Académique Documents

Professionnel Documents

Culture Documents

Lịch Bảo Dưỡng Máy Nén Khí Quincy

Transféré par

Canh LuongtienDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lịch Bảo Dưỡng Máy Nén Khí Quincy

Transféré par

Canh LuongtienDroits d'auteur :

Formats disponibles

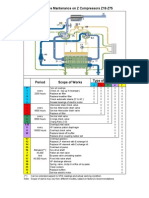

INTERVAL

Daily

(8 hours maximum)

Weekly

(40 hours)

Monthly

(160 Hours)

Every 3 months

(or 1000 Hours)

Yearly

(2000 Hours)

3103 Mike Collins Drive

Eagan, MN 55121

jhfoster.com

Providing innovative compressed air solutions since 1938

800.582.5162

651.452.8452

fax 651.681.9368

Normal Operating Temperatures

Oil inlet temperature - 140 to 170F

Air outlet temperature - 170 to 200

Rotary Screw Maintenance Schedule

ACTION

Monitor all gauges and indicators for normal operation

Check oil level

Drain control line flter

Observe for oil leaks

Observe for unusual noise or vibration

Fill out Daily Check List

Check safety valve operation

Drain any air receivers in system

Drain water out of oil

Check to make sure moisture separator is draining

Service air flter as needed (daily or weekly if extremely dirty conditions

exist)

Clean aftercooler and oil cooler fns (air-cooled only)

Wipe entire unit down to maintain appearance

Take synthetic oil sample

Change compressor oil flter

Change petroleum oil

Go over unit and check all bolts for tightness

Check full load amps

Check all pressure settings

Change oil separator every 4,000 8,000 hours with synthetic oil

Change air flter - 2,000 hours

Lubricate motors

Check safety shutdown system

Contact a Qualifed Serviceman

Additional Parameters for Filter Changes

Separator flters differential 8 psi

Oil flter differential 10 psi

Air flter 14 of water column

Vous aimerez peut-être aussi

- Zabatt Compressor MaintenanceDocument5 pagesZabatt Compressor MaintenanceMuhammad ArslaanPas encore d'évaluation

- Reciprocating Maintenance ChecklistDocument1 pageReciprocating Maintenance ChecklistEllyson IlanoPas encore d'évaluation

- Compressor ChecklistDocument5 pagesCompressor ChecklistJuanPabloAlvarezPas encore d'évaluation

- Compressor ChecklistDocument4 pagesCompressor ChecklistEber.CV100% (1)

- Compressor Daily Maintenance Check ListDocument1 pageCompressor Daily Maintenance Check ListramseyPas encore d'évaluation

- 724K John Deere MantenimientoDocument2 pages724K John Deere MantenimientoErwin Castro100% (1)

- Up Series Training Updated 2021 For PheDocument62 pagesUp Series Training Updated 2021 For PheTetenDerichardPas encore d'évaluation

- Before Starting The Engine:: CAT 3512 B and C Series MaintenanceDocument6 pagesBefore Starting The Engine:: CAT 3512 B and C Series MaintenanceAbdelghani ZitouniPas encore d'évaluation

- Doosan Xhp1170fcat t3 Bid SpecDocument7 pagesDoosan Xhp1170fcat t3 Bid Specmuhammad afiqPas encore d'évaluation

- Preventive Maintenance Manual - DRFDocument115 pagesPreventive Maintenance Manual - DRFmliugong100% (8)

- Oil Mist Training - Maintenance LevelDocument63 pagesOil Mist Training - Maintenance LevelMatthew MontgomeryPas encore d'évaluation

- SS TLS T40140-T40180 S3a-B1ct-B33g-EnDocument2 pagesSS TLS T40140-T40180 S3a-B1ct-B33g-EnAhmed El-AdawyPas encore d'évaluation

- Basic Compressor KnowledgeDocument87 pagesBasic Compressor Knowledgelrpatra100% (1)

- Emergency DG SetDocument26 pagesEmergency DG SetMiltonPas encore d'évaluation

- CVHF Presentation - Basic OperationDocument38 pagesCVHF Presentation - Basic OperationBer Salazar Jr100% (7)

- Maintenance Instruction V03Document18 pagesMaintenance Instruction V03Farooq AhmadPas encore d'évaluation

- LGCY Compressor Maintenance ScheduleDocument5 pagesLGCY Compressor Maintenance Schedulerais sultanPas encore d'évaluation

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhPas encore d'évaluation

- Air System: Cummins Training CentreDocument82 pagesAir System: Cummins Training CentreHydromech PartsPas encore d'évaluation

