Académique Documents

Professionnel Documents

Culture Documents

GP 04-10 22 Feb 2006

Transféré par

mailmaverick8167Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

GP 04-10 22 Feb 2006

Transféré par

mailmaverick8167Droits d'auteur :

Formats disponibles

Guidance on Practice for

Drainage Systems

GP 04-10

BP GROUP

ENGINEERING TECHNICAL PRACTICES

Document No. GP 04-10

Applicability Group

Date 22 February 2006

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 2 of 58

Foreword

This is the first issue of Engineering Technical Practice (ETP) BP GP 04-10. This Guidance on

Practice (GP) is based on parts of heritage documents from the merged BP companies as follows:

British Petroleum

RP 4-1 Drainage Systems.

Amoco

A CV-PLT-DISP-G CivilPlantDisposal SystemsGuide.

A CV-PLT-DISP-E CivilPlantDisposal SystemsEngineering Specification.

A CV-PLT-DISP-S CivilPlantDisposal SystemsConcrete Protection SS Lined

TrenchSpecification.

A CV-PLT-BGDS-C CivilPlantBelow-Grade Gravity Drainage & Sewer Systems

Construction Specification.

Arco

ES 801 Civil Design and Construction (Section 5).

Copyright 2006, BP Group. All rights reserved. The information contained in this

document is subject to the terms and conditions of the agreement or contract under which

the document was supplied to the recipients organization. None of the information

contained in this document shall be disclosed outside the recipients own organization

without the prior written permission of the Director of Engineering, BP Group, unless the

terms of such agreement or contract expressly allow.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 3 of 58

Table of Contents

Page

Foreword .............................................................................................................................................. 2

1. Scope.......................................................................................................................................... 6

2. Normative references ................................................................................................................. 6

3. Symbols and abbreviations ........................................................................................................ 7

4. Basic requirements..................................................................................................................... 8

5. Legislation and standards .......................................................................................................... 8

6. Design......................................................................................................................................... 8

6.1. General ............................................................................................................................ 8

6.2. Integration with processes .............................................................................................. 8

6.3. Waste minimisation......................................................................................................... 9

6.4. Fugitive emissions of hydrocarbon gases ...................................................................... 9

6.5. Future developments ...................................................................................................... 9

6.6. Design factors ................................................................................................................. 9

6.7. Effluents........................................................................................................................... 9

6.8. Effluent types................................................................................................................. 10

6.9. Effluent segregation ...................................................................................................... 11

6.10. Types of system............................................................................................................ 12

7. Effluent volumes....................................................................................................................... 14

7.1. Systems draining paved and/or unpaved areas........................................................... 14

7.2. Rainfall intensities ......................................................................................................... 14

7.3. Firewater volumes......................................................................................................... 15

7.4. Groundwater infiltration................................................................................................. 17

7.5. Bunded (diked) tank area flow capacity........................................................................ 17

7.6. Water discharge............................................................................................................ 17

8. Layout and configuration.......................................................................................................... 17

8.1. Layout of drainage systems.......................................................................................... 17

8.2. Process areas ............................................................................................................... 17

8.3. Offsites areas ................................................................................................................ 20

8.4. Treatment ...................................................................................................................... 22

8.5. Measurement of effluent discharge rate....................................................................... 23

9. Hydraulic design....................................................................................................................... 23

9.1. General .......................................................................................................................... 23

9.2. Gravity based drainage systems .................................................................................. 23

9.3. Closed drainage systems.............................................................................................. 26

10. Structural design of buried pipework........................................................................................ 29

10.1. Backfill ........................................................................................................................... 29

10.2. Road and rail crossings................................................................................................. 30

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 4 of 58

10.3. Loads during testing...................................................................................................... 30

10.4. Thermal expansion........................................................................................................ 30

10.5. Submerged pipes.......................................................................................................... 30

10.6. Settlement ..................................................................................................................... 31

11. Secondary containment............................................................................................................ 31

11.1. General .......................................................................................................................... 31

11.2. Exfiltration...................................................................................................................... 31

11.3. Infiltration....................................................................................................................... 31

12. Ancillary structures ................................................................................................................... 31

12.1. Manholes....................................................................................................................... 31

12.2. Gully traps ..................................................................................................................... 35

12.3. Open ditches and channels .......................................................................................... 36

12.4. Effluent collection and treatment (neutralisation) pits .................................................. 36

12.5. Pumping sumps............................................................................................................. 37

12.6. Soakaways and land drains.......................................................................................... 37

12.7. Cesspools and septic tanks .......................................................................................... 37

13. Control of fugitive gas emissions and venting of drainage systems........................................ 37

13.1. Control of fugitive gas emissions.................................................................................. 37

13.2. Design of vents for open gravity drainage systems...................................................... 38

13.3. Extraction and treatment of vented gases.................................................................... 39

14. Materials ................................................................................................................................... 39

14.1. General .......................................................................................................................... 39

14.2. Resistance to effluents.................................................................................................. 40

14.3. Strength......................................................................................................................... 40

14.4. Joints ............................................................................................................................. 40

14.5. Other.............................................................................................................................. 40

15. Construction and workmanship................................................................................................ 41

15.1. General .......................................................................................................................... 41

15.2. Construction .................................................................................................................. 41

15.3. Connections to existing sewers .................................................................................... 41

15.4. Testing........................................................................................................................... 41

15.5. Back filling ..................................................................................................................... 42

15.6. Cleaning ........................................................................................................................ 42

16. Operation and maintenance..................................................................................................... 42

16.1. General .......................................................................................................................... 42

16.2. Cleaning ........................................................................................................................ 42

16.3. Inspection...................................................................................................................... 42

16.4. Rehabilitation................................................................................................................. 43

16.5. Operational procedures (closed system only) .............................................................. 44

Bibliography ....................................................................................................................................... 58

List of Tables

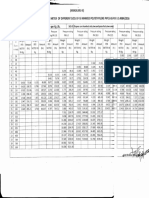

Table 1 - Advantages and disadvantages of alternative drainage systems ..................................... 46

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 5 of 58

Table 2 Material Selection .............................................................................................................. 47

List of Figures

Figure 1 - Pressurised drainage systems - typical arrangements .................................................... 49

Figure 2 - Pressurised drainage system - typical connection arrangement ..................................... 50

Figure 3 - Pressurised drainage system - typical line diagram of collection..................................... 51

Figure 4 - Pumped drainage system - typical arrangements............................................................ 52

Figure 5 - Manhole gully detail........................................................................................................... 53

Figure 6 - Typical sealed manhole covers......................................................................................... 54

Figure 7 - Typical standard 150 mm gully trap.................................................................................. 55

Figure 8 - Trapping of drain inlets to manholes................................................................................. 56

Figure 9 - Typical offsites storage tank oily and clean water drainage layout .................................. 57

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 6 of 58

1. Scope

This GP provides guidance for selection, design, and installation of open and closed drainage systems

in refineries, terminals, pipeline associated installations, chemical plants, drill sites, and jetties.

