Académique Documents

Professionnel Documents

Culture Documents

Final TPP

Transféré par

api-277623008Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Final TPP

Transféré par

api-277623008Droits d'auteur :

Formats disponibles

Problem Statement:

I wanted to compare the weight of an aluminum tube and steel tube of equal

stiffness. So I wanted to find the differences between trying to use a stiffer Steel

frame on light weight designs such as airplanes, cars and bicycles. While I was

looking into lightweight steel frames I was told that you can use a lighter material

such as aluminum, a lighter and weaker material that when it is used with the same

dimensions as the steel frame will be weaker. So if you make it slightly bigger you

can make an aluminum frame the same stiffness as the steel frame and it is

significantly lighter. If you want to learn more, go to this website:

http://en.wikipedia.org/wiki/Specific_modulus .

Tube 1 Dimensions

Inner Diameter (d) = 1 m

Outer Diameter (D) = 2m

Length (L) = 5 m

1) Calculate the Weight of Tube 1 (Steel)

Density X Volume = Weight

The Density of Steel = 7850 Kg /m

Volume of a hollow tube:

2

(2 1 )

5=11.79 m

4

Weight of Steel Tube 1:

7850

kg

11.79 m3=92,521.2 kg

3

m

2) Calculate the Weight of Tube 1 (Aluminum)

The Density of Aluminum = 2712 kg/m

2712 kg/m 11.79=31,974.46 kg

3) Calculate the Bending Stiffness (E*I) of Tube 1 (Steel and Aluminum)

Elastic modulus (Esteel) of Steel

2.00 e11

Elastic modulus (Ealuminum) of Aluminum

N/m

10

6.9 e

N/m

Moment Area of Inertia (I1) of hollow Tube 1

( D 4d 4 )

I1 =

64

Bending Stiffness of Steel Tube 1:

E steel (D4 d 4 )

Esteel I 1 =

64

e 11 (241 4)

Esteel I 1 =2.00

64

11

Esteel I 1 =1.47 e Nm

Bending Stiffness of Aluminum Tube 1:

Ealuminum ( D4d 4 )

Ealuminum I 1=

64

e10 (241 4)

Ealuminum I 1=6.9

64

Ealuminum I 1=5.08 e 10 Nm

4) Calculate new D2 to make an Aluminum Tube 2 equivalent to Steel Tube

1's Bending Stiffness.

Set the bending stiffness for both steel and aluminum tubes from section 3 equal

and solve for a new D for aluminum tube.

d4

Es ( 4 4 )

D d

Ea

2.00e11 ( )

15

6.9e10

1/ 4

=D

2

1 /4

=D2

( 3.90 x 15 ) 4 =2.58 m

D2=2.58 m

Plug the New D2 back in to make sure that the aluminum tube 2 bending stiffness is

equal to that of the steel tube 1 bending stiffness.

10

e ( 2.58 1 )

Ealuminum I 2=6.9

64

11

Ealuminum I 2=1.47 e Nm

Ealuminum I 2=E steel I 1

5) Calculate the Weight of Tube 2 Aluminum:

First we have to calculate the new Volume of tube 2

2

(2.58 1 )

5=22.21 m

4

Next, calculate the weight of tube 2 aluminum

Density x volume = weight

22.21 m * 2712 kg/m = 60,233.52 Kg

The results of this investigation are summarized in table 1 below

Parameter

Value (units)

Weight of Steel Tube 1

92,521 (kg)

Weight of Aluminum Tube

60,233 (kg)

2

Table 1. Summary of Results

Conclusions

The steel tube 1, of equivalent bending stiffness, weighs 50% more than the

aluminum tube 2 while only increasing the outer diameter of tube 2 by 25%.

Understanding the fundamentals of material mechanics is critical for reducing

weight in aerospace, automobile and bicycle designs.

