Académique Documents

Professionnel Documents

Culture Documents

Valve Data Sheet: As Per Asme B16.34 For Material Group 1.1

Transféré par

Margaret DaughertyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Valve Data Sheet: As Per Asme B16.34 For Material Group 1.1

Transféré par

Margaret DaughertyDroits d'auteur :

Formats disponibles

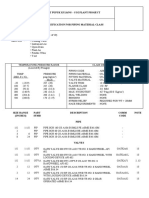

VALVE DATA SHEET

Conoco Indonesia Inc Ltd

VALVE SIZE:

MINIMUM:

1" NB

MAXIMUM:

Dresser Kellogg Energy

Services

4" NB

DESIGN REQUIREMENTS

1

2 VALVE RATING

ASME CLASS 300

3 DESIGN TEMPERATURE RANGE

-20F TO 300F

4 DESIGN PRESSURE

AS PER ASME B16.34 FOR MATERIAL GROUP 1.1

5 PIPING MATERIAL CLASS

B1 & B5

6 PORT

FULL

7 END STYLE

FLANGED RF, FINISH TO ASME B16.5 ( NOTE 3 )

8 FACE TO FACE STANDARD

ASME B 16.10

9 DESIGN/CONSTRUCTION

DESIGN TO BS 5351 / API 6D

1"

10

END ENTRY CONSTRUCTION

2"

15

11

FLOATING BALL

3"

12

ANTI-STATIC

4"

13

BLOW-OUT PROOF STEM

14

AUTO BODY CAVITY PRESSURE RELIEF

15

RENEWABLE SEATS

VALVE QTY (NOs)

Size

01

16

17 OPERATOR

LEVER

FORGED

CARBON STEEL ASTM A105N

FORGED

ASTM A182 Gr F316

24 STEM

ASTM A182 Gr F316 WITH 0.001" E.N.P

25 SEAT RING

26 SEAT

FILLED TFE FIRESAFE SEAT

27 SEALS

VITON/ R.PTFE

29 GLAND PACKING

PTFE

30 GASKETS

31 BOLTING

18

19 MATERIALS

20 BODY

21

22 BALL

23

(NOTE 4)

28

STUD BOLTS TO ASTM A193 Gr. B7 / A194 Gr. 2H HOT DIP SPUN GALVANISED

32

33

34 PAINTING

EXTERNAL PAINTING OF VALVES SHALL BE AS PER DOC. No. B-84505-1000-5L-004 (SYSTEM 2)

EN 10204 TYPE 3.1 B

FIRE SAFE CERTIFICATION TO BS 6755 PART II / API 607 / API 6FA

35

36 CERTIFICATION REQUIREMENTS

37

38

39 SPECIAL REQUIREMENTS

40

41

INSPECTION AND TESTING REQUIREMENTS

42

REQUIRED

43

44 VISUAL EXAMINATION (NOTE A)

100%

INSPECTION AND TESTING NOTES

A WHERE VISUAL EXAMINATION INDICATES AREAS OF POTENTIAL CONCERN, LPI OR MPI

45 MAGNETIC PARTICLE EXAMINATION (NOTE A)

AS REQ'D

46 LIQUID PENETRANT EXAMINATION (NOTE A)

AS REQ'D

B AS PER VALVE SPEC. DOC. No. B-84505-1000-1L-002

47 RADIOGRAPHIC EXAMINATION (NOTE B)

AS REQ'D

C HYDROSTATIC TEST :-

48

49 PRESSURE TESTING (NOTE C)

REQ'D

50 AMBIENT GAS LEAK TESTING (NOTE D)

NOT REQ'D

51 LOW TEMP.GAS LEAK TESTING (NOTE E)

NOT REQ'D

EXAMINATION SHALL BE APPLIED IN ACCORDANCE WITH ASME V ARTICLE 6 ( LPI ) OR ARTICLE 7 ( MPI ).

BODY : 1110

PSIG

AIR UNDER WATER :-

SEAT :

80

PSIG

TEST DURATION :-

BODY : 15

BODY :

BODY :

D AMBIENT TEST (GN2 / GHE) :TEST DURATION :E LOW TEMP.GAS TEST (GN2 / GHE) :-

52

53 SPECIAL REQUIREMENTS

AS REQ'D

TEST DURATION :-

SEAT :

814

PSIG

MIN.

SEAT :

MIN.

PSIG

SEAT :

PSIG

MIN.

SEAT :

MIN.

