Académique Documents

Professionnel Documents

Culture Documents

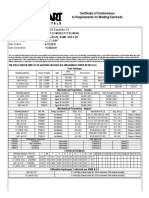

UltraCore SR-12C Suite

Transféré par

H_DEBIANECopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UltraCore SR-12C Suite

Transféré par

H_DEBIANEDroits d'auteur :

Formats disponibles

FLUX-CORED GAS-SHIELDED (FCAW-G) WIRE

UltraCore SR-12C

(AWS E71T-12C-JH8)

MECHANICAL PROPERTIES(1) As Required per AWS A5.36/5.36M

Charpy V-Notch

Yield Strength(2) Tensile Strength Elongation

J (ftlbf)

MPa (ksi)

MPa (ksi)

%

@ -40C (-40F) @ -46C (-50F)

Requirements

AWS A5.20 - E71T-12C-JH8

As-Welded with 100% CO2

AWS A5.36 - E71T1-C1A5-CS2-H8

As-Welded with 100% CO2

AWS A5.36 - E71T1-C1P5-CS2-H8

Stress Relieved 1hr. @ 620C (1150F) with

100% CO2

Test Results(3)

As-Welded with 100% CO2

Stress-Relieved 1 hr. @ 620C (1150F) with

100% CO2

480-620 (70-90)

400 (58) min.

480-655 (70-95)

27 (20) min.

27 (20) min.

27 (20) min.

47 (34)

-

61 (45)

92 (68)

22 min.

480-655 (70-95)

490 (71)

435 (63)

550 (80)

545 (79)

22

32

DEPOSIT COMPOSITION(1) As Required per AWS A5.36/5.36M

%C

Requirements

AWS A5.20 - E71T-12C-JH8 As-Welded with 100% CO2

AWS A5.36 - E71T1-C1A5-CS2-H8 As-Welded with

100% CO2

Test Results(3)

As-Welded with 100% CO2

TYPICAL OPERATING PROCEDURES

Diameter, Polarity

Shielding Gas

CTWD(4) Wire Feed Speed

mm (in) m/min (in/min)

4.4 (175)

6.4 (250)

0.045 in. (1.1 mm), DC+

7.6 (300)

As-Welded with

25 (1)

10.2 (400)

100% CO2

12.7 (500)

5.2 (600)

0.052 in. (1.3 mm), DC+

As-Welded with

100% CO2

1/16 in. (1.6 mm), DC+

As-Welded with

100% CO2

(1)

Typical all weld metal.

(2)

%Mn

%Si

%S

%P

%Ni

Diffusible Hydrogen

(mL/100g weld

deposit)

0.12 1.75 max. 0.90 0.03 max. 0.03 max. 0.50

max. 1.60 max. max. 0.030 max. 0.030 max. max.

0.05

Voltage

(Volts)

23-28

24-29

25-30

25-30

26-31

27-32

1.42

0.52

0.007

0.016

3.0 max.

0.02

5.9

Approx. Current Melt-Off Rate Deposition Rate Efficiency

(Amps)

kg/hr (lb/hr)

kg/hr (lb/hr)

(%)

115

1.8 (3.9)

1.5 (3.4)

140

2.5 (5.6)

2.1 (4.6)

155

3.1 (6.8)

2.6 (5.8)

85-88

185

4.1 (9.0)

3.4 (7.5)

215

5.1 (11.3)

4.4 (9.8)

245

6.1 (13.5)

5.1 (11.3)

25 (1)

3.8

6.4

8.9

10.8

12.7

(150)

(250)

(350)

(425)

(500)

23-28

25-30

26-31

26-31

27-32

140

180

225

255

290

2.1

3.5

5.0

6.0

7.1

(4.7)

(7.8)

(11.0)

(13.3)

(15.6)

1.7

3.0

4.2

5.1

6.0

(3.8)

(6.5)

(9.2)

(11.2)

(13.3)

85-88

25 (1)

3.8

5.1

6.4

7.6

10.2

(150)

(200)

(250)

(300)

(400)

22-27

23-28

24-29

25-30

26-31

200

230

255

300

360

2.9

3.7

4.8

5.5

6.7

(6.4)

(8.1)

(10.6)

(12.1)

(14.8)

2.4

3.0

4.1

4.6

5.8

(5.3)

(6.7)

(9.1)

(10.2)

(12.8)

85-88

Measured with 0.2% offset.

(3)

See test results disclaimer on pg. 18.

(4)

To estimate ESO, subtract 1/4 in. (6.0 mm) from CTWD.

