Académique Documents

Professionnel Documents

Culture Documents

Aa 036322 001

Transféré par

petronashscribdidTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aa 036322 001

Transféré par

petronashscribdidDroits d'auteur :

Formats disponibles

990

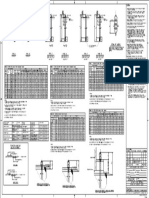

NOTES:

PLANT NO.

AA-036322

001

DRAWING NUMBER

INDEX

08

SHT. NO.

REV. NO.

1. ANCHOR BOLTS SHALL BE SET ACCURATELY AND HELD IN

LENGTH

THREAD

TOP OF ROUGH

CONC.

2. PLASTIC ANCHOR BOLT SLEEVES SHALL BE USED WHERE

SPECIFIED IN

CONSTRUCTION DRAWINGS. CENTER SLEEVES

AROUND BOLTS.

4d o

PROJ.

CONC.

LENGTH

THREAD

TOP OF ROUGH

4d o

PROJ.

CONC.

LENGTH

THREAD

TOP OF ROUGH

4d o

PROJ.

CONC.

LENGTH

THREAD

TOP OF ROUGH

4d o

CONC.

Lt

TOP OF ROUGH

PROJ.

LENGTH

THREAD

PROJ.

LENGTH

Lt

PROJ.

THREAD

PLACE BY A TEMPLATE.

TOP OF ROUGH

3. THE BOTTOM OF ANCHOR BOLTS SHALL BE SECURED TO

CONC.

PREVENT MOVEMENT OR TILTING OF THE BOLTS DURING

SLEEVE

SLEEVE

( SEE NOTE 8 )

( SEE NOTE 8 )

( SEE NOTE 8 )

SD

SL

SLEEVE

SL

SL

CONCRETE PLACEMENT.

SD

4. FULLY THREADED ASTM A36/A36M RODS MAY BE USED TO

CUT LINE

FABRICATE TYPE 2 OR TYPE 2S ANCHOR BOLTS.

SD

5. FULLY THREADED ASTM A193/A193M RODS MAY BE USED TO

SL

do

hef

do

hef

do

hef

do

hef

L

hef

L

hef

FABRICATE TYPE 3 OR TYPE 3S ANCHOR BOLTS.

SD

do

6. ANCHOR BOLT DESIGN SHALL COMPLY WITH SAES-Q-005

AND ACI 318-02, APPENDIX D.

do

7. THE FINAL TIGHTENING OF ANCHOR BOLTS SHALL BE AS

FOLLOWS; AFTER GROUTING OF THE BASE PLATE THE

ANCHOR BOLTS SHALL BE BROUGHT TO A SNUG TIGHT

CONDITION. THIS IS DEFINED AS THE TIGHTNESS THAT

EXISTS AFTER A FEW IMPACTS FROM AN IMPACT WRENCH

OR THE FULL EFFORT OF A MAN USING A SPUD WRENCH.

AT THIS POINT ALL SURFACES SHOULD BE IN FULL

T1

L1

T1

L1

T1

L1

L1

T1

CONTACT.

8. ANCHOR BOLT SLEEVES SHALL BE FULLY GROUTED IN

ACCORDANCE WITH SAES-Q-010 AFTER THE BASE PLATE

HAS BEEN POSITIONED.

TACK

TACK

WELD

WELD

9. THE SPACING, EMBEDMENT AND EDGE DISTANCE

DETAIL OF SLEEVE

DIMENSIONS SHOWN ON THIS DRAWING ARE MINIMUM

FOR NUT INSTALLATION

VALUES. EVERY ANCHOR BOLT MUST BE DESIGN PER

( SEE NOTE 10 )

PLASTIC ANCHOR BOLT SLEEVES SHALL BE USED

ACI 318-02 AND MINIMUM DIMENSIONS MAY NEED TO BE

WHERE REQUIRED BY DESIGN. TOP OF SLEEVE

INCREASED AS REQUIRED BY DESIGN.

