Académique Documents

Professionnel Documents

Culture Documents

f-15 Rear Door Inner LH 8875 B Blank

Transféré par

api-273257329Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

f-15 Rear Door Inner LH 8875 B Blank

Transféré par

api-273257329Droits d'auteur :

Formats disponibles

Gestamp Union, South Carolina

Strain analysis service provided to AK Steel by Phoenix Services LLC

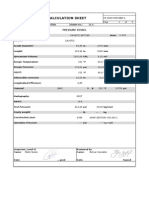

STATUS PANEL REPORT

Report No. :

NA

Rear Door Inner LH "B" Blank

7288875

NA

NA

12/17/13

N/A

Part Name :

Part Number :

Line No. :

Forming Date :

Report Date :

Reason for Report:

Formability Status : SAFE 16%

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

7288875

Date of Forming: NA

Material

Steel Supplier: AK Steel

Coil ID: NA

Grade: CR 5

Coil Width: NA

Coating: Hot Dipped

Blank Size:

NA

X

NA

Specified Gage: NA

Blank Shape: NA

Blank Loc. Analysis: NA

Blanked At: NA

Mechanical Properties

Yield

Tensile

Elongation

N- Value

R- Value

Strength

Strength

in 2 inches

Mpa

Mpa

%

(-3 sigma)

NA

NA

NA

NA

NA

Lubricant

Mill

Press Line

Type: NA

Type: NA

Application Method: NA

Application Method: NA

Amount: NA

Amount: NA

Location: NA

Location: NA

Press/Die

Press Number: NA

Cushion Pressure: NA

Die Material: NA

Bolster:

NA

X

NA

Shut Height Inner: NA

Press Speed: NA

Shut Height Outer: NA

Type of Form: NA

Counterbalance Inner: NA

Surface Treatment: NA

Counterbalance Outer: NA

Blocks and Shims: See Setup Recipe

Press Loads

Inner Ram (Kn)

Left Rear Inner:

NA

Right Rear Inner:

NA

Left Front Inner:

NA

Right Front Inner:

NA

Inner Ram Total:

NA

Outer Ram (Kn)

Left Rear Outer:

NA

Right Rear Outer:

NA

Left Front Outer:

NA

Right Front Outer:

NA

Outer Ram Total:

NA

Current Strain Status

Safe: N/A

Marginal: N/A

Failure: N/A

Circle Grid Analysis

FLDo:

36.2

Marginal Zone:

26.2

Pt. 1:

16

7

Pt. 9:

10

6

Pt. 17: N/A

N/A

Pt. 25: N/A

N/A

Pt. 2:

15

5

Pt. 10:

21

3

Pt. 18: N/A

N/A

Pt. 26: N/A

N/A

Pt. 3:

14

4

Pt. 11:

15

8

Pt. 19: N/A

N/A

Pt. 27: N/A

N/A

Pt. 4:

12

4

Pt. 12:

22

-2

Pt. 20: N/A

N/A

Pt. 28: N/A

N/A

Pt. 5:

8

0

Pt. 13:

18

3

Pt. 21: N/A

N/A

Pt. 29: N/A

N/A

Pt. 6:

14

5

Pt. 14: N/A

N/A

Pt. 22: N/A

N/A

Pt. 30: N/A

N/A

Pt. 7:

11

3

Pt. 15: N/A

N/A

Pt. 23: N/A

N/A

Pt. 31: N/A

N/A

Pt. 8:

14

1

Pt. 16: N/A

N/A

Pt. 24: N/A

N/A

Pt. 32: N/A

N/A

Ultrasound Thickness

Critical Thickness:

0.584

Marginal Thickness:

0.630

Pt. 1:

0.6540

Pt. 9:

0.6940

Pt. 17:

N/A

Pt. 25:

N/A

Pt. 2:

0.6500

Pt. 10:

0.6440

Pt. 18:

N/A

Pt. 26:

N/A

Pt. 3:

0.6730

Pt. 11:

0.6380

Pt. 19:

N/A

Pt. 27:

N/A

Pt. 4:

0.6800

Pt. 12:

0.6620

Pt. 20:

N/A

Pt. 28:

N/A

Pt. 5:

0.7300

Pt. 13:

0.6470

Pt. 21:

N/A

Pt. 29:

N/A

Pt. 6:

0.6710

Pt. 14:

N/A

Pt. 22:

N/A

Pt. 30:

N/A

Pt. 7:

0.6850

Pt. 15:

N/A

Pt. 23:

N/A

Pt. 31:

N/A

Pt. 8:

0.6830

Pt. 16:

N/A

Pt. 24:

N/A

Pt. 32:

N/A

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

Date of Forming: NA

7288875

Observations

"B" blank portion of door inner is 14% safe strain state as evaluated using Circle Grid analysis

supported with ultrasonic thickness readings.,

Analyst was not present when Panel was gridded or formed.

