Académique Documents

Professionnel Documents

Culture Documents

UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPP

Transféré par

mkchy12Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPP

Transféré par

mkchy12Droits d'auteur :

Formats disponibles

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.

:

PRESSURE SAND FILTER (PSF-DM) Prep. By : 6

Sheet 1 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

9.000

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

13.500

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 2

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 3400

8 h Height of shell mm 2500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.39468487

12 P

1 Tot.design press. Kg/cm2 9.395 p+ps

13 R Vessel inside radius mm 1700 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 13.404

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 7.671430923

16 t

m Design thk.incl.Mill Tolerance. mm 14.074

17 t

s Adopted shell thickness mm 16.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.40336974

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

20 P

2 Tot. design pressure kg/cm2 9.40336974 p+ph

21 L Inside crown radius mm 2720.000

22 r Inside knuckle radius mm 340.000

23 M Factor 1.457

24 E Joint efficiency 1.000 100% radiography Ref:Table UW 12

25 t

min Min. Required thickness mm 15.261

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 18.024

27 t

h Adopted plate thickness for Head mm 20.00

(3+L/r)/4

Ref : ASME Sec. VIII, Div. 1

Project :

Equipment:

Ref : ASME Sec. VIII, Div. 1

MT = 5%

P1*R/(2*S*E+0.4*P1)+CA

Ref : ASME Sec. VIII, Div. 1

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Max(tmin1,tmin2)+MT

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

Calculation Formula

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

CLIENT INPUT

Shell design(per ASME Sec.VIII D1,UG-27)

tmin+TA+MT

UEEPL THICKNESS CALCULATION FOR PSF FOR DM PLANT RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Ref : ASME Sec. VIII, Div. 1

100% Radiography

P1*R/(S*E-0.6*P1)+CA

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

PRESSURE SAND FILTER (PSF-POT) Prep. By : 6

Sheet 2 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

11.000

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

16.500

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 2

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 2400

8 h Height of shell mm 2500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.352130496

12 P

1 Tot.design press. Kg/cm2 11.3521305 p+ps

13 R Vessel inside radius mm 1200 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 11.735

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 6.836145893

16 t

m Design thk.incl.Mill Tolerance. mm 12.322

17 t

s Adopted shell thickness mm 14.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.358260993

20 P

2 Tot. design pressure kg/cm2 11.35826099 p+ph

21 L Inside crown radius mm 1920.000

22 r Inside knuckle radius mm 240.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 13.308

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 15.974

27 t

h Adopted plate thickness for Head mm 16.00

Equipment:

UEEPL THICKNESS CALCULATION FOR PSF FOR POTABLE SERVICE RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

Project :

Calculation Formula

CLIENT INPUT

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

MT = 5%

100% Radiography

Ref : ASME Sec. VIII, Div. 1

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Max(tmin1,tmin2)+MT

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

tmin+TA+MT

Ref : ASME Sec. VIII, Div. 1

(3+L/r)/4

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

Ref : ASME Sec. VIII, Div. 1

P1*R/(2*S*E+0.4*P1)+CA

Ref : ASME Sec. VIII, Div. 1

100% radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

Shell design(per ASME Sec.VIII D1,UG-27)

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

P1*R/(S*E-0.6*P1)+CA

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

ACTIVATED CARBON FILTER Prep. By : 6

Sheet 3 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

9.00

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

13.500

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 2

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 2800

8 h Height of shell mm 2500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.369152246

12 P

1 Tot.design press. Kg/cm2 9.369152246 p+ps

13 R Vessel inside radius mm 1400 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 11.366

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 6.65791346

16 t

m Design thk.incl.Mill Tolerance. mm 11.934

17 t

s Adopted shell thickness mm 12.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.376304492

20 P

2 Tot. design pressure kg/cm2 9.376304492 p+ph

21 L Inside crown radius mm 2240.000

22 r Inside knuckle radius mm 280.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 12.889

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 15.534

27 t

h Adopted plate thickness for Head mm 16.00

MT = 5%

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Max(tmin1,tmin2)+MT

Calculation Formula

100% Radiography

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

(Make-up Water pump shut-off

head+Max.Suction Head)x1.05

Shell design(per ASME Sec.VIII D1,UG-27)

