Académique Documents

Professionnel Documents

Culture Documents

PTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1

Transféré par

Balderas Rosas WilibaldoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1

Transféré par

Balderas Rosas WilibaldoDroits d'auteur :

Formats disponibles

ER

ING

ED

AL

L R GE

IG

(

HT SIN

S R GA

ES POR

ER

V E E) P T

D

E

STUD BOLTS ASTM A193 / A193M

HIGH TEMPERATURE SERVICE

AVAILABLE MATERIALS

FERRITIC STEEL

AUSTENITIC STEEL

MATERIAL GRADES

For material grades, please refer to our specification

page for all products..

DIMENSIONAL STANDARDS

ASME B18.2.1

ASME B18.2.3.1M

THREAD STANDARDS

ASME B1.1

ASME B1.13M

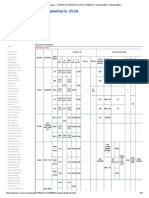

DIMENSIONAL SPECIFICATION ( INCH ) FOR STUD BOLTS AS PER ASME B18.2.1

Nom. Thread Diameter ( D )

1 /4

5/16

3/8

7/16

1/2

5/8

Nominal Length ( L )

Nom. Thread Diameter ( D )

3/4

7/8

11/8

11/4

13/8

11/2

13/4

1 20 inches

21/4

21/2

Nominal Length ( L )

23/4

31/4

31/2

33/4

1 20 inches

DIMENSIONAL SPECIFICATION ( METRIC ) FOR STUD BOLTS AS PER ASME B18.2.3.1M

Nom. Thread Diameter ( D )

M6

M8

M10

M12

Nominal Length ( L )

Nom. Thread Diameter ( D )

EN

G

INE

Nominal Length ( L )

M16

M20

M24

M30

M80

M90

M100

20 500 mm

M42

M48

M56

M64

M72

20 500 mm

M36

ASTM A193 / A193M

LT

D

DESCRIPTION

ASTM A193 / A193M

LT

D

ER

ING

ED

AL

L R GE

IG

(

HT SIN

S R GA

ES POR

ER

V E E) P T

D

E

Grade Marking

See table below for their

respective markings.