Vous aimerez peut-être aussi

- Continental Racing Tires Flyer 2017Document7 pagesContinental Racing Tires Flyer 2017Keith VonHertellPas encore d'évaluation

- Pre-Trip Inspection Tractor TrailerDocument15 pagesPre-Trip Inspection Tractor TrailerEngine Tuning UP100% (3)

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkD'EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkPas encore d'évaluation

- Scomposite-24.24Document87 pagesScomposite-24.24manish sharmaPas encore d'évaluation

- Bottom Bracket Standards ReferenceDocument2 pagesBottom Bracket Standards ReferenceMeoZulPas encore d'évaluation

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyPas encore d'évaluation

- hp52 2001Document13 pageshp52 2001GoodBikesPas encore d'évaluation

- 6th Velomobile Seminar Copenhagen 2009Document232 pages6th Velomobile Seminar Copenhagen 2009Khuyen NguyenPas encore d'évaluation

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationJagal Udaya100% (3)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsD'EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsPas encore d'évaluation

- A2b HybridDocument38 pagesA2b HybridHector Tadeo LopezPas encore d'évaluation

- Composite ColumnsDocument49 pagesComposite ColumnsPrasad GN100% (2)

- Design of Helical SpringDocument11 pagesDesign of Helical SpringNarender Kumar100% (1)

- Simple Stress StrainDocument141 pagesSimple Stress Strainjs kalyana ramaPas encore d'évaluation

- Beam Jacketing MSDocument10 pagesBeam Jacketing MSdraganugPas encore d'évaluation

- Pedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Document35 pagesPedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Ing Manolo HernandezPas encore d'évaluation

- 4 ME Som Model Examination 2013Document3 pages4 ME Som Model Examination 2013BIBIN CHIDAMBARANATHANPas encore d'évaluation

- ME 2254 - STRENGTH OF MATERIALS Nov - Dec 2010Document3 pagesME 2254 - STRENGTH OF MATERIALS Nov - Dec 2010Punitha KumarPas encore d'évaluation

- Ijce V3i11p101Document6 pagesIjce V3i11p101Mahesh YadavPas encore d'évaluation

- Som Dec 2010Document2 pagesSom Dec 2010MANOJ MPas encore d'évaluation

- CE 6306 / Strength of Materials Mechanical Engineering 2016-17Document6 pagesCE 6306 / Strength of Materials Mechanical Engineering 2016-17amdevaPas encore d'évaluation

- Behavior of Composite Steel Columns Filled With Normal Concrete and OthersDocument8 pagesBehavior of Composite Steel Columns Filled With Normal Concrete and Othersdivyadevc_mPas encore d'évaluation

- Ce 6452 SM Int IDocument2 pagesCe 6452 SM Int Iandrw1987Pas encore d'évaluation

- Shear Behavior of Self Compacting R.C. I-BeamsDocument16 pagesShear Behavior of Self Compacting R.C. I-BeamsThomás LimaPas encore d'évaluation

- Composite Concrete ColumnDocument17 pagesComposite Concrete Columnpragati singhPas encore d'évaluation

- Torsion 01Document20 pagesTorsion 01Danielle Ruthie GalitPas encore d'évaluation

- ACI Structural Journal (January 2014)Document11 pagesACI Structural Journal (January 2014)Tian NgPas encore d'évaluation

- Torque Shaft OptimisationDocument8 pagesTorque Shaft OptimisationJonathan CraigmilePas encore d'évaluation

- Me 2254 ModelDocument2 pagesMe 2254 Modeldevarajs2010Pas encore d'évaluation

- CiviDocument11 pagesCiviSaidi ReddyPas encore d'évaluation

- MOM Assignment IDocument3 pagesMOM Assignment IAll_regPas encore d'évaluation

- CFST PoleDocument11 pagesCFST PoleGracePas encore d'évaluation

- MSE 227 HW9 F10 SolutionsDocument5 pagesMSE 227 HW9 F10 Solutionsputri nur shahidaPas encore d'évaluation

- Beam Design TheoryDocument34 pagesBeam Design TheoryRishabhAgrawalPas encore d'évaluation

- How To Calculate The Unit Weight of Steel BarsDocument10 pagesHow To Calculate The Unit Weight of Steel BarsRon Gerald RicaPas encore d'évaluation