No press settings or die recipe were recorded at time of forming.

Coil number was not available, analysis based on actual thickness measured on formed part

and minimum specified "N" value.

Binder surface show wrinkles at bottom of door then opposite hand panel.

Blank material remains on binder surface outside bead, above window header area after

forming.

Material left on binder at front and rear of window opening is well balanced with no excess

blank on binder after forming (no opportunity from blank reduction).

Recommendations

Second die redraws hinge area of panel deeper. A circle grid evaluation of that forming

operation should be conducted prior to chroming the draw die.

Review weld line location on punch and binder surfaces to document location of blank. Use

this panel as guide in reviewing potential relocation (regauging) of Right hand Rear door blank.

A review of press log for potential set-up changes on this die should be reviewed. If no

changes are documented, a current production draw panel should be obtained, with press and

die recipe recorded.

A thinning analysis and panel comparison should be conducted to verify that Circle Grid panel

matches current production conditions.

If thickness and quality checks confirm part duplication, press and die settings should be

established as production recipe.

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

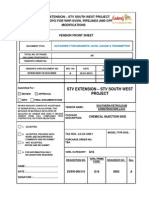

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

Date of Forming: NA

7288875

Forming Limit Diagram

90

80

70

Critical

% Major Strain

60

50

Marginal

40

30

Safe

20

12

10

13

10

1

32

6 11

74 9

0

-30

-20

-10

10

20

% Minor Strain

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

30

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

Date of Forming: NA

7288875

Final Thickness

Thickness Strain Analysis

0.000

Data Points

0.100

Critical Thickness

0.200

Marginal Thickness

Original Thickness

0.300

0.400

0.500

0.600

0.700

Safe

0.800

0.900

11 13 15 17

19 21 23

25 27 29

Measurement Point

Critical Thickness

Marginal Thickness

Original Thickness - Inches

Minimum n - VALUE

FLDo

FLD Marginal

0.584

0.630

0.795

0.220

36.2

26.2

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

31

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

Date of Forming: NA

7288875

4

2

5

6

12

13

8

10

11

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

Part Name: Rear Door Inner LH "B" Blank

Die Number: NA

Part Number:

Date of Forming: NA

*** WHEN PRINTED THIS BECOMES AN UNCONTROLLED COPY ***

7288875

Vous aimerez peut-être aussi

- f-15 Front Door Inner LH 8855 B BlankDocument8 pagesf-15 Front Door Inner LH 8855 B Blankapi-273257329Pas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- f-15 Rear Door Inner LH 8875 A BlankDocument7 pagesf-15 Rear Door Inner LH 8875 A Blankapi-273257329Pas encore d'évaluation

- How to Rebuild & Modify Rochester Quadrajet CarburetorsD'EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsÉvaluation : 5 sur 5 étoiles5/5 (2)

- F 15 Front Door Inner LH 8855 A BlankDocument7 pagesF 15 Front Door Inner LH 8855 A Blankapi-273257329Pas encore d'évaluation

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2D'EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Pas encore d'évaluation

- GA Sample Full ICOG PDFDocument17 pagesGA Sample Full ICOG PDFAnagha DebPas encore d'évaluation

- HP 1Document12 pagesHP 1api-273257329Pas encore d'évaluation

- Model-7 (1-4)Document23 pagesModel-7 (1-4)Sayyed FaqruddinPas encore d'évaluation

- 14-7-15 f25 Bodyside Outer LH 2122Document10 pages14-7-15 f25 Bodyside Outer LH 2122api-273257329Pas encore d'évaluation

- Quotation For WINORAC PriceDocument2 pagesQuotation For WINORAC PriceKasarachi AmadiPas encore d'évaluation

- GA Sample Full ICOG PDFDocument17 pagesGA Sample Full ICOG PDFSundaresan SabanayagamPas encore d'évaluation

- 8 March 2022Document14 pages8 March 2022Kasarachi AmadiPas encore d'évaluation

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Pas encore d'évaluation

- Modernización de refinería proyecto acumulador de condensadoDocument3 pagesModernización de refinería proyecto acumulador de condensadoeskra garzonPas encore d'évaluation