W E L D I N G C O N S U M A B L E S C ATA L O G

133

Vous aimerez peut-être aussi

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANEPas encore d'évaluation

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANEPas encore d'évaluation

- Superglide S6: Diameters / PackagingDocument1 pageSuperglide S6: Diameters / PackagingH_DEBIANEPas encore d'évaluation

- Innershield NR 211 MP SuiteDocument1 pageInnershield NR 211 MP SuiteH_DEBIANEPas encore d'évaluation

- Innershield NR-212 SuiteDocument1 pageInnershield NR-212 SuiteH_DEBIANEPas encore d'évaluation

- Innershield NR 203 MP SuiteDocument1 pageInnershield NR 203 MP SuiteH_DEBIANEPas encore d'évaluation

- SuperGlide S3 ER70S3Document1 pageSuperGlide S3 ER70S3H_DEBIANEPas encore d'évaluation

- Metalshield MC - 90 SuiteDocument1 pageMetalshield MC - 90 SuiteH_DEBIANEPas encore d'évaluation

- Metalshield MC - 110 SUITEDocument1 pageMetalshield MC - 110 SUITEH_DEBIANEPas encore d'évaluation

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkePas encore d'évaluation

- Innershield NR-311 Ni SuiteDocument1 pageInnershield NR-311 Ni SuiteH_DEBIANEPas encore d'évaluation

- WCC Vs WCBDocument2 pagesWCC Vs WCBSATHISHKUMAR RPas encore d'évaluation

- Superarc La-75: Diameters / PackagingDocument1 pageSuperarc La-75: Diameters / PackagingH_DEBIANEPas encore d'évaluation

- 1756 Controllogix ChassisDocument14 pages1756 Controllogix Chassispustakam123Pas encore d'évaluation

- ControlLogix Technical Data - ChassisDocument12 pagesControlLogix Technical Data - ChassisWesleyNahPas encore d'évaluation

- UltracoreDocument3 pagesUltracorerpcampbellPas encore d'évaluation

- 1756 td006 - en eDocument14 pages1756 td006 - en eNguyễn TrươngPas encore d'évaluation

- As Catalog - enDocument1 pageAs Catalog - enRanndolf JavierPas encore d'évaluation

- Ultracore 712A80: Conformances Key FeaturesDocument1 pageUltracore 712A80: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Certificado de Cumplimiento Alambre 0.062Document2 pagesCertificado de Cumplimiento Alambre 0.062gizaloPas encore d'évaluation

- Cree Xlamp XP-G Leds: Product Family Data SheetDocument12 pagesCree Xlamp XP-G Leds: Product Family Data SheetLaura VerlindenPas encore d'évaluation

- Olympian GEP 450 PrimeDocument4 pagesOlympian GEP 450 PrimeMTU650100% (1)

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANEPas encore d'évaluation

- Carte Tehnica Panou Solar Cu Celule Monocristaline SunPower 345 WDocument4 pagesCarte Tehnica Panou Solar Cu Celule Monocristaline SunPower 345 WphatdoggPas encore d'évaluation

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345Pas encore d'évaluation

- Metalshield MC - 90: Conformances Key FeaturesDocument1 pageMetalshield MC - 90: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Xitanium Prog LeafletDocument8 pagesXitanium Prog LeafletCarlos Jose Sanchez EsparzaPas encore d'évaluation

- Third Generation Air Winch SeriesDocument6 pagesThird Generation Air Winch Seriesvkannan07666Pas encore d'évaluation

- API 2H Grade 50 Plates - Arrow Pipes & Plate IndustriesDocument5 pagesAPI 2H Grade 50 Plates - Arrow Pipes & Plate IndustriesYash MehtaPas encore d'évaluation

- Atv630 - Fusiveis e DisjuntoresDocument2 pagesAtv630 - Fusiveis e DisjuntoresKym VincentPas encore d'évaluation

- Technical Data & StandardsDocument4 pagesTechnical Data & StandardsmrhomPas encore d'évaluation

- Se UL1741 Short Circuit Currents Three Phase Inverters Tech NoteDocument2 pagesSe UL1741 Short Circuit Currents Three Phase Inverters Tech NoteoespanaPas encore d'évaluation

- Powerplus™ Technical Specifications: DescriptionDocument4 pagesPowerplus™ Technical Specifications: DescriptionkevinjcoffmanPas encore d'évaluation

- RelayDocument16 pagesRelayVasu Iyer100% (1)

