Académique Documents

Professionnel Documents

Culture Documents

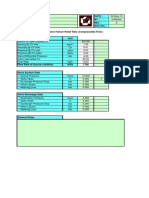

PSV Scenario and Calculation

Transféré par

minhphuongphamCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PSV Scenario and Calculation

Transféré par

minhphuongphamDroits d'auteur :

Formats disponibles

PSV Calculation and Philosophy

1

Role of Pressure Safety Valve (PSV) Role of Pressure Safety Valve (PSV)

PSVs are installed to make sure that

Accumulated Pressure Maximum Allowable Accumulated Pressure

as dictated by applicable code & standard

Pressure Vessels

(ASME Sect VIII, API 520 & 521)

Unfired Boilers

(ASME Sect I)

Piping

(ASME B16.5 and 31.3)

2

Design Code & Standard (Pressure Vessel) Design Code & Standard (Pressure Vessel)

- ASME Section VIII

- API 520 Sizing, Selection and Installation of Pressure-Relieving

Devices in Refineries Devices in Refineries

Source : API 520

Set pressure = Pressure at which PSV is set to open

3

Design Code & Standard (Unfired Boiler) Design Code & Standard (Unfired Boiler)

ASME Section I

106 106 106

103

106

106

Kerosene Pumparound

LP Steam Generator LP Steam Generator

4

PROCEDURES FOR PSV CALCULATION PROCEDURES FOR PSV CALCULATION

LOCATE PSV and SPECIFY

RELIEF PRESSURE RELIEF PRESSURE

DEVELOP SCENARIOS

(WHAT CAN GO WRONG?)

CALCULATE PSV SIZE

Required Information

CHOOSE WORST CASE

DESIGN OF RELIEF SYSTEM

(Flare Header, etc)

5

PSV SCENARIOS

(Refer API 521) (Refer API 521)

FOCUS ON COMMON CASES :

- Closed Outlets on Vessels

- External Fire

- Failure of Automatic Controls

- Hydraulic Expansion Hydraulic Expansion

- Heat Exchanger Tube Rupture

- Total Power Failure

P i l P F il - Partial Power Failure

- Cooling Water Failure

- Reflux Loss

- Failure of Air-Cooled Heat X

DOUBLE JEOPARDY NOT

CONSIDERED

6

(Simultaneous occurrence of two or

more unrelated causes of

overpressure)

Source : API 521

Closed outlets on vessels Closed outlets on vessels

Cause

Outlet valve is blocked while there is

i i l f hi h continuous inlet from high pressure

source

Effects

Outlet valve closed

Effects

Pressure built-up in vessel

Calculation

Can PSV be opened in Closed Outlet Case?

R li f

Pressure source (pump, compressor,

high pressure header)

No

Calculation

Can PSV be opened in Closed Outlet Case?

(Is maximum inlet pressure > PSV set pressure?)

For pump :

Is maximum pump shut off pressure PSV set

Relief case not

considered

Relief rate =

Yes

No

Is maximum pump shut-off pressure PSV set

pressure?

Relief rate

maximum inlet flow

7

External Fire (1/4) External Fire (1/4)

Cause

External pool fire caused by accumulated hydrocarbon on the

ground or other surfaces

Effects Effects

- Vaporization of liquid inside the vessel,

leading to pressure building up within the vessel g p g p

Calculation

Refer next slides Refer next slides

8

External Fire - Liq. Vessel (2/4) External Fire Liq. Vessel (2/4)

Relief rate (W) = Heat absorbed by liquid from external fire (Q)

Latent Heat of Vaporization of liquid ()

Case 1 :

If adequate drainage necessary to control the spread of major

ill f t th d t t l f d i spills from one area to another and to control surface drainage

and refinery waste water.

Q = 43,200 x F x A

0.82

C 2

7 6 m

Case 2 :

If adequate drainage and firefighting equipment do not exist.

