation

- Progress by LengthDocument160 pagesProgress by LengthAnushke HennayakePas encore d'évaluation

- Katiri ChurchDocument1 pageKatiri ChurchAnushke HennayakePas encore d'évaluation

- Cs - Exam PaperDocument7 pagesCs - Exam PaperAnushke HennayakePas encore d'évaluation

- Concrete UsageDocument10 pagesConcrete UsageAnushke HennayakePas encore d'évaluation

- Post Contract ManagementDocument43 pagesPost Contract ManagementAnushke HennayakePas encore d'évaluation

- Completed Sections-Status Report May 2014Document8 pagesCompleted Sections-Status Report May 2014Anushke HennayakePas encore d'évaluation

- AsphaltDocument13 pagesAsphaltAnushke HennayakePas encore d'évaluation

- KDA Weerasinghe & Co: (PVT) LTD B-157 Aluthgama Southern Expressway (42+600 - 53+670) Mix DesignDocument2 pagesKDA Weerasinghe & Co: (PVT) LTD B-157 Aluthgama Southern Expressway (42+600 - 53+670) Mix DesignAnushke HennayakePas encore d'évaluation

- 18 Cost Report.......Document57 pages18 Cost Report.......Anushke HennayakePas encore d'évaluation

- Progress MonitoringDocument22 pagesProgress MonitoringAnushke HennayakePas encore d'évaluation

- Ictad SBD 01Document119 pagesIctad SBD 01Anushke HennayakePas encore d'évaluation

- BOQ To Manjula-2Document17 pagesBOQ To Manjula-2Anushke HennayakePas encore d'évaluation

- Epc ChecklistDocument181 pagesEpc ChecklistRajaram Jayaraman100% (1)

- Everest Green SolutionDocument20 pagesEverest Green SolutionVengatesh HariPas encore d'évaluation

- Modular KitchenDocument33 pagesModular Kitchenimpranayjha100% (4)

- IBC - Egress: 2015 Group A Proposed Changes To The I-Codes Memphis Committee Action HearingsDocument227 pagesIBC - Egress: 2015 Group A Proposed Changes To The I-Codes Memphis Committee Action Hearingsvin ssPas encore d'évaluation

- HardieFlex Product SampleDocument8 pagesHardieFlex Product SamplewaaaPas encore d'évaluation

- Expansion-And Movement Joint Profiles: ApplicationsDocument16 pagesExpansion-And Movement Joint Profiles: ApplicationsHead'in CloudsPas encore d'évaluation

- Dukkaboard CatalogueDocument40 pagesDukkaboard CatalogueAbhinav SainiPas encore d'évaluation

- Times Leader 06-02-2012Document50 pagesTimes Leader 06-02-2012The Times LeaderPas encore d'évaluation

- RevitKeynotes NZLDocument50 pagesRevitKeynotes NZLPranshu LondasePas encore d'évaluation

- Godrej 24 - FlipchartDocument55 pagesGodrej 24 - FlipchartPooja shettyPas encore d'évaluation

- Estimate of BuildingDocument32 pagesEstimate of BuildingD.V.Srinivasa Rao100% (1)

- Grade 9 LM For DecongestingDocument49 pagesGrade 9 LM For DecongestingKim Paolo Carlos BacsalPas encore d'évaluation

- Flats and Apartments FINALDocument29 pagesFlats and Apartments FINALAditi SharmaPas encore d'évaluation

- Kalsi Building Boards BrochureDocument28 pagesKalsi Building Boards BrochureJoemadz Dela CruzPas encore d'évaluation

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- WetDocument32 pagesWetJesús Rodríguez RodríguezPas encore d'évaluation

- Carpet Abu CC IfDocument17 pagesCarpet Abu CC IfTarek TarekPas encore d'évaluation

- Project Report On Artificial/synthetic Marble ProductionDocument5 pagesProject Report On Artificial/synthetic Marble ProductionEIRI Board of Consultants and PublishersPas encore d'évaluation

- Arkaz Product BroucherDocument5 pagesArkaz Product Brouchersk mukhtarPas encore d'évaluation

- Project Report 1 PDFDocument15 pagesProject Report 1 PDFDipu GeorgePas encore d'évaluation

- Tremix Flooring PDFDocument4 pagesTremix Flooring PDFdinkad29Pas encore d'évaluation

- 170 - Help Points List PDFDocument6 pages170 - Help Points List PDFRaju PuttaswamyPas encore d'évaluation

- BCM - 40-42 (Presentation On Flooring (1732016)Document38 pagesBCM - 40-42 (Presentation On Flooring (1732016)Mahesh RamtekePas encore d'évaluation

- Civil - Rate Analysis - 066 67Document188 pagesCivil - Rate Analysis - 066 67ujjwal100% (1)

- Aalco Road TransportDocument111 pagesAalco Road TransportEnrico959Pas encore d'évaluation

- Is 777 For Glazed TilesDocument15 pagesIs 777 For Glazed TilesMadhu BabuPas encore d'évaluation

- Astm f2170 19 Standard Test Method For DeterminingDocument4 pagesAstm f2170 19 Standard Test Method For DeterminingMonraj BikooPas encore d'évaluation

- Analysis of Rates of Various Building ItemsDocument3 pagesAnalysis of Rates of Various Building Itemsveera_swamy250% (2)

- Nexway ElevatorDocument21 pagesNexway ElevatormostafaarafatPas encore d'évaluation