- Generator AuxiliariesDocument37 pagesGenerator AuxiliariesAshwani Dogra100% (1)

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezPas encore d'évaluation

- Session - 16 - Eliminator - Oil - Filter (Compatibility Mode)Document42 pagesSession - 16 - Eliminator - Oil - Filter (Compatibility Mode)agvass100% (1)

- TECHNICAL SPECIFICATIONS of of Transformer Oil Filter MachineDocument5 pagesTECHNICAL SPECIFICATIONS of of Transformer Oil Filter MachineS.KAMBAN100% (1)

- Compressor and Sealing SystemDocument40 pagesCompressor and Sealing Systemprabhjotbhangal67% (3)

- 180CW 210CW Uptime Maintenance PlannerDocument2 pages180CW 210CW Uptime Maintenance PlannerAlex Sandro dos SantosPas encore d'évaluation

- TT Oil Flooded Rotary Air CompressorDocument2 pagesTT Oil Flooded Rotary Air Compressorajo2402Pas encore d'évaluation

- MAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Document32 pagesMAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Harishbhusan PanigrahiPas encore d'évaluation

- Doosan XHP1070WCAT T1 Bid Spec (Ficha - Tecnica) PDFDocument5 pagesDoosan XHP1070WCAT T1 Bid Spec (Ficha - Tecnica) PDFJuan Carlos Callas GarayPas encore d'évaluation

- John Deere 524KDocument2 pagesJohn Deere 524KMMM-MMMPas encore d'évaluation

- Steam TurbineDocument21 pagesSteam Turbinemellow100% (1)

- PSA Oxymat Servicio de MantenimientoDocument28 pagesPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezPas encore d'évaluation

- 4b Compressor TrainingDocument22 pages4b Compressor Trainingmostafafouad19707723Pas encore d'évaluation

- Air Compressors 1170cfm T4Document2 pagesAir Compressors 1170cfm T4death666darkPas encore d'évaluation

- 310G, 310SG and 315SG: As RequiredDocument2 pages310G, 310SG and 315SG: As Requiredp0t2g047Pas encore d'évaluation

- Generator Operation PMIDocument30 pagesGenerator Operation PMIrohit_0123100% (2)

- MHI 700MW Turbine RollingDocument51 pagesMHI 700MW Turbine RollingSomnath Gupta100% (3)

- Cummins K19 Maintainence ScheduleDocument13 pagesCummins K19 Maintainence Schedulesxturbo100% (1)

- John DeereDocument2 pagesJohn DeereMMM-MMMPas encore d'évaluation

- Steps For Commissioning of Drive, Pumps andDocument13 pagesSteps For Commissioning of Drive, Pumps andSam100% (1)

- Commissioning Generators and Its Auxiliary SystemDocument90 pagesCommissioning Generators and Its Auxiliary SystemSam100% (2)

- Generator AuxiliariesDocument37 pagesGenerator AuxiliariesAshwani DograPas encore d'évaluation

- VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSG Compressor: For Natural Gas and Process Gas ApplicationsbracioPas encore d'évaluation

- Preventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsDocument1 pagePreventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsHatem AbdelrahmanPas encore d'évaluation

- EngineDocument31 pagesEngineSOUMIK DEYPas encore d'évaluation

- Rover V8 Fuel Injection SystemsDocument16 pagesRover V8 Fuel Injection SystemsClint Cooper100% (1)

- Axial Reaction Fan - Double Stage: Operation & Maintenance ManualDocument44 pagesAxial Reaction Fan - Double Stage: Operation & Maintenance ManualNidhiPas encore d'évaluation

- Service - Service Manual Code 950 - 994 - 653Document30 pagesService - Service Manual Code 950 - 994 - 653Victor UribePas encore d'évaluation

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesPas encore d'évaluation

- Procedure of Turbine Cold Startup?Document3 pagesProcedure of Turbine Cold Startup?sunil601100% (1)

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Tolias EgwPas encore d'évaluation

- 3 Data+center+generatorsDocument24 pages3 Data+center+generatorsAndré BandaziPas encore d'évaluation

- Maintenance Management AssignmentDocument19 pagesMaintenance Management AssignmentSatadeep DattaPas encore d'évaluation

- SR22 - EngineDocument14 pagesSR22 - EngineJoao AlmeidaPas encore d'évaluation

- ROCK Valve Maintenance GuidanceDocument1 pageROCK Valve Maintenance GuidanceAdhityaPahlefiPas encore d'évaluation

- TG Lube Oil FlushingDocument3 pagesTG Lube Oil FlushingS V NAGESHPas encore d'évaluation