Q = 70,900 x F x A

0.82

7.6 m

Q = Heat absorbed by liquid from external fire(W)

F = Environment Factor

A = Wetted Surface Area (m

2

)

9

External Fire - Liq. Vessel (3/4) External Fire Liq. Vessel (3/4)

Wetted Surface Area (A)

Source : API 521

10

External Fire

Liq. Vessel (4/4)

Environment Factor (F)

Liq. Vessel (4/4)

Latent Heat of Vaporization of liquid ()

for multi-component mixture

5 wt% flashed

= Dew Point Vapor Enthalpy

Relief Pressure

Bubble point T

Bubble Point Liquid Enthalpy

For column, use composition of For column, use composition of

1. Second tray from top (or reflux

composition if unavailable)

2. Bottoms

Ch th t i l PSV i

Source : API 521

Choose one that require larger PSV size

11

Failure of Automatic Control (1/3) Failure of Automatic Control (1/3)

Cause

- Failure of a single automatic control valve

Consider this control valve fail

- Control valves are assumed to fail to non-favorable

position (not necessarily to their specified fail

position).

Consider this control valve fail

in full-open although it is

specified as fail-close

Effects

- Control valve fail open : maximum fluid flow

through valve

N2

Header

Flare

FC FO

SPLIT-RANGE

g

- Control valve fail close : no fluid flow

- Effect of control valve fail open or close to be

considered on case-by-case basis

FC FO

PIC

Calculation

Calculation of maximum fluid flow in control valve

fail open case, refer next slide p ,

12

Failure of Automatic Control (2/3) Failure of Automatic Control (2/3)

CALCULATION OF MAX. FLOW THROUGH CONTROL VALVES

1. Find Valve CV value (from manufacturer).

2. If by-pass valve is installed, consider possibility that by-pass

valve may be partially open Add 50% margin to CV value in valve may be partially open. Add 50% margin to CV value in

1.

3. For Calculate maximum flow through control valve (refer

calculation sheet)

4. Find relief rate (to consider on case-by-case basis)

13

Failure of Automatic Control (1/3) Failure of Automatic Control (1/3)

EXAMPLE :

1 FEED SURGE DRUM

N2

Header

Flare

PV01 PV02

SPLIT-RANGE

1. FEED SURGE DRUM

Relief rate = maximum flow through PV01

flow through PV02

Header PV01 PV02

PIC

flow through PV02

2. LPG VAPORIZER

Relief rate =

LPG Generated by max. steam flow

normal LPG outlet flow

14

Hydraulic expansion (1/2) Hydraulic expansion (1/2)

Cause

Liquid is blocked in and later heated up (by hot fluid steam Liquid is blocked-in and later heated up (by hot fluid, steam

tracing / jacket or by solar radiation).

Effects

Liquid expands upon heating, leading to pressure build-up in

vessel or blocked in section of piping/pipeline.

15

Hydraulic expansion (1/2) Hydraulic expansion (1/2)

Calculation

Refer calculation sheet for relief rate calculation

If applicable (e.g. in

cooling circuit) consider cooling circuit), consider

administrative control in

place of relief valve.

16

Heat Exchanger Tube Rupture (1/3) Heat Exchanger Tube Rupture (1/3)

Cause

Tube rupture in shell & tube heat exchanger exposing lower Tube rupture in shell & tube heat exchanger, exposing lower

pressure side to high pressure fluid.

Effects Effects

Lower pressure side is exposed to high pressure fluid

Note : No need to consider if design pressure of lower pressure g p p

side is 10/13 or more of design pressure of high pressure side.

Calculation

Use orifice equation with

double cross-sectional area.

17

Heat Exchanger Tube Rupture (2/3) Heat Exchanger Tube Rupture (2/3)

18

Heat Exchanger Tube Rupture (3/3) Heat Exchanger Tube Rupture (3/3)

19

Total Power Failure (1/5) Total Power Failure (1/5)

Cause

Di i i l l di l i l f il f h Disruption in power supply, leading to electrical power failure of the

whole site.

Effects

- Loss of operation for pumps, air-cooled heat exchangers, all electrically-

driven equipments

- For Fractionating Column worst case design, assume steam system

continues to operate

Calculation

For Fractionation Column : Enthalpy Balance Method

Note

Usually controlling case for flare capacity

20

Total Power Failure (2/5) Total Power Failure (2/5)

Enthalpy balance around Fractionator Column to find

excess heat (Q), which would cause vapor generation.

