Académique Documents

Professionnel Documents

Culture Documents

UltraCore HD-12M Suite

Transféré par

H_DEBIANECopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UltraCore HD-12M Suite

Transféré par

H_DEBIANEDroits d'auteur :

Formats disponibles

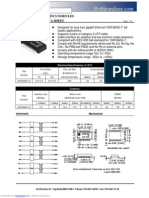

FLUX-CORED GAS-SHIELDED (FCAW-G) WIRE

UltraCore HD-12M

(AWS E71T-1MJ, E71T-9MJ, E71T-12MJ H8)

DEPOSIT COMPOSITION(1) As Required per AWS A5.20/5.20M

Requirements

AWS E71T-1MJ, E71T-9MJ, E71T-12MJ H8

As-Welded with 75-80% Ar / Balance CO2

%C

%Mn

%Si

%Ni

0.12 max.

1.75 max.

0.90 max.

0.50 max.

0.05

1.40

0.39

0.40

%S

%P

0.03 max.

0.03 max.

0.01

0.01

(4)

Typical Results

As-Welded with 75% Argon / 25% CO2

(3)

Requirements(4)

AWS E71T-1MJ, E71T-9MJ, E71T-12MJ H8

As-Welded with 75-80% Ar / Balance CO2

Diffusible Hydrogen

(mL/100g weld deposit)

8 max.

Typical Results(3)

As-Welded with 75% Argon / 25% CO2

4-7

TYPICAL OPERATING PROCEDURES

Diameter, Polarity

Shielding Gas

0.045 in (1.1 mm), DC+

As-Welded with

75% Ar/25% CO2

0.052 in (1.3 mm), DC+

As-Welded with

75% Ar/25% CO2

1/16 in (1.6 mm), DC+

As-Welded with

75% Ar/25% CO2

CTWD(5)

mm (in)

Wire Feed

Speed

m/min (in/min)

Voltage

(volts)

Approx.

Current

(amps)

Melt-Off

Rate

kg/hr (lb/hr)

Deposition

Rate

kg/hr (lb/hr)

Efficiency

(%)

25 (1)

4.4

6.4

7.6

8.9

10.2

11.4

12.7

14.0

15.2

(175)

(250)

(300)

(350)

(400)

(450)

(500)

(550)

(600)

23-28

24-29

25-30

25-30

25-30

26-31

26-31

27-32

27-32

115

140

155

170

185

200

215

230

245

1.8

2.5

3.1

3.6

4.1

4.6

5.1

5.6

6.1

(3.9)

(5.6)

(6.8)

(7.9)

(9.0)

(10.1)

(11.3)

(12.4)

(13.5)

1.5

2.2

2.6

3.1

3.5

4.0

4.4

4.9

5.3

(3.4)

(4.8)

(5.8)

(6.8)

(7.8)

(8.8)

(9.8)

(10.8)

(11.7)

85-88

25 (1)

3.8

5.1

6.4

7.6

8.9

9.5

10.8

12.1

12.7

(150)

(200)

(250)

(300)

(350)

(375)

(425)

(475)

(500)

23-28

24-29

25-30

25-30

26-31

26-31

26-31

27-32

27-32

140

160

180

205

225

235

255

275

290

2.1

2.9

3.5

4.3

5.0

5.3

6.0

6.8

7.1

(4.7)

(6.3)

(7.8)

(9.4)

(11.0)

(11.7)

(13.3)

(14.9)

(15.6)

1.7

2.4

3.0

3.6

4.2

4.5

5.1

5.7

6.0

(3.8)

(5.2)

(6.5)

(7.9)

(9.2)

(9.9)

(11.)

(12.6)

(13.3)

85-88

25 (1)

3.8

4.4

5.1

5.7

6.4

7.6

8.3

8.9

10.2

(150)

(175)

(200)

(225)

(250)

(300)

(325)

(350)

(400)

22-27

23-28

23-28

23-28

24-29

24-29

25-30

25-30

26-31

200

215

230

245

255

285

300

310

340

2.9

3.4

3.9

4.4

4.8

5.8

6.3

6.7

7.7

(6.4)

(7.5)

(8.5)

(9.6)

(10.6)

(12.7)

(13.8)

(14.8)

(16.9)

2.4

2.9

3.3

3.7

4.1

4.9

5.4

5.8

6.7

(5.3)

(6.3)

(7.2)

(8.1)

(9.1)

(10.9)

(11.9)

(12.8)

(14.7)

85-88

Typical all weld metal. (2)Measured with 0.2% offset. (3)See test results disclaimer on pg. 18. (4)As-Welded with 100% CO2. (5)To estimate ESO, subtract 1/4 in (6.0 mm) from CTWD.