SHALL BE CUT OFF TO MAINTAIN EMBEDMENT

LENGTH.

10. TIGHTEN NUTS TO LOCK. APPLY TORQUE TO BOTTOM

NUT. LOCK BOTH NUTS IN POSITION BY COUNTER

TYPE 1

TYPE 1S

ASTM A307

ASTM A307

TYPE 2

ASTM A36/A36M or

ASTM F1554, Gr. 36

ASTM A36/A36M or

ASTM F1554, Gr. 36

( SEE NOTE 4 )

PUNCHING THE THREADS AT JUNCTURE OF NUTS

TYPE 3

TYPE 3S

ASTM A193/A193M or

ASTM F1554, Gr. 105

ASTM A193/A193M or

ASTM F1554, Gr. 105

TYPE 2S

( SEE NOTE 4 )

( SEE NOTE 5 )

AND BOLT.

11. INSTALLATION TOLERANCES FOR ANCHOR BOLTS:

ANCHOR BOLTS AND FOUNDATION BOLTS ARE TO BE SET IN

ACCORDANCE WITH AN APPROVED DRAWING. THEY MUST NOT

( SEE NOTE 5 )

VARY FROM THE DIMENSIONS SHOWN ON THE DRAWINGS BY

MORE THAN THE FOLLOWING:

( a )

Table 3 - ASTM A193, ASTM F1554 Grade 105 Anchor Rods-Inch Series

Bolt Properties

Table 1- ASTM A307, Grade A Bolt Sizes-Inch Series

Table 2 - ASTM A36, ASTM F1554 Grade 36 Anchor Rods-Inch Series

Bolt Properties

Type 1

Size

Max. Proj.

Area

( note c )

12d o

2

( in )

(mm)

(mm)

Lt

do

Type

(in)

1/2

h efmin.

Stress

TP1

(in)

Hex

1.50

13

0.142

107

152

Type 1S

Length (L)

Edge Dist.

Spacing

Proj.+ hef

4do 100+do/2

6d o

SL+150

Proj.+ hef

(mm)

(mm)

(mm)

(in)

(in)

10

108

76

h efmin.

Length (L)

275

Edge Dist.

(note d)

Spacing

(note e)

(mm)

(mm)

15

Bolt Properties

127

114

Sleeve

Size

SD

SL

do

(mm)

(mm)

(in)

TP1

1/2

13

Type 2

L1

T1

h efmin.

Edge Dist.

Spacing

Area

do+13

2d o

12d o

4do 100+do/2

6d o

SL+150

(note b)

2

( in )

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

125

0.142

26

25

5/8

11

0.226

29

32

10

0.334

32

152

do

Type 2S

Stress

50

Size

h efmin.

108

76

275

191

110

95

325

38

229

111

114

Edge Dist.

Spacing

(mm)

127

(in)

Sleeve

(note c)

TP1

Type 3

Stress

L1

T1

Area

2do+13

3do

2

( in )

(mm)

(mm)

AN ANCHOR BOLT GROUP, WHERE AN ANCHOR BOLT GROUP

IS DEFINED AS THE SET OF ANCHOR BOLTS WHICH RECEIVE

Type 3S

A SINGLE FABRICATED STEEL SHIPPING PIECE .

Edge Dist.

Spacing

h efmin.

12do

6do 100+do/2

6d o

SL+150

(note b)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

h efmin.

Edge Dist.

Spacing

(note c)

Sleeve

( b )

SD

SL

(mm)

(mm)

SD

SL

3/4

10

0.334

51

57

229

114

114

325

130

145

50

175

(mm)

(mm)