BODY :

PSIG

SEAT :

PSIG

BODY :

MIN.

SEAT :

MIN.

NOTES

54

55

1 VALVE MARKING TO BE TO MSS-SP-25.

56

2 IN ADDITION TO NAME PLATE , VALVE SHALL BE SUPPLIED WITH A SS316 TAG STAMPED VB-31 FIXED TO THE GLAND BOLTING OR HAND WHEEL WITH SS316 WIRE

57

3 FLANGE FACE FINISH SHALL HAVE A ROUGHNESS BETWEEN 125 in. to 250 in.

58

4 ELASTOMER SEAL MATERIAL SHALL HAVE RESISTANCE TO EXPLOSIVE DECOMPRESSION

59

5 ALL VALVES TO BE PROVIDED WITH LOCK OPEN / CLOSE FACILITIES

60

61

THIS VALVE DATA SHEET SHALL BE READ IN CONJUNCTION WITH VALVE SPEC. No. B-84505-1000-1L-002

CONTRACT/PROJECT No.:

OWNER:

CB021

MANUFACTURER:

LOCATION:

CONOCO INDONESIA INC. LTD

PCC BV

FIGURE No:

BELANAK FPSO FIELD DEVELOPMENT

VALVE TYPE:

VALVE TAG No:

01

23.04.02

RG

BV

ISSUED FOR PURCHASE

GBD

BM

REV

DATE

PREP

CHKD

DESCRIPTION

ENG

APPR

DOCUMENT No.

B-84505-1000-1M-005

BALL

VB-31

REV.

01

VB-31_01

SHEET

Vous aimerez peut-être aussi

- 3500 TroubleshootingSEK PDFDocument33 pages3500 TroubleshootingSEK PDFMargaret Daugherty50% (2)

- Kobelco - 6E Hydraulic SchematicDocument23 pagesKobelco - 6E Hydraulic SchematicHai Van100% (7)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Air Comp INGERSOLL-RAND SEK PDFDocument16 pagesAir Comp INGERSOLL-RAND SEK PDFMargaret Daugherty100% (1)

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- Eil Piping Material SpecDocument48 pagesEil Piping Material Specnisargkedar60% (10)

- Crankcase Ventilation (LEBW4958)Document20 pagesCrankcase Ventilation (LEBW4958)József Nagy100% (2)

- Piping SpecificationsDocument67 pagesPiping SpecificationsVedran Kosanovic100% (3)

- Pressure Testing & QC Test PackDocument10 pagesPressure Testing & QC Test Packravi00098Pas encore d'évaluation

- As 1271 Safety Valves & GuagesDocument50 pagesAs 1271 Safety Valves & Guagespvdang100% (4)

- Kamos Gasket RTJDocument7 pagesKamos Gasket RTJCahya Adi YeftaPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Directional Control ValveDocument12 pagesDirectional Control ValveManojkumar ThilagamPas encore d'évaluation

- ARIEL CompressorSEK PDFDocument80 pagesARIEL CompressorSEK PDFMargaret Daugherty100% (1)

- Centrifugal PumpDocument23 pagesCentrifugal Pumpheri monawir zebuaPas encore d'évaluation

- Valve Data SheetsDocument17 pagesValve Data Sheetszaldy1985Pas encore d'évaluation

- Caterpillar G3500 Top End Overhaulesek PDFDocument18 pagesCaterpillar G3500 Top End Overhaulesek PDFMargaret Daugherty75% (4)

- P&ID ChecklistDocument3 pagesP&ID Checklistkkannan732153Pas encore d'évaluation

- Pressure Safety Valve DatasheetDocument1 pagePressure Safety Valve DatasheetAlvin Smith100% (5)

- Manual Ingersoll RandDocument18 pagesManual Ingersoll RandJunior Francisco QuijanoPas encore d'évaluation

- PIP Line ListDocument2 pagesPIP Line Listomgmatt100% (1)

- TBDP A M DS 0007 2Document7 pagesTBDP A M DS 0007 2Bùi Văn HợpPas encore d'évaluation

- BS en 1092Document21 pagesBS en 1092Pranay Kharbe100% (5)

- Piping Material ClassesDocument42 pagesPiping Material Classest_i_f_anoPas encore d'évaluation

- Schlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsDocument16 pagesSchlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsnvnvPas encore d'évaluation

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Fire Pump Installation GuideDocument3 pagesFire Pump Installation GuideJeff D. AgustinPas encore d'évaluation