- Weight Calculation of Steel Bars (Formula and Examples) - Civil Engineering ForumDocument1 pageWeight Calculation of Steel Bars (Formula and Examples) - Civil Engineering ForumAl-MehmdiPas encore d'évaluation

- R5210103 Strength of Materials - IDocument1 pageR5210103 Strength of Materials - IsivabharathamurthyPas encore d'évaluation

- Singly Reinforced Beam Design ProcedureDocument33 pagesSingly Reinforced Beam Design ProcedureAnonymous ALBuK8vOm100% (1)

- A Fδll Fδl4.7 A Fδll Fδl3.5Document11 pagesA Fδll Fδl4.7 A Fδll Fδl3.5ASHUTOSH KUMARPas encore d'évaluation

- CE2001 MS Ass1Document1 pageCE2001 MS Ass1Varghese NjaliathPas encore d'évaluation

- How To Calculate The Unit Weight of Steel BarsDocument11 pagesHow To Calculate The Unit Weight of Steel BarsProperty Baguio ListingPas encore d'évaluation

- ConcreteDocument62 pagesConcreteMahmoud ShakerPas encore d'évaluation

- Optimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqiDocument5 pagesOptimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqimargitorsiPas encore d'évaluation

- 18ME404 Assignment 1Document2 pages18ME404 Assignment 1BharanitharanPas encore d'évaluation

- Structural Steel Educational CouncilDocument8 pagesStructural Steel Educational CounciljfonfriaPas encore d'évaluation

- TrueDocument12 pagesTrueDoğan ArslanPas encore d'évaluation

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyPas encore d'évaluation

- PROBLEM: Check Fatigue Stress at Diaphragm Connection Plate Which Is Welded To TheDocument5 pagesPROBLEM: Check Fatigue Stress at Diaphragm Connection Plate Which Is Welded To TheRandy ViolaPas encore d'évaluation

- The Tension TestDocument5 pagesThe Tension TestPhilip WuPas encore d'évaluation

- Som I Iat Ques 2019Document3 pagesSom I Iat Ques 2019Siva RamanPas encore d'évaluation

- Som Prob SetDocument50 pagesSom Prob SetAnonymous mXicTi8hBPas encore d'évaluation

- Mech. Properties of SolidsDocument15 pagesMech. Properties of SolidsRakesh SPas encore d'évaluation

- Mechanical Design1Document23 pagesMechanical Design1Atie AtirahPas encore d'évaluation

- Design of Helical SpringDocument11 pagesDesign of Helical SpringnikhilPas encore d'évaluation

- Prepared by Jishnu V Engineer Bhel-IsgDocument38 pagesPrepared by Jishnu V Engineer Bhel-IsgmSNDjvnsnPas encore d'évaluation

- SOM Assignment Unit 1Document1 pageSOM Assignment Unit 1MANOJ MPas encore d'évaluation

- The Weight Formula For SteelDocument5 pagesThe Weight Formula For SteelosmanokursoyPas encore d'évaluation

- Strength of Materials-II 2-2 Set-3 (A)Document18 pagesStrength of Materials-II 2-2 Set-3 (A)Sri DPas encore d'évaluation

- 1p2 2013 14 Materials Examples Paper 6Document5 pages1p2 2013 14 Materials Examples Paper 6davidsmith24026Pas encore d'évaluation

- Mechanics of SolidsDocument8 pagesMechanics of Solidsprashanthreddy26Pas encore d'évaluation

- 5 - Design of Reinforced Concrete BeamDocument25 pages5 - Design of Reinforced Concrete BeamyakaPas encore d'évaluation

- Tubular Stainless and Mild Steel Double-Skin ColumnsDocument6 pagesTubular Stainless and Mild Steel Double-Skin ColumnsIhab El AghouryPas encore d'évaluation

- 3rd Year 2nd Sem QuestionsDocument98 pages3rd Year 2nd Sem Questionssourav_jucivilPas encore d'évaluation