Q

C

FEED

DISTILLATE

H

F

H

D

F

D

Q

R

BOTTOMS

H

B

B

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

Note : All values are taken from relieving condition

21

Total Power Failure (3/5) Total Power Failure (3/5)

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

All t l f f d di till t d b tt All pumps stop loss of feed, distillate and bottoms

Condenser Duty (Q

C

)

1. Water-cooled (Q

C

= 0)

2 Air-cooled 2. Air-cooled

May consider credit

for natural draft effects

(20 30% of normal duty) (20-30% of normal duty)

22

Total Power Failure (4/5) Total Power Failure (4/5)

Reboiler Duty (Q

R

)

1. Thermosyphon using steam

(Q = Normal Duty)

2. Fired Heater

No flow to fired heater, but consider the

possibility that remaining fluid inside tube is

(Q

R

= Normal Duty)

p y g

heated up by heat from refractory surfaces

(Q

R

= 30% of normal duty)

Steam

High Integrity Pressure Protection System (HIPPS)

2. Fired Heater

Heat from refractory surfaces

1. Thermosyphon using steam

(Q

R

= 0)

(Q

R

= 30% of normal duty)

(

R

)

FUEL

23

Total Power Failure (5/5) Total Power Failure (5/5)

Relief load = V

Vapor cannot be condensed

(loss of condenser duty)

Relief Load = Vapor generated by excess heat

= Excess Heat (Q)

Latent Heat of Vaporization of 2

nd

tray liquid

Vapor generated (V)

Latent Heat of Vaporization of 2 tray liquid

Excess Heat (Q)

24

Partial Power Failure (1/3) Partial Power Failure (1/3)

Cause

Disruption in a single feeder, bus, circuit or line, leading to partial power

failure

Effects

- Varies, pending on power distribution system

- For Fractionating Column, worst case considered for Partial Power

Failure is simultaneous loss of reflux pump and air-cooled condenser,

while there is continuous heat input into column while there is continuous heat input into column.

Calculation

For Fractionating Column : Enthalpy Balance Method g py

Internal Reflux Method (alternative)

Note

Usually controlling case for column PSV sizing Usually controlling case for column PSV sizing

25

Partial Power Failure (2/3) Partial Power Failure (2/3)

Worst case : simultaneous loss of reflux pump and air-

cooled condenser

Q

C

FEED

DISTILLATE

H

F

H

D

F

D

Q

R

BOTTOMS

H

B

B

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

26

Partial Power Failure (3/3) Partial Power Failure (3/3)

Temp (T

H

)

Latent Heat of Vaporization (

H

)

Mass Flow (m

H

) (

H

)

Reflux

Specific heat (C

p,R

)

Mass flow (m

R

) , Temp (T

R

)

Internal Reflux

Mass flow (m

IR

)

Alternative : Internal reflux method

Relief load = m

H

+ m

IR

m

R

C

p,R

(T

R

-T

H

) + m

IR

H

= 0

m

m C (T -T )

Relief load m

H

m

IR

m

IR =

m

R

C

p,R

(T

H

-T

R

)

H

27

Cooling Water Failure (1/3) Cooling Water Failure (1/3)

Cause

Cooling Water Pump failure loss of make up water etc Cooling Water Pump failure, loss of make-up water, etc.

Effects

Loss of duty for water cooled heat exchangers - Loss of duty for water-cooled heat exchangers

- Operation of pumps that require cooling water for lube oil cooling may

also be effected

Calculation Calculation

For Fractionating Column : Enthalpy Balance Method

Internal Reflux Method (Alternative)

28

Cooling Water Failure (2/3) Cooling Water Failure (2/3)

Q

C

H

F

H

D

FEED

DISTILLATE

F

D

Q

BOTTOMS

H

B

B

Q

R

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

Note : Need to recalculate D and H

D

Alternative : Internal Reflux Method (refer Partial Power Failure case (

with re-calculated reflux temp, flowrate and specific heat)

29

Cooling Water Failure (3/3) Cooling Water Failure (3/3)

Temp (T

H

)

Latent Heat of Vaporization (

H

)

Mass Flow (m

H

) (

H

)

m

R

C

p,R

(T

R

-T

H

) + m

IR

H

= 0

m

IR =

m

R

C

p R

(T

H

-T

R

)

Alternative : Internal reflux method

Reflux

Specific heat (C

p,R

)

Mass flow (m

R

) , Temp (T

R

)

IR R p,R

(

H R

)

H

Internal Reflux

Mass flow (m

IR

)

1. Find internal reflux without considering cooling

water failure (m

IR,normal

)

2. Recalculate reflux flowrate, temperature and

specific heat for cooling water failure case

3. Find internal reflux considering cooling water

failure (m

IR,CWFail

)

