Académique Documents

Professionnel Documents

Culture Documents

Acid Pickling Process

Transféré par

rsaimahesh0 évaluation0% ont trouvé ce document utile (0 vote)

85 vues2 pagesprocess

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentprocess

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

85 vues2 pagesAcid Pickling Process

Transféré par

rsaimaheshprocess

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

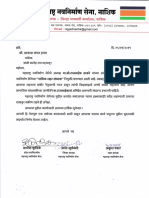

COMPONENT ENGINEERING

W201,MIDC AMBAD, NASHIK - 422010.

ACID PICKLING PROCESS

Instructions:-

Acid pickling is done for the stainless steel castings to

prevent them from rusting. The method followed is explained below:Standard Reference:- ASTM A 380.

First of all chemical cleaning is done to remove all extraneous matter, dirt, dust,

grease, oil, welding slag, loose rust, oxide scales that may be present on the S S

Castings to avoid the contamination by way of iron pick up.

Sequence of operation:- Cleaning of segments shall be carried out in the

following sequence:

a.

b.

c.

d.

Flushing with the water to remove dirt, loose rust and foreign Matter.

Degreasing

Acid cleaning

Final rinsing and drying.

Chemicals:01] Caustic potash rayon.

02] Nitric acid

03] Hydrofluoric acid confirming to ASTM or equivalent. In any case, purity should

not be less than 50%

HF by wt.

4] Water/chloride free water (chloride level 50 ppm) should be used for flushing and

rinsing operation.

Pickling operation:1.

All the SS castings required pickling should be flushed with water/chloride

free water [chloride up to 50ppm] to remove all extraneous matter, dirt and

dust etc.

2.

After flushing, degreasing shall be carried out in a Pickling bath to remove

grease, oil and organic coating if any. Degreasing solution shall be Potassium

Hydroxide of concentration 50 gm/lit[100% purity basis] Temp. of solution

during pickling shall be 50-55 deg. Cel. for a duration of about 01Hr.

After degreasing, above segments should be rinsed with above quality of

water. Rinsing should be continued till the neutral PH is obtained.

After step 3, above segments shall be pickled with acid mixture of Nitric

acid[HNO3] and Hydrofluoric acid[HF]. Composition of the pickling solution

should be20% HNO3 by vol.(on 100%purity basis)and 0.5%HF by vol.(on

100% purity basis). Pickling solution can be prepared at room temperature

and for duration of 15-30 minutes. However exact concentration of acid

mixture and duration shall depend on cleaning of the above segments based

on visual inspection.

After pickling above segments should be rinsed with water.

Finally dry all the segments by clean air.

3.

4.

5.

6.

Note :- Pickling solution can be prepared in suitable bath and cleaning of above

segments can be done by dipping or immersion method. Separate bath should

be used for each operation.

After acid pickling the inspection should be carried out & recorded in a register.

We have Acid Pickling Plastic Tank of size 5X5X6 01 no.

Mixture solution =[100 lit water+ 20 lit HNO3+5LIT HF]

Vous aimerez peut-être aussi

- 609e PDFDocument3 pages609e PDFderimanaPas encore d'évaluation

- Manual de Monitoramento de Condições LCM20 - EN PDFDocument41 pagesManual de Monitoramento de Condições LCM20 - EN PDFRafael G OliveiraPas encore d'évaluation

- Chemical Cleaning of Carbon and Stainless Steel PipingDocument3 pagesChemical Cleaning of Carbon and Stainless Steel PipingMohamed100% (1)

- Appendix G - Painting ProcedureDocument4 pagesAppendix G - Painting ProcedureKandula RajuPas encore d'évaluation

- 800D SeriesDocument3 pages800D Seriesvkeie0206Pas encore d'évaluation

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbPas encore d'évaluation

- Original: Mill Test CertificateDocument3 pagesOriginal: Mill Test CertificateAhmad NafilulhudaPas encore d'évaluation

