Académique Documents

Professionnel Documents

Culture Documents

Attachment 1-Heat Transfer Calculation Sheet

Transféré par

Erica MartinDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Attachment 1-Heat Transfer Calculation Sheet

Transféré par

Erica MartinDroits d'auteur :

Formats disponibles

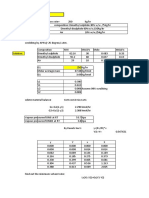

DAI HUNG GAS PIPELINE

HEAT TRANSFER CALCULATION SHEET

Description: Heat Transfer Calculation

Doc. Title:

Pipeline Cathodic Protection Design

Case:

16-inch Dai Hung Gas Pipeline

Doc. No.:

DHG-PVE-DD-2-CR-REP-102

Appendix:

Prepared:

Checked:

Rev.

Date:

Date:

Purpose: The evaluation of anode surface temperature installed in 16" gas pipeline. Anodes are installed on 3LPE anti-corrosion

coating.

I. Pipeline parameters:

Inside diameter:

ID

374.6

mm

Outside diameter:

OD

406.4

mm

Wall thickness:

WT

15.9

mm

II. Input data:

Thermal conductivity:

Thickness,

Thermal conductivity,

mm

W/m.K

Carbon steel

15.9

54

FBE

0.25

0.38

PE

3.3

0.2

EM

0.2

0.32

Aluminium

40

204

Item

Thermal coefficient:

Heat convection coefficient of

gas (1)

100

W/m2.K

Heat convection coefficient of

seawater (2)

600

W/m2.K

45

28

Temperature:

Maximum operating temperature of

pipeline (T1)

Maximum seawater temperature at

seabed (T2)

III. Calculation:

t4

Heat transfer coefficient equation:

t5

t6

t3

t7

t2

t1

Gas

Seawater

Heat transfer coefficient:

K=

33.40003958

W/m2.K

567.8006729

W/m

39.32

Heat Transfer:

q=

CS

Temperature at surface layers:

t2 =

C

Page1

FBE

PE

EM

Al

t8

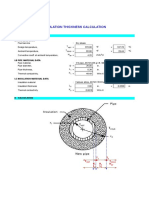

DAI HUNG GAS PIPELINE

HEAT TRANSFER CALCULATION SHEET

Description: Heat Transfer Calculation

Doc. Title:

Pipeline Cathodic Protection Design

Case:

16-inch Dai Hung Gas Pipeline

Doc. No.:

DHG-PVE-DD-2-CR-REP-102

Appendix:

Prepared:

Checked:

Rev.

Date:

Date:

t3 =

t4 =

t5 =

t6 =

t7 =

39.15

38.78

29.41

29.06

28.95

29.06

IV. Result:

Temperature at surface anode:

T=t6

Notes:

CS: Carbon Steel

FBE: Fusion Bonded Epoxy

PE: Polyethylene

EM: Epoxy Mastic (Coating for internal surface of anode)

Page2

Vous aimerez peut-être aussi

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićPas encore d'évaluation

- Pipe Size Calc - Gas - LINDocument1 pagePipe Size Calc - Gas - LINjollyPas encore d'évaluation

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyPas encore d'évaluation

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002Pas encore d'évaluation

- Kod SizingDocument2 pagesKod SizingCan YıldırımPas encore d'évaluation

- Pressure Gauge DatasheetDocument2 pagesPressure Gauge DatasheetazlanPas encore d'évaluation

- Flash CalculationsDocument10 pagesFlash CalculationsHamza AliPas encore d'évaluation

- Pressure Drop Via The Karman MethodDocument2 pagesPressure Drop Via The Karman MethodAtul kumar KushwahaPas encore d'évaluation

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLEPas encore d'évaluation

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosPas encore d'évaluation

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPPas encore d'évaluation

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLOPas encore d'évaluation

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsPas encore d'évaluation

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertPas encore d'évaluation

- Jet Impingement CoolingDocument9 pagesJet Impingement CoolingDanish AbbasPas encore d'évaluation

- Emergency Scrubber DesignDocument36 pagesEmergency Scrubber DesignSurajit das0% (1)

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156Pas encore d'évaluation

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009Pas encore d'évaluation

- Insulation Calculation For 36 inDocument18 pagesInsulation Calculation For 36 inSaepul RochmanPas encore d'évaluation

- Vent Sizing (61-65)Document26 pagesVent Sizing (61-65)mieiroluiz12Pas encore d'évaluation

- Leak Detection TechnologyDocument10 pagesLeak Detection TechnologymasoudPas encore d'évaluation

- Input:: Note de Calcul Calculation NoteDocument4 pagesInput:: Note de Calcul Calculation NotekardujorgePas encore d'évaluation

- Steam-Water Two-Phase Flow in Large Diameter Vertical PipingDocument11 pagesSteam-Water Two-Phase Flow in Large Diameter Vertical Pipingfujiman35Pas encore d'évaluation