- PL NB301Document5 pagesPL NB301Alaa ElsisiPas encore d'évaluation

- Alloy 7068 BrochureDocument6 pagesAlloy 7068 BrochuredaviescdPas encore d'évaluation

- Stratix Ethernet Switch Specifications: Technical DataDocument24 pagesStratix Ethernet Switch Specifications: Technical DatajesusortegavPas encore d'évaluation

- Low Hydrogen Mild Steel ElectrodesDocument6 pagesLow Hydrogen Mild Steel ElectrodesAdura OgunnuPas encore d'évaluation

- API Casing Color CodesDocument2 pagesAPI Casing Color CodesRajmohan BabuPas encore d'évaluation

- Low HydrogenDocument3 pagesLow Hydrogenseeralan balakrishnanPas encore d'évaluation

- Innershield NR - 305: Typical Applications Key FeaturesDocument1 pageInnershield NR - 305: Typical Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- 9Crmov-N: Typical Applications Key FeaturesDocument1 page9Crmov-N: Typical Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- The 85000 Series ProvidesDocument2 pagesThe 85000 Series ProvidesMauricio AndresPas encore d'évaluation

- CL Rtu-1 MCNDocument18 pagesCL Rtu-1 MCNArq Javier Larios ArciniegaPas encore d'évaluation

- Dados Tec - c2500Document5 pagesDados Tec - c2500Sandro MunizPas encore d'évaluation

- ATV900 Getting Started Annex NHA61583 01Document2 pagesATV900 Getting Started Annex NHA61583 01Daniel BravoPas encore d'évaluation

- Pipeliner 70S-G: Conformances Key FeaturesDocument2 pagesPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaPas encore d'évaluation

- BS ANT 5.15-5.875/60V - P/N 872444 Technical SpecificationDocument2 pagesBS ANT 5.15-5.875/60V - P/N 872444 Technical SpecificationИван КадигробPas encore d'évaluation

- Triplex Pump PDFDocument3 pagesTriplex Pump PDFArgonauta_navegadorPas encore d'évaluation

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoPas encore d'évaluation

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoPas encore d'évaluation

- 2-Stage Filter For 3-Phase Systems: Description ApplicationsDocument4 pages2-Stage Filter For 3-Phase Systems: Description ApplicationsRicardo UrioPas encore d'évaluation

- Vs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsDocument9 pagesVs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsrrebollarPas encore d'évaluation

- Total Temperature and Pressure ProbesDocument2 pagesTotal Temperature and Pressure ProbeszubbbuPas encore d'évaluation

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Soft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesD'EverandSoft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesPas encore d'évaluation

- E 399Document31 pagesE 399H_DEBIANEPas encore d'évaluation

- Outershield 71 SupremeDocument1 pageOutershield 71 SupremeH_DEBIANEPas encore d'évaluation

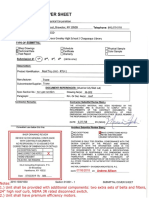

- WPS 904a-3857-R1-1Document3 pagesWPS 904a-3857-R1-1H_DEBIANEPas encore d'évaluation

- Ultracore Sr-12C: Applications Key FeaturesDocument1 pageUltracore Sr-12C: Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- Outershield 71 Elite: Conformances Key FeaturesDocument1 pageOutershield 71 Elite: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore712A80 H SuiteDocument1 pageUltraCore712A80 H SuiteH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore Sr-12M: Typical Applications Key FeaturesDocument1 pageUltracore Sr-12M: Typical Applications Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore HD-12M SuiteDocument1 pageUltraCore HD-12M SuiteH_DEBIANEPas encore d'évaluation

- UltraCore HD-M SuiteDocument1 pageUltraCore HD-M SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 71A75 DualDocument1 pageUltraCore 71A75 DualH_DEBIANEPas encore d'évaluation

- Ultracore 712A80: Conformances Key FeaturesDocument1 pageUltracore 712A80: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- UltraCore HD-12C SuiteDocument1 pageUltraCore HD-12C SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANEPas encore d'évaluation

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANEPas encore d'évaluation

- Ultracore HD-C: Conformances Key FeaturesDocument1 pageUltracore HD-C: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore 71c SuiteDocument1 pageUltracore 71c SuiteH_DEBIANEPas encore d'évaluation

- Ultracore HD-M: Conformances Key FeaturesDocument1 pageUltracore HD-M: Conformances Key FeaturesH_DEBIANEPas encore d'évaluation

- Ultracore 71a85 SuiteDocument1 pageUltracore 71a85 SuiteH_DEBIANEPas encore d'évaluation