This GP does not include requirements for drainage systems on offshore platforms.

This GP does not include a comprehensive listing of legislation, regulations, codes

of practice, and standards applicable to the detailed design of drainage systems. The

designer is responsible for ensuring that the most recent version of the appropriate

codes of practice and standards relevant to the proposed location are used for the

design, construction, and testing of the systems.

2. Normative references

The following normative documents contain requirements that, through reference in this text,

constitute requirements of this technical practice. For dated references, subsequent amendments to, or

revisions of, any of these publications do not apply. However, parties to agreements based on this

technical practice are encouraged to investigate the possibility of applying the most recent editions of

the normative documents indicated below. For undated references, the latest edition of the normative

document referred to applies.

BP

GP 04-30 Guidance on Practice for Civil Engineering.

GP 24-10 Guidance on Practice for Fire Protection - Onshore.

GP 42-10 Guidance on Practice for Design of Piping Systems (ASME B31.3).

American Concrete Institute (ACI)

ACI 372R Design and Construction of Circular Wire- and Strand-Wrapped

Prestressed Concrete Structures.

ACI 373R Design and Construction of Circular Prestressed Concrete Structures with

Circumferential Tendons.

American Petroleum Institute (API)

API Spec 5L Specification for Line Pipe.

API 15LR Specification for Low Pressure Fiberglass Line Pipe and Fittings.

British Standards (BS)

BS 65 Vitrified clay pipes, fittings and ducts, also flexible mechanical joints for

use solely with surface water pipes and fittings.

BS 534 Steel pipes, joints and specials for water and sewage.

BS 1452 Piping systems for water supply.

BS 1600 Dimensions of steel pipe for the petroleum industry.

BS 2633 Class I arc welding of ferritic steel pipe work for carrying fluids.

BS 2971 Class II arc welding of carbon steel pipework for carrying fluids.

BS 3505 Unplasticised polyvinyl chloride pressure pipes for cold potable water.

BS 3506 Unplasticised PVC pipes for industrial purposes.

BS 3602 Steel pipes and tubes for pressure purposes: Carbon and carbon steel with

specified elevated temperature properties.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 7 of 58

BS 3604 Steel pipes and tubes for pressure purposes: Ferritic alloy steel with

elevated temperature properties.

BS 3605 Austenitic stainless steel pipes and tubes for pressure purposes.

BS 4515 Process of welding of steel pipelines.

BS 4622 Grey iron pipes and fittings.

BS 4660 Unplasticised PVC pipe and plastics fittings nominal sizes 110 and 160

for below ground gravity drainage and sewerage.

BS 4772 Ductile iron pipes and fittings.

BS 4870 Approval testing of welding procedures.

BS 4871 Approval testing welders working to approved welding procedures.

BS 4991 Propylene copolymer pressure pipe.

BS 5178 Prestressed concrete pipes and fittings for drainage and sewerage.

BS 5391 Acrylonitrile butadiene styrene pressure pipe: Pipe for industrial uses.

BS 5392 ABS - Fittings for use with ABS pressure pipe Part 1.

BS 5480 Glass reinforced plastics, joints and fittings for use for water supply or

sewerage.

BS 5481 Unplasticised PVC pipe and fittings for gravity sewers.

BS 5556 General requirements for dimensions and pressure rating of pipe of

thermoplastics materials.

BS 5911 Precast concrete pipes and fittings for drainage and sewerage.

BS 6437 Polyethylene pipes (type 50) in metric diameters for general purposes.

BS 6464 Reinforced plastics pipes, fittings and joints for process plant.

BS 6572 Blue polyethylene pipes up to nominal size 63 for below ground use for

potable water.

BS 6730 Black polyethylene pipes up to nominal size 63 for above ground use for

potable water.

BS 7336 Polyethylene fusion fittings with integral heating elements for use with

polyethylene pipes for the conveyance of gaseous fuels.

BS 8010 Code of practice for pipelines.

International Standards Organisation (ISO)

ISO 2531 Ductile iron pipes, fittings, and accessories for pressure.

3. Symbols and abbreviations

For the purpose of this GP, the following symbols and abbreviations apply:

ABS Acrylonitrile butadiene styrene.

d Internal pipe diameter.

EDPM Ethylene - propylene terpolymer.

GRE Glass reinforced epoxy.

GRP Glass reinforced plastics.

k

s

Surface roughness.

TEL Tetraethyl lead.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 8 of 58

TML Tetramethyl lead.

UPVC Unplasticised polyvinyl chloride.

VOC Volatile organic compound.

4. Basic requirements

a. Detailed specification of material for closed systems, if appropriate, shall be performed in

accordance with GP 42-10.

b. Drainage system shall provide safe, reliable, and economic system for collection and

transport of effluents and surface water to treatment areas and discharge points.

c. Effect of effluent beyond point of discharge with respect to quantities and quality of

effluent should be a major consideration.

d. Overall system should be kept as simple as possible in terms of construction, operation,

and maintenance. To meet this objective, open, gravity based drainage systems should be

used for wastewater effluent drainage, if legislation permits.

e. Design of plant drainage and sewer systems shall be subject to BP approval.

f. Conceptual design should/shall be agreed with BP before detailed design.

5. Legislation and standards

a. Handling and disposal of effluents and surface water drainage shall be subject to approval

of local authorities and subject to legislation within that country or state.

b. Standards relating to gaseous emissions, contaminants, and waste sludges shall be

considered together with quality and quantity of effluent discharged.

c. If constructing or upgrading drainage system, consideration should be given to compliance

with new and potential future standards.

d. If standards set by local authority, BP standards, and current legislation are different, most

stringent standard shall be adopted.

6. Design

6.1. General

a. Drainage system should be considered in very early stages of design of plant as part of

initial infrastructure development layout.

b. Drainage system should be designed in accordance with locally recognised and accepted

standards except as otherwise described below.

1. Standards shall be subject to review by BP.

2. In the UK, BS 8005 and BS 6297 are acceptable, if applicable.

6.2. Integration with processes

Consideration should be given to integration of drainage into process facilities.

If process conditions permit, this may provide financial savings.

It may be useful to incorporate the drainage system into the P&I diagram.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 9 of 58

6.3. Waste minimisation

Waste should be minimised.

a. Unnecessary mixing of water, oils, and chemicals before entering the drainage system

should be reduced.

E.g., oil slops can be collected in drums and not poured into the drains, solid wastes

can be screened, and local separators can be used.

b. Procedures should be revised and equipment should be modified so that waste is reduced.