GRADE CLASSIFICATION AND HEAT TREATMENTS FOR STUD BOLTS AS PER ASTM A193 / A193M

FERRITIC STEELS

Class

No Classification Quenched and Tempered

Grade

B5

Marking

B6

B6X

B7

B7M

B16

AUSTENITIC STEELS

1 Carbide Solution Treated

Grade

B8

B8C

B8M

B8P

B8T

B8LN

B8MLN

Marking

B8

B8C

B8M

B8P

B8T

B8F

B8G

Class

Class

1A Carbide Solution Treated After Finishing

Grade

B8A

B8CA

B8MA

B8PA

B8TA

B8LNA

B8MLNA

B8NA

B8MNA

B8MLCuNA

Marking

B8A

B8B

B8D

B8H

B8J

B8L

B8K

B8V

B8W

B9K

Class

1B - Carbide Solution Treated Nitrogen-Bearing S/Steel

Grade

Marking

Class

B8N

B8MN

B8MLCuN

B8N

B8Y

B9J

1C - Carbide Solution Treated Nitrogen-Bearing S/Steel

Grade

B8R

B8RA

B8S

B8SA

Marking

B8P

B8T

B8F

B8G

Class

1D Carbide Solution Treated By Rapid Cooling from Rolling Temperature

B8

B8M

B8P

B8LN

B8MLN

B8N

B8MN

B8R

B8S

Marking

B94

B95

B96

B97

B98

B99

B100

B101

B102

Class

Grade

2 Carbide Solution Treated and Strain-Hardened

B8

B8C

B8P

B8T

B8N

B8M

B8MN

B8MLCuN

B8

B8C

B8P

B8T

B8N

B8M

B8Y

B9J

EN

G

Marking

INE

Grade

Class

2B Carbide Solution Treated and Strain-Hardened

Grade

B8

B8M2

Marking

B9

B9G

Class

Grade

Marking

2C Carbide Solution Treated and Strain-Hardened

B8M3

B9H

Ferritic Steel

Chemical Composition Limits, %

Material

Mn

Si

Cr

Ni

Mo

Ti

Nb & Ta

Others

B5

5% Chromium

0.1

0.04

0.03

4-6

0.4 - 0.65

B6, B6X

410 Stainless Steel

0.15

0.04

0.03

11.5-13.5

B7, B7M

4140, 4142, 4145,

0.37-0.49 0.65 - 1.1

4140H, 4142H, 4145H

Stainless Steel

0.035

0.04

0.15-0.35 0.75-1.2

0.15-0.25

B16

CrMoV Steel

0.035

0.04

0.15-0.35 0.8-1.15

0.5-0.65

V 0.25-0.35

Al 0.015 c

Appendix

ER

ING

ED

AL

L R GE

IG

(

HT SIN

S R GA

ES POR

ER

V E E) P T

D

E

Grade

0.36-0.47 0.45-0.7

Values are maximum, unless otherwise stated.

The intentional additional of Bismuth (Bi), Selenium (Se), Tellurium (Te) and Lead (Pb) is not permitted.

Total Aluminium, soluble and insoluble.

ASTM A193 / A193M

LT

D

MATERIAL CHEMICAL COMPOSITION FOR STUD BOLTS AS PER ASTM A193 / A193M

Austenitic Steel

Material

B8, B8A

304 Stainless Steel

B8C, B8CA

Chemical Composition Limits, %

Mn

Sd

Si

Cr

Ni

Mo

Ti

Nb & Ta

Others

0.08

0.045

0.03

18 - 20

8 - 11

347 Stainless Steel

0.08

0.045

0.03

17 - 19

9 - 12

10 x C

B8M, B8MA 316 Stainless Steel

B8M2,B8M3

0.08

0.045

0.03

16 - 18

10 -14

2-3

B8P, B8PA

305 Stainless Steel

0.12

0.045

0.03

17 - 19

11 - 13

B8N, B8NA

304N Stainless Steel

0.08

0.045

0.03

18 - 20

8 - 11

0.1 - 0.16

B8LN,

B8LNA

304LN Stainless Steel

0.03

0.045

0.03

18 - 20

8 - 11

0.1 - 0.16

B8MN,

B8MNA

316N Stainless Steel

0.08

0.045

0.03

16 - 18

10 - 13

2-3

0.1 - 0.16

B8MLN,

B8MLNA

316LN Stainless Steel

0.03

0.045

0.03

16 - 18

10 - 13

2-3

0.1 - 0.16

B8T, B8TA

321 Stainless Steel

0.08

0.045

0.03

17 - 19

9 - 12

5(C+N) to

0.7 max

B8R, B8RA

XM19 Stainless Steel

0.06

4-6

0.045

0.03

1.5 - 3

0.1 - 0.3

0.2 - 0.4

V 0.1-0.3

B8S, B8SA

218 Stainless Steel

0.1

7-9

0.06

0.03

3.5 - 4.5

0.08-0.18

0.02

0.03

0.01

0.8

6 - 6.5

0.18-0.22 Cu 0.5 - 1

B8MLCuN, UNS: S31254

B8MLCuNA Stainless Steel

Appendix

20.5-23.5 11.5-13.5

16 - 18

19.5-20.5 17.5-18.5

Values are maximum, unless otherwise stated.

The intentional additional of Bismuth (Bi), Selenium (Se), Tellurium (Te) and Lead (Pb) is not permitted.