(3+L/r)/4

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

tmin+TA+MT

Ref : ASME Sec. VIII, Div. 1

100% Radiography

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

Ref : ASME Sec. VIII, Div. 1

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

Ref : ASME Sec. VIII, Div. 1

UEEPL THICKNESS CALCULATION FOR ACF FOR DM PLANT RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Project :

Equipment:

Ref : ASME Sec. VIII, Div. 1

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

STRONG ACID CATION Prep. By : 6

Sheet 4 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

9.00

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

13.500

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 0

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 2800

8 h Height of shell mm 4000

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.519152246

12 P

1 Tot.design press. Kg/cm2 9.519152246 p+ps

13 R Vessel inside radius mm 1400 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 9.516

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 4.73238576

16 t

m Design thk.incl.Mill Tolerance. mm 9.992

17 t

s Adopted shell thickness mm 10.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.526304492

20 P

2 Tot. design pressure kg/cm2 9.526304492 p+ph

21 L Inside crown radius mm 2240.000

22 r Inside knuckle radius mm 280.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 11.064

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 13.617

27 t

h Adopted plate thickness for Head mm 14.00

(Make-up Water pump shut-off

head+Max.Suction Head)x1.05

Nil. 4.5 mm. Thk Rubber Lined

UEEPL THICKNESS CALCULATION FOR SAC FOR DM PLANT RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

Project :

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Max(tmin1,tmin2)+MT

tmin+TA+MT

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

Ref : ASME Sec. VIII, Div. 1

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

(3+L/r)/4

Ref : ASME Sec. VIII, Div. 1

100% Radiography

Ref : ASME Sec. VIII, Div. 1

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

Equipment:

MT = 5%

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Shell design(per ASME Sec.VIII D1,UG-27)

Calculation Formula

100% Radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

Ref : ASME Sec. VIII, Div. 1

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

STRONG BASE ANION Prep. By : 6

Sheet 5 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

6.50

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

9.750

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 0

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 2600

8 h Height of shell mm 4800

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.590641371

12 P

1 Tot.design press. Kg/cm2 7.090641371 p+ps

13 R Vessel inside radius mm 1300 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 6.575

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 3.274406079

16 t

m Design thk.incl.Mill Tolerance. mm 6.904

17 t

s Adopted shell thickness mm 8.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.597282742

20 P

2 Tot. design pressure kg/cm2 7.097282742 p+ph

21 L Inside crown radius mm 2080.000

22 r Inside knuckle radius mm 260.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 7.653

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 10.0

27 t

h Adopted plate thickness for Head mm 10.00

Project :

Equipment:

UEEPL THICKNESS CALCULATION FOR SBA FOR DM PLANT RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

Calculation Formula

Shell design(per ASME Sec.VIII D1,UG-27)

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

(Degassed Water pump shut-off

head+Max.Suction Head)x1.05

Ref : ASME Sec. VIII, Div. 1

Nil. 4.5 mm. Thk Rubber Lined

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

tmin+TA+MT

(3+L/r)/4

Ref : ASME Sec. VIII, Div. 1

1.5 times design pressure

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

MT = 5%

Ref : ASME Sec. VIII, Div. 1

100% Radiography

Ref : ASME Sec. VIII, Div. 1

100% Radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

Max(tmin1,tmin2)+MT

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

MIXED BED EXCHANGER Prep. By : 6

Sheet 6 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

6.50

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

9.750

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 0

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 1800

8 h Height of shell mm 2500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.326597872

12 P

1 Tot.design press. Kg/cm2 6.826597872 p+ps

13 R Vessel inside radius mm 900 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 4.382

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 2.182563007

16 t

m Design thk.incl.Mill Tolerance. mm 4.601

17 t

s Adopted shell thickness mm 6.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.331195745

20 P

2 Tot. design pressure kg/cm2 6.831195745 p+ph

21 L Inside crown radius mm 1440.000

22 r Inside knuckle radius mm 180.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 5.099

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 7.354

27 t

h Adopted plate thickness for Head mm 8.00

Calculation Formula

(Degassed Water pump shut-off

head+Max.Suction Head)x1.05

1.5 times design pressure

Nil. 4.5 mm. Thk Rubber Lined

Equipment:

UEEPL THICKNESS CALCULATION FOR MB FOR DM PLANT RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

Project :

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Shell design(per ASME Sec.VIII D1,UG-27)

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

Max(tmin1,tmin2)+MT

MT = 5%

Ref : ASME Sec. VIII, Div. 1

100% Radiography

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

tmin+TA+MT

Ref : ASME Sec. VIII, Div. 1

(3+L/r)/4

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

Ref : ASME Sec. VIII, Div. 1

Ref : ASME Sec. VIII, Div. 1

100% Radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

HOT WATER TANK FOR ALKALI DILUTION Prep. By : 6

Sheet 7 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

6.50

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

9.750

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 0

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 2400

8 h Height of shell mm 3500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.452130496

12 P

1 Tot.design press. Kg/cm2 6.952130496 p+ps

13 R Vessel inside radius mm 1200 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 5.951

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 2.963543964

16 t

m Design thk.incl.Mill Tolerance. mm 6.248

17 t

s Adopted shell thickness mm 8.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.458260993

20 P

2 Tot. design pressure kg/cm2 6.958260993 p+ph

21 L Inside crown radius mm 1920.000

22 r Inside knuckle radius mm 240.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 6.925

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 9.272

27 t

h Adopted plate thickness for Head mm 10.00

Project :

Equipment:

THICKNESS CALCULATION FOR HOT WATER TANK FOR DM RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Ref : ASME Sec. VIII, Div. 1

UEEPL

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

tmin+TA+MT

(3+L/r)/4

(Degassed Water pump shut-off

head+Max.Suction Head)x1.05

Ref : ASME Sec. VIII, Div. 1

Calculation Formula

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

Nil. 4.5 mm. Thk Rubber Lined

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

Max(tmin1,tmin2)+MT

Shell design(per ASME Sec.VIII D1,UG-27)

MT = 5%

Ref : ASME Sec. VIII, Div. 1

100% Radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

Ref : ASME Sec. VIII, Div. 1

100% Radiography

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

ROSA THERMAL POWER PROJECT Doc. No. : Rev. No.:

AIR RECEIVING VESSEL Prep. By : 6

Sheet 8 OF 8

Shell/Torispherical head thickness calculation

Sl.No. Symbol Description Unit Input Data Results

1 p Design pres. Kg/cm

2

10.00

2 T Design temp. deg.C 60

3 p

HYD Hydrotest pres. Kg/cm

2

15.000

4 sg Op.fluid s.g. 1.00

5 CA Corrosion Allowance mm 2

6 TA Thinning Allowance mm 2

7 d Vessel inside dia. mm 1600

8 h Height of shell mm 2500

9 MT Milling Tolerance % 5

MOC SA 516 GR.70

9 S Allow. stress Kg/cm

2

1406.14

10 E Jt.efficiency 1.000 Ref: Table UW 12

11 p

s St.head press. Kg/cm2 0.318086998

12 P

1 Tot.design press. Kg/cm2 10.318087 p+ps

13 R Vessel inside radius mm 800 d/2

14

t

min1

Min.Required thickness(Longitudinal Joints)

mm 7.896

15

t

min2

Min.Required thickness(Circumferential Joints)

mm 4.930850871

16 t

m Design thk.incl.Mill Tolerance. mm 8.291

17 t

s Adopted shell thickness mm 10.00

MOC SA 516 GR.70

18 S Allow. Stress kg/cm2 1406.14

19 p

h St. head press. kg/cm2 0.322173995

20 P

2 Tot. design pressure kg/cm2 10.322174 p+ph

21 L Inside crown radius mm 1280.000

22 r Inside knuckle radius mm 160.000

23 M Factor 1.457

24 E Joint efficiency 1.000 Ref: Table UW 12

25 t

min Min. Required thickness mm 8.851

26 t

m Design thk.incl.Thinning allow. & Mill tol. mm 11.293

27 t

h Adopted plate thickness for Head mm 12.00

Shell design(per ASME Sec.VIII D1,UG-27)

MT = 5%

(Degassed Water pump shut-off

head+Max.Suction Head)x1.05

Ref : ASME Sec. VIII, Div. 1

Calculation Formula

1.5 times design pressure

TA = 15% of min. reqd. Head thk or 2 mm.(Min.)