7/8

0.462

57

67

267

133

133

325

147

161

50

175

0.606

64

76

305

152

152

400

177

202

75

250

171

171

421

195

218

75

250

125

1/2-INCH CENTER TO CENTER OF ANY TWO BOLTS WITHIN

114

50

127

129

50

175

1-1/8

0.790

70

86

343

325

127

145

50

175

1-1/4

1.000

77

95

381

191

191

441

212

234

75

250

5/8

Hex

1.75

11

0.226

115

191

12

110

95

325

17 1/2

127

129

50

175

3/4

Hex

2.00

10

0.334

123

229

14

111

114

325

17 1/2

127

145

50

175

3/4

7/8

Hex

2.25

0.462

131

267

15 1/2

113

133

325

18

127

161

50

175

7/8

0.462

35

44

267

113

133

325

127

161

50

175

1-3/8

1.234

83

105

419

210

210

460

230

250

75

250

Hex

2.50

0.606

139

305

17 1/2

114

152

400

21

139

202

75

250

0.606

38

51

305

114

152

400

139

202

75

250

1-1/2

1.492

89

114

457

229

229

604

260

291

100

375

1-1/8

Hex

2.75

0.763

146

343

19 1/2

116

171

421

22 1/2

139

218

75

250

1-1/8

0.763

42

57

343

116

171

421

139

218

75

250

1-3/4

2.082

102

133

533

267

267

642

294

322

100

375

1-1/4

Hex

3.00

0.969

154

381

21

127

191

441

23 1/2

149

234

75

250

1-1/4

0.969

45

64

381

127

191

441

149

234

75

250

2-1/4

3.557

127

171

686

343

343

793

364

386

100

450

1-3/8

Hex

3.25

1.155

162

419

23

140

210

460

24 1/2

160

250

75

250

1-3/8

1.155

48

70

419

140

210

460

160

250

75

250

2-1/2

4.442

140

191

762

381

381

981

424

468

150

600

1-1/2

Hex

3.50

1.405

170

457

24 1/2

152

229

604

30 1/2

183

291

100

375

1-1/2

1.405

51

76

457

152

229

604

183

291

100

375

2-3/4

5.425

153

210

838

419

419

1019

459

499

150

600

1.899

57

89

533

178

267

642

206

322

100

375

6.506

165

229

914

457

457

1057

494

531

150

600

1/4-INCH CENTER TO CENTER OF ADJACENT ANCHOR BOLT

GROUP .

( c )

ELEVATION OF THE TOP OF ANCHOR BOLTS + 1/2-INCH.

( d )

MAXIMUM ACCUMULATION OF 1/4-INCH PER HUNDRED FEET

ALONG THE ESTABLISHED COLUMN LINE OF MULTIPLE

ANCHOR BOLT GROUPS, BUT NOT TO EXCEED A TOTAL OF

1 IN ., WHERE THE ESTABLISHED COLUMN LINE IS THE

ACTUAL FIELD LINE MOST REPRESENTATIVE OF THE

1-3/4

Heavy Hex

4.00

1.899

186

533

28 1/2

178

267

642

32 1/2

206

322

100

375

1-3/4

Heavy Hex

4.50

4.5

2.498

202

610

32

203

305

755

37 1/2

228

354

100

450

4.5

2.498

64

102

610

203

305

755

228

354

100

450

2-1/4

Heavy Hex

5.00

4.5

3.248

218

686

35 1/2

229

343

793

40

250

386

100

450

2-1/4

4.5

3.248

70

114

686

229

343

793

250

386

100

450

2-1/2

Heavy Hex

5.50

3.999

234

762

39

254

381

981

48

297

468

150

600

2-1/2

4.0

3.999

77

127

762

254

381

981

297

468

150

600

2-3/4

Heavy Hex

6.00

4.934

250

838

43

279

419

1019

50

319

499

150

600

2-3/4

4.0

4.934

83

140

838

279

419

1019

319

499

150

600

Heavy Hex

6.50

5.967

266

914

46 1/2

305

457

1057

52

342

531

150

600

4.0

5.967

89

152

914

305

457

1057

342

531

150

600

CENTERS OF THE AS-BULIT ANCHOR BOLT GROUPS ALONG

A LINE OF COLUMNS .

( e )

1/4-INCH FROM THE CENTER OF ANY ANCHOR BOLT GROUP

TO THE ESTABLISHED COLUMN LINE THROUGH THAT GROUP .