6.4. Fugitive emissions of hydrocarbon gases

Fugitive emissions of hydrocarbon gases from conventional gravity drainage systems should be

reduced by changing work practices and methods of operation (see 13).

If required, new drain systems may be installed that can almost eradicate fugitive

emissions (see 6.10.3). These new drains are, however, expensive to install and more

complex to operate. Thus, major cost savings can be derived by avoiding discharge

of oily materials into the drainage system.

6.5. Future developments

Future use of technology to automatically monitor flow rates and effluent

composition in drainage systems may allow operations to be better regulated.

6.6. Design factors

The following technical and financial considerations should be assessed by designer in selection

and planning of drainage systems:

a. Safety of system with respect to site for which it is selected.

b. Nature and quantity of effluent to be conveyed.

c. Effluent segregation requirements.

d. Legislative/environmental/social considerations.

e. Cost:

1. Construction.

2. Operation and maintenance.

f. Design life.

g. Location of existing buildings and services (to be connected or negotiated).

h. Topography of site.

i. Method of construction and associated disruption of operations.

j. Material, jointing method, size, length, and depth of pipework.

k. Condition of existing service.

l. Secondary containment requirements.

m. Site ground conditions that may affect method and materials of construction and,

consequently, cost.

n. Ground contamination.

6.7. Effluents

a. At early stage of design, every source of effluent should be identified.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 10 of 58

The range of possible effluents may vary significantly.

b. Characteristics of materials present in system shall be assessed, including:

1. Estimated maximum and minimum rates of flow.

2. Concentration.

3. Maximum temperature (and temperature fluctuations) of effluent.

4. Potential chemical reactions.

5. Effluent pressure upon entry.

6. Details of potential future additional materials in system.

c. Every effort should be made to segregate clean and contaminated water.

If connecting to existing plant or drainage systems, effluent details may be provided

by BP. Otherwise, the process design contractor should provide this information.

6.8. Effluent types

6.8.1. General

a. Potential effluents are described in 6.8.2 through 6.8.10.

b. Descriptions are a guide, and there are no distinct boundaries between categories.

c. Exact definitions shall depend on legislation and treatment facilities available.

6.8.2. Clean water

Clean water is water that is not liable to be contaminated under normal operating conditions and

should normally be discharged from site without further treatment.

This usually originates as rainwater or in some cases as emergency fire cooling

water.

6.8.3. Contaminated water

Contaminated water is water from areas liable to be contaminated, e.g.:

a. Runoff from contaminated paved areas.

b. Use of hoses for washdown and firefighting in contaminated areas.

c. Laboratory wastes.

Some areas may be contaminated indirectly, e.g., by particle fallout from stacks -

this may even come from outside the site boundary.

6.8.4. Oily water

Oily water is water contaminated by oil to varying degrees and may originate at the following

sources:

a. Drainage from pipe trenches.

b. Spillages and leaks from process equipment.

c. Cooling water from water cooled glands and bearings.

d. Drainage from sample points, level gages, drain cocks, etc.

e. Water from transformer bays.

f. Pump stations, meter proving stations, manifolds, roof drains from floating storage tanks.

g. Drainage from circulating cooling water systems that may be contaminated with oil.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 11 of 58

6.8.5. Acids, chemicals, solvents, and other process fluids

a. Discharges of these effluents should generally be regulated as part of production process.

b. Reference should be made to P&I diagrams for details.

c. These effluents should be intercepted and reprocessed rather than discharged after

treatment.

6.8.6. Liquefied gas LPG/LNG

Discharges result from spills and routine maintenance.

6.8.7. Lead-alkyl compounds

Lead-alkyl compounds are found at the following sources:

a. Leaded motor spirit tankage.

b. TEL/TML blending plants.

c. Leaded motor spirit pumps.

6.8.8. Detergents

Detergents may be used in washing down plant or vehicles.

6.8.9. Solids

a. Solid waste may be either particulate matter, such as clay particles, or product of industrial

process, such as pellets or granules.

b. Solid effluents should be avoided if possible (with exception of 6.8.10).

6.8.10. Domestic sewage

Domestic sewage includes waste from toilets, washrooms, kitchens, and cleaners sinks (but not

from laboratories).

Domestic sewage systems are also known as foul or sanitary drainage systems.

6.9. Effluent segregation

6.9.1. Number and types of systems

Number and types of systems should be optimised because of limits on cost and available space

taken by systems.

Ideally, each effluent has its own segregated drainage system, with each system

specified in terms of capacity, ancillary structures, fittings, and materials in

accordance with the particular requirements of that effluent. The waste treatment

facility would also be effluent specific, hence, more efficient.

6.9.2. Degree of effluent segregation

Degree of effluent segregation depends on various factors that are covered in 6.9.2.1 through

6.9.2.4.

6.9.2.1. System specification

a. Specification and features of system containing mixture of effluents shall be those of

effluent that requires highest level of integrity and treatment. If concentration of the

effluent requiring most treatment is below legislative requirements, the requirement for the

highest level of integrity may be varied subject to acceptance by BP.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 12 of 58

b. Branches and feeders joining system shall also meet this specification, unless special

precautions are taken to isolate them, e.g., suitable water seals.

6.9.2.2. Reactions

Effluents shall not be mixed if physical, chemical, or biological reactions occur.

For example, detergents in oily wastes harm the treatment process and solvent

mixing with water (at temperature above solvent boiling point) causes boil outs - a

release of vapour.

6.9.2.3. Treatment

Concentrated effluent should not be diluted by large volumes of water if the effect of the larger

volume of less concentrated effluent is more severe.

6.9.2.4. Varying flow rates

a. To prevent siltation and blockages in pipes, minimum velocity shall be achieved.

b. Velocity may be compromised if shared system is sized to cater for intermittent large flows

while continuous flows are smaller (see 9.2.3 through 9.2.6).

6.10. Types of system

6.10.1. General

a. Vented piped gravity drain systems are inexpensive and should be used in most situations.

b. Higher integrity drainage systems should be considered if increase in costs can be justified

for reasons, such as environmental, safety, or legislative requirements.

c. The following sections provide guidance on types of drainage systems that should be used.

Table 1 lists advantages and disadvantages of main drainage system types.

Table 1 is intended to provide initial guidance. The final type(s) of system and the

features required depends on the types and quantities of effluent to be drained and

the legislative requirements.

6.10.2. Open gravity systems

6.10.2.1. Vented piped gravity drain system

Effluent in vented piped gravity drain systems in pipes laid to falls between manholes should be

subject to the following:

a. Manhole and gully inlets shall be trapped to prevent spread of fire if effluent system

contains flammable gases or liquids.

b. Manholes shall also be vented to maintain atmospheric pressure in each section of pipe to

help avoid pressure locks developing in system.

c. Vapours expelled from system should be kept to a minimum.

d. Traps in manholes are achieved by installing dip pipes. An example of a typical dip pipe is

shown in Figure 8.

