Académique Documents

Professionnel Documents

Culture Documents

AGIP STD - Valves Specification Sheet

Transféré par

halim_kaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AGIP STD - Valves Specification Sheet

Transféré par

halim_kaDroits d'auteur :

Formats disponibles

AGIP

04056.PIP.MEC.SDS

INTERNAL NORMALIZATION

Revisions

PIPING PROJECT SPECIFICATION

SERVICE : NON CORROSIVE HYDROCARBONS - GLYCOL BLOW DOWN - VENTS - DRAINS (T < 120C)

Sheet

of

REFERENCE SPECIFICATIONS

E 12

ITEM

COMPONENTS

20376 / 20368.PIP.MEC.FUN

1500 # RJ

MAT.

CODES - Design : ASME B 31.3

RED. THDD FLG.S

15016

A 105

Dimensions : ASME B 16.5 / B 16.34

WELDS EXAMINATION

20377.PIP.MEC.FUN

DRIP RINGS

15011

A 105

MATERIALS (if not otherw.stated)

ASTM STANDARDS

SPECTACLE BLINDS

15038

A 105

15039

A 105

50

246,4

----

----

---

100

231,8

----

----

120

229,2

----

----

-------

-------

-------

-------

14380

-----

SPACERS & BLINDS

THDD FITTINGS

14381

-----

TEMP. STRAINERS 15050-15007

NIPPLES

S.W. FITTINGS

NORMAL (from pipe)

14383

SWAGES (from pipe)

14382

THICKNESS

mm

PIPES

INCH

WALL THK.

mm

SCHEDULE

MATERIAL

FLANGES

-----

STUDDED TEE

SOCKET WELD

14356

THREADED

14357

SLIP ON

14358

LAP JOINT

14359

BLIND

14360

14365

STUD BOLTS & NUTS

14368

15801

CHECK

15801

7,47 7,82

1/2" 3/4"

---

---

---

1"

1"

2"

HEADER SIZE

2"

3"

4"

6"

8"

10" 12"

14"

P - bar

248,2

T - C

----

P - bar

----

16" 18" 20" 24" 30" 36"

---

---

6,35 7,14 8,74 9,52 11,13 13,49 18,26 23,01 28,58 33,32 35,71 40,49 45,24 50,01

---

---

---

---

---

160

---

---

---

160

160

160

160

160

160

160

160

160

160

160

160

160

A 105 / 1500# - RJ

A 105 / 1500# - RJ

81 A 05

A 193 Gr.B7 / A 194 Gr.2H (ZINC COATING) (1)

VB 517 AG 5C2 RJ

VB 517 AG 1C1 - RJ (R.B.) O VB 517 AG 4C1 - RJ (R.B. TOP ENTRY)

(2) VB 517 AG 2C1 - RJ (F.B.) O VB 517 AG 3C1 - RJ (F.B. TOP ENTRY)

VD 317 AG A01 - RJ

VD 317 AG 7C1 RJ

VD 317 AG 5C1

RJ (5)

VDR 717 AG 6C1 - RJ (WAFER)

VDR 717 AG AC1 RJ

VDR 717 AG 9C1 - RJ (10)

VS 117 AG AC1 RJ (11)

15701

90-45 ELBOWS

14370

A 234 Gr.WPB

1/2

CONC.REDUCTIONS

14372

A 234 Gr.WPB

3/4

ECC.REDUCTIONS

14372

ELLIPT.CAPS

14374

A 234 Gr.WPB

A 234 Gr.WPB

STEE

STEE

STEE

DN"

API 6A 60K

01267

-----

15801

MANUAL CONTROL

T - C

-29 38

SMLS

14355

DESIGN CONDITIONS

API 5L Gr.B

GASKETS

VALVES

API 5L Gr.B SMLS (2)

14350

WELDING NECK

LJ STUB ENDS

14375

PIPE BENDS

15023

METER ELBWS

STEE

15020

15021

STEE

Mark

STEE

INTERSECTIONS

STEE

10

STEE

12

STEE

14

SWLT

Components

Material

STEE STRAIGHT BW TEE

14371

A 234 Gr.WPB

RTEE REDUCTION BW TEE

14371

A 234 Gr.WPB

STSC STRAIGHT THDD TEE

14381

RTSC REDUCTION THDD TEE

14381

STSW STRAIGHT SW TEE

14380

RTSW REDUCTION SW TEE

14380

SWLT SWEEPOLETS

15003

WLET WELDOLETS

15004

30

TLET THREDOLETS

14381

36

SLET SOCKOLETS

14380

NLET NIPOLETS THDD

14381

PTOP PIPE TO PIPE

15012

STEE

RTEE

16

STEE

18

20

STEE

STEE

24

1/2 3/4 1 1 2

1 mm

---

" Y " STRAINERS

F

G

CORR.ALLOWANCE

15017

SPECIAL USE

0

0

2

5

Date

RED. S.O. FLG.S

ON / OFF

T

U

B

20367.PIP.MEC.FUN

MANIFACTURE

M

E

C

PIPING CLASS

NOMINAL SIZE

M

O

D

06--97

Rating & Facing

WELDING AND HEAT TREATMENT

Compiled

6

DN"

10

12

14

16

BRANCH SIZE

18

20

24

30

36

A 105

NOTES:

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coating

(hot-dip) to ASTM A-153

2) To be used where required by P&I drawings only

3) Threaded Ends and connections are allowed for instrument taps only (15801).

5) Angle valve.

10) Depressurization "NOZZLE CHECK" type valve.

11) Valve Inst. on flowlines up stream sep. "EXPANDING GATE" type (20451).

Company's sole property document . Company will protect his right by law.

Vous aimerez peut-être aussi

- Technical Service Information: The 01J Multitronic®Document75 pagesTechnical Service Information: The 01J Multitronic®Fernando Bas100% (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Inter-M A-60 - 120 Service ManualDocument9 pagesInter-M A-60 - 120 Service ManualGaniza Long0% (2)

- A11Document1 pageA11liviu_dovaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_ka100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- NAD 3020 ServiceManualDocument6 pagesNAD 3020 ServiceManualmartin-d-johnsonPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Marine Electrical Practice: Marine Engineering SeriesD'EverandMarine Electrical Practice: Marine Engineering SeriesÉvaluation : 4 sur 5 étoiles4/5 (8)

- Level Past Paper Questions - Physics O: TOPIC-14 DC Circuits PAPER-1 Multiple ChoiceDocument17 pagesLevel Past Paper Questions - Physics O: TOPIC-14 DC Circuits PAPER-1 Multiple Choiceelty Tan50% (2)

- How Do Pdas WorkDocument3 pagesHow Do Pdas WorkManel DulunayPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaPas encore d'évaluation

- A09Document1 pageA09liviu_dovaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- Agip STD - Piping Project SpecificationDocument1 pageAgip STD - Piping Project Specificationhalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- A17Document1 pageA17liviu_dovaPas encore d'évaluation

- D11Document1 pageD11liviu_dovaPas encore d'évaluation

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- A02Document1 pageA02liviu_dovaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- Class A1D1Document8 pagesClass A1D1SalimPas encore d'évaluation

- Ea 682808 001 R05Document7 pagesEa 682808 001 R05anbarasusivaprakasam100% (1)

- 6877-SM-LM-99-00-09049-U1A1 Document Number: Merlin Version 2.2 12-JAN-05 14:01:06 Detailed ReportDocument8 pages6877-SM-LM-99-00-09049-U1A1 Document Number: Merlin Version 2.2 12-JAN-05 14:01:06 Detailed ReportSalimPas encore d'évaluation

- rc91261 G10-UscDocument8 pagesrc91261 G10-Usceww08Pas encore d'évaluation

- 11422Document10 pages11422balajivangaruPas encore d'évaluation

- Supplier Documents - Petrobras (01 June 2012)Document8 pagesSupplier Documents - Petrobras (01 June 2012)Rapha SuzartPas encore d'évaluation

- Bomba de PistonDocument22 pagesBomba de PistonAlexSora100% (1)

- Токарный инструмент IscarDocument250 pagesТокарный инструмент IscarstctoolPas encore d'évaluation

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08Pas encore d'évaluation

- 61502YDocument9 pages61502YbalajivangaruPas encore d'évaluation

- WAGP-1-PAR-9A-M-SAS-99-0011 Hydrocarbons 1500 ANSI E1Document4 pagesWAGP-1-PAR-9A-M-SAS-99-0011 Hydrocarbons 1500 ANSI E1tope odumboniPas encore d'évaluation

- Pp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTDocument2 pagesPp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTfaiyazirfanPas encore d'évaluation

- Ta38107 1 PDFDocument20 pagesTa38107 1 PDFVyasaraj KumarPas encore d'évaluation

- Piping ComponentDocument19 pagesPiping Componentreach_arindomPas encore d'évaluation

- Masoneilan Equipment DataDocument3 pagesMasoneilan Equipment DataalvimranPas encore d'évaluation

- Yuken DSHGDocument28 pagesYuken DSHGDian PramadiPas encore d'évaluation

- Valve Description Code PagesDocument13 pagesValve Description Code PagesAdrian GallegosPas encore d'évaluation

- Material EquivalentsDocument25 pagesMaterial EquivalentsAditya B. Ryanto100% (6)

- Ev DG05Document14 pagesEv DG05mtbecerrapPas encore d'évaluation

- Ms Pipe and Fittings 24.1.13Document7 pagesMs Pipe and Fittings 24.1.13chandrasencciPas encore d'évaluation

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryD'EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryPas encore d'évaluation

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaPas encore d'évaluation

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaPas encore d'évaluation

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- DGS-CU-016-R2 Testing LaboratoryDocument17 pagesDGS-CU-016-R2 Testing Laboratoryhalim_kaPas encore d'évaluation

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaPas encore d'évaluation

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaPas encore d'évaluation

- 15378E01Document1 page15378E01halim_kaPas encore d'évaluation

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaPas encore d'évaluation

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaPas encore d'évaluation

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaPas encore d'évaluation

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaPas encore d'évaluation

- Appendix B. Sample Problem: Chevron Corporation B-1 March 1991Document2 pagesAppendix B. Sample Problem: Chevron Corporation B-1 March 1991halim_kaPas encore d'évaluation

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaPas encore d'évaluation

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaPas encore d'évaluation

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaPas encore d'évaluation

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaPas encore d'évaluation

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaPas encore d'évaluation

- 15378E01Document1 page15378E01halim_kaPas encore d'évaluation

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaPas encore d'évaluation

- SDS23 71 00 00.fullDocument12 pagesSDS23 71 00 00.fullPierre LepagePas encore d'évaluation

- 50ucupv PSD enDocument58 pages50ucupv PSD enMohd AzharPas encore d'évaluation

- DT 31Document2 pagesDT 31workshop baruPas encore d'évaluation

- Opss - Prov 127 - Jan 2021Document83 pagesOpss - Prov 127 - Jan 2021Pamela Joyce MaddumaPas encore d'évaluation

- TT3020Document75 pagesTT3020Romeish KelaartPas encore d'évaluation

- 7 Ways To Improve Pump Efficiency - Smaller-CompressedDocument1 page7 Ways To Improve Pump Efficiency - Smaller-CompressedCharina Malolot VillalonPas encore d'évaluation

- Annexure - 37C Construction of Ug Cable Railway Track Crossing For 33Kv LineDocument7 pagesAnnexure - 37C Construction of Ug Cable Railway Track Crossing For 33Kv LineLokeswaraRaoPas encore d'évaluation

- Airtronic D2-D4 Diagnostic and RepairManualDocument33 pagesAirtronic D2-D4 Diagnostic and RepairManualPSPas encore d'évaluation

- RSS SectionDocument8 pagesRSS SectionMarcos BarrosPas encore d'évaluation

- Cylinder 243 LTRDocument2 pagesCylinder 243 LTRMarwa AlkarakiPas encore d'évaluation

- Taper Turning PDFDocument10 pagesTaper Turning PDFMaria Mehar0% (1)

- Volume Control Damper CatalogueDocument2 pagesVolume Control Damper CatalogueMaster A/CPas encore d'évaluation

- Woodworking Crafts February 2018Document92 pagesWoodworking Crafts February 2018edgar velasco50% (2)

- Chrystalace Wedding Stationery Free Printable Wedding Planner BlueDocument6 pagesChrystalace Wedding Stationery Free Printable Wedding Planner BlueBeatriz Blazquez SanchezPas encore d'évaluation

- Draco K8N ManualDocument2 pagesDraco K8N ManualSamuel OdeiaddoPas encore d'évaluation

- IRIS Assoc Sample ReportDocument12 pagesIRIS Assoc Sample Reportyessicanavarrete02Pas encore d'évaluation

- IECD Capsule NotesDocument59 pagesIECD Capsule NotesANANTHU PRADEEPPas encore d'évaluation

- 9883511790ENUWADocument8 pages9883511790ENUWAhalexPas encore d'évaluation

- Portable Power Pack 44ah: User Manual and Product SpecificationsDocument8 pagesPortable Power Pack 44ah: User Manual and Product SpecificationsKarun AgarwalPas encore d'évaluation

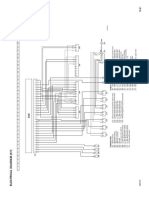

- Esquema Transmision CarraroDocument1 pageEsquema Transmision CarraroDavid Solis100% (1)

- HTO Sensor Air Humidity and Temp SensorDocument8 pagesHTO Sensor Air Humidity and Temp SensorZill RafiPas encore d'évaluation

- Automated Double-Sided Hand-Held Dishwashing Device (Adhdd) : Review of Related LiteratureDocument1 pageAutomated Double-Sided Hand-Held Dishwashing Device (Adhdd) : Review of Related LiteratureKyle Brian Lacson EscarillaPas encore d'évaluation

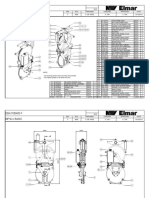

- MP16 II PARTES DDA11024221 mp16 Measuring Head. PDFDocument9 pagesMP16 II PARTES DDA11024221 mp16 Measuring Head. PDFROGERPas encore d'évaluation

- 45 Harmony Xb4 Xb5 Xb7 Push ButtonsDocument217 pages45 Harmony Xb4 Xb5 Xb7 Push ButtonsAntonioPas encore d'évaluation

- Optyma Controller For Condensing unit™PlusSW Version 3.6xDocument18 pagesOptyma Controller For Condensing unit™PlusSW Version 3.6xNikolas ChionasPas encore d'évaluation

- DeLonghi Magnifica PDFDocument24 pagesDeLonghi Magnifica PDFDan IspasPas encore d'évaluation

- Indesit Idce745euDocument13 pagesIndesit Idce745euMилош ЛукићPas encore d'évaluation