( f )

THE TOLERANCE OF PARAGRAPHS b, c AND d APPLY TO

OFFSET DIMENSIONS SHOWN ON THE PLAN, MEASURED

PARALLEL AND PERPENDICULAR TO THE NEARST

ESTABLISHED COLUMN LINE FOR INDIVIDUAL COLUMN SHOWN

ON THE PLANS TO BE OFFSET FROM ESTABLISHED COLUMN

LINES .

NOTES:

( g )

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

UNLESS SHOWN OTHERWISE, ANCHOR BOLTS ARE SET

PERPENDICULAR TO THE THEORETICAL BEARING SURFACE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

MISALIGNMENT FROM VERTICAL MAY NOT EXCEED 1:40 .

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

NOTES:

NOTES:

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

b. ASTM A307 BOLT LENGTHS MAY NOT BE AVAILABLE FOR THE LARGER

d. TPI = THREADS PER INCH.

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

DIAMETER TYPE 1S BOLTS.

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

c. IF THE REQUIRED PROJECTION EXCEED THE MAXIMUM PROJECTION

IN THE TABLE ABOVE, USE A TYPE 2 ANCHOR BOLT.

d. TPI = THREADS PER INCH.

Table 3M - ASTM A193M Anchor Rods - Metric

d. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY

Bolt Properties

( SD-do )/2

Table 2M - ASTM A36 Anchor Rods - Metric

e. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD- do )

Bolt Properties

f. TPI= THREADS PER INCH.

Sizes

Profile

Specification

1/2 " thru 1-1/2"

Thread

Nut Material

Profile

Specification

L1

T1

& thread pitch

Area

do+13

2d o

12d o

2

(mm )

(mm)

(mm)

(mm)

(mm)

(mm)

M12x1.75

84.3

25

24

144

106

72

275

M16x2

157

29

32

192

108

96

M20x2.5

245

33

40

240

110

M24x3

353

37

48

288

Rod

1/2 " thru 3"

Rod

Edge Dist.

SL

(mm)

(mm)

(mm)

125

110

50

125

275

125

130

50

125

120

325

125

150

50

175

112

144

400

138

195

75

250

(note b)

(mm)

(mm)

(note c)

ASME B1.1, UNC, Class 2

ASTM A563, Gr. A

Galvanized to ASTM A153/A153M,

M27x3

459

40

54

324

114

162

400

138

210

75

250

ASME B1.13M

Heavy Hex

Class C or ASTM B695, Class 50

M30x3.5

561

43

60

360

120

180

400

143

225

75

250

ASME B1.1, UNC, Class 2

ASTM A563, Gr. A

Galvanized to ASTM A153/A153M,

M36x4

817

49

72

432

144

216

525

176

280

100

375

Heavy Hex

Class C or ASTM B695, Class 50

M42x4.5

1120

55

84

504

168

252

525

197

310

100

375

ASME B1.1, 8 UN, Class 2

ASTM A563, DH Heavy Hex

Galvanized to ASTM A153/A153M,

M48x5

1470

61

96

576

192

288

600

218

340

100

450

ASME B1.13M

or ASTM A194/A 194M

Class C or ASTM B695, Class 50

M56x5.5

2030

69

112

672

224

336

672

246

380

100

450

ASME B1.1, 8 UN, Class 2

ASTM A563, DH Heavy Hex

Galvanized to ASTM A153/A153M,

M64x6

2680

77

128

768

256

384

768

299

470

150

600

or ASTM A194/A 194M

Class C or ASTM B695, Class 50

M72x6

3460

85

144

864

288

432

864

327

510

150

600

ASTM F1554, Gr.36

3/4 " thru 3"

Bolts/Rods

Nominal Dia. ( do )

Stress

L1

& thread pitch

Area

2d o+13

2

(mm )

(mm)

(mm)

(mm)

Sleeve

SD

6d

SL+150

Spacing

Class C or ASTM B695, Class 50

ASTM A36/A36M

M12 thru M72

4do 100+do/2

Spacing

Heavy Hex

Heavy Hex Bolt

1/2 " thru 3"

Edge Dist.