INE

EN

G

8-9

Grade

Ferritic Steel

B5

B6

B6X

B7

B7M

B16

Thread Diameter

Inch (Metric)

Tensile Strength, Min

Yield Strength, 0.2% Offset

Elongation in

Reduction

4D, min, % Area, min, %

ER

ING

ED

AL

L R GE

IG

(

HT SIN

S R GA

ES POR

ER

V E E) P T

D

E

Material Grade

ksi

Mpa

ksi

Mpa

4 (M100)

100

690

80

550

16

4 (M100)

110

759

85

585

4 (M100)

90

621

70

2 (M64)

125

862

> 2 (M64)

< 4 (M100)

115

> 4 (M100)

< 7 (M180)

4 (M100)

Hardness

Rockwell

Brinell

50

15

50

485

16

50

26 HRC

105

720

16

50

35 HRC

321 HB

793

95

655

16

50

35 HRC

321 HB

100

690

75

515

18

50

35 HRC

321 HB

100

690

80

550

18

50

99 HRB

235 HB

> 4 (M100)

< 7 (M180)

100

690

75

515

18

50

99 HRB

235 HB

2 (M64)

125

862

105

725

18

50

35 HRC

321 HB

> 2 (M64)

< 4 (M100)

110

759

95

655

17

45

35 HRC

321 HB

> 4 (M100)

< 8 (M180)

100

690

85

586

16

45

35 HRC

321 HB

ASTM A193 / A193M

LT

D

MECHANICAL PROPERTIES FOR STUD BOLTS AS PER ASTM A193 / A193M

Austenitic Steel

Class

Grade

ksi

Mpa

ksi

Mpa

Rockwell

Brinell

1, 1D

B8, B8M, B8P,

B8LN, B8MLN

All Diameters

75

515

30

207

30

50

96 HRB

223 HB

B8C, B87

All Diameters

75

515

30

207

30

50

97 HRB

224 HB

1A

B8A, B8CA, B8MA,

B8PA, B8TA, B8LNA,

B8MLNA, B8NA,

B8MNA, B8MLCuNA

All Diameters

75

515

30

207

30

50

90 HRB

192 HB

1B,

1D

B8N, B8MN,

B8MLCuN

All Diameters

80

550

35

241

30

40

96 HRB

223 HB

1C,

1D

B8R

All Diameters

100

690

55

379

35

55

28 HRC

271 HB

1C

B8RA

All Diameters

100

690

55

379

35

55

29 HRC

272 HB

1C,

1D

B8S

All Diameters

95

655

50

345

35

55

30 HRC

273 HB

1C

B8SA

All Diameters

95

655

50

345

35

55

31 HRC

274 HB

B8, B8C, B8P, B8T,

B8N

(M20)

125

860

100

690

12

35

35 HRC

321 HB

> (M20)

< 1 (M24)

115

795

80

552

15

35

35 HRC

321 HB

> 1 (M24)

< 1 (M30)

105

725

65

448

20

35

35 HRC

321 HB

> 1 (M30)

< 1 (M36)

100

690

50

345

28

45

35 HRC

321 HB

(M20)

110

760

96

662

15

45

35 HRC

321 HB

> (M20)

< 1 (M24)

100

690

80

552

20

45

35 HRC

321 HB

> 1 (M24)

< 1 (M30)

95

655

65

448

25

45

35 HRC

321 HB

> 1 (M30)

< 1 (M36)

90

620

50

345

30

45

35 HRC

321 HB

2 (M48)

95

655

75

517

25

40

35 HRC

321 HB

> 2 (M48)

< 2 (M64)

90

620

65

448

30

40

35 HRC

321 HB

> 2 (M64)

< 3 (M72)

80

585

55

379

30

40

35 HRC

321 HB

2 (M48)

85

585

65

450

30

60

35 HRC

321 HB

> 2 (M48)

85

585

60

415

30

60

35 HRC

321 HB

B8, B8M2

EN

G

2B

INE

B8M, B8MN,

B8MLCuN

2C

B8M3

Thread Diameter

Inch (Metric)

Tensile Strength, Min

Reduction

Area,

min, %

Hardness

Yield Strength, 0.2%

Offset

Elongation

in 4D, min,

%

Material

Vous aimerez peut-être aussi

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Classif AçosDocument7 pagesClassif AçoslavascudoPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesD'EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesPas encore d'évaluation

- CR StandardsDocument6 pagesCR Standardsalpha_beta48Pas encore d'évaluation

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72Pas encore d'évaluation

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 pagesEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriPas encore d'évaluation