4 Relief load = overhead vapor normal +

30

4. Relief load overhead vapor_normal +

(m

IR,normal

- m

IR,CWFail

)

Reflux Loss(1/2) Reflux Loss(1/2)

Cause

Failure of reflux pumps Failure of reflux pumps

Effects

Loss of reflux to column - Loss of reflux to column

- Liquid level in overhead receiver rises, ultimately flooding the condenser,

causing loss of condensing duty

Calculation Calculation

For Fractionating Column : Enthalpy Balance Method

Alternative : Internal Reflux Method

31

Reflux Loss (2/2) Reflux Loss (2/2)

Q

H

Q

C

FEED

H

F

F

H

D

D

DISTILLATE

H

B

B

BOTTOMS

Q

R

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

B

BOTTOMS

Alternative : Internal Reflux Method (refer Partial Power Failure case)

32

Failure of air-cooled heat exchanger (1/2) Failure of air cooled heat exchanger (1/2)

Cause

l f d d l l d h h Failure of individual air-cooled heat exchanger

Effects

- Loss of condensing duty in fractionating column

Calculation

For Fractionating Column : Enthalpy Balance Method

Internal Reflux Method (Alternative)

33

Failure of air-cooled heat exchanger (2/2) Failure of air cooled heat exchanger (2/2)

Q

C

H

H

Q

C

FEED

DISTILLATE

H

F

F

H

D

D

BOTTOMS

H

B

B

Q

R

Excess Heat (Q) = H

F

F H

D

D H

B

B Q

C

+ Q

R

B

Note : Need to recalculate D and H

D

Alternative : Internal Reflux Method (refer cooling water failure case)

34

THANK YOU

February 3, 2014

35

Vous aimerez peut-être aussi

- Anchor Bolt Embedment DesignDocument128 pagesAnchor Bolt Embedment Designminhphuongpham100% (1)

- PSV Sizing - API-520 PDFDocument8 pagesPSV Sizing - API-520 PDFAnonymous da6X60VpII100% (1)

- PSV Sizing CalculationsDocument53 pagesPSV Sizing CalculationsAMITH OK93% (28)

- Relief Valve Calculations - According With API 520Document4 pagesRelief Valve Calculations - According With API 520ionutlaur86100% (2)

- PSV Sizing For Two Phase FlowDocument28 pagesPSV Sizing For Two Phase FlowSyed Haideri100% (1)

- PSV SizingDocument6 pagesPSV SizingBui Khoi Nguyen100% (1)

- Heat Transfer CalculationsDocument729 pagesHeat Transfer Calculationskikin_i6364100% (1)

- Depressurization Case StudyDocument21 pagesDepressurization Case StudyOke Adesina GaniyuPas encore d'évaluation

- Sizing and Selection Procedure of Pressure Relieving Devices - R0Document47 pagesSizing and Selection Procedure of Pressure Relieving Devices - R0balajikrishnan100% (1)

- Control Valve DPDocument8 pagesControl Valve DPAmit SawantPas encore d'évaluation

- Corbel DesignDocument3 pagesCorbel DesignManoj JaiswalPas encore d'évaluation

- 7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDocument65 pages7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDucViking100% (1)

- Blowdown Calculation Final Rev B1 PDFDocument23 pagesBlowdown Calculation Final Rev B1 PDFAwwalin Bocah Ilang100% (1)

- Water Side Corrosion and Boiler Feedwater IssuesDocument72 pagesWater Side Corrosion and Boiler Feedwater IssuesSyavash EnshaPas encore d'évaluation

- Deep Water Drilling Fluid Design ExampleDocument65 pagesDeep Water Drilling Fluid Design Examplecrown212Pas encore d'évaluation

- Estimate Settle-Out Pressure and Temperature in Compressor LoopDocument3 pagesEstimate Settle-Out Pressure and Temperature in Compressor LoopFahad Maqsood100% (1)

- PRV Sizing For Exchanger Tube RuptureDocument5 pagesPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- Line Sizing GuidelinesDocument32 pagesLine Sizing Guidelinesyunjun12100% (2)

- PSV Sizing - Two Phase (Two-Points)Document2 pagesPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradPas encore d'évaluation

- Relief Valve Sizing for ColumnsDocument10 pagesRelief Valve Sizing for ColumnsbalajikrishnanPas encore d'évaluation