Galvanized to ASTM A153/A153M,

ASME B18.2.1, UNC

over 1-1/2"

h efmin.

Stress

ASTM A563, Gr. A

Hex Bolt

ASTM A307, Grade A

Coating Type

h efmin.

Type 2S

Nominal Dia. ( do )

(mm)

Anchor Material

Type 2

Type 3

T1

3d

h efmin.

Edge Dist.

Type 3S

Spacing

12d o

6do 100+do/2

(mm)

(mm)

(mm)

6d o

h efmin.

Edge Dist.

SL+150

(note b)

(mm)

(mm)

Spacing

(note c)

Sleeve

SD

SL

(mm)

(mm)

(mm)

M20x2.5

245

53

60

240

120

120

325

135

150

50

175

M24x3

353

61

72

288

144

144

400

170

195

75

250

M27x3

459

67

81

324

162

162

400

186

210

75

250

M30x3.5

561

73

90

360

180

180

400

203

225

75

250

M36x4

817

85

108

432

216

216

525

248

280

100

375

M42x4.5

1120

97

126

504

252

252

525

281

310

100

375

M48x5

1470

109

144

576

288

288

600

314

340

100

450

M56x5.5

2030

125

168

672

336

336

672

358

380

100

450

M64x6

2680

141

192

768

384

384

768

427

470

150

600

M72x6

3460

157

216

864

432

432

864

471

510

150

600

ASTM A193/A193M, Gr. B7

M20 thru M72

3/4 " thru 3"

Rod

ASTM F1554 Gr. 105

M20 thru M72

NOTES:

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

NOTES:

FORMAT FOR ANCHOR BOLT

CALL OUT ON DRAWINGS

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

DWG. RESPONSIBILITY:

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

ONSHORE STRUCTURES STANDARDS COMMITTEE

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

ANCHOR BOLT TYPE

3 d

BOLT DIAMETER (do )

AB 3S-1-1/2"-100-600-(2)

NUMBER OF NUTS

VESSEL SKIRT

08

DEC.20

MSM

07

AUG02

MNL

REV.

NO.

DATE

REVISED AS MARKED-UP PRINT

CCB

TOP OF THE GROUT

TOP OF BASE PL

PROJ.

PROJ.

TOP OF BASE PL

INCH SIZES

3 d

2 d

PROJECTION

TOP OF CONCRETE

TOP OF THE GROUT

ANCHOR BOLT TYPE

VESSEL BASE RING

COMPLETELY REDRAWN. CHANGED

PROJ.

VESSEL CHAIR HEIGHT

BOLT LENGTH ( L )

DWG. SIZE FROM B TO A.

BY

DESCRIPTION

JO/EWO

SAUDI

ARABIAN

OIL

CHKD.

APPD.

COMPANY

CHECKED BY

DRAWN BY

CERT.

SCALE:

TOP OF CONCRETE

BOLT DIAMETER (do )

TOP OF GROUT

DATE STARTED

DATE COMPLETED

AB 3S-M24-100-600-(2)

TOP OF CONCRETE

NUMBER OF NUTS

ENG. DEPT.

OPRG. DEPT.

d

APPD. FOR CONST.

BOLT LENGTH ( L )

THIS DRAWING IS NOT TO BE USED FOR

PROJECTION

CERTIFIED

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED

BY

DATE

ANCHOR BOLT DETAILS

METRIC SIZES

REQUIRED ANCHOR BOLT PROJECTION-SINGLE NUT

PROJ.=GROUT THICKNESS + BASE L

P THICKNESS + 2d

INCH AND METRIC SIZES

REQUIRED ANCHOR BOLT PROJECTION-DOUBLE NUT

PROJ.=GROUT THICKNESS + BASELP THICKNESS + 3d

STD. DWG.