In the case of third party or acquired installations, existing traps may consist of a

totally submerged system controlled by a weir in the downstream manhole or by use

of a system with conventional straight through manholes but with totally

submerged pipes laid as inverted siphons.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 13 of 58

6.10.2.2. Ditch gravity drain system

Channels/ditches carrying effluent flow in open channels or drains shall be trapped to prevent

spread of fire.

6.10.3. Closed systems

6.10.3.1. General

a. Systems closed to atmosphere shall be provided if there is legislation or safety reasons that

restrict gaseous emissions to atmosphere from oily water or chemical drainage systems.

b. Process information should also be used to identify which effluent streams should also be

closed.

c. Three types of closed system may be considered:

1. Closed gravity systems.

2. Pumped systems.

3. Pressurised systems (or vapour recovery/purged systems).

The United States is leading the way with rigorous legislation on air quality and

ground contamination related to drainage systems on industrial sites. There are

restrictions on the amount of volatile organic compounds (VOCs) that can be

released to the atmosphere. Several European countries are also developing

legislation that will have an impact on the types of drainage system commonly used

by BP, such as vented systems with traditional uncontained spigot and socket pipes.

In all cases, the maximum process pressure must be established and used to design

the pipework.

6.10.3.2. Closed gravity systems

a. System should be configured as conventional gravity system with sealed access manholes

and gas vent collecting system.

b. Materials and construction techniques used should be of higher integrity than with open

systems.

c. Generally, joints should be welded and tested to higher standards than with open systems.

d. Connections to drainage system shall be by airtight connections at tanks, bunds (dikes),

process units, etc.

e. At changes of gradient and direction, bends should be used instead of manholes.

f. Changes of pipe size should be made using flat backed tapers.

g. Connections from laterals to main sewer line should be by flat tees or branches.

h. To ease cleaning of system, rodding points should be provided. These points should take

form of a Y branch on sewer pipe, with rodding branch pointing upwards and extended

to suitable access point.

6.10.3.3. Pumped systems

a. Pumped system may be run below or above ground.

b. Lift stations or fully pumped systems should be considered in drainage design.

Effluent lift stations lift flow from one gravity system and deliver to a second similar

system. Such stations contain only short lengths of pressurised pumping main local

to the lift station.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 14 of 58

Pumping stations with associated pumping mains lift and deliver to a distant

treatment facility. Such systems contain long lengths of pressurised pumping main.

These are normally located aboveground but can be buried as necessary.

The main components of pumped systems are:

Localised gravity systems feeding to the lift/pumping station sump.

The effluent lift/pumping station.

A pressurised pumping main.

6.10.3.4. Pressurised systems

a. Pressurised drainage systems should flow under gravity but without access manholes and

without conventional venting.

b. Vapour space above liquid flow shall be large enough to allow displacement of gases

above liquid level. This air space shall then be filled with inert gas at low positive pressure.

c. Inert gas should be injected at discrete points in system to prevent accumulation of

hazardous vapours. Venting of inert gas/vapour mix should be provided at controlled vent

facility where gases are removed for treatment.

d. Connections to drainage system shall be by airtight connections that shall have pressure

reducing and isolating valve. These connections should be aboveground for ease of access.

e. Bends, pipe size changes, connections to laterals, and rodding points should be as for

closed gravity systems (see 6.10.3.2).

This system is difficult to operate and maintain and is expensive to install and

operate.

7. Effluent volumes

7.1. Systems draining paved and/or unpaved areas

a. Systems draining paved and/or unpaved areas should be designed for greater of the

following:

1. Firewater = firewater plus effluent.

2. Rainwater = rainwater plus effluent.

b. Effluent shall include all dry weather flow. Drainage systems carrying these effluents shall

not be allowed to flood.

Usually, process and domestic effluents flow continuously in comparatively limited

volumes. These volumes can be obtained from process information or standard

tables.

It is more difficult to determine water quantities, whether the source is rain or

firewater.

7.2. Rainfall intensities

a. Range of storm return periods between 1 and 10 yr should be used for different areas on

site, depending on how acceptable risk of flooding is in each catchment area and balance of

risk and cost.

For example, in tank farms, where risk is low and some flooding could be tolerated,

a return period of average once in 1 yr would be acceptable. If design capacity

cannot be exceeded so frequently, e.g., sections of treatment plant, an acceptable

return period would be higher, e.g., average once in 10 yr.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 15 of 58

A storm with an average return period of once in 10 yr is of the order of 25% to

50% greater than a 1 yr return period storm, although this depends on the rainfall

history of the area. This affects the size of the drainage system required.

b. Contributing area for rainfall drainage to sewers shall be assumed to be 100% of paved

area.

c. Contribution of runoff from unpaved areas should be considered on case by case basis and

may constitute significant proportion of flow.

d. If time of concentration is less than 10 min, maximum hourly rate of rainfall should be

applied as flat rate.

If rainfall rates are not specified, design should be based on formulae derived from

local records or, in the UK, BS 8005, Table 3.

7.3. Firewater volumes

7.3.1. Area - fire exposed envelope

a. Area in which fire should be contained shall be determined.

b. This could be bunded (diked) area or part of process unit.

c. Area shall be determined by considering consequence of fire incident spreading from one

area to another (fire risk analysis - see GP 24-10).

7.3.2. Volumes

7.3.2.1. General

a. Volumes of firewater should be contained or controlled in predetermined area (fire

exposed envelope) such that firewater does not cause spread of fire by flowing into

adjacent areas.

b. Water should be directed into drainage system and/or areas where water can do no harm.

There are several methods of calculating firewater volumes. The first, in 7.3.2.2, is

recommended for initial sizing of the firewater system. For a more accurate

calculation of volumes, the methods in 7.3.2.3 through 7.3.2.6 should be followed,

referring to GP 24-10.

7.3.2.2. Preliminary design

a. Total firewater demand for installations with fire risk/hazard should be between 800 m

3

/hr

(59 gal/s) and 2 000 m

3

/hr (147 gal/s). Average rate of 1 360 m

3

/hr (100 gal/s) should be

sufficient, unless plant is particularly congested, for which higher figure should be used.

b. For preliminary design purposes, it should be assumed that water will be applied as

follows:

1. 70% evenly distributed over area of 1 000 m

2

(1 200 yd

2

) located anywhere within

process area.

This is intended to cater for large plant areas, where the firewater would

realistically be concentrated over a section only (i.e., 1 000 m

2

(1 200 yd

2

) - and not

dispersed over the whole area resulting in an inadequately designed drain capacity).