- Two Phase Relief SizingDocument9 pagesTwo Phase Relief Sizingashirwad shetty75% (4)

- Cooling Towers Design Feb12 - CHENG PDFDocument6 pagesCooling Towers Design Feb12 - CHENG PDFisosicaPas encore d'évaluation

- Overpressure Scenarios Overview - FinalDocument52 pagesOverpressure Scenarios Overview - FinalRajiv Natkar100% (4)

- Rigorously Size Relief Valves For Critical FluidsDocument10 pagesRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Steam Flow Through Safety Valve Vent PipesDocument11 pagesSteam Flow Through Safety Valve Vent PipesminhphuongphamPas encore d'évaluation

- Depressuriation Using HysisDocument30 pagesDepressuriation Using HysisArunvpm100% (5)

- API-521 Flare KOD Design and Even More - Part 2.desbloqueadoDocument6 pagesAPI-521 Flare KOD Design and Even More - Part 2.desbloqueadoFernando Mendez100% (1)

- Calculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP MethodDocument3 pagesCalculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Methodrohitkush80% (5)

- Flare SystemDocument60 pagesFlare Systemmmairaja100% (1)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsD'EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsÉvaluation : 3.5 sur 5 étoiles3.5/5 (14)

- DespresurizaciónDocument3 pagesDespresurizaciónmatrix69Pas encore d'évaluation

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentD'EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentPas encore d'évaluation

- PSV Calculations FlareDocument0 pagePSV Calculations FlareSrinivas BobbyPas encore d'évaluation

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshPas encore d'évaluation

- Supercritical Fluids PSV SizingDocument5 pagesSupercritical Fluids PSV SizingVikram Singh100% (5)

- Depressurisation - A Practical GuideDocument20 pagesDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- API520 RVsizingDocument7 pagesAPI520 RVsizingdemem09100% (3)

- Gas Line SizingDocument11 pagesGas Line SizingEbby OnyekwePas encore d'évaluation

- Absorption Chillers 07Document52 pagesAbsorption Chillers 07Sujadi Cherbond100% (1)

- M&E RequirementDocument11 pagesM&E Requirementmunim87100% (1)

- B 912-02 Passivation of Stainless Steels Using ElectropolishingDocument4 pagesB 912-02 Passivation of Stainless Steels Using ElectropolishingminhphuongphamPas encore d'évaluation

- Liquid Line SizingDocument6 pagesLiquid Line SizingManoj KumarPas encore d'évaluation

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocument4 pagesUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1Pas encore d'évaluation

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenPas encore d'évaluation

- Tank relief designDocument12 pagesTank relief designsachinumaryePas encore d'évaluation

- 1st Law of Thermo WorksheetDocument2 pages1st Law of Thermo WorksheetAngelica Calamba CalicaPas encore d'évaluation

- Natural Gas Processing from Midstream to DownstreamD'EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirPas encore d'évaluation

- Fill Depressuring HEAT FLUX CorrelationDocument13 pagesFill Depressuring HEAT FLUX CorrelationYan Laksana100% (1)

- PSV Thermal SizingDocument16 pagesPSV Thermal Sizingahmad santoso0% (1)

- Blocked Outlet (Liquid)Document30 pagesBlocked Outlet (Liquid)Jagan BosePas encore d'évaluation

- Depressuring Study and Application On BP-A ProjectDocument35 pagesDepressuring Study and Application On BP-A ProjectTruong Minh Hoang100% (6)

- GPSA SeparationDocument18 pagesGPSA SeparationEslamShebl100% (1)

- Master's thesis verifies PSV sizing for Alvheim gas process equipmentDocument94 pagesMaster's thesis verifies PSV sizing for Alvheim gas process equipmentMiquel Àngel Artiol FerroPas encore d'évaluation

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing Calculationphavlo3Pas encore d'évaluation

- Rupture Disc SizingDocument8 pagesRupture Disc Sizing이가람100% (1)

- Optimization and Design of Dehydration Unit and NGL ProcessDocument51 pagesOptimization and Design of Dehydration Unit and NGL ProcessHoracio RodriguezPas encore d'évaluation

- Pressure Safety Valves: Selection, Sizing & Design in 40 CharactersDocument19 pagesPressure Safety Valves: Selection, Sizing & Design in 40 CharactersAbdulAbdulPas encore d'évaluation