REQUIRED ANCHOR BOLT PROJECTION FOR VERTICAL VESSELS (WITH CHAIRS)

PLANT NO.

INDEX

PROJ.=GROUT THICKNESS + CHAIR HEIGHT + 3 d

990

DRAWING NUMBER

SHT. NO.

AA-036322

001

REV. NO.

08

Saudi Aramco 2615 ENG. (3/91)

CADD-02

Vous aimerez peut-être aussi

- Saes R 004Document8 pagesSaes R 004nadeem shaikh100% (1)

- 12 Samss 007 PDFDocument30 pages12 Samss 007 PDFMohammadAseef100% (1)

- PIP STF05520 Dec 2019 - Pipe Guardrails - CompleteDocument43 pagesPIP STF05520 Dec 2019 - Pipe Guardrails - Completetylerstearns100% (2)

- PIP STS03600 (Nonshrink Cementitous Grout Specification)Document8 pagesPIP STS03600 (Nonshrink Cementitous Grout Specification)Javad Monfared100% (1)

- AA-036322-001 - Anchor Bolt Details - Inch and Metric Sizes PDFDocument1 pageAA-036322-001 - Anchor Bolt Details - Inch and Metric Sizes PDFSHAIK ASIMUDDINPas encore d'évaluation

- Pip Vefv1102Document1 pagePip Vefv1102ParkerPas encore d'évaluation

- Pipe Support FluorDocument79 pagesPipe Support FluorWaldomiroCano100% (8)

- PIP CVS02100Site Preparation, Excavation, and Backfill SpecificationDocument20 pagesPIP CVS02100Site Preparation, Excavation, and Backfill Specificationivanov55590% (1)

- Saes A 113 PDFDocument39 pagesSaes A 113 PDFYAZAN ALFARRAPas encore d'évaluation

- PIP STE05121 (Anchor Bolt Design Guide)Document55 pagesPIP STE05121 (Anchor Bolt Design Guide)bowitchhazelPas encore d'évaluation

- 12 Samss 020Document46 pages12 Samss 020NizaModdin50% (4)

- Screw Jack DesignDocument17 pagesScrew Jack DesignMayur Prakash Jagtap75% (4)

- Structural Steel Design Fabrication and Construction 00Document60 pagesStructural Steel Design Fabrication and Construction 00Dedy KristiantoPas encore d'évaluation

- Saes B 054Document14 pagesSaes B 054Tarek Mustafa100% (1)

- 12 Samss 007Document29 pages12 Samss 007umer.shariff87100% (1)

- List of Civil PIP CodesDocument1 pageList of Civil PIP Codesmassive85100% (1)

- Sabq-Q-004-Horizontal Vessels PDFDocument55 pagesSabq-Q-004-Horizontal Vessels PDFVignesh KishorekumarPas encore d'évaluation

- Saes L 440 PDFDocument14 pagesSaes L 440 PDFSana Ullah HashemiPas encore d'évaluation

- Structural List of PipDocument1 pageStructural List of Pipstr_designPas encore d'évaluation

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- 32 Samss 017Document11 pages32 Samss 017naruto256Pas encore d'évaluation

- PIP - STD - STS05130 Struct Erection 2-2002Document11 pagesPIP - STD - STS05130 Struct Erection 2-2002John ClaytonPas encore d'évaluation

- 09-SAMSS-097 - Ready-Mixed Concrete PDFDocument9 pages09-SAMSS-097 - Ready-Mixed Concrete PDFMohamed Reda HusseinPas encore d'évaluation

- Saes H 101Document77 pagesSaes H 101Henry Ocbina Luares100% (6)

- Pip STF 05501 - 2012Document17 pagesPip STF 05501 - 2012Денис Пекшуев100% (1)

- Ste 03350Document34 pagesSte 03350WPas encore d'évaluation

- Sabp Q 006Document31 pagesSabp Q 006ilyaskureshi100% (1)

- Pip STS03001Document6 pagesPip STS03001Omisawant100% (1)