2. 100% evenly distributed over whole of process area.

c. For process areas of smaller than 1 430 m

2

(1 710 yd

2

), maximum design intensity should

not exceed that given by a., unless BP specifies otherwise.

d. In assessing total firewater demand for any site, area of plant with largest firewater demand

should be used as governing factor. If this demand exceeds 2 000 m

3

/hr (2 600 yd

3

/hr,

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 16 of 58

consideration should be given to separation of part of area or plant in question by passive

means (e.g., physical separation by fire walls to reduce demand to more reasonable level).

7.3.2.3. Minimum flow

Minimum flow is that required to contain fire and is not normally used for design of drainage

systems.

Guidance is given in GP 24-10 on the volume of water that may be applied in

different types of process or tank storage areas and is based on the surface area of

plant and volumes of cooling water applied per unit area.

7.3.2.4. Design flow

a. Design flow should ideally be used as basis of drainage design and is the figure contained

in pre fire plans.

b. Design flow is based on minimum flow and is adjusted in fire risk analysis and firewater

losses deducted.

Design Flow = Min. Flow + V

1

(actual output) - V

2

(firewater losses)

Typically, the increase from minimum flow to design flow is 25% to 30%, depending

on the equipment used, as the equipment can exceed its rated output. Mobile

monitors may need to deliver twice the volume of water to achieve the same cover as

a fixed system.

7.3.2.5. Firewater losses

It is recognised that some losses occur between firewater being applied and water

entering drainage system due to overspray, evaporation, infiltration into

surrounding ground, etc.

These losses are influenced by factors, including climatic conditions, ground

infiltration (see 7.4), duration of water application, type of application, and

structural types, and should be assessed on case by case basis.

7.3.2.6. Maximum flow

a. Maximum flow shall be total flow rate from firefighting equipment (both fixed and

mobile) that could conceivably be directed to a fire in fire exposed envelope.

b. Consequences of over application of water by flooding drainage system shall be evaluated

with respect to escalating fire.

Maximum flow rates should only be used if it is likely that design flow rates would

be exceeded by the firefighters.

7.3.3. Combined flow rates

a. Consequences of applying design flow rates (or parts of these) to adjacent areas shall be

considered.

If, for example, a tank on fire threatens three adjacent bunded (diked) tanks, the

total amount of water that must be drained is the design flow for each of the tanks,

plus any allowance for foam for the tank on fire.

b. Design of downstream pipework should allow for combination of flow rates from adjacent

areas.

c. Design of effluent treatment and discharge facilities should be checked against combined

flow rates.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 17 of 58

7.4. Groundwater infiltration

a. No allowance for groundwater infiltration should be made in design of new drainage

systems.

b. In analysis of existing systems, allowance may be made, based on site observations.

7.5. Bunded (diked) tank area flow capacity

a. Flow capacity of bunded (diked) tank area drainage system shall allow for greater of:

1. Drainage of accumulated rainwater within bund (dike) in less than 4 hr.

2. Continuous drainage of firewater used for cooling purposes (see 7.3.1).

b. Tank base shall not become submerged.

7.6. Water discharge

Water discharge proposals for new facilities shall be subject to BP approval (see 8.4.2).

Many countries require all drainage, including that used for fire protection, to be

rendered harmless before being discharged into local authority drains, rivers, or

sea. The exception to this is where water is being used for the protection of life.

8. Layout and configuration

8.1. Layout of drainage systems

a. Layout of drainage systems should be decided at same time as plant layout.

b. Impact on drainage systems of future developments in plant, waste treatment facilities, and

improved practices, such as waste treatment and vent gas extraction, should be considered.

c. If possible, main drain lines should run along edge of plant areas and roads to minimise

impact of future drainage work on operational areas.

8.2. Process areas

8.2.1. Paved areas

a. Process units shall be paved and divided into catchment areas to contain water using

paving gradients and kerbing/bunds (dikes).

b. Catchment areas shall be arranged and drained in such a way as to prevent, in fire incident,

spread of firewater and/or flammable liquids to unaffected areas (see 7.3.1).

c. Paved areas beneath pipework or plant carrying LNG shall not be subject to ponding. To

prevent Rapid Phase Transition, the paved area shall have sufficient fall to remove water

from the area at risk.

8.2.2. Area layout

a. Shape and size of catchment area draining to each manhole/gully should be related to

process equipment which it surrounds such that leakage of liquids from equipment is not

directed under other equipment before reaching drainage system.

b. Layout should be determined at early stage of design, in conjunction with plant layout and

using risk assessment techniques.

c. Size of each catchment area should be minimised, while taking account of most efficient

drainage layout.

d. Within process areas, paving should be sloped at gradient no flatter than 1 in 80 in large

open areas or 1 in 60 in restricted areas.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 18 of 58

e. Vertical fall across paving should not exceed 250 mm (10 in).

The use of 100 mm (4 in) kerbing/bunding (diking) around the perimeter of the

catchment area and around sensitive process units aids containment of firewater

and the separation of effluents.

In determining the shape and features of each catchment area, it is important to

maintain safe and convenient access routes for people and vehicles. Kerbs in certain

areas may create trip hazards and limit vehicle access - ramps may be necessary.

8.2.3. Entry points for effluent into drain system

8.2.3.1. General

a. There are four main types of collection point for effluent entering drain system:

1. Manhole gullies.

2. Gully traps.

3. Tundishes.

4. Channels.

b. Manhole gullies, gully traps, and tundishes shall have rodding points.

8.2.3.2. Manhole gullies

If rain/firewater is to be drained from paved areas, centre of each catchment area should have

combined manhole gully.

Figure 5 shows typical details for a manhole gully. Details of manhole gullies are

given in 12.1.3.

8.2.3.3. Gully trap connections

a. Individual trapped gullies should be used if lower volumes of effluent have to be collected.

b. Figure 7 shows typical details which meet the requirements of this GP.

c. Within process plot limits, gullies should generally be connected by individual lines from

each to manhole, which shall be trapped on entry to manhole. An example which complies

with this GP is shown in Figure 8.

If the physical obstruction of foundations makes it difficult for gullies to be

connected to manholes in their section of the process area, connections may be

made to adjacent areas, provided that they are suitably trapped.

Each end of the pipe connecting a gully to a manhole is to be trapped using a water

seal. This can lead to the following double trapping effects.

Depression of water seals and escape of vapour through the weakest.

Increase in flow resistance, requiring additional hydraulic head on the upstream

side of the gully to maintain hydraulic capacity. This can lead to flooding.