- Tank Relief PhilosophyDocument8 pagesTank Relief Philosophyking4lifePas encore d'évaluation

- Comparison of General Ventilation Air Filter Test Standards Between America and EuropeDocument8 pagesComparison of General Ventilation Air Filter Test Standards Between America and EuropeminhphuongphamPas encore d'évaluation

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaPas encore d'évaluation

- Ambient Crude Oil StorageDocument13 pagesAmbient Crude Oil StoragesachinumaryePas encore d'évaluation

- L4-Superconductivity Lecture NotesDocument34 pagesL4-Superconductivity Lecture NoteswellplacedcommaPas encore d'évaluation

- Valve SizingDocument38 pagesValve SizingEmmanuel JohnsonPas encore d'évaluation

- Handbook Milk Powder Manufacture PDFDocument265 pagesHandbook Milk Powder Manufacture PDFWaqar Hassan100% (9)

- Aad PrasadestaDocument244 pagesAad PrasadestaIlyas Rangga Ramadhan100% (1)

- S9 - End-Of-Unit 8 TestDocument2 pagesS9 - End-Of-Unit 8 TestShahana Ahth100% (2)

- Blowdown Calc FormulaeDocument1 pageBlowdown Calc FormulaeWayne MonneryPas encore d'évaluation

- PSV Scenario and CalculationDocument35 pagesPSV Scenario and CalculationBaba Johneh0% (1)

- Hot Crude Oil StorageDocument13 pagesHot Crude Oil Storagesachinumarye100% (1)

- Calculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006Document3 pagesCalculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006bogusiPas encore d'évaluation

- Acids HandlingDocument8 pagesAcids Handlingminhphuongpham0% (1)

- Pump selection and head calculation exampleDocument37 pagesPump selection and head calculation exampleIhsan Wiratama100% (1)

- Gas Pipeline Blowdown TimeDocument3 pagesGas Pipeline Blowdown Timeankur2061Pas encore d'évaluation

- Measure Minor Losses in Pipe FittingsDocument26 pagesMeasure Minor Losses in Pipe Fittingsdainer08Pas encore d'évaluation

- Losses in Bends FittingsDocument26 pagesLosses in Bends FittingsKunalPas encore d'évaluation

- A Basic Design Guideline For Mechanical Engineering SystemsDocument10 pagesA Basic Design Guideline For Mechanical Engineering SystemsmdazmizakiPas encore d'évaluation

- Chemical Engineering World - January 2015Document110 pagesChemical Engineering World - January 2015minhphuongpham100% (1)

- NASA Report On Explosion Accidents in The ASU 1970Document125 pagesNASA Report On Explosion Accidents in The ASU 1970minhphuongphamPas encore d'évaluation

- Misc GP Response To Public Comments - FinalDocument38 pagesMisc GP Response To Public Comments - FinalminhphuongphamPas encore d'évaluation

- Training Valves FAINAL 2013 AugustDocument6 pagesTraining Valves FAINAL 2013 Augustwidada007Pas encore d'évaluation

- NPSH MarginDocument32 pagesNPSH MarginminhphuongphamPas encore d'évaluation

- Training Valves FAINAL 2013 AugustDocument6 pagesTraining Valves FAINAL 2013 Augustwidada007Pas encore d'évaluation

- Choked FlowDocument4 pagesChoked Flowroberto_man5003Pas encore d'évaluation

- G L MultiPhase DELP Cal FinalDocument8 pagesG L MultiPhase DELP Cal FinalminhphuongphamPas encore d'évaluation

- Control of Erosion CorrosionDocument2 pagesControl of Erosion CorrosionminhphuongphamPas encore d'évaluation

- Ductile Brittle Transition Temp For SA-53 & SA-106Document29 pagesDuctile Brittle Transition Temp For SA-53 & SA-106minhphuongphamPas encore d'évaluation

- SinglePhase Linesizing DELP FINALDocument10 pagesSinglePhase Linesizing DELP FINALminhphuongphamPas encore d'évaluation

- ASME-Imp 1998 Thermo WellDocument6 pagesASME-Imp 1998 Thermo WellminhphuongphamPas encore d'évaluation

- ASME 2011 Complimentary Salary Report v-VIDocument1 pageASME 2011 Complimentary Salary Report v-VIminhphuongphamPas encore d'évaluation