- Saic A 1001Document3 pagesSaic A 1001Tayyab KhanPas encore d'évaluation

- PIP STI03310 Concrete General Notes and Typical DetailsDocument16 pagesPIP STI03310 Concrete General Notes and Typical Detailsusotapioca0% (1)

- Standard Drawing For Stationary Equipment (1) - 2Document76 pagesStandard Drawing For Stationary Equipment (1) - 2SYedZYnAlePas encore d'évaluation

- Sabp Q 003 PDFDocument41 pagesSabp Q 003 PDFVignesh KishorekumarPas encore d'évaluation

- Saudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralDocument12 pagesSaudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralAbid HussainPas encore d'évaluation

- Materials System Specification: Saudi Aramco Desktop StandardsDocument14 pagesMaterials System Specification: Saudi Aramco Desktop StandardsMoustafa Bayoumi100% (1)

- 175 325100Document2 pages175 325100sridhar100% (1)

- 12 Samss 014Document31 pages12 Samss 014rab_forcePas encore d'évaluation

- Saes Q 010Document4 pagesSaes Q 010Nazir Hussain100% (2)

- SAES-M-001 PDF Download - Structural Design Criteria For Non-Building Structures - PDFYAR - Engineering Notes, Documents & LecturesDocument10 pagesSAES-M-001 PDF Download - Structural Design Criteria For Non-Building Structures - PDFYAR - Engineering Notes, Documents & LecturesZahidRafiquePas encore d'évaluation

- Anchor Bolt DesignDocument60 pagesAnchor Bolt DesignS.s. LeePas encore d'évaluation

- ARAMCO DrawingDocument1 pageARAMCO DrawingLainhatanhPas encore d'évaluation

- Saic M 1037Document3 pagesSaic M 1037Hussain Nasser Al- Nowiesser100% (1)

- Saes Q 001Document22 pagesSaes Q 001ahmed hashemPas encore d'évaluation

- Anchor Bolts DesignDocument54 pagesAnchor Bolts DesignYash Paul73% (11)

- 12 Samss 007Document33 pages12 Samss 007marghoobPas encore d'évaluation

- EIL Painting Spec B16!79!41 PLS 01Document61 pagesEIL Painting Spec B16!79!41 PLS 01mANISH THIRANI100% (3)

- SAES-Q-005 (Concrete Foundations)Document1 pageSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroPas encore d'évaluation

- PIP STS03001 (Plain & Reinforced Concrete Specification)Document15 pagesPIP STS03001 (Plain & Reinforced Concrete Specification)mobin1978Pas encore d'évaluation

- Windload CalculationDocument89 pagesWindload Calculationjpsingh823632Pas encore d'évaluation

- Saes D 001Document36 pagesSaes D 001Syed Zain Ali100% (2)

- Saes D 100 PDFDocument22 pagesSaes D 100 PDFShajin Mohammed Shamsudhin0% (1)

- 175 000003Document1 page175 000003zhangPas encore d'évaluation

- 6-79-0016 Rev 1Document11 pages6-79-0016 Rev 1abhishek100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistphilipyapPas encore d'évaluation

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserPas encore d'évaluation

- Stress Relief Boreback BoxDocument3 pagesStress Relief Boreback BoxDaisuke Numata100% (1)

- Bolts - LRFDDocument6 pagesBolts - LRFDalexortiz83Pas encore d'évaluation

- SRTDocument3 pagesSRTDaniel SamokovliaPas encore d'évaluation

- MS16995H ScrewDocument9 pagesMS16995H ScrewacparaujoPas encore d'évaluation

- F 1018 - 87a R99 - RJEWMTG - PDFDocument12 pagesF 1018 - 87a R99 - RJEWMTG - PDFRománBarciaVazquezPas encore d'évaluation

- PipelineDocument3 pagesPipelineKrystle FlowersPas encore d'évaluation

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현Pas encore d'évaluation

- A2 1 16junDocument2 pagesA2 1 16junamitrai86Pas encore d'évaluation

- 12, Hari Nagar-F.floorDocument1 page12, Hari Nagar-F.floorpetronashscribdidPas encore d'évaluation