Hydraulic analysis of this situation has shown that the BP Standard 100 mm (4 in)

gully fails in bullet one above by allowing vapours to be released back into the

process area. Larger sized gullies (150 mm (6 in) [see Figure 7] and 200 mm (8 in))

designed in accordance with 12.2.2 permit sufficient head to prevent escape of

vapours upstream and overcome the flow resistance in bullet two. If possible, it is

recommended that combined manhole gullies (see 8.3.1) are used to overcome the

double trapping effect.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 19 of 58

8.2.3.4. Process drain connections

a. Process drain connections should be via tundishes.

b. If several process drains connect to underground drain system at same or closely adjacent

locations, collector drains and branches should be used. In such cases, collector drain shall

be connected direct to manhole and trapped on entry.

8.2.3.5. Drainage channels

Drainage channels should only be used to collect flows (especially large volumes of water), if

there is no risk of fire spread from flammable liquids and vapours and combined drainage

system is appropriate.

The disadvantage of open channels is that they could contain burning hydrocarbon

for the unrestricted length of the channel.

The use of concrete channels can simplify the drainage layout by reducing the

number of manholes and associated underground pipework. The grading of the

paving can also be simplified with a single fall to the channel. Several proprietary

drainage channel systems are available. However, some of these contain plastic

components or polymer/concrete mixes that may be susceptible to chemical or

hydrocarbon damage and should be checked for suitability before use.

8.2.3.6. Valves

a. Valves should be incorporated into open and closed systems to isolate sections of pipe.

b. Valves located underground should be mounted in suitable concrete valve pits.

8.2.4. Manhole location

a. Manhole location should be determined at early stage in layout design to allow vents to

discharge in safe areas with minimum length of underground vent pipe.

b. Manholes should generally not be located in accessways within process units or where

crane outriggers may be placed.

c. Manholes located outside or on edge of process units should generally be at least 5 m

(16 ft) from edge of road.

8.2.5. Drains crossing foundations

a. Drains should not be laid below or through structural foundations.

b. Drainage system and foundations should be designed such that drains can be laid above

upper surface of foundation that they cross.

Precautions should be taken to allow for differential settlement where drains laid in

unsupported ground (outside the limits of a piled foundation) join those laid within

or above a foundation.

Drainage positions and foundation types should be examined at an early stage with

respect to groundwater conditions to ensure compatibility.

8.2.6. Other features

Placing roofs over items of process equipment or tanks reduces amount of rainwater

that becomes contaminated. This is especially useful if there is a low fire risk or if

the firewater drain could be valved.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 20 of 58

8.3. Offsites areas

8.3.1. Oily water

8.3.1.1. Oily water from storage tanks

a. Water drawoff from oil storage tanks and roof drains (floating roofs only) should be

drained to oily water drainage system (see Figure 9).

The most efficient way to carry out drawoff is to use an automatic valve that shuts if

the amount of oil reaches a predetermined level. If this is not possible, some form of

segregation at source, usually consisting of a sump connected to the oily water

system, may be necessary if control of the drawoff cannot be guaranteed. Excess oil

released into the sump can be recovered.

b. Connection to oily water system should be valved outside bund (dike). Valve should

remain closed except if draining oily water, under control, from area.

c. Areas within bunded (diked) area that are heavily contaminated with oil (e.g., under

valves/manifolds) should ideally be paved and bunded (diked) and connected to oily water

system (instead of clean water system).

d. Storage areas should be sized to contain products that are spilled, until such products can

either be passed into drainage system or returned to tank.

The tops of the walls of any sumps should be sufficiently high to prevent rainwater

from within the bund (dike) flooding into the sumps during periods of intense and

prolonged rain.

8.3.1.2. Oily water from storage tanks with leaded product

a. Effluent from leaded motor spirit tanks shall pass to combined separator within bunded

(diked) area.

b. Water shall be drained off to oily water drainage system and motor spirit pumped back into

storage tanks.

c. Outlet to pit shall connect to valve outside bund (dike). Valve shall normally be kept

closed such that drainage is only let into system if known to be lead free. Figure 9 shows a

typical example which complies with this GP.

The tops of the walls of any sumps should be at the elevation indicated in 8.3.1.1.

8.3.1.3. Oily water from other leaded product areas

a. Effluent from leaded motor spirit pumps shall pass to combined separator within bunded

(diked) area.

b. Water shall be drained off to oily water drainage system and motor spirit recovered.

c. Drainage from TEL/TML blending plants shall be intercepted by holding pit.

d. Outlet to pit shall connect to valve that is normally kept closed.

8.3.1.4. Oily water from transformer bays

a. Generally, drainage shall be to oily water system via a trapped gully.

b. If transformer bays are remote from oily water sewer, discharge may be to clean sewer,

although valved collecting sump should be used.

The requirement for oily water drainage can be removed in areas of high rainfall if

a roof is constructed over the transformer bay and a sump is used to collect

intermittent spills that can then be pumped out.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 21 of 58

8.3.2. Clean effluent

8.3.2.1. Clean water from storage tank areas

a. Rain and firewater from storage tank areas should be drained by clean water drainage

system (An example of this is shown in Figure 9).

b. If surface of storage area is not naturally impermeable, lining material (rigid or flexible)

shall be provided for both surface and features, such as ditches and sumps. Lining material

should be integrated properly with under tank lining system.

c. Open channel

1. Surface of ground within tank bunds (dikes) should be graded to shallow open

channel around inside of bund (dike).

2. Channel should discharge into silt chamber and via pipe through bund (dike).

3. Drain should be valved outside bund (dike) in convenient position to enable discharge

to be controlled without operator having to enter bunded (diked) area.

4. Valve should be normally closed.

d. If necessary to meet local authority or statutory requirements, interceptor pits shall be

provided. Pits should generally be sited outside bund (dike) but before final discharge from

site.

8.3.2.2. Clean water from storage tank areas with leaded product

Requirements for clean water drainage should be same as in 8.3.2.1.

8.3.2.3. Clean water from LPG storage areas

Drainage of surface water from area around and under liquefied gas storage vessels should be

discussed and agreed with BP.

LPG storage areas in the UK are designed in accordance with HSG-34.

Excessive amounts of LPG depress the water seals in the system and allow LPG to

pass through the traps. This negates both the integrity of the trap and the hydraulic

performance of the system.

If there is a discharge of LPG, there is a possibility that the gully seal may freeze.

This phenomenon has previously been taken advantage of by designing LPG tank

bund (dike) outlets such that the water seal freezes quickly to prevent loss of

containment. Further advice is necessary if this is being considered as a solution.

8.3.2.4. Clean water from area land drainage

a. Rainwater falling on unpaved uncontaminated ground within process area should normally

be disposed of by natural percolation into subsoil and evaporation.

b. If land is not sufficiently permeable for natural removal to be effective without undue

ponding, surface should be graded to suitably located trapped gullies discharging to buried

pipe system.

c. If this is not practical, land drains should be provided.

Pipe drains, if required, should be arranged to discharge into the clean water

drainage system or such other system as may be specified by BP. It may be

necessary to remove additional sludge and grit from this system, and so larger

sumps should be provided.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 22 of 58

8.3.3. Drainage from buildings

8.3.3.1. Industrial buildings/workshops

a. Floor drains in pump or compressor houses and workshops shall be connected to fully

trapped and vented manholes if they form part of system draining oily or chemical

contaminants.

b. Hazardous gases shall not be allowed to enter building from drainage system.

8.3.3.2. Control rooms

a. Drains shall not be located within control rooms.

b. Other areas of control buildings, electric substations, and switchrooms should have

appropriate type of drainage systems (usually sewage wastewater).

8.3.3.3. Laboratory drainage

a. To maintain control over waste disposal, laboratory collection points should be used.

b. Uncontaminated waste liquids should be drained to sewage wastewater system.

It is not good practice to dispose of laboratory waste via the sink system, as this can

involve the need for costly glass drainage systems within the laboratory.

8.3.4. Other buildings

a. Other buildings should be connected to sewage wastewater system, if domestic type

waste is being drained.

b. Canteens shall be connected via grease trap.

8.4. Treatment

8.4.1. Effluent treatment

Treatment of oily and chemical waste and subsequent discharge shall comply with requirements

of local and national authorities, in addition to BP requirements relating to health, safety, and

environment.

It is anticipated that an effluent treatment plant would feature low shear pumps,

storage capacity, primary separation, filters, and biological treatment.

8.4.2. Holding basins

Discharge of system will be specified by BP.

Although some local authorities may permit direct discharge into a river or the sea,

it should generally be assumed that future, more stringent requirements may require

some form of holding basin and/or treatment plant to be installed. Specific

provisions should be made for example to accommodate future requirements on

layout and the direction of flow.

A suitable holding basin would be designed to capture and retain the first 10 mm

(3/8 in) of rainfall (or equivalent firewater) from paved areas.

8.4.3. Sewage treatment

Sewage handling and treatment shall comply with requirements of local authority and BP.

Failing any such requirements, the design and construction should comply with the

British Standard Codes of Practice or approved alternatives.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 23 of 58

The drainage should preferably be discharged to the nearest local authority sewer.

If this is not economical or practical, biological treatment may be necessary. In the

case of isolated buildings, there are three alternatives to the above options:

cesspools, septic tanks, and prefabricated sewage treatment plants. Cesspools are

the most basic and cheapest, but septic tanks are the preferred choice if there is no

possibility of polluting underground potable water supplies.

8.4.4. Removal of solids

a. Process solids, such as pellets and granules, should be removed at source before entry into

drainage system using screens that can be regularly cleaned.

b. Alternatively, decanting system further downstream may be appropriate if solids are

coming from a number of sources.

8.5. Measurement of effluent discharge rate

Simple weir or monitoring device should be installed at or near final effluent discharge point.

9. Hydraulic design

9.1. General

a. Drainage systems should be gravity based open drainage systems.

b. On occasion, particularly for process drainage, closed drains may be appropriate because

of technical, safety, or legislative requirements.

The design methods and criteria for both open and closed systems are closely

related.

Gases or vapours that may be carried forward with effluent or evolved during

course of treatment or due to contact with other effluent may affect flow regime of

system.

c. Hydraulic design involves consideration of the following:

1. Maximum and minimum flows.

2. Sediment transport capacity.

3. Degree of surcharge or controlled flooding that can be tolerated.

4. Hydraulic capacity required that necessitates determination of pipe size, gradient and

condition, nature of liquid to be carried, and vapour pressure likely to arise in system.

9.2. Gravity based drainage systems

9.2.1. General

a. Guidelines in 9.2.2 through 9.2.12 may be applied to open gravity systems in which

controlled surcharging is allowed and closed gravity systems with partially full (0,7d)

pipes (i.e., no surcharging) operating at or near to atmospheric pressure.

b. For equipment requirements of closed gravity systems, see 9.3.1.

9.2.2. Design methods

Colebrook-White formula may be used for design of gravity drainage systems.

For most drainage designs, hand methods of calculation are adequate for the small

areas involved. If firewater (including dry weather effluent flow) is the critical

design case, these constant flows shall directly provide the design flows throughout

the system. If the rainfall case (including dry weather effluent flow) is to be checked,

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 24 of 58

flows should be calculated throughout the system by the Modified Rational Method

or the procedures of BS 8005 or similar document.

Design may be performed by computer if appropriate software is available. Steady

state design can be produced on a spreadsheet. Rational method design can be done

using proprietary software, such as Hydraulics Research Ltd's WALLRUS and

SPIDA.

Some software allows direct production of sewer long sections for import into

propriety CAD software. More complex computer programs are available for the

design and analysis of large and complex sewer networks. Examples are WALLRUS-

SIM and WALLRUS-HYD in the UK and the U.S. Stormwater management model

(SWMM). Such programs should only be used for drainage if:

Rainwater flows are critical.

The design involves major modifications to an existing drainage system that may

result in under capacity of existing sewers.

Calculation of open channel flows should be done using the Manning formula.

9.2.3. Velocities

a. Velocities shall be kept within range that prevents damage to pipes and fittings and allows

self cleansing.

b. Pipe runs should be designed to accommodate maximum expected flow if running just full.

c. For some lengths of drain, flow from emergency use of fire hoses may greatly exceed

normal process and rainwater flows.

9.2.4. Design velocity

a. Design velocity (from combined process and rainwater flows) should be approximately

1 m/s (3,3 ft/s).

b. Velocities for firewater or emergency flows may exceed 1 m/s (3,3 ft/s).

9.2.5. Minimum velocity

a. If possible, piped drains shall be designed to attain minimum velocity of 0,75 m/s

(2,46 ft/s) )either from process flows alone or from combined process and rainwater flows

(return period of 1 in 2 mo).

b. Velocity shall be attained minimum of six times per year to achieve periodic cleansing of

drains.

9.2.6. Maximum velocity

a. High velocities present problems due to high friction losses and, hence, head losses.

b. If design velocities exceed 3 m/s (9,8 ft/s) at any point in system, pipe manufacturer should

be consulted to ensure no erosion will take place.

c. In oily water systems, velocities should not exceed 1,2 m/s (3,93 ft/s) to avoid

emulsification.

9.2.7. Open ditches

a. Ditches in fine sands or silts should be lined.

b. In unlined open ditches, velocity should be kept sufficiently low to prevent scouring.

c. Velocity shall be selected in accordance with local soil conditions and construction but

may typically be in the range 0,5 to 0,8 m/s (1,6 to 2,6 ft/s).

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 25 of 58

d. If velocity is likely to be high (e.g., greater than 0,8 m/s (2,6 ft/s)), such that scouring of

the bed or sides would result, ditches in cohesive soils or coarse sands shall be suitably

revetted.

e. Higher velocities shall be necessary if oily water is being drained.