- US Army Corp Piping - c-4Document20 pagesUS Army Corp Piping - c-4minhphuongphamPas encore d'évaluation

- Blast and Eplosion Effects On Fixed and Portable Structures - Raymond BennettDocument66 pagesBlast and Eplosion Effects On Fixed and Portable Structures - Raymond BennettminhphuongphamPas encore d'évaluation

- Equipment Over Pressure ProtectionDocument8 pagesEquipment Over Pressure ProtectionminhphuongphamPas encore d'évaluation

- Materials Chemistry C: Journal ofDocument7 pagesMaterials Chemistry C: Journal ofMohon MaapPas encore d'évaluation

- Envirotemp 200Document2 pagesEnvirotemp 200Zoar Damaris PadronPas encore d'évaluation

- PhysioEx 9.1 Exercise 1 Act 4Document4 pagesPhysioEx 9.1 Exercise 1 Act 4Juan AlemánPas encore d'évaluation

- Styrene Acrylic FTIRDocument9 pagesStyrene Acrylic FTIRDesi Rahma PrihandiniPas encore d'évaluation

- Chemistry ks4 Lesson CHM Y11 U1 l10Document19 pagesChemistry ks4 Lesson CHM Y11 U1 l10Sri WahyuningsihPas encore d'évaluation

- A2 CHM 07 Solubility NotesDocument8 pagesA2 CHM 07 Solubility NotesZim Ahmed ZavianPas encore d'évaluation

- Characteristic Reactions of Organic HalidesDocument6 pagesCharacteristic Reactions of Organic HalidesJules Patrick JacobPas encore d'évaluation

- L:3 T:1 P:0 Credit:4: MEC 216 Thermal EngineeringDocument91 pagesL:3 T:1 P:0 Credit:4: MEC 216 Thermal EngineeringAmit aroraPas encore d'évaluation

- Computational Fluid Dynamic and Thermal Analysis of Lithium-IonDocument10 pagesComputational Fluid Dynamic and Thermal Analysis of Lithium-IonAntonio BatataPas encore d'évaluation

- Understanding Gas Laws with Kinetic Molecular Theory SimulationsDocument5 pagesUnderstanding Gas Laws with Kinetic Molecular Theory SimulationsAdam CrabbPas encore d'évaluation

- Evaporative Cooler - Wikipedia, The Free EncyclopediaDocument11 pagesEvaporative Cooler - Wikipedia, The Free Encyclopediabzkizo_sbbPas encore d'évaluation

- Carbon Air FiltersDocument6 pagesCarbon Air Filtersmister_no34Pas encore d'évaluation

- Kim ReformerDocument2 pagesKim ReformeralejandroPas encore d'évaluation

- Hidróxido de Sodio: Nombre: Ruber Torrez TupaDocument2 pagesHidróxido de Sodio: Nombre: Ruber Torrez TupaJessica FloresPas encore d'évaluation

- Corrosion Protection Properties and Interfacial Adhesion MechanismDocument20 pagesCorrosion Protection Properties and Interfacial Adhesion MechanismMaría Flores ToledoPas encore d'évaluation

- 8E-8F TestDocument11 pages8E-8F TestCatherine FishPas encore d'évaluation

- Chapter 9 Printable Handout PDFDocument15 pagesChapter 9 Printable Handout PDFRaymond LeoPas encore d'évaluation

- HATM 11 FormAdjvDocument6 pagesHATM 11 FormAdjvcristian alvezPas encore d'évaluation

- Book Chapter - Measuring Surface Tension and Free Surfce EnergyDocument13 pagesBook Chapter - Measuring Surface Tension and Free Surfce EnergyIhlas AhamedPas encore d'évaluation

- Multi-Phase Flow Measurment by Orifice MeterDocument8 pagesMulti-Phase Flow Measurment by Orifice MeterAbdeldjalil AchourPas encore d'évaluation

- 12U Chem Final June 05bDocument14 pages12U Chem Final June 05bedecePas encore d'évaluation

- Chapter 2 Light PropagationDocument70 pagesChapter 2 Light PropagationAyah TayyanPas encore d'évaluation

- Biogas: Purification of Biogas For Biomethane ProductionDocument7 pagesBiogas: Purification of Biogas For Biomethane ProductionNicolaPas encore d'évaluation