(1)

W E L D I N G C O N S U M A B L E S C ATA L O G

127

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- E 399Document31 pagesE 399H_DEBIANEPas encore d'évaluation

- UltraCore HD-12C SuiteDocument1 pageUltraCore HD-12C SuiteH_DEBIANEPas encore d'évaluation

- UltraCore712A80 H SuiteDocument1 pageUltraCore712A80 H SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANEPas encore d'évaluation

- UltraCore HD-M SuiteDocument1 pageUltraCore HD-M SuiteH_DEBIANEPas encore d'évaluation

- Ultracore 71a85 SuiteDocument1 pageUltracore 71a85 SuiteH_DEBIANEPas encore d'évaluation

- Ultracore 71c SuiteDocument1 pageUltracore 71c SuiteH_DEBIANEPas encore d'évaluation

- UltracoreDocument3 pagesUltracorerpcampbellPas encore d'évaluation

- Metalshield MC-710XL: Conformances Key FeaturesDocument3 pagesMetalshield MC-710XL: Conformances Key FeaturesRumman Ul AhsanPas encore d'évaluation

- Ultracore 712A80: Conformances Key FeaturesDocument1 pageUltracore 712A80: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Metalshield MC-6 SuiteDocument1 pageMetalshield MC-6 SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 71A75 DualDocument1 pageUltraCore 71A75 DualH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANEPas encore d'évaluation

- Metalshield MC - 706 SUITEDocument1 pageMetalshield MC - 706 SUITEH_DEBIANEPas encore d'évaluation

- Ultracore 71A85: Conformances Key FeaturesDocument1 pageUltracore 71A85: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Metalshield MC - 706: Conformances Key FeaturesDocument3 pagesMetalshield MC - 706: Conformances Key FeaturesGerson HenriquesPas encore d'évaluation

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkePas encore d'évaluation

- Superarc La-75: Diameters / PackagingDocument1 pageSuperarc La-75: Diameters / PackagingH_DEBIANEPas encore d'évaluation

- Ultracore HD-M: Conformances Key FeaturesDocument1 pageUltracore HD-M: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Superglide S6: Diameters / PackagingDocument1 pageSuperglide S6: Diameters / PackagingH_DEBIANEPas encore d'évaluation

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANEPas encore d'évaluation

- Outershield MC - 409: Conformances Key FeaturesDocument2 pagesOutershield MC - 409: Conformances Key FeaturesNurPurnamaSariPas encore d'évaluation

- Outershield 71 SupremeDocument1 pageOutershield 71 SupremeH_DEBIANEPas encore d'évaluation

- Flux Cored WiresDocument43 pagesFlux Cored Wiresesltirchy0% (1)

- Metalshield MC - 80NI1 SUITEDocument1 pageMetalshield MC - 80NI1 SUITEH_DEBIANEPas encore d'évaluation

- SuperArc L 50NDocument1 pageSuperArc L 50NH_DEBIANEPas encore d'évaluation

- Metalshield MC-6: Conformances Key FeaturesDocument1 pageMetalshield MC-6: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Metalshield MC-710XL: Conformances Key FeaturesDocument1 pageMetalshield MC-710XL: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite: Conformances Key FeaturesDocument1 pageOutershield 71 Elite: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Dual Shield 7100 LC PDFDocument3 pagesDual Shield 7100 LC PDFNicolas MaximilianoPas encore d'évaluation

- FabCO 811N1Document2 pagesFabCO 811N1Sleyda MunozPas encore d'évaluation

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngPas encore d'évaluation

- FCAW For COR TEN Structure: Technical and Economical ConsiderationsDocument9 pagesFCAW For COR TEN Structure: Technical and Economical ConsiderationsDan PopaPas encore d'évaluation

- Innershield NR - 440ni2: Typical Applications Key FeaturesDocument1 pageInnershield NR - 440ni2: Typical Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- BL Q39a 42 PDFDocument5 pagesBL Q39a 42 PDFsorayanasiri70Pas encore d'évaluation