Torispherical Head design(per ASME Sec.VIII D1,Appendix-I)

Nil. 4.5 mm. Thk Rubber Lined

[h+L-{(L-r)

2

-(d/2-r)

2

}]sg/10000

Project :

Equipment:

THICKNESS CALCULATION FOR ARV FOR DM RPSCL: 2 X 300 MW ROSA TPP, Shajahanpur

DOCUMENT NO. UEEPL-RTPP-NVM-119-R-7004

Ref : ASME Sec. VIII, Div. 1

UEEPL

P

2

*L*M/(2*S*E-0.2*P

2

)+CA

tmin+TA+MT

(3+L/r)/4

Ref : ASME Sec. VIII, Div. 1

100% Radiography

[h+2(L-{(L-r)

2

-(d/2-r)

2

})]sg/10000

Ref : ASME Sec. VIII, Div. 1

100% Radiography

P1*R/(S*E-0.6*P1)+CA

P1*R/(2*S*E+0.4*P1)+CA

Max(tmin1,tmin2)+MT

Vous aimerez peut-être aussi

- Rectangular Vessel Stress CalculationDocument2 pagesRectangular Vessel Stress Calculationpastyl100% (1)

- Plumbing CalculationDocument12 pagesPlumbing Calculationmkchy12100% (9)

- CalculationDocument15 pagesCalculationTohid Karimi67% (3)

- ASME Pressure Vessel Design-ADocument190 pagesASME Pressure Vessel Design-AWidyAdityaPas encore d'évaluation

- Developmental AssessmentDocument15 pagesDevelopmental AssessmentShailesh MehtaPas encore d'évaluation

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datPas encore d'évaluation

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Pump Foundation DesignDocument18 pagesPump Foundation DesignSourav92% (12)

- External Pressure DesignDocument395 pagesExternal Pressure DesignrsubramaniPas encore d'évaluation

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Arlington Value's 2013 LetterDocument7 pagesArlington Value's 2013 LetterValueWalk100% (7)

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Schematic For Potable Water SystemDocument17 pagesSchematic For Potable Water Systemmkchy12Pas encore d'évaluation

- Schematic For Potable Water SystemDocument17 pagesSchematic For Potable Water Systemmkchy12Pas encore d'évaluation

- Schematic For Potable Water SystemDocument17 pagesSchematic For Potable Water Systemmkchy12Pas encore d'évaluation

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123Pas encore d'évaluation

- Design of Pressure Vessel NewDocument200 pagesDesign of Pressure Vessel NewneelPas encore d'évaluation

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanPas encore d'évaluation

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindePas encore d'évaluation

- ASME Air Tank DesignDocument2 pagesASME Air Tank Designchethan100% (1)

- Calculation - ASME VIII Div.1Document10 pagesCalculation - ASME VIII Div.1bargez100% (1)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Asme Sec. Viii Div-1) : Shell Plate (Disk) ConversionDocument33 pagesAsme Sec. Viii Div-1) : Shell Plate (Disk) ConversionuzairmetallurgistPas encore d'évaluation

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- 8KL FERMENTER DESIGN CALCULATIONSDocument3 pages8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryPas encore d'évaluation

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaPas encore d'évaluation

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelPas encore d'évaluation

- Tank design calculations sheet analysisDocument5 pagesTank design calculations sheet analysisapminshull88% (8)

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroPas encore d'évaluation

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocument12 pagesDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasPas encore d'évaluation

- ROM Laboratory v1.00Document548 pagesROM Laboratory v1.00Carlos Reaper Jaque OlivaresPas encore d'évaluation

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczPas encore d'évaluation

- Design of Pressure Vessel NewDocument442 pagesDesign of Pressure Vessel NewkhanfaqihPas encore d'évaluation

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralPas encore d'évaluation

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818Pas encore d'évaluation

- 015.B.0 - Blow Down Quench Water CalculationDocument2 pages015.B.0 - Blow Down Quench Water Calculationmkchy12Pas encore d'évaluation

- Stoichiometric Calc VisaDocument4 pagesStoichiometric Calc Visamkchy12Pas encore d'évaluation

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatPas encore d'évaluation

- Underground Pipe THK CalDocument12 pagesUnderground Pipe THK Calmkchy12100% (3)

