Académique Documents

Professionnel Documents

Culture Documents

Assignment 0

Transféré par

Vaidish SumariaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assignment 0

Transféré par

Vaidish SumariaDroits d'auteur :

Formats disponibles

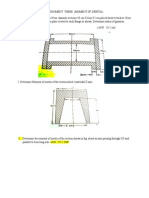

The P&ID describes a chemical reactor in which A reacts with B.

LC1 in a Level Controller for the pressure vessel that contains the reactant A.

PC1 is the Pressure Control which controls the pressure of the vessel containing

reactant B.

M1 motor feeds the reactant A to the reactor. The process line contains a control

valve V1 and a Flow controller FC1. The valve can be controlled according to the

flow rate decided by the flow controller.

The reactant B is feed to the reactor. The feed line consists of a control valve V2 and

the Flow controller FC2.

M2 is an agitator (motor that moves it) that homogenizes the reacting mixture.

LC2 and TC1 are level and temperature controllers of the chemical reactor

respectively.

The gaseous product of the reaction is sent to the scrubber after cooling down using

the Cooling water (CW) controlled by the valve V7. The flow of the gaseous products

to the scrubber is controlled by valve V6. TC2 is a Temperature controller that

checks the temperature of the cooled gaseous product.

AB is a gaseous product BAB is a liquid product. The liquid product flow is controlled

by the valve V3. The liquid product is pumped to the storage vessel by a pump M3

and controlled by the valve V4.

The level controller LC3 controls the level of liquid product BAB.

LC4 controls the level in the scrubber.

Product AB is pumped out using the pump M4 and flow is controlled using a control

valve V8.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Generative and Reinforcement Learning Physics Workshop ApplicationDocument1 pageGenerative and Reinforcement Learning Physics Workshop ApplicationVaidish SumariaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Mass transfer effects in porous catalystsDocument11 pagesMass transfer effects in porous catalystsVaidish SumariaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Reactions ExtentDocument8 pagesReactions ExtentVaidish SumariaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Table of ContentsDocument6 pagesTable of ContentsVaidish SumariaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 09 Jun 00Document29 pages09 Jun 00Vaidish SumariaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- FenomenosDocument6 pagesFenomenosenriqueg_53Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- MajorhdahDocument8 pagesMajorhdahVaidish SumariaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- ChE 299 Winter 2019 SyllabusDocument1 pageChE 299 Winter 2019 SyllabusVaidish SumariaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- OptimizationDocument2 pagesOptimizationVaidish SumariaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Cheat SheetDocument1 pageCheat SheetVaidish SumariaPas encore d'évaluation

- RequirementsDocument1 pageRequirementsVaidish SumariaPas encore d'évaluation

- Serial NumberDocument1 pageSerial NumberVaidish SumariaPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Qwerty 3Document1 pageQwerty 3Vaidish SumariaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Edriveassgnsem 7Document3 pagesEdriveassgnsem 7Vaidish SumariaPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- SsssssssssssssDocument1 pageSsssssssssssssVaidish SumariaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- WDocument1 pageWVaidish SumariaPas encore d'évaluation

- Placement LetterDocument1 pagePlacement LetterVaidish SumariaPas encore d'évaluation

- QwertyDocument1 pageQwertyVaidish SumariaPas encore d'évaluation

- Mat.T Manuals OrientationDocument24 pagesMat.T Manuals OrientationVaidish SumariaPas encore d'évaluation

- Resume FormatDocument2 pagesResume FormatSiddhant SharmaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- IAS Fellowship FormDocument2 pagesIAS Fellowship FormVaidish SumariaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Read MeDocument1 pageRead MeNatePas encore d'évaluation

- Course Plan PDU Jan - June 2015Document14 pagesCourse Plan PDU Jan - June 2015Vaidish SumariaPas encore d'évaluation

- AdsorptionDocument19 pagesAdsorptionArun DubeyPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- P&IDsDocument4 pagesP&IDsRamadhan PrasetyaPas encore d'évaluation

- Edited Paper For SchemconDocument9 pagesEdited Paper For SchemconVaidish SumariaPas encore d'évaluation

- Assignment FourDocument3 pagesAssignment FourVaidish SumariaPas encore d'évaluation

- Types of RefineriesDocument2 pagesTypes of RefineriesVaidish SumariaPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)