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresPas encore d'évaluation

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRPas encore d'évaluation

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuPas encore d'évaluation

- Insulated Pipe - Temperature Loss CalculationDocument5 pagesInsulated Pipe - Temperature Loss CalculationnopPas encore d'évaluation

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyPas encore d'évaluation

- Gas Line Capacity CalcDocument2 pagesGas Line Capacity CalcMario Mendoza100% (1)

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 pagesFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismPas encore d'évaluation

- Insulation Thickness Calculation of Pipe: T T T T Input RequiredDocument3 pagesInsulation Thickness Calculation of Pipe: T T T T Input RequiredEddie FongPas encore d'évaluation

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaPas encore d'évaluation

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyPas encore d'évaluation

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRIPas encore d'évaluation

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- Thermal Insulation Thickness Calculation For Pipes (WiP)Document1 pageThermal Insulation Thickness Calculation For Pipes (WiP)Ah BengPas encore d'évaluation

- Snamprogetti: CustomerDocument3 pagesSnamprogetti: CustomeradesloopPas encore d'évaluation

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973Pas encore d'évaluation

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaPas encore d'évaluation

- Pipes. Maxi 1Document1 pagePipes. Maxi 1Nasrul AdliPas encore d'évaluation

- Steam HXDocument1 pageSteam HXrajachemPas encore d'évaluation

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajPas encore d'évaluation

- Underground Steam & Condensate Piping PDFDocument26 pagesUnderground Steam & Condensate Piping PDFZacky JoePas encore d'évaluation

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Pas encore d'évaluation

- Hitungan PPDocument30 pagesHitungan PPHamdan ShdPas encore d'évaluation

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639Pas encore d'évaluation

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinPas encore d'évaluation

- Tractebel SpecificationDocument69 pagesTractebel SpecificationShyam MurugesanPas encore d'évaluation

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHPas encore d'évaluation

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- Air Ingress CalculationsDocument5 pagesAir Ingress CalculationsMallinatha PNPas encore d'évaluation

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDocument1 pageSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilPas encore d'évaluation

- H2 EmbrittlementDocument57 pagesH2 EmbrittlementrodneyrlrPas encore d'évaluation

- Appendix E1 Ages SP 09 002Document13 pagesAppendix E1 Ages SP 09 002SandeepNBabuPas encore d'évaluation

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Pas encore d'évaluation

- OVSOL Evacuated-Tube CollectorDocument7 pagesOVSOL Evacuated-Tube CollectorTanveer ShaikhPas encore d'évaluation

- #1 N5013DQ1A Technical Specification Cirmac Membrane N2Document12 pages#1 N5013DQ1A Technical Specification Cirmac Membrane N2Chakravarthy BharathPas encore d'évaluation

- Comparative Study Summary 07 2004 enDocument32 pagesComparative Study Summary 07 2004 enthmaraishriPas encore d'évaluation

- Comparative Study On Pressure Equipment StandardsDocument32 pagesComparative Study On Pressure Equipment Standardsmih1Pas encore d'évaluation

- 2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersDocument6 pages2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersGuruchell ChellguruPas encore d'évaluation

- Tank Ft4 KKCDocument1 pageTank Ft4 KKCErica MartinPas encore d'évaluation

- Tank Ft4 KKCDocument1 pageTank Ft4 KKCErica MartinPas encore d'évaluation

- ITP For Pressure VesselDocument48 pagesITP For Pressure VesselErica MartinPas encore d'évaluation

- Tank FT4 KKC PDFDocument1 pageTank FT4 KKC PDFErica MartinPas encore d'évaluation

- ITP For Pressure Vessel PDFDocument4 pagesITP For Pressure Vessel PDFErica MartinPas encore d'évaluation

- Swiber PJW3000 Crane Lift Chart - FIDocument1 pageSwiber PJW3000 Crane Lift Chart - FIErica MartinPas encore d'évaluation

- Catalog A 1 Filter Driers - 42015Document32 pagesCatalog A 1 Filter Driers - 42015Erica MartinPas encore d'évaluation

- Dynamics of Fixed Marine Structures N. D. P. Barltrop A. J. AdamsDocument396 pagesDynamics of Fixed Marine Structures N. D. P. Barltrop A. J. AdamsErica MartinPas encore d'évaluation

- Ans Mod PDFDocument250 pagesAns Mod PDFErica MartinPas encore d'évaluation

- Deshpande Uta 2502M 10951 PDFDocument65 pagesDeshpande Uta 2502M 10951 PDFErica MartinPas encore d'évaluation

- Sea-Struct Groutbag PDFDocument2 pagesSea-Struct Groutbag PDFErica MartinPas encore d'évaluation

- Ansys Mode Tutorials - MacrosDocument27 pagesAnsys Mode Tutorials - Macrosvicksgeorge9750Pas encore d'évaluation

- ANSYS TutorialDocument44 pagesANSYS Tutorialsauravc88Pas encore d'évaluation

- L2 WinDocument4 pagesL2 WinErica MartinPas encore d'évaluation

- L2 WinDocument4 pagesL2 WinErica MartinPas encore d'évaluation