- ChlorinationDocument7 pagesChlorinationJomer Levi PortuguezPas encore d'évaluation

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandPas encore d'évaluation

- Powder Coating TrainingDocument22 pagesPowder Coating Trainingakash.vd.1603Pas encore d'évaluation

- Astm G85Document6 pagesAstm G85Abdul MunirPas encore d'évaluation

- Aws D1.1-Tabla 8.1 - Seccion 8Document1 pageAws D1.1-Tabla 8.1 - Seccion 8cesarPas encore d'évaluation

- How To Create Pid: Yohanneti RWH Process EngineerDocument22 pagesHow To Create Pid: Yohanneti RWH Process Engineeryohanneti rwhPas encore d'évaluation

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaPas encore d'évaluation

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Esd Floor Coating Certificate Iso Goldmin Detail 1Document11 pagesEsd Floor Coating Certificate Iso Goldmin Detail 1laiju cs100% (1)

- Rust-O-Cap FC: Technical DataDocument1 pageRust-O-Cap FC: Technical DataGunjan GaganPas encore d'évaluation

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpPas encore d'évaluation

- D3230 19 PDFDocument7 pagesD3230 19 PDFalexanderPas encore d'évaluation

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraPas encore d'évaluation

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- 02 - Paint ApplicationDocument6 pages02 - Paint ApplicationChrisDanger2Pas encore d'évaluation

- Potassium PersulfateDocument2 pagesPotassium PersulfateHuyen NguyenPas encore d'évaluation

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971Pas encore d'évaluation

- Sheet Pile Wall: A Presentation OnDocument22 pagesSheet Pile Wall: A Presentation OnRajaPas encore d'évaluation

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument4 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriPas encore d'évaluation

- Hydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)Document1 pageHydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)mansih457100% (1)

- Samson Globe Control ValveDocument12 pagesSamson Globe Control ValveShishir DwivediPas encore d'évaluation

- Vinyl Ester-Glass Flake PaintDocument4 pagesVinyl Ester-Glass Flake PaintSimbu ArasanPas encore d'évaluation

- Ga 250Document16 pagesGa 250g9g9Pas encore d'évaluation

- AISI 420 Data SheetDocument2 pagesAISI 420 Data SheetVicky GautamPas encore d'évaluation

- ASTM G1 Standard PracticeDocument8 pagesASTM G1 Standard PracticeHeri SusantoPas encore d'évaluation

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobitePas encore d'évaluation

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedPas encore d'évaluation

- Asme Section Ii A-2 Sa-451 PDFDocument6 pagesAsme Section Ii A-2 Sa-451 PDFAnonymous GhPzn1xPas encore d'évaluation

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarPas encore d'évaluation

- HRSGDocument12 pagesHRSGAshwinKumar Goswami100% (1)

- Din/ Iso Astm RangeDocument2 pagesDin/ Iso Astm RangeSumitBhaumikPas encore d'évaluation

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanPas encore d'évaluation

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamPas encore d'évaluation

- Msds Degreaser Qatar GalvDocument5 pagesMsds Degreaser Qatar GalvRaj KumarPas encore d'évaluation

- Hardness, Calcium: Titration Method With Edta Method 8222 0-25,000 MG/L As Caco Buret TitrationDocument8 pagesHardness, Calcium: Titration Method With Edta Method 8222 0-25,000 MG/L As Caco Buret TitrationYanuar PaksiPas encore d'évaluation

- Procedure For Rapid Chloride Penetration Test: 1.1 Personnel, Material, and Equipment RequirementsDocument3 pagesProcedure For Rapid Chloride Penetration Test: 1.1 Personnel, Material, and Equipment RequirementsShyamPas encore d'évaluation

- Project To Estimate The New Shot Blasting & Painting Facility For New ProjectDocument24 pagesProject To Estimate The New Shot Blasting & Painting Facility For New ProjectHarshad_SPas encore d'évaluation