- Design of Concrete-Filled Steel Tubular Members According To The Australian Standard As 5100 Model and CalibrationDocument18 pagesDesign of Concrete-Filled Steel Tubular Members According To The Australian Standard As 5100 Model and Calibrationoui6592Pas encore d'évaluation

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationHani AboobackerPas encore d'évaluation

- MN - 2015 10 20Document32 pagesMN - 2015 10 20mooraboolPas encore d'évaluation

- Portfolio Liz HageyDocument21 pagesPortfolio Liz HageyLiz HageyPas encore d'évaluation

- Final Skatepark Design Report Public ExhibitionDocument27 pagesFinal Skatepark Design Report Public ExhibitionAnonymous DTtDTj100% (1)

- Japan: EDI CT OF GovernmentDocument37 pagesJapan: EDI CT OF GovernmentHan Win AungPas encore d'évaluation

- CMRC AtvDocument3 pagesCMRC Atvapi-26009013Pas encore d'évaluation

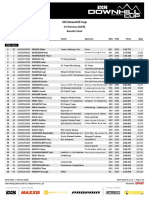

- Results Finals DHC #4 Ilmenau 2023Document12 pagesResults Finals DHC #4 Ilmenau 2023racementPas encore d'évaluation

- 2009 McEwen Cross Festival FlyerDocument3 pages2009 McEwen Cross Festival FlyerMcEwenCrossFestivalPas encore d'évaluation

- Bai Tap Tieng Anh Lop 7 Thi Diem Unit 7 TrafficDocument4 pagesBai Tap Tieng Anh Lop 7 Thi Diem Unit 7 TrafficBùi Linh100% (1)

- 2003 Headshok Damper Cartridge Castle Tools Technote enDocument1 page2003 Headshok Damper Cartridge Castle Tools Technote enxjcaiPas encore d'évaluation

- Rohloff Speedhub 500.14 - Owners Manual PDFDocument27 pagesRohloff Speedhub 500.14 - Owners Manual PDFsdanPas encore d'évaluation

- 23.06.10 Inv Avai Pan-Usa e (Componets Parts), S BpsDocument6 pages23.06.10 Inv Avai Pan-Usa e (Componets Parts), S BpsJose De La OPas encore d'évaluation

- Water Tower 2015 CalendarDocument11 pagesWater Tower 2015 CalendarMac MoneyPas encore d'évaluation

- History of BlataDocument2 pagesHistory of BlataAndy BrodiePas encore d'évaluation

- Analysis of Mointain Bike Frame by FEMDocument13 pagesAnalysis of Mointain Bike Frame by FEMPablo FadulPas encore d'évaluation

- Truvativ Tech Manual Rev 1Document56 pagesTruvativ Tech Manual Rev 1fikcePas encore d'évaluation

- Yamaha 2015 YZF-R125Document5 pagesYamaha 2015 YZF-R125Harshal DhanawadePas encore d'évaluation

- CUBE Bike Manual English 2015Document37 pagesCUBE Bike Manual English 2015nenad cvijicPas encore d'évaluation

- ''Materi Maths-EnglishDocument54 pages''Materi Maths-EnglishBagasDiwangkaraPas encore d'évaluation

- procrosscountryREV20150418 PDFDocument10 pagesprocrosscountryREV20150418 PDFrachellefrazerPas encore d'évaluation

- Skoda Fabia AccessoriesDocument40 pagesSkoda Fabia Accessorieshotmaleprabhu100% (1)

- 206-06 Hydraulic Brake ActuationDocument19 pages206-06 Hydraulic Brake ActuationMiguel AngelPas encore d'évaluation

- YMCA Program Guide - 2016Document44 pagesYMCA Program Guide - 2016Pickens County YMCAPas encore d'évaluation

- "Fabrication of Smart Bicycle": Project Reference No.: 37S1127Document9 pages"Fabrication of Smart Bicycle": Project Reference No.: 37S1127Sumanth NPas encore d'évaluation

- SCHWALBE-Bicycle-Tires 2020 ENDocument100 pagesSCHWALBE-Bicycle-Tires 2020 ENpetarlPas encore d'évaluation