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadPas encore d'évaluation

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunPas encore d'évaluation

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- ASME SECTION I CALCULATION FOR TUBE WALL THICKNESSDocument9 pagesASME SECTION I CALCULATION FOR TUBE WALL THICKNESSgopaltryPas encore d'évaluation

- Valve List Rev. 0 Material of ConstructionDocument2 pagesValve List Rev. 0 Material of Constructionmkchy12Pas encore d'évaluation

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidPas encore d'évaluation

- Thermal InsulationDocument27 pagesThermal Insulationmkchy12Pas encore d'évaluation

- Internal Control QuestionnaireDocument19 pagesInternal Control QuestionnaireIchsanPas encore d'évaluation

- Calculation SPDocument87 pagesCalculation SPmkchy12Pas encore d'évaluation

- Horizontal Pressure Vessel Calculation (Eng)Document59 pagesHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasPas encore d'évaluation

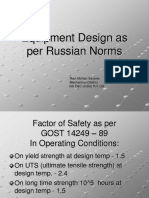

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikasPas encore d'évaluation

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaPas encore d'évaluation

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanPas encore d'évaluation

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuPas encore d'évaluation

- 105.a.0 - RO-DM Plant Chain Sizing CalcDocument7 pages105.a.0 - RO-DM Plant Chain Sizing Calcmkchy12Pas encore d'évaluation

- Presentation of h2 Generation PlantDocument41 pagesPresentation of h2 Generation Plantmkchy12100% (1)

- Motor Efficiency and Power Factor TableDocument1 pageMotor Efficiency and Power Factor Tablemkchy12Pas encore d'évaluation

- ASME Div 1Document4 pagesASME Div 1Sudhanshu67Pas encore d'évaluation

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Pas encore d'évaluation

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainPas encore d'évaluation

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalPas encore d'évaluation

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaPas encore d'évaluation

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Internal CoilDocument2 pagesInternal CoilwhngomjPas encore d'évaluation

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiPas encore d'évaluation

- Class Will and TestamentDocument4 pagesClass Will and TestamentAllan Tomas33% (3)

- Doshi Ion Exchange & Chemical Ind. LTD.: Material DataDocument7 pagesDoshi Ion Exchange & Chemical Ind. LTD.: Material DataMakrand Sakpal100% (5)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoPas encore d'évaluation

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocument8 pagesPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalPas encore d'évaluation

- ASME VIII Calc - Shell - HeadsDocument4 pagesASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarPas encore d'évaluation

- Design 1Document29 pagesDesign 1Nikki RobertsPas encore d'évaluation

- Cone dimensions and calculationsDocument4 pagesCone dimensions and calculationsanil4u29100% (1)

- CIS EVA (SideWall) 6320 SDWL 01Document29 pagesCIS EVA (SideWall) 6320 SDWL 01Nasrul AdliPas encore d'évaluation

- Asme Demo 125lDocument10 pagesAsme Demo 125lUdoy Hossen KhanPas encore d'évaluation

- 2.define and Collect DataDocument26 pages2.define and Collect Datavinit testPas encore d'évaluation

- Anising and VisualisingDocument46 pagesAnising and VisualisingWajid AliPas encore d'évaluation

- 4.descriptive Measures 1Document80 pages4.descriptive Measures 1mkchy12Pas encore d'évaluation

- Annex 1 Condensate System SettingDocument2 pagesAnnex 1 Condensate System Settingmkchy12Pas encore d'évaluation

- LDO System CalculationDocument4 pagesLDO System Calculationmkchy12Pas encore d'évaluation

- 101.F.0 - CT Basin & CW ChannelDocument11 pages101.F.0 - CT Basin & CW Channelmkchy12Pas encore d'évaluation

- 1.statistics IntroductionDocument21 pages1.statistics Introductionmkchy12Pas encore d'évaluation

- Pump SelectionDocument28 pagesPump Selectionmkchy12Pas encore d'évaluation

- MSS List of Active StandardDocument2 pagesMSS List of Active Standardmkchy12Pas encore d'évaluation

- 1.00.00 Pump Shaft Input Power Calculation As Per Is-1710Document3 pages1.00.00 Pump Shaft Input Power Calculation As Per Is-1710mkchy12Pas encore d'évaluation