- AI Hempel's Galvosil 15700 EnglishDocument7 pagesAI Hempel's Galvosil 15700 EnglishvitharvanPas encore d'évaluation

- Final ESCO NB PDFDocument1 pageFinal ESCO NB PDFRio CahyantoPas encore d'évaluation

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Surfacepreparation StandardDocument11 pagesSurfacepreparation StandardAri SupramonoPas encore d'évaluation

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaPas encore d'évaluation

- Kansai Paint System Guide: Environmental CorrosivelyDocument16 pagesKansai Paint System Guide: Environmental Corrosivelyscribdfreeasus100% (1)

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتPas encore d'évaluation

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienPas encore d'évaluation

- Sequential Leaching For The Production of Alumina From A Nigerian ClayDocument7 pagesSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- Pickling and Passivation Procedure A380Document3 pagesPickling and Passivation Procedure A380Suyog Gawande100% (3)

- Pickling and Passivation ProcedureDocument4 pagesPickling and Passivation ProcedureWaqas Waqas89% (18)

- Pickling & Passivation ProcedureDocument2 pagesPickling & Passivation ProcedureSunil Kumar GoudaPas encore d'évaluation

- Chemical Testing Procedure SSDocument3 pagesChemical Testing Procedure SSpanduranganraghurama100% (1)

- 650e PDFDocument7 pages650e PDFsonchemenPas encore d'évaluation

- Produced Water Treatment Field ManualD'EverandProduced Water Treatment Field ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Operating InstructionsDocument1 pageOperating Instructionsrsaimahesh100% (1)

- Sinumerik ManualDocument214 pagesSinumerik ManualMike SteinfeltPas encore d'évaluation

- Component Engineering: Installation, Operation & Maintenance ManualDocument1 pageComponent Engineering: Installation, Operation & Maintenance ManualrsaimaheshPas encore d'évaluation

- AKASHDocument1 pageAKASHrsaimaheshPas encore d'évaluation

- 802Dsl LIS 0206 en PDFDocument222 pages802Dsl LIS 0206 en PDFrsaimaheshPas encore d'évaluation

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Sadullah TaşkınPas encore d'évaluation

- A Worm GearDocument19 pagesA Worm GearrsaimaheshPas encore d'évaluation

- Part-Turn Worm Gearboxes Gs 40Document2 pagesPart-Turn Worm Gearboxes Gs 40rsaimaheshPas encore d'évaluation

- Lean SynopsisDocument30 pagesLean SynopsisrsaimaheshPas encore d'évaluation

- LoopByte - 42535Document2 pagesLoopByte - 42535rsaimaheshPas encore d'évaluation

- 0 5nptprogramDocument2 pages0 5nptprogramrsaimaheshPas encore d'évaluation

- HyderabadDocument86 pagesHyderabadVara Prasad100% (2)

- Class 2500 Ball Valve: FeaturesDocument4 pagesClass 2500 Ball Valve: FeaturesrsaimaheshPas encore d'évaluation

- Component Engineering List of MachinesDocument1 pageComponent Engineering List of MachinesrsaimaheshPas encore d'évaluation

- Corrugated BoxesDocument3 pagesCorrugated BoxesAditya GhatgePas encore d'évaluation

- Pipe Thread Types and DesignationsDocument6 pagesPipe Thread Types and Designationsvijayn33Pas encore d'évaluation

- Smart NegotiatingDocument192 pagesSmart Negotiatingsebastian2749100% (3)

- Understanding The Indianboiler Regulations 1950Document7 pagesUnderstanding The Indianboiler Regulations 1950IPSITPas encore d'évaluation

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123Pas encore d'évaluation

- Time and India AstrologyDocument81 pagesTime and India AstrologysamaanPas encore d'évaluation

- 01 Introduction To Manufacturing and MachiningDocument10 pages01 Introduction To Manufacturing and MachiningTarun MehtaPas encore d'évaluation