Académique Documents

Professionnel Documents

Culture Documents

PQR Form (Welding)

Transféré par

jasmineamma0 évaluation0% ont trouvé ce document utile (0 vote)

287 vues2 pagesppppppppp

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentppppppppp

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

287 vues2 pagesPQR Form (Welding)

Transféré par

jasmineammappppppppp

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

1

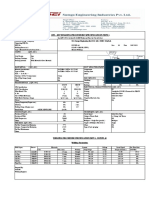

PROCEDURE QUALIFICATION RECORD (PQR)

(In Accordance to ASME Section IX Boiler & Pressure Vessel Code, 2007 Edition)

Supporting PQR No. Date

WPS No. Date

JOB No. Date

Welding Process Type

JOINT (QW-402) :

(For Combination Qualifications, the deposited weld metal thickness shall be recorded for each filler metal or

process used)

POST WELD HEATREATMENT (QW-407)

Temperature

Time

Other

BASE METAL (QW-403)

Material Spec.

Type or Grade

P. No.

Thickness of

test coupon

Diameter of

test coupon

Other

GAS (QW 408 )

Precent Composition

Gas Mixture Flow Rate

Shielding

Trailing

Backing

FILLER METALS (QW-404)

SFA

Specification

AWS

Classification

F-No.

A-No.

Size of Filler

metal

Trade Name

Weld metal

Thickness

Other

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Polarity

Ampere

Volt

Tungsten Electrode

size

Tungsten Electrode

Type

Other

POSITION (QW-405)

Position

Weld

Progression

Other

PREHEAT (QW 406 )

Preheat Temperature

Interpass

Temperature

Others

TECHNIQUE (QW 410 )

Travel Speed

String or Weave Bead

Oscillation

Multi pass or Single

pass (per side)

Multi or Single

Electrode

Other

*) Each Base metal and filler metal combination should be recorded individually

N/A = Not Applicable

2

PQR No. : Page of

WELDING PARAMETER

Layer No.

Type & Size of Filler

Ampere (A)

Volt (V)

Duration Time Per

Layer (min)

Travel Speed

(mm/minute)

Time Lapse Between

Pass

TENSILE TEST (QW - 150)

Specimen

No.

Width Thickness Area Ultimate Total

Load (Lb)

Ultimate Unit

Stress (psi)

Type of Failure &

Location

GUIDE BEND TEST (QW 160 )

Type & Figure Result

CHEMICAL COMPOSITION ANALYSIS :

DATA REPORT AND ATTACHMENT

Welder Name

Penetrant Test Conducted by Report No.

Mech. Test Conducted by Report No.

Chemical Test Conducted by Report No.

We Certify that the statement in this record are correct and the test weld were prepared, welded and tested

in accordance with the requirement of Section IX of the ASME Code, 2007 Edition.

Manufacturer :

Date :

Prepared by, APPROVED BY,

Vous aimerez peut-être aussi

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- PQRDocument3 pagesPQRnazirulhakimPas encore d'évaluation

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoPas encore d'évaluation

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonPas encore d'évaluation

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaPas encore d'évaluation

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarPas encore d'évaluation

- WPS FormatDocument2 pagesWPS FormatAmit SarkarPas encore d'évaluation

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaPas encore d'évaluation

- Welding Parameter Record SheetDocument2 pagesWelding Parameter Record SheetPravin Patil100% (1)

- WPS Blank FormDocument4 pagesWPS Blank FormAhmet SerdengectiPas encore d'évaluation

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- Revised Wps For Gtaw - Xls Dated 25.01.2017Document2 pagesRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathPas encore d'évaluation

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasPas encore d'évaluation

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1Pas encore d'évaluation

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyPas encore d'évaluation

- WPS FGPDocument1 pageWPS FGPShabbir HussainPas encore d'évaluation

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSPas encore d'évaluation

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejPas encore d'évaluation

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarPas encore d'évaluation

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28Pas encore d'évaluation

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielPas encore d'évaluation

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamPas encore d'évaluation

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoPas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalPas encore d'évaluation

- Sample of Procedure Qualification Record (PQR) : Joint DetailsDocument4 pagesSample of Procedure Qualification Record (PQR) : Joint Detailshancur_27Pas encore d'évaluation

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPS - 024Document4 pagesWPS - 024MAT-LIONPas encore d'évaluation

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaPas encore d'évaluation

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabPas encore d'évaluation

- QIR 101 Welder Qualification CertificateDocument1 pageQIR 101 Welder Qualification CertificateSamer BayatiPas encore d'évaluation

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26Pas encore d'évaluation

- Welding Repair ProcdureDocument16 pagesWelding Repair Procdureprem nautiyal100% (1)

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnPas encore d'évaluation

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhPas encore d'évaluation

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraPas encore d'évaluation

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielPas encore d'évaluation

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- wps63 PDFDocument4 pageswps63 PDFErick HoganPas encore d'évaluation

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviPas encore d'évaluation

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPSDocument42 pagesWPSjoehodoh100% (1)

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Document8 pagesQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MartePas encore d'évaluation

- PQR TemplateDocument2 pagesPQR TemplateBruno PlachaPas encore d'évaluation

- QW - 483.desbloqueadoDocument3 pagesQW - 483.desbloqueadoJason PalmerPas encore d'évaluation

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyPas encore d'évaluation

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusPas encore d'évaluation

- 14033Document2 pages14033Priyanathan ThayalanPas encore d'évaluation

- (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record of The Actual Conditions Used To Weld Test CouponDocument3 pages(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record of The Actual Conditions Used To Weld Test CouponRaul Fernando GalarzaPas encore d'évaluation

- BPVC Ix QW-483Document2 pagesBPVC Ix QW-483ganesh82Pas encore d'évaluation

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarPas encore d'évaluation

- Surface PreparationDocument4 pagesSurface PreparationjasmineammaPas encore d'évaluation

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Corrosion Op MondayDocument2 pagesCorrosion Op MondayjasmineammaPas encore d'évaluation

- 13 01 15 Expediting Report GoodrichGasketsDocument2 pages13 01 15 Expediting Report GoodrichGasketsjasmineamma100% (1)

- 30 12 14 Expediting Report GoodrichGasketsDocument2 pages30 12 14 Expediting Report GoodrichGasketsjasmineamma100% (1)

- Expediting Report MIL-30Sept FINALDocument2 pagesExpediting Report MIL-30Sept FINALjasmineamma100% (1)

- 13 01 15 Expediting Report GoodrichGasketsDocument2 pages13 01 15 Expediting Report GoodrichGasketsjasmineamma100% (1)

- Bolster Engineering Solutions Pvt. LTD.: From TO Expense in Inr Remarks 1 7/10/2016Document1 pageBolster Engineering Solutions Pvt. LTD.: From TO Expense in Inr Remarks 1 7/10/2016jasmineammaPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Expediting Report MIL-18AugDocument3 pagesExpediting Report MIL-18AugjasmineammaPas encore d'évaluation

- Bolster Engineering Solutions Pvt. LTD.: SR No Place From To Expenses INR RemarksDocument1 pageBolster Engineering Solutions Pvt. LTD.: SR No Place From To Expenses INR RemarksjasmineammaPas encore d'évaluation

- 2E-1103 Final Report Train-2 MI April-2013Document4 pages2E-1103 Final Report Train-2 MI April-2013jasmineammaPas encore d'évaluation