- SuperArc LA-100 SuiteDocument1 pageSuperArc LA-100 SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore 360 M81: Conformances Key FeaturesDocument3 pagesUltracore 360 M81: Conformances Key FeaturesDaniel Lvqve GarciaPas encore d'évaluation

- Outershield 71M: Conformances Key FeaturesDocument3 pagesOutershield 71M: Conformances Key FeatureswilmercristianPas encore d'évaluation

- Idalloy: C MN Si CR Mo V P S CuDocument1 pageIdalloy: C MN Si CR Mo V P S CuiocephPas encore d'évaluation

- Gst5009 Transformer NetworkDocument1 pageGst5009 Transformer Networkmanlu1001565Pas encore d'évaluation

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1Pas encore d'évaluation

- Metalshield MC - 110 SUITEDocument1 pageMetalshield MC - 110 SUITEH_DEBIANEPas encore d'évaluation

- FabCO 811N1 PDFDocument2 pagesFabCO 811N1 PDFAlejandroAcuñaMaureiraPas encore d'évaluation

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1Pas encore d'évaluation

- Tratos Flex000Document64 pagesTratos Flex000twinvbooksPas encore d'évaluation

- 71T-1C Carbon Steel Flux-Cored Wire: Cert # 05-R0925Document1 page71T-1C Carbon Steel Flux-Cored Wire: Cert # 05-R0925kanha15102003Pas encore d'évaluation

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoPas encore d'évaluation

- ACEA 2010 Oil SequencesDocument3 pagesACEA 2010 Oil SequencesamsoilromaniaPas encore d'évaluation

- Metalshield Clarity MC - 707: Conformances Key FeaturesDocument2 pagesMetalshield Clarity MC - 707: Conformances Key FeaturesRumman Ul AhsanPas encore d'évaluation

- Igus Control CablesDocument27 pagesIgus Control CablesigusukPas encore d'évaluation

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorPas encore d'évaluation

- G8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted ApplicationsDocument6 pagesG8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted Applicationsyocus_ooiPas encore d'évaluation

- Data Shett 8eth06pbDocument9 pagesData Shett 8eth06pbDolly Arthur SiregarPas encore d'évaluation

- Adsl 402Document9 pagesAdsl 402edward blancoPas encore d'évaluation

- Datasheet FuelCell Rev 100909Document2 pagesDatasheet FuelCell Rev 100909Radu Victor TapuPas encore d'évaluation

- Flyer Rotar FMR Rev3Document2 pagesFlyer Rotar FMR Rev3Catarino FloresPas encore d'évaluation

- SAW Filter 836mhzDocument5 pagesSAW Filter 836mhzAdolfo MoraPas encore d'évaluation

- ACPL312TDocument18 pagesACPL312Tcms_saPas encore d'évaluation

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDocument13 pagesThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Pas encore d'évaluation

- Aws A 5.10Document38 pagesAws A 5.10বিপ্লব পালPas encore d'évaluation

- Sample Questions For Welding EngineeringDocument8 pagesSample Questions For Welding EngineeringH_DEBIANEPas encore d'évaluation

- WPS 904a-3857-R1-1Document3 pagesWPS 904a-3857-R1-1H_DEBIANEPas encore d'évaluation

- Pages From ASME B-31-3Document91 pagesPages From ASME B-31-3H_DEBIANEPas encore d'évaluation

- Brosjyre Nemesis 9000Document12 pagesBrosjyre Nemesis 9000H_DEBIANEPas encore d'évaluation

- Outershield 71MDocument1 pageOutershield 71MH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANEPas encore d'évaluation

- Outershield 71 SupremeDocument1 pageOutershield 71 SupremeH_DEBIANEPas encore d'évaluation

- Outershield 71MDocument1 pageOutershield 71MH_DEBIANEPas encore d'évaluation

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite: Conformances Key FeaturesDocument1 pageOutershield 71 Elite: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12C: Applications Key FeaturesDocument1 pageUltracore Sr-12C: Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12M: Typical Applications Key FeaturesDocument1 pageUltracore Sr-12M: Typical Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12C: Applications Key FeaturesDocument1 pageUltracore Sr-12C: Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore 712A80-H: Conformances Key FeaturesDocument1 pageUltracore 712A80-H: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore Hd-12M: Conformances Key FeaturesDocument1 pageUltracore Hd-12M: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore Hd-12C: Conformances Key FeaturesDocument1 pageUltracore Hd-12C: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation