Académique Documents

Professionnel Documents

Culture Documents

Mondi Brochure1

Transféré par

thoma111s0 évaluation0% ont trouvé ce document utile (0 vote)

158 vues16 pagesssd

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentssd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

158 vues16 pagesMondi Brochure1

Transféré par

thoma111sssd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 16

}

,

ae 8

Acid Piping Technology, Inc. //,

[

Cah

TTC eg

Amy r 1

Sulfuric

Yama

Cent

Series

Seid

MONDI™ Piping Systems—Proven Performance

MONOI, a special ally of ductile ion wit unique metalluray

was developed to hance 92-99% suri acid at temperatures

up to 300° F (145°).

‘Acid Piping Technology's MONI systems offer you unique

improvements i

+ MONDI metallurgy

+ Heavy wal thickness

+ Fitting design

+ Flange face fish

+ Sten Bing Faun Gylen™ gasket

APT’s experience and commitment to quality deli

Superior Performance

These features result in superior piping systems that wil

provide 20 plus years of excallent sevice:

+ Superior dutty eliminates the catastrophic failure

and breakage that can occur with bile gray cas ion.

+ Pipe and fitings hae durable heavy wall construction

+ Mast patterns for itings have been imgroved to

eliminate chaplets,

+ Special lange fae finish has serrated spiral gives

with a pointed profile that bites into the gasket for a

ight sea

+ APT's special step gasket

is made of Fan Gon.

It provides an excellent seal

inthe critical sealing area at the

ibe inside diameter.

MONDI’s Benefits Improve Plant Reliability

Proven Technology

MONDE has been the industry standard for reliable performance

in sufi acid piants since 1983. APT has supplied over 700

MONDE systems in North America, South America, Australi,

Arica and Asa sine 1981.

Long Operating Lite

Reduced maintenance witha sence life up to four ties

the life of standard metallurgy ductile ion,

Operating Safety

collet ductility and durable contruction provides soe,

{rouble-tre operation

Environmental

‘Special lange face finish and step ring gasket provides a tight

lealfree seal at the pipe LD. These Fawn Gylon step ring

gaskets have excellent recovery to thermal cyling over years of

‘operation and excellent resistance to hot concentrated acid.

Resistance ta Concentration Changes

‘tough sua fl provides corrosion resistance when weaker

acids formed due to process upset or shutdown contions.

Cost-tective and Easy To Retrofit

APT's piping systems are the most economical systems

providing very reliable performance. MONDI piping can be used

to retrofit existing systems.

Acid

MONO Flange Piping

Gaskets

Tower Internals

Converter Internals

Aly Piping

Valves and Instrumentation

rs the most cost-effective piping systems available

ing Technology Products include:

Pipe Spools

Fitings

Special Bossd Fitings

Sleeves and Nozze Liners

Toner Distributor Fitings

Reducing Flanges

Spacers

Thermowells

Step Ring

[MOND Distributors

Troughs and Downspouts

Spargers

Drilled Pipes

Ceramic Packing Saddles

‘and Supports

vids

Division Piates

‘Support Columns

Pipe and Fittings

rice Plates

Bolts

Pine Hangers

Valves

Actuated Valves

Instrumentation

MONDI Corrosion Resistance

Reliability, economical cost, ong service fe and demonstrated

performance are very important eritera for sulture acd piping

systems, MONDI piping meets all ofthese criteria and has dem

‘onstrated low corrosion rates in acd plants since 1983.

Measured corrosion rates from many years of actual plant oper-

‘ation are the true measure of MONDI performance. The

initial corrosion of MONDL i higher as te tough suifat film

is formed onthe surface. after formation this sulfate film

remains to protect the surface and corrasion rate is greatly

reduced. The resuiting low corrosion rate provides piping

system relly, long service life and exellent performance.

‘Sometime during the operation of an acid plant, the acid

‘concentration nthe drying or absorbing systoms wll experince

a weaker acid excursion due to process upset or equipment

rmlfunction, Weaker acé excursions below 96% wil accelerate

corrosion to austenitic stainless ste! piping

‘and decease its service ie. Many plants have reported that

their MONDI piping systoms with 939% have operated through

weaker acid excursions. These plants also reported thatthe

MOND piping di nat show significant corrosion after the excur-

sions. MOND pining is very foriving and provides reliable sys

‘tem performance

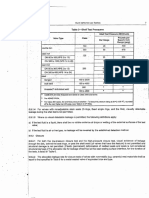

Plant Corrosion Rate-MONDI Piping

MONDI's Corrosion Resi

‘The following i @ comparison of MOND piping and Austenitic

Stainless Ste! pining systems,

MONDI Stainless Steel

System

System Flanged Welded

Maintenance Requirements Simpl Sills Special Welding

Basic Hand Technique with

Tools High End

Fauipment

Velocity Fet/second 68s 810

Wall Thickness 14” Size Pipe 0.66 25

Fitings 0.89" 025°

Corrosion Rate Mils/Year 5-10 35

Cost Economical 3-5 Times

Higher

Avalbilty Large ”

Inventory

3 Locations

lance Provides Reliability

The APT Assurance of Quality

‘Our personal assurance of quality backs p every product

|we make. The prncinals of Acid Piping Technology have

‘ver BD years combined experience in providing products

tthe suifric acid indusry. Tere isnot a product which

leaves ou plan, ora service delivered to you, that does

not cary our personal uarantee.

You nave our word ont

ef be

4 knoll

President

ality Assurance. Al APT cast pipe and fitings are

produced in state-of-the-art foundries. Chemical and physical

tests are performed on each foundry heat with material

certification for traceability.

Testing. All MOND! pipe is hydrostatcally tested to 500 ps

‘and ultrasonic thickness tests are performed in close incre-

‘ments when manufactured. Flange pipe spools are air tested

under water at 50 psi to ensure thread seal and pipe integrity.

Inspection. Materials are subjected to rigorous 100%

inspection for quality, workmanship, dimensions and review

‘of pertinent materia erticaions. Additional testing

includes hardness tests and crass sectional examination of

random castings.

(ur quality contro process is your assurance that APT products

wil povie years of excellent performance.

Extensive Stock and Quick Turnaround

Assures Exceptional Service

APT's inventory availability wll minimize your downtime.

‘Our extensive stock of MONDI pipe and standar¢ fitings is

‘the largest inventor in the world. Whether your needs are

routine or emergency, you can count on APT ta have what you

reed when you need it

APT stocks 3” through 30” size in pipe and flanges and 2”

‘hough 30” siz in fitings. We stock approximately 2000

fittings with a fll range of sizes in standard elbows, tees

and reducers available fo same day shipment. This stock

can realace the complete oipna systems in two 3000 T/D

acd plants.

Special fitings, tower distributors, converter internals and

other products are cast o order and are shipped ina timely

schedule to meet your requirements. This reduces downtime

and provides the correct repair for your pant.

Pariadic visits by APT professionals provide support to your

plant personne! for our products

MONDI’s Pipe and Fittings Ha

Flanged Pipe Spools Are Machined

For Leak-Free Seal

Ty HJ AI APT pipe spools are

sally cast MONDT poe with

the proper heavy wall

thickness and special

Hib threaded anges.

Spools are manufactured in

‘accordance wit ANSE stan

dards 021.51 and AZ.

Maximum spool lengths for

3" (mm) through 6” (150 mm) sizes 195 fet (5944nm),

8 (200mm) through 30”

(750 mm) sizes have a maximum length of 17.5 fet

(6334 mn), Flanges have ANST25 psi ol pattems or other

Standard paters.

Pipes ct to the required length and threaded tae

tolerances to match each flange thread and taper. Flanges

‘are tightened toa spectc torque for leakfree pipe-fiange

thread sal Flange centrlines and bolt holes are aligned to

proper poston in our custom mactine. Spools wth special

‘lange rotation ae aged inthis macine which eiintes errs.

Fange faces and end of pine are machined flat and

perpendicular tothe pine barrel with a special phonograpic

finish. Flange faces are protected with rust preventative

and lange covers if roquied

MONOI fittings are cast in special patterns with heavy wall

thickness for large corrosion allowance needed inthe acid

industry These patterns have thicker wal than 250 psi

ductile iron patters. See wall thickness by size for our pipe

and ftings. For example ~2 14” 90° MOND elbow has a

wall thickness of 0:82" and weight of 330 pounds versus a

wall thickness of 0.66" for 250 psi ductile iron and weight

of 250 pounds use inthe water industry.

Center to face dimensions meet ANSI/AWIWA C110/AZ1.10,

standards. The inside diameter ofthe itings matches the

inside ciameter ofthe pipe. Flanges have ANS 125 psi bolt

ling or other bolt ling if required. Bosse fitings and

other special fitings are avaiable

Patterns for tings ae designed to virtually eliminate all

chaplets. When a chapet must be use, itis made of MONDI

with a special finned design which fuses into the fiting. APT

fittings have both the MONOL metallurgy and heavy wall

thickness for superior performance.

Flange facas have the special phonographicfnish which bites

into the gasket for a proper seal. Flanges faces are protected

with rust preventative and lange covers if requirad,

WALL WEIGHT FLANGE BOLT FLANGE BOLT BOLT NO. GASKET

THICK LB/FT. O.D.IN. CIRCLE THICK HOLE DIA. BOLTS 1.0.0.

IN WIN OIN, IN IN. IN.

ou 122 «750 «60 «075 07S 325 537

VB 900750 0940758 400 687

311100950 1000875 600 875

a4 us us 12 oo Os 800 11.00

586 ©1600-1425 «119 Loo 1000 1337

767 1900 1700125 «10087 1200 1612

%5 200 16751372100 1400 1775

M68 35020 1600 2025

93 500-2275«156 15 1800 216

1678-750 5.00 13 1 7000 23.87

707 3200 2950 fe) 2400 2825

372538753600 137135 2975 3475

SHORT RADIUS SHORT RADIUS LONG RADIUS

DIMENSIONS-IN. WEIGHT-LB. ‘90°

90° 45° DIM.-IN. WEIGHT

CEGEe 6908 ass Cr LB

diye ea 775 2B

4 6 «800 6

pi eee ss ist 5 7

$5 590100 us ues

65 1650 20 mow

7s 25 15 «100 350

ee) 2150 —_—

0 2400 on - ]

pay aes a a toxe naps}

2m 080 mow |

ies 7010

1354s 20

us Stringent Quality eNOS

la Oy

FLANGED CONCENTRIC AND FLANGED TEES

pate ea tala) AND CROSSES

SIZE-IN. _DIMENSIONS-IN. WEIGHT SIZE-IN. DIMENSIONS-IN. WEIGHT-LB.

1G. SM. T LENGTH LB. RUN BRANCH RUN BRANCH TEE CROSS.

FF i

048 60 oss

052 70 ase

055, 20

060 m0

068 320

075 140

082 160

180

0.96 wo

20

116 240

137 300

8

8

6

38

15

96

150,

70

0

a0

x0

a0

70

es

aio

75

As

‘Wen ordering reducing ities,

ive sie of each opening by sequence

of the ltters a, b,c and

SSR eeeeEeR

Multi-Purpose Bossed Fittings Reduce

System Costs and Save Space

'MONDI fittings are used for flanged connections of

Bosses are adel tothe outside

recice the wal thickness or service life o

all ofthe iting and donot

Using @ boss will make the fting mult-purpose and can

simply a piping system to reduce costs. Bosses are typically

used on elbows and tees and can be placed at diferent

locations. The diameter of the boss matches the outside

ameter ofthe connecting lange. The face ofthe boss is

drilled and tapped for stud bolts and machine for a good

gasket surface. Bosses are used for 1/2" to 12" size

flanged connections.

‘ee te information for boss location and sizes avaliable.

Contact APT for boss locations on other types of fitings

f required

[BOSS LOCATION

1

Juce System Cost

Spacers For System Fit-Up Simplify Installation

‘Snacersasitin instalation of the piping system. We

recommend that a spacer be used in each horizontal and

vertical run of piping to adust for dimensional ferences.

Spacers are avaiable as filer flanges and ring spacers.

Spacers can be machined in the field during system itup.

‘This is important for existing piping systems where dimen-

sions may have changed due to seting of foundations over

the years,

Fier flanges are fll face with fle bolt hoes and spiral

‘groore phonograph nish on both sides fora good gasket

surface. They match the pipe inside diameter and flange

outside ciameter. They are available in sizes 3" through 30”

and thickness as required fr system. We maintain

stock of /2", 1", 2" and 3” thick ier flanges in the

diferent pipe sizes.

During field fitup, tapered file flanges can be used if mating

flanges are nt paral.

Ring spacers match the pipe inside diameter and ft inside the

‘lange bot cle. They ar avaliable in 3” trough 30” sizes

in specific thicknesses or in standard 12" length. The

standard 12" length can be cut tothe required thickness

and machined with a gasket surface.

Retrofit MONDI Systems To Metric Systems

'MONDI piping with ANSI.125 ps flanges and conter to face

dimensions utilize the avaiable itings patterns and pipe

sizes alan economical cost. Any ferences between center

to face dimensions of ANSI ftngs and metric fittings can be

adjusted by length ofthe spools. Piping elevations ané length

of pve uns canbe easily maintained.

Metric or otter Asian, European or South American standard

‘connections can be joined atte tie-in points with an adapter

spool or adapter flange as sown. For adapter spools one

‘lange i dled fr ANST boling and one flange is drilled for

the other standard bolting. With an adanter ange one side is.

Vous aimerez peut-être aussi

- Engineering Village Citation 11-16-2014 17560616Document1 pageEngineering Village Citation 11-16-2014 17560616thoma111sPas encore d'évaluation

- Grinding Operations DesignDocument50 pagesGrinding Operations DesignLe Hoang LongPas encore d'évaluation

- Como RoscarDocument0 pageComo RoscarxaviocaPas encore d'évaluation

- MNT en 4.9 Testing ProceduresDocument95 pagesMNT en 4.9 Testing Proceduresthoma111sPas encore d'évaluation

- GRP Pipe Socket JointDocument80 pagesGRP Pipe Socket JointMAGUNAM100% (1)

- GDT Spring 2010tDocument278 pagesGDT Spring 2010tYanaki HristovPas encore d'évaluation

- Acrobat Reader IFilter ConfigurationDocument31 pagesAcrobat Reader IFilter Configurationthoma111sPas encore d'évaluation

- Specifications TorqueDocument20 pagesSpecifications Torquethoma111s100% (2)

- Analyze Oil Wear DebrisDocument2 pagesAnalyze Oil Wear Debristhoma111sPas encore d'évaluation

- Research ArticleDocument8 pagesResearch Articlethoma111sPas encore d'évaluation

- Valve Testing N Inspeksi PDFDocument13 pagesValve Testing N Inspeksi PDFh4rajukuPas encore d'évaluation

- Wind Turbine TribologyDocument48 pagesWind Turbine TribologyJoao Carlos DrumondPas encore d'évaluation

- Sensors 08 02188Document20 pagesSensors 08 02188thoma111sPas encore d'évaluation

- GRL+Prosp - EDocument2 pagesGRL+Prosp - Ethoma111sPas encore d'évaluation

- Ansi B16.5Document6 pagesAnsi B16.5foobar2016Pas encore d'évaluation

- PSV Data BookDocument16 pagesPSV Data Bookkenoly123Pas encore d'évaluation

- Mineral Identification ChartDocument4 pagesMineral Identification Chartskhairnar@gmail.comPas encore d'évaluation

- Research ArticleDocument8 pagesResearch Articlethoma111sPas encore d'évaluation

- Teacher Preparation Notes For Metal Identification LabDocument3 pagesTeacher Preparation Notes For Metal Identification Labthoma111sPas encore d'évaluation

- 2222-5000 Ball Mill Baghouse 1 & 2 Operational InspectionDocument5 pages2222-5000 Ball Mill Baghouse 1 & 2 Operational Inspectionthoma111sPas encore d'évaluation

- Gasketed Plate Heat Exchangers Installation PDFDocument23 pagesGasketed Plate Heat Exchangers Installation PDFCastoriadisPas encore d'évaluation

- Spar Question 3Document1 pageSpar Question 3thoma111sPas encore d'évaluation

- 905 BarbieKeiserDocument119 pages905 BarbieKeiserthoma111sPas encore d'évaluation

- Full Page PhotoDocument1 pageFull Page Photothoma111sPas encore d'évaluation

- GRP Pipe Socket JointDocument80 pagesGRP Pipe Socket JointMAGUNAM100% (1)

- Corrosion Threats HandbookDocument28 pagesCorrosion Threats Handbookthoma111s100% (1)

- AG-AG-AMI-01421-10.1 PP Identifying+Metals+and+Their+PropertiesDocument18 pagesAG-AG-AMI-01421-10.1 PP Identifying+Metals+and+Their+Propertiesthoma111sPas encore d'évaluation

- Spar Question 4Document1 pageSpar Question 4thoma111sPas encore d'évaluation

- PowerCoil thread repair kits flyerDocument2 pagesPowerCoil thread repair kits flyerthoma111sPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)