- 600 MW Plant Equipment DescriptionDocument2 pages600 MW Plant Equipment Descriptionmkchy12Pas encore d'évaluation

- Industrial Building PlumbingDocument11 pagesIndustrial Building Plumbingmkchy120% (1)

- Valve List Rev 0 with 53 Manual Butterfly ValvesDocument2 pagesValve List Rev 0 with 53 Manual Butterfly Valvesmkchy12Pas encore d'évaluation

- Draft SystemDocument5 pagesDraft Systemmkchy12Pas encore d'évaluation

- 115.G.0 Reinforcement CalculationDocument4 pages115.G.0 Reinforcement Calculationmkchy12Pas encore d'évaluation

- 103.a.0 Oil ConsumptionDocument1 page103.a.0 Oil Consumptionmkchy12Pas encore d'évaluation

- American Cows in Antarctica R. ByrdDocument28 pagesAmerican Cows in Antarctica R. ByrdBlaze CPas encore d'évaluation

- 05-Program Design and AnalysisDocument78 pages05-Program Design and AnalysisTarq AbdullahPas encore d'évaluation

- Research Methodology: by Asaye Gebrewold (PHD Candidate)Document17 pagesResearch Methodology: by Asaye Gebrewold (PHD Candidate)natnael hailePas encore d'évaluation

- Brochure Manuthera 242 ENDocument4 pagesBrochure Manuthera 242 ENSabau PetricaPas encore d'évaluation

- A Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoDocument12 pagesA Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoSansa LauraPas encore d'évaluation

- SPEC 2 - Module 1Document21 pagesSPEC 2 - Module 1Margie Anne ClaudPas encore d'évaluation

- Dec50103 PW2 F1004Document14 pagesDec50103 PW2 F1004Not GamingPas encore d'évaluation

- Corporate Governance Committees in India: Key Reports and RecommendationsDocument39 pagesCorporate Governance Committees in India: Key Reports and Recommendationskush mandaliaPas encore d'évaluation

- REYHER Technical Information 2010Document194 pagesREYHER Technical Information 2010andreiwlPas encore d'évaluation

- Anatomija Za Umetnike PDFDocument4 pagesAnatomija Za Umetnike PDFДанило ВујачићPas encore d'évaluation

- Frame Fit Specifications 2019 MTB Components Rev CDocument167 pagesFrame Fit Specifications 2019 MTB Components Rev Cpicko 86Pas encore d'évaluation

- 9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent CommissionersDocument10 pages9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent Commissionerscristina.llaneza02100% (1)

- The Man Who Married A Hen, Stories of A Zambian SchoolboyDocument78 pagesThe Man Who Married A Hen, Stories of A Zambian SchoolboyGerard StoutPas encore d'évaluation

- 279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered SolutionsDocument52 pages279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered Solutionsapi-251312018Pas encore d'évaluation

- BonBonB What Map ReviewsDocument396 pagesBonBonB What Map Reviewstoyi kamiPas encore d'évaluation

- Active and Passive Cooling Technologies For Thermal Management of AvionicsDocument10 pagesActive and Passive Cooling Technologies For Thermal Management of AvionicsdavidPas encore d'évaluation

- Appendix A. Second QuantizationDocument24 pagesAppendix A. Second QuantizationAgtc TandayPas encore d'évaluation

- Grand Caravan Couch BedDocument8 pagesGrand Caravan Couch BedfraniviajeraPas encore d'évaluation

- General and Local AnesthesiaDocument1 pageGeneral and Local Anesthesiaahmedhelper300Pas encore d'évaluation

- Why I Am Not A Primitivist - Jason McQuinnDocument9 pagesWhy I Am Not A Primitivist - Jason McQuinnfabio.coltroPas encore d'évaluation

- Eight Lane Vadodara Kim ExpresswayDocument11 pagesEight Lane Vadodara Kim ExpresswayUmesh SutharPas encore d'évaluation

- 06Document11 pages06junaid_ishaquePas encore d'évaluation

- The Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiDocument192 pagesThe Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiShenandoa LeãoPas encore d'évaluation

- 1814 d01 PDFDocument20 pages1814 d01 PDFteletrabbiesPas encore d'évaluation