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- OOO OOO PPPP Hhhi Iiiiiiii: DesarrolloDocument5 pagesOOO OOO PPPP Hhhi Iiiiiiii: DesarrolloRaulCaballeroCubasPas encore d'évaluation

- Setup Sheet Report: Doosan Lynx 220LMYDocument10 pagesSetup Sheet Report: Doosan Lynx 220LMYMiguel Angel MartinezPas encore d'évaluation

- Data Sheet Fuel Gas Filter Rev 0Document22 pagesData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoPas encore d'évaluation

- Weld Map Pressure VesselDocument32 pagesWeld Map Pressure Vesseljasmineamma100% (4)

- Calculation Sheet: Pressure VesselDocument8 pagesCalculation Sheet: Pressure Vesselbgonzalez1981Pas encore d'évaluation

- Vessel CalculationDocument106 pagesVessel CalculationBhadresh PatelPas encore d'évaluation

- Service Manual: MODEL: MACRO830/1400/2400Document38 pagesService Manual: MODEL: MACRO830/1400/2400Osmar ContreirasPas encore d'évaluation

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocument11 pagesB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskPas encore d'évaluation

- Pt. Bahana Karya Mandiri: Data SheetDocument8 pagesPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoPas encore d'évaluation

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- W8x28 Beam To W6x15 Column CalcDocument8 pagesW8x28 Beam To W6x15 Column CalcDinesh GuruPas encore d'évaluation

- Air Receiver Sample CalcDocument49 pagesAir Receiver Sample CalcBrian Edwin RodriguezPas encore d'évaluation

- Informe Inspección V324 REV1Document9 pagesInforme Inspección V324 REV1bgonzalez1981Pas encore d'évaluation

- SR5080 Booklet Finisher RTBsDocument22 pagesSR5080 Booklet Finisher RTBsTecnica CPY Copiadoras del ParaguayPas encore d'évaluation

- Event Electronics ASP8 Amplifier Service Manual and BOMDocument7 pagesEvent Electronics ASP8 Amplifier Service Manual and BOMt1o2m3Pas encore d'évaluation

- STV SW Project Level Gauge DatasheetDocument4 pagesSTV SW Project Level Gauge Datasheetnguyenquoc1988Pas encore d'évaluation

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellPas encore d'évaluation

- Spare Parts CatalogDocument75 pagesSpare Parts Catalograhulmahajan_b100% (1)

- Sello Mecánico PDFDocument3 pagesSello Mecánico PDFatenciajPas encore d'évaluation

- Spec Sheet for Steam Globe ValveDocument3 pagesSpec Sheet for Steam Globe ValveGastonBalcarcelPas encore d'évaluation

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Chetak Spare Parts Catalog Rev Dec 2004Document75 pagesChetak Spare Parts Catalog Rev Dec 2004mnc19Pas encore d'évaluation

- Tank Calculation Kasikan Gs Rev BDocument20 pagesTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocument6 pagesTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutPas encore d'évaluation

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Sko0061283 R2Document52 pagesSko0061283 R2ciwidop390Pas encore d'évaluation

- Parts Catalogue Elegan 250absDocument113 pagesParts Catalogue Elegan 250absHairulIzhamIshakPas encore d'évaluation

- V383773001X00 PDFDocument4 pagesV383773001X00 PDFSIVAPas encore d'évaluation

- Ap Racing Ibiza Cupra cp6607-30cd - Sheet1Document1 pageAp Racing Ibiza Cupra cp6607-30cd - Sheet1Gabriele BertaggiaPas encore d'évaluation

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Piping Material SpecificationDocument50 pagesPiping Material Specificationroxym123456Pas encore d'évaluation

- 100-155 Filter and Heater UnitDocument3 pages100-155 Filter and Heater Unitapi-290859192Pas encore d'évaluation

- APNEA-J-DSH-0002 Rev. 1Document3 pagesAPNEA-J-DSH-0002 Rev. 1Michelle MartinezPas encore d'évaluation

- 7 Drawing Shown Same As Specification DSP - 34-1974 P.A.T. T.Nkam Bule V.SINGH 11.04.2011Document3 pages7 Drawing Shown Same As Specification DSP - 34-1974 P.A.T. T.Nkam Bule V.SINGH 11.04.2011atholPas encore d'évaluation

- Gasmin Draw PDFDocument17 pagesGasmin Draw PDFRizzal JosePas encore d'évaluation