If considered necessary, ditches may be bottomed in concrete to facilitate cleaning.

9.2.8. Siltation

a. If possible, introduction of solids into drainage system should be avoided.

b. Drainage system should be capable of carrying solids in system with minimum

maintenance effort.

c. If minimum velocities for periodic cleansing of system cannot be obtained through process

or rainwater flows, flushing facilities should be installed to provide flow of 0,75 m/s

(2,46 ft/s) in each pipe run of system.

Flushing facilities should be actively considered at arid sites with occasional or

unreliable rainfall or if large quantities of sediment are likely to enter the system.

Fine solid particulate matter, such as clay particles from storm water runoff on

unpaved areas, should, if possible, be excluded from oily water drains. The solids

adhere to oil droplets forming neutrally buoyant particles that are difficult to

separate in a gravity oily water separator.

d. If lengths of sewer are designed to be permanently flooded either for hydraulic reasons or

for reasons of safety (e.g., ditch firetraps), design flows should be increased by 10% as

allowance for siltation.

e. Further analysis should performed if large quantities of solid material are able to enter

system.

9.2.9. Surcharging and flooding

a. In open gravity systems only, surcharging of drains should be taken into account in

emergency conditions (or extreme rainfall) to provide sufficient hydraulic capacity,

provided that surface flooding is not increased.

b. Under maximum flow conditions described in a., hydraulic gradient within drainage

system should extend no higher than 300 mm (12 in) below any point of entry into system.

c. If there is risk of flooding, each drainage catchment area should be assessed using

recognised risk assessment technique.

If some flooding can be accepted, sensitive areas should be bunded (diked) or

kerbed and the water directed away using the paving falls. Allowing flooding in a

controlled manner in safe areas can provide additional storage for the drainage

system until the peak flow conditions have eased.

9.2.10. Pipe roughness

In assessing frictional head loss of effluents flowing in drains, pipe roughness factors (k

s

) shall

be chosen to take account of future mature condition of pipe, considering materials of

construction and nature of effluents drained.

Use of conservative values increases hydraulic gradient and depth of system and

consequently cost of excavation required to meet design flow.

If effluent is likely to produce large quantities of chemical precipitate, the roughness

values are greatly increased. Special consideration of roughness values is necessary

in such conditions. An increase in k

s

from 0,3 mm to 6,0 mm (0,012 in to 0,250 in)

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 26 of 58

reflecting a 10% loss in cross section due to precipitate build-up reduces the design

flow by nearly 40%.

9.2.11. Head losses at manholes and fittings

Hydraulic designs of sewers should take due account of likely head losses at manholes and

fittings.

These losses are dependent upon the detailed design, and it is not therefore possible

to give exact figures - most design manuals provide approximations. By choosing

certain standard details, head losses can be reduced. For example, the introduction

of a socket or bell mouth outlet instead of a plain straight end pipe reduces the exit

head losses by between 40% and 80%. Alternative sections increase cost, though.

Bell mouths are approximately 3 times more expensive than plain ends, although

sockets are only 1,1 times more expensive (based on average UK costs).

9.2.12. Gradients

a. Trench excavation should be limited to 6 m (19 ft 8 in) depth because of construction

difficulties and associated high cost - especially if water tables are high.

b. Physical difficulties with accurate laying of pipe at very flat gradients dictates minimum

gradient.

c. Minimum gradients for pipe size ranges should be as follows:

Pipe diameter Gradient

Less than DN 150 (NPS 6) 1 in 80

DN 150 (NPS 6) to DN 450 (NPS 18) 1 in 250

Greater than DN 450 (NPS 18) 1 in 500

In the UK, reference should be made to BS 8301 for foul drainage to ensure that

pipes are self cleansing.

9.3. Closed drainage systems

9.3.1. Closed gravity systems

9.3.1.1. General

Backflow from high pressure to low pressure systems across common drain systems in event of

mal operation should be considered during design.

9.3.1.2. Drainage lines and headers

Drainage lines should fall towards closed drain drum.

9.3.1.3. Closed drain drum

a. Sizing of closed drain drum should be based on largest item of equipment likely to be

drained to closed drain drum and contents of inlet drains.

For very large vessels, there should be provision to reduce the inventory to a

minimum using normal process outlets. The size of the drain drum can then be based

on the lowest practical inventory of the vessel and piping. Consider supply

operations and the likely overflow from storage tanks.

b. Requirement for electric heaters to maintain temperature of liquid in drum should be

considered.

c. Centre section of the drum shall have extra high liquid level switch.

d. Operation of extra high liquid level switch should open emergency dump valve.

22 February 2006 GP 04-10

Guidance on Practice for Drainage Systems

Downloaded Date: 6/17/2008 10:04:33 PM

The latest update of this document is located in the BP ETP and Projects Library

Page 27 of 58

Operation of the extra high liquid level switch shall cause an emergency dump valve

to open, allowing the drum contents to discharge. It should be noted that the high

level control should be designed to avoid the risk of liquid carryover to the flare

system.

9.3.2. Pumped systems

a. Flows from process units, tanks, drains, etc., should be fed by short gravity sections

designed by conventional methods to pumping station wet well. Figure 4 provides typical

details of arrangement of pumped drainage system.

Pumping station design should comply with GP 04-30 or other suitable codes, such

as BS 8005 and WAA Sewers for Adoption.

b. Wet wells and pumping mains shall not be oversized.

This is to avoid excessive retention times of the effluent.

c. Pumps should be located in dry wells or aboveground to facilitate maintenance and

removal.

d. Wet wells shall be of air tight construction with adequate venting to provide hydraulic

stability.

If wet well pumps are used (with lifting guide rails for maintenance), the airtight

construction requirement remains and must not be compromised.

e. Pump heads and capacities

1. Pump heads and capacities should be chosen to accommodate both normal process

flows and emergency fire water flows or rainwater flows.

2. Separate pumps may be needed for each of these duties.

3. No less than 33% standby capacity shall be provided at pumping stations.

f. Pump and pumping pipework design should be performed by normal hand methods of

calculation.

g. Pump and pipe capacities shall be defined as peak flows in system.

h. Pumps for liquids containing oils

1. Emulsification of oil globules makes treatment and separation difficult.

2. For liquids containing oils, pumping stations shall be designed using low speed screw

impeller pumps to minimise emulsification.

3. Pumping plant should generally be low speed centrifugal pumps with operating

speeds below 970 rpm.

4. Consideration should be given to use of Archimedean screw pumps, particular care

being taken in design to achieve adequate venting of screw.

i. Computer aided analysis should be used to determine transient pressures due to pump

operation or failure.

Proprietary programs are available for this analysis.

j. In order to limit both silting and emulsion, pumping mains shall be designed for velocity of