- A) Surface Test EquipmentsDocument122 pagesA) Surface Test EquipmentsSaad TiganiPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Major Process Equipment Maintenance and RepairD'EverandMajor Process Equipment Maintenance and RepairÉvaluation : 4 sur 5 étoiles4/5 (4)

- Kimair MAM880 User Manual en V.1vDocument23 pagesKimair MAM880 User Manual en V.1vCanh LuongtienPas encore d'évaluation

- External & Internal KM Locknut Socket: 44K7 64K7 44K8 64K8 1/2" 1/2" 3/4" 3/4"Document1 pageExternal & Internal KM Locknut Socket: 44K7 64K7 44K8 64K8 1/2" 1/2" 3/4" 3/4"Canh LuongtienPas encore d'évaluation

- TG19264A (L) : Tinsharp Electronics Co - LTDDocument1 pageTG19264A (L) : Tinsharp Electronics Co - LTDCanh LuongtienPas encore d'évaluation

- Kaeser SK 26 Technical Manual PDFDocument84 pagesKaeser SK 26 Technical Manual PDFSharad Kokate67% (3)

- 도루코 200마력 소모품 견적서2015.01.21Document1 page도루코 200마력 소모품 견적서2015.01.21Canh LuongtienPas encore d'évaluation

- Kimair SI Series Instruction Manual K30SI K75SI 20190814Document36 pagesKimair SI Series Instruction Manual K30SI K75SI 20190814Canh LuongtienPas encore d'évaluation

- The Prologue One Aabb Upgrade Neville RobertsDocument6 pagesThe Prologue One Aabb Upgrade Neville RobertsCanh LuongtienPas encore d'évaluation

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002Pas encore d'évaluation

- Oil Seal and Shaft SleeveDocument6 pagesOil Seal and Shaft SleeveCanh LuongtienPas encore d'évaluation

- FAI - Trouble Shooting GuideDocument13 pagesFAI - Trouble Shooting GuideCanh LuongtienPas encore d'évaluation

- Protecting Your Airend Is Our BusinessDocument1 pageProtecting Your Airend Is Our BusinessCanh LuongtienPas encore d'évaluation

- Music and Poetry: Hifi Exclusive Integrated AmplifiersDocument3 pagesMusic and Poetry: Hifi Exclusive Integrated AmplifiersCanh LuongtienPas encore d'évaluation

- Biến tần any hz PDFDocument187 pagesBiến tần any hz PDFCanh LuongtienPas encore d'évaluation

- Biến tần any hz PDFDocument187 pagesBiến tần any hz PDFCanh LuongtienPas encore d'évaluation

- Oil Seal and Shaft SleeveDocument6 pagesOil Seal and Shaft SleeveCanh LuongtienPas encore d'évaluation

- Centrifugal Compressor HandbookDocument186 pagesCentrifugal Compressor HandbookHalil İbrahim Küplü100% (1)

- Activated Remove Oil MistDocument9 pagesActivated Remove Oil MistCanh LuongtienPas encore d'évaluation

- Donalson PDFDocument347 pagesDonalson PDFMiguel Angel Delgadillo Esquivel100% (1)

- Orion Ice Dryer&FilterDocument8 pagesOrion Ice Dryer&FilterCanh LuongtienPas encore d'évaluation

- Osp 37vanDocument20 pagesOsp 37vanJuan ManuelPas encore d'évaluation

- Sotras: Filters & Products For CompressorsDocument5 pagesSotras: Filters & Products For CompressorsCanh LuongtienPas encore d'évaluation

- Air Compressor Maintenance Log PDFDocument2 pagesAir Compressor Maintenance Log PDFCanh Luongtien100% (3)

- Air Compressor Maintenance Log PDFDocument2 pagesAir Compressor Maintenance Log PDFCanh Luongtien100% (3)

- Ffilsan Cross Ref. 2013Document78 pagesFfilsan Cross Ref. 2013Daniel ArbeláezPas encore d'évaluation

- Synthetics History Qa BrochureDocument24 pagesSynthetics History Qa BrochureCanh LuongtienPas encore d'évaluation

- An5030 PDFDocument20 pagesAn5030 PDFCanh LuongtienPas encore d'évaluation

- EB Distributor Certificate PDFDocument1 pageEB Distributor Certificate PDFCanh LuongtienPas encore d'évaluation

- MH EDM Environment en PDFDocument6 pagesMH EDM Environment en PDFCanh LuongtienPas encore d'évaluation

- 12 Basic Exercises Molly GalbraithDocument22 pages12 Basic Exercises Molly GalbraithCanh LuongtienPas encore d'évaluation