- Details of BracketDocument15 pagesDetails of BracketVenkatesh ArumugamPas encore d'évaluation

- FW PumpDocument15 pagesFW PumpAJAY1381100% (1)

- Column-Beam Connection Design Calculation SheetDocument13 pagesColumn-Beam Connection Design Calculation SheetShamik Ghosh0% (1)

- Air ConditionerDocument74 pagesAir Conditionermuzaaj100% (1)

- Sample13 DrawingDocument2 pagesSample13 DrawingSourav HaitPas encore d'évaluation

- Catalogo de Partes - Bajaj LEGENDDocument75 pagesCatalogo de Partes - Bajaj LEGENDAlexander Muñetón Be.Pas encore d'évaluation

- RFI Material Varioust HOSE-VendorDocument24 pagesRFI Material Varioust HOSE-Vendorychandra495Pas encore d'évaluation

- Rev 12Document2 pagesRev 12api-273257329Pas encore d'évaluation

- Gestamp Monthly Action PlanDocument3 pagesGestamp Monthly Action Planapi-273257329Pas encore d'évaluation

- CustomerDocument4 pagesCustomerapi-273257329Pas encore d'évaluation

- 2092 Rev 2Document2 pages2092 Rev 2api-273257329Pas encore d'évaluation

- Rev 12Document2 pagesRev 12api-273257329Pas encore d'évaluation

- Rev 10Document3 pagesRev 10api-273257329Pas encore d'évaluation

- Rev 10Document3 pagesRev 10api-273257329Pas encore d'évaluation

- Corrective Action Request (CAR) 8-Discipline Steps: Form DescriptionDocument3 pagesCorrective Action Request (CAR) 8-Discipline Steps: Form Descriptionapi-273257329Pas encore d'évaluation

- Rev 8Document2 pagesRev 8api-273257329Pas encore d'évaluation

- Rev 8Document2 pagesRev 8api-273257329Pas encore d'évaluation

- 8d Gestamp Ak 4 Lamination and Inclusions Rev 2Document4 pages8d Gestamp Ak 4 Lamination and Inclusions Rev 2api-273257329Pas encore d'évaluation

- Ak-2 Class A Release Criteria Rev 3Document4 pagesAk-2 Class A Release Criteria Rev 3api-273257329Pas encore d'évaluation

- HSM Gouges and Scratches: Continuous Improvement Action ItemsDocument1 pageHSM Gouges and Scratches: Continuous Improvement Action Itemsapi-273257329Pas encore d'évaluation

- 2085 Rev 6Document1 page2085 Rev 6api-273257329Pas encore d'évaluation

- Lamination Ci Update Nov 2014Document6 pagesLamination Ci Update Nov 2014api-273257329Pas encore d'évaluation

- 10-2-2014 Gestamp Part 2302Document7 pages10-2-2014 Gestamp Part 2302api-273257329Pas encore d'évaluation

- HP 2Document10 pagesHP 2api-273257329Pas encore d'évaluation

- Gestamp - Eg Body Side - Surface FeaturesDocument9 pagesGestamp - Eg Body Side - Surface Featuresapi-273257329Pas encore d'évaluation

- 05aDocument1 page05aapi-273257329Pas encore d'évaluation

- 14-7-15 f25 Bodyside Outer LH 2122Document10 pages14-7-15 f25 Bodyside Outer LH 2122api-273257329Pas encore d'évaluation

- 2122 Rev 8Document1 page2122 Rev 8api-273257329Pas encore d'évaluation

- Defectmanual 2Document37 pagesDefectmanual 2api-273257329Pas encore d'évaluation

- Surgical Nursing Calculation PracticesDocument2 pagesSurgical Nursing Calculation PracticesJéssica OinonenPas encore d'évaluation

- PERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Document10 pagesPERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Angel Ombid100% (1)

- Profile Prince Decoware Furniture HandlesDocument54 pagesProfile Prince Decoware Furniture HandlesRushabh ShahPas encore d'évaluation

- Evs Exercise Week 1 Vura Sai Nikhil 210953204Document11 pagesEvs Exercise Week 1 Vura Sai Nikhil 210953204Nikhil VuraPas encore d'évaluation

- AL REScheck CertificateDocument6 pagesAL REScheck Certificatebcap-oceanPas encore d'évaluation

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイPas encore d'évaluation

- Chemistry SBA7 ReportDocument6 pagesChemistry SBA7 ReportSam ChanPas encore d'évaluation