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarPas encore d'évaluation

- Cat Astm A312Document0 pageCat Astm A312Nguyễn Thanh CườngPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fastenal - Mechanical Properties of Inch FastenersDocument4 pagesFastenal - Mechanical Properties of Inch FastenersbclarkeoobPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Fasteners GradeDocument4 pagesFasteners GradeGilbert PereiraPas encore d'évaluation

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryD'EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Quality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaDocument7 pagesQuality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Pas encore d'évaluation

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Piping Equipment SpecificationsDocument4 pagesPiping Equipment Specificationsmabrouk2013Pas encore d'évaluation

- Equivalents of Carbon Steel QualitiesDocument7 pagesEquivalents of Carbon Steel QualitieshardywillimPas encore d'évaluation

- Applied Welding Engineering: Processes, Codes, and StandardsD'EverandApplied Welding Engineering: Processes, Codes, and StandardsPas encore d'évaluation

- Speeds & Feeds DrillsDocument9 pagesSpeeds & Feeds DrillsHolleyMoorePas encore d'évaluation

- Boiler Tube Selection CriteriaDocument67 pagesBoiler Tube Selection Criteriapatidar11100% (6)

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Cross Reference of The Engg MaterialDocument18 pagesCross Reference of The Engg Materialrksahay100% (1)

- AAP S8 SS Buttweld Fittings & Flanges E2 SDocument12 pagesAAP S8 SS Buttweld Fittings & Flanges E2 SMalouk CheniouniPas encore d'évaluation

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonPas encore d'évaluation

- HOT-ROLLED STEEL PRODUCTSDocument8 pagesHOT-ROLLED STEEL PRODUCTS25091972Pas encore d'évaluation

- Standards MaterialDocument1 pageStandards MaterialFarzad MirzavandPas encore d'évaluation

- Multi-Material Sheet Metal Spec SheetDocument27 pagesMulti-Material Sheet Metal Spec SheetLuis EstevesPas encore d'évaluation

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- AISI SteelDocument7 pagesAISI SteelEtiPas encore d'évaluation

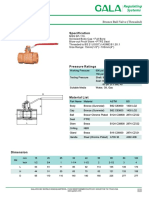

- GALA Valves PDFDocument14 pagesGALA Valves PDFPrudencio Almonte IIIPas encore d'évaluation

- Steel - Equivalent GradesDocument17 pagesSteel - Equivalent Gradessmsett100% (5)

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDocument4 pagesCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausPas encore d'évaluation

- 42CrMo4 10083Document5 pages42CrMo4 10083DavindRa SoniPas encore d'évaluation

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiPas encore d'évaluation

- Swagelok Fitting PDFDocument16 pagesSwagelok Fitting PDFmattuiffPas encore d'évaluation

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- AAP S7 SS316 Threaded Fittings SDocument11 pagesAAP S7 SS316 Threaded Fittings Syocus_ooiPas encore d'évaluation

- Rhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Document3 pagesRhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Yerson JuarezPas encore d'évaluation

- 0737 11SMnPb37Document1 page0737 11SMnPb37rgi178Pas encore d'évaluation

- Swagelok CatalogueDocument16 pagesSwagelok CatalogueZacharia JohnPas encore d'évaluation

- CSC STEEL PRODUCT GUIDEDocument43 pagesCSC STEEL PRODUCT GUIDEedgarc999Pas encore d'évaluation

- Pipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsDocument16 pagesPipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsMehmet YılmazPas encore d'évaluation

- Spec 4140 & 4130Document7 pagesSpec 4140 & 4130Nisa_nishePas encore d'évaluation

- A07-297 OD Expanded Small PartsDocument12 pagesA07-297 OD Expanded Small PartsKyle DriscollPas encore d'évaluation

- Quality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Pas encore d'évaluation

- Metric Seamless Tube Stock Sizes & SpecificationsDocument1 pageMetric Seamless Tube Stock Sizes & SpecificationsmcrajpuraPas encore d'évaluation

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494Pas encore d'évaluation

- SCR 420 (Japan / Jis) : Material PropertiesDocument7 pagesSCR 420 (Japan / Jis) : Material PropertiesldqtPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvPas encore d'évaluation

- Ap11t Ap101t Ap102t Ap141tDocument2 pagesAp11t Ap101t Ap102t Ap141tBalderas Rosas WilibaldoPas encore d'évaluation

- T-413-B, Class 125 Bronze Check ValvesDocument1 pageT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoPas encore d'évaluation

- Chapter 1Document1 pageChapter 1Balderas Rosas WilibaldoPas encore d'évaluation

- Step 1: Start Your Estimate With A Gut Check: RELATED: 16 Tips For New Project ManagersDocument1 pageStep 1: Start Your Estimate With A Gut Check: RELATED: 16 Tips For New Project ManagersBalderas Rosas WilibaldoPas encore d'évaluation

- DrawingDocument1 pageDrawingBalderas Rosas WilibaldoPas encore d'évaluation

- Pipe 1Document1 pagePipe 1Balderas Rosas WilibaldoPas encore d'évaluation

- WAF Indicators Progress Report#1Document3 pagesWAF Indicators Progress Report#1Balderas Rosas WilibaldoPas encore d'évaluation

- Step 2: Build A Bottoms-Up Estimate With Data: RELATED: 16 Tips For New Project ManagersDocument4 pagesStep 2: Build A Bottoms-Up Estimate With Data: RELATED: 16 Tips For New Project ManagersBalderas Rosas WilibaldoPas encore d'évaluation

- PRDocument3 pagesPRBalderas Rosas WilibaldoPas encore d'évaluation

- SkillsDocument1 pageSkillsBalderas Rosas WilibaldoPas encore d'évaluation

- Chapter 1Document1 pageChapter 1Balderas Rosas WilibaldoPas encore d'évaluation

- Chapter 1Document1 pageChapter 1Balderas Rosas WilibaldoPas encore d'évaluation

- Pipe 1Document1 pagePipe 1Balderas Rosas WilibaldoPas encore d'évaluation

- Pipe 1Document1 pagePipe 1Balderas Rosas WilibaldoPas encore d'évaluation

- PipeDocument3 pagesPipeBalderas Rosas WilibaldoPas encore d'évaluation

- Pipe 1Document1 pagePipe 1Balderas Rosas WilibaldoPas encore d'évaluation

- PipeDocument3 pagesPipeBalderas Rosas WilibaldoPas encore d'évaluation

- Pipe 1Document1 pagePipe 1Balderas Rosas WilibaldoPas encore d'évaluation

- ReadmeDocument1 pageReadmeAdekimi EmmanuelPas encore d'évaluation

- General Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesDocument25 pagesGeneral Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesBalderas Rosas WilibaldoPas encore d'évaluation

- Benefits From Project ManagementDocument2 pagesBenefits From Project ManagementBalderas Rosas WilibaldoPas encore d'évaluation

- General Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesDocument14 pagesGeneral Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesBalderas Rosas WilibaldoPas encore d'évaluation

- Lear ObjetivesDocument1 pageLear ObjetivesBalderas Rosas WilibaldoPas encore d'évaluation

- General Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesDocument1 pageGeneral Responsibilities of Engineering and Design Personnel Following Are The Key Responsibilities Applicable To All Individuals Participating in Engineering and Design Project Delivery ActivitiesBalderas Rosas WilibaldoPas encore d'évaluation

- Lear ObjetivesDocument1 pageLear ObjetivesBalderas Rosas WilibaldoPas encore d'évaluation

- Benefits From Project ManagementDocument2 pagesBenefits From Project ManagementBalderas Rosas WilibaldoPas encore d'évaluation

- Benefits From Project ManagementDocument2 pagesBenefits From Project ManagementBalderas Rosas WilibaldoPas encore d'évaluation

- Lear ObjetivesDocument1 pageLear ObjetivesBalderas Rosas WilibaldoPas encore d'évaluation

- Lear ObjetivesDocument1 pageLear ObjetivesBalderas Rosas WilibaldoPas encore d'évaluation

- 14x14tbar PDFDocument1 page14x14tbar PDFBalderas Rosas WilibaldoPas encore d'évaluation

- Micron Precision Screws: Leading automotive and industrial fastener manufacturer since 1979Document18 pagesMicron Precision Screws: Leading automotive and industrial fastener manufacturer since 1979rakeshsaini81Pas encore d'évaluation

- DESIGN CODE IS:800-2007 SPLICE PLATEDocument2 pagesDESIGN CODE IS:800-2007 SPLICE PLATEmaheshbandhamPas encore d'évaluation

- RITZ Screw SpecificationDocument12 pagesRITZ Screw Specificationmx100sanookPas encore d'évaluation

- Structure October 2019Document61 pagesStructure October 2019Matumbi NaitoPas encore d'évaluation

- StockhamCastSteelCV 807 PDFDocument24 pagesStockhamCastSteelCV 807 PDFchabibPas encore d'évaluation

- Tekla Steel - Modeling TipsDocument29 pagesTekla Steel - Modeling TipsMel YaunPas encore d'évaluation

- Bomba de Calor JandyDocument96 pagesBomba de Calor JandyHumberto TorresPas encore d'évaluation

- Catalogue AMF Hand ToolsDocument72 pagesCatalogue AMF Hand ToolskitofanecoPas encore d'évaluation

- Parts Catalog: TH 6X4 Gator™ Utility Vehicle (Diesel)Document240 pagesParts Catalog: TH 6X4 Gator™ Utility Vehicle (Diesel)alisson mateus oliveira pereira100% (3)

- Section Seven: Cash Acceptor, DPT & DialsDocument46 pagesSection Seven: Cash Acceptor, DPT & DialsJulian Camilo Moreno CárdenasPas encore d'évaluation

- 2008 Winchester Parts PricelistDocument74 pages2008 Winchester Parts PricelistMiguel100% (1)

- ATAD Brochure August 10 2018 PDFDocument127 pagesATAD Brochure August 10 2018 PDFHai Tran0% (1)

- MAB 103B-24 - Parts - 2011Document60 pagesMAB 103B-24 - Parts - 2011Centrifugal SeparatorPas encore d'évaluation

- ESR - 2948 FisherDocument14 pagesESR - 2948 FisherReinel OrjuelaPas encore d'évaluation

- Packomat Mounted Ploughs: Spare Parts ListDocument86 pagesPackomat Mounted Ploughs: Spare Parts ListMariusz MurawskiPas encore d'évaluation

- Structural Steel Framing - SMM7 ExplainedDocument2 pagesStructural Steel Framing - SMM7 Explaineddohaqs123Pas encore d'évaluation

- 805steel Gravity Water TanksDocument20 pages805steel Gravity Water TanksAMITaXWIPas encore d'évaluation

- Rotork E370E AWT Range Installation and Maintenance InstructionDocument36 pagesRotork E370E AWT Range Installation and Maintenance Instructionahmedsalehawad100% (1)

- Md17iu 001BW PDFDocument72 pagesMd17iu 001BW PDFVictorAndradeRPas encore d'évaluation

- Volkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)Document210 pagesVolkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)jerryalfaPas encore d'évaluation

- Arema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierDocument13 pagesArema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierToni Garrote Ferrero100% (2)

- FixingsDocument31 pagesFixingsGabor OlahPas encore d'évaluation

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihPas encore d'évaluation

- Serial Number Range: From SN TZ5004-001Document188 pagesSerial Number Range: From SN TZ5004-001Святослав ВороновPas encore d'évaluation

- Steel MCQ MergedDocument44 pagesSteel MCQ MergedNischal thapaliyaPas encore d'évaluation

- Asme B5.60-2014 (2019)Document112 pagesAsme B5.60-2014 (2019)윤규섭0% (1)

- GYPSUM BOARD Guide Specification National Gypsum CompanyDocument19 pagesGYPSUM BOARD Guide Specification National Gypsum CompanyJerome PalictePas encore d'évaluation

- Manual Vulcan Copperhead RevADocument8 pagesManual Vulcan Copperhead RevAJesus MoralesPas encore d'évaluation

- Metric Heavy Structural Bolts: American National StandardDocument22 pagesMetric Heavy Structural Bolts: American National StandardArun CherianPas encore d'évaluation