- Book Sle AdminDocument464 pagesBook Sle AdminIrina GrosuPas encore d'évaluation

- Install en PDFDocument150 pagesInstall en PDFIrhas KholikPas encore d'évaluation

- Train Ticket Booking DetailsDocument2 pagesTrain Ticket Booking DetailspetronashscribdidPas encore d'évaluation

- Printer Usage Report For The Month of July-2015Document2 pagesPrinter Usage Report For The Month of July-2015petronashscribdidPas encore d'évaluation

- HP LaserJet M5035 MFP SeriesDocument2 pagesHP LaserJet M5035 MFP SeriespetronashscribdidPas encore d'évaluation

- Y S T Fuse Terminal DatasheetDocument2 pagesY S T Fuse Terminal DatasheetpetronashscribdidPas encore d'évaluation

- Thermal Analysis of FRP Chimneys Using Consistent Laminated Shell ElementDocument20 pagesThermal Analysis of FRP Chimneys Using Consistent Laminated Shell ElementpetronashscribdidPas encore d'évaluation

- Introducing Adobe® Media Server 5: Secure Video Experiences Consistent Across DevicesDocument32 pagesIntroducing Adobe® Media Server 5: Secure Video Experiences Consistent Across DevicespetronashscribdidPas encore d'évaluation

- TestDocument1 pageTestpetronashscribdidPas encore d'évaluation

- Mr. S.Sugumar,: Deputy Director & Head - HLC Cipet Thiru - Vi.ka Industrial Estate, Guindy, Chennai - 600 032Document1 pageMr. S.Sugumar,: Deputy Director & Head - HLC Cipet Thiru - Vi.ka Industrial Estate, Guindy, Chennai - 600 032petronashscribdidPas encore d'évaluation

- TestDocument1 pageTestpetronashscribdidPas encore d'évaluation

- Introducing Adobe® Media Server 5: Secure Video Experiences Consistent Across DevicesDocument32 pagesIntroducing Adobe® Media Server 5: Secure Video Experiences Consistent Across DevicespetronashscribdidPas encore d'évaluation

- D ME Project PH 2 Specimen PS-01Document1 pageD ME Project PH 2 Specimen PS-01petronashscribdidPas encore d'évaluation

- Vel MuruganDocument6 pagesVel MuruganpetronashscribdidPas encore d'évaluation

- Direct Analysis MethodDocument31 pagesDirect Analysis MethodgayalamPas encore d'évaluation

- TNPSC Annual Planner Table (2012-2013)Document2 pagesTNPSC Annual Planner Table (2012-2013)training2jobsPas encore d'évaluation

- I LL Ino I: Production NoteDocument44 pagesI LL Ino I: Production NotepetronashscribdidPas encore d'évaluation

- Introduction - Metallic Expansion Joint PDFDocument16 pagesIntroduction - Metallic Expansion Joint PDFsdmel100% (2)

- Room ActivitiesDocument1 pageRoom ActivitiespetronashscribdidPas encore d'évaluation

- B3 Magesh Mani B5 15mins 1Document2 pagesB3 Magesh Mani B5 15mins 1petronashscribdidPas encore d'évaluation

- Beam DeflectionDocument9 pagesBeam DeflectionpetronashscribdidPas encore d'évaluation

- LTADocument1 pageLTApetronashscribdidPas encore d'évaluation

- Design of Monorail Systems WhitepaperDocument40 pagesDesign of Monorail Systems Whitepaperhelden50229881Pas encore d'évaluation

- Basic API650Document52 pagesBasic API650Eslam Nagy100% (3)

- 5 1 ViragZoltan V5N1Document15 pages5 1 ViragZoltan V5N1petronashscribdidPas encore d'évaluation

- PdmsDocument133 pagesPdmspetronashscribdidPas encore d'évaluation