- Constant HeadDocument14 pagesConstant HeadfujiPas encore d'évaluation

- Waterproofing: Hydrostop 4 Py-SDocument2 pagesWaterproofing: Hydrostop 4 Py-SPrashantBaruaPas encore d'évaluation

- Applied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinDocument10 pagesApplied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinEko RaharjoPas encore d'évaluation

- Power Distribution at NFC EeeDocument70 pagesPower Distribution at NFC EeeTeEbhan ChAnthira SeEkaranPas encore d'évaluation

- Water WastewaterDocument20 pagesWater WastewaterterryjoseePas encore d'évaluation

- Final - Report Hydroelectric Power PlantDocument39 pagesFinal - Report Hydroelectric Power PlantnisarPas encore d'évaluation

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 pagesPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- Insect PestsDocument164 pagesInsect PestsKenneth100% (11)

- Selig Sealing ProductsDocument60 pagesSelig Sealing Productslaurentiu29Pas encore d'évaluation

- ANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleDocument12 pagesANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleParmeshwarPaulPas encore d'évaluation

- Astm D1785-15Document11 pagesAstm D1785-15david franco0% (1)

- Distillation Lecture Note-2Document20 pagesDistillation Lecture Note-2BasseyPas encore d'évaluation

- SeminarDocument15 pagesSeminarAditi ChandraPas encore d'évaluation

- Top 305 Companies in Pune RegionDocument39 pagesTop 305 Companies in Pune RegionNiraj Thakkar0% (1)

- Dust Collection Design and Maintenance GuideDocument36 pagesDust Collection Design and Maintenance GuideMadan YadavPas encore d'évaluation

- Deltaweld 652Document26 pagesDeltaweld 652Hugo RodriguezPas encore d'évaluation

- Literature Review 26 JuneDocument42 pagesLiterature Review 26 JuneSanjeev NehruPas encore d'évaluation

- Thermodynamics Chapter OverviewDocument40 pagesThermodynamics Chapter OverviewdeusleanPas encore d'évaluation

- 20b. Global S CycleDocument15 pages20b. Global S CyclerossydaPas encore d'évaluation

- Redox Reactn McqsDocument12 pagesRedox Reactn McqsIlma GaurPas encore d'évaluation

- RE - Unit 1Document84 pagesRE - Unit 1Faraj NabiyevPas encore d'évaluation

- CAB Cable Rings and SaddlesDocument5 pagesCAB Cable Rings and SaddlesgoyalmanojPas encore d'évaluation

- Coating and Drying Defects: Troubleshooting Operating ProblemsD'EverandCoating and Drying Defects: Troubleshooting Operating ProblemsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeD'EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeD'EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeD'EverandChemistry for Breakfast: The Amazing Science of Everyday LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (14)

- The Periodic Table: A Very Short IntroductionD'EverandThe Periodic Table: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsD'EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsÉvaluation : 4 sur 5 étoiles4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableD'EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilD'EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilÉvaluation : 5 sur 5 étoiles5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeD'EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeÉvaluation : 4 sur 5 étoiles4/5 (9)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksD'EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksÉvaluation : 5 sur 5 étoiles5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingD'EverandIt's Elemental: The Hidden Chemistry in EverythingÉvaluation : 4 sur 5 étoiles4/5 (10)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolD'EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolPas encore d'évaluation

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsD'EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeD'EverandChemistry for Breakfast: The Amazing Science of Everyday LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (90)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableD'EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TablePas encore d'évaluation

- Napoleon's Buttons: 17 Molecules That Changed HistoryD'EverandNapoleon's Buttons: 17 Molecules That Changed HistoryÉvaluation : 4 sur 5 étoiles4/5 (25)

- Guidelines for Asset Integrity ManagementD'EverandGuidelines for Asset Integrity ManagementÉvaluation : 5 sur 5 étoiles5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeD'EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeÉvaluation : 4 sur 5 étoiles4/5 (1)

- The History of Chemistry (Vol.1&2): Complete EditionD'EverandThe History of Chemistry (Vol.1&2): Complete EditionÉvaluation : 1 sur 5 étoiles1/5 (1)

- Chemistry: a QuickStudy Laminated Reference GuideD'EverandChemistry: a QuickStudy Laminated Reference GuideÉvaluation : 5 sur 5 étoiles5/5 (1)

- Perfume Engineering: Design, Performance and ClassificationD'EverandPerfume Engineering: Design, Performance and ClassificationÉvaluation : 4 sur 5 étoiles4/5 (5)