- Data Sheet Ball ValveDocument1 pageData Sheet Ball ValveIkhsan Hj SiratPas encore d'évaluation

- EAM MetersDocument20 pagesEAM MetersVictor MillanPas encore d'évaluation

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- Datasheet For Ball ValveDocument16 pagesDatasheet For Ball ValveDamu JankerboyPas encore d'évaluation

- Niikura CatalogueDocument54 pagesNiikura Cataloguemsimran11100% (1)

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- 3500 Engine Oil and Filter - ChangeSEK PDFDocument11 pages3500 Engine Oil and Filter - ChangeSEK PDFMargaret DaughertyPas encore d'évaluation

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 pagesPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroPas encore d'évaluation

- VibrationDocument24 pagesVibrationDaniel Codina100% (1)

- MTC, Test Report & Packing ListDocument63 pagesMTC, Test Report & Packing Listjubair100% (1)

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NPas encore d'évaluation

- Valve SheetDocument23 pagesValve SheetAris KancilPas encore d'évaluation

- lIQUID FUEL SYSTEM PDFDocument23 pageslIQUID FUEL SYSTEM PDFJJPas encore d'évaluation

- BoilerDocument90 pagesBoilerMargaret DaughertyPas encore d'évaluation

- Control Valves PDFDocument6 pagesControl Valves PDFIlham Bayu TiasmoroPas encore d'évaluation

- Piston Check Bolted SW - Red B. 800Document1 pagePiston Check Bolted SW - Red B. 800gigiphiPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument4 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- Ball Valve 150 - GODocument1 pageBall Valve 150 - GOJohnPas encore d'évaluation

- 150# Cs Ball Valve Datasheet: GeneralDocument3 pages150# Cs Ball Valve Datasheet: GeneralVijay GaikwadPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument5 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- VGL 65Document1 pageVGL 65gigiphiPas encore d'évaluation

- S.S ValveDocument1 pageS.S Valvedelaram_mir2500Pas encore d'évaluation

- VAAS C47 Series Cryo Ball Valve CatalogueDocument8 pagesVAAS C47 Series Cryo Ball Valve CatalogueDanielle JohnsonPas encore d'évaluation

- Flow Tek C4700 Series Cryo Ball ValveDocument8 pagesFlow Tek C4700 Series Cryo Ball ValveDanielle JohnsonPas encore d'évaluation

- Cs Gate Valve 1500# - RedactedDocument1 pageCs Gate Valve 1500# - RedactedVijay GaikwadPas encore d'évaluation

- Asymbling SCV>VDocument3 pagesAsymbling SCV>VHartomo Batahan SiahaanPas encore d'évaluation

- Your Company Name: COMPRESS Pressure Vessel Design CalculationsDocument4 pagesYour Company Name: COMPRESS Pressure Vessel Design Calculationsdskr fkshPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument5 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- C-3045367-ODS-02 (Meltapar) Control Materiales EcopetrolDocument32 pagesC-3045367-ODS-02 (Meltapar) Control Materiales EcopetrolKatherine Toloza AcostaPas encore d'évaluation

- Specification of StrainerDocument3 pagesSpecification of StrainermishtinilPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument7 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- Piping Class K2a1Document9 pagesPiping Class K2a1jast111Pas encore d'évaluation

- BK16-M-DS-003 - A - Data Sheet For Manual ValvesDocument3 pagesBK16-M-DS-003 - A - Data Sheet For Manual ValvesHiếu NguyênPas encore d'évaluation

- G V - B B - F P: Lobe Alves Olted Onnet ULL ORTDocument1 pageG V - B B - F P: Lobe Alves Olted Onnet ULL ORTboroumandPas encore d'évaluation

- Butterfly Valve 150# DatasheetDocument1 pageButterfly Valve 150# DatasheetDjohnMaPas encore d'évaluation

- Masoneilan Equipment DataDocument3 pagesMasoneilan Equipment DataalvimranPas encore d'évaluation

- Datasheet CHK VLV (14in #150)Document1 pageDatasheet CHK VLV (14in #150)chintanPas encore d'évaluation

- IFRVT1Document2 pagesIFRVT1Shilpa SinghPas encore d'évaluation

- Cs Ball Valve 600#Document4 pagesCs Ball Valve 600#Vijay GaikwadPas encore d'évaluation

- F9001 Plano Facet para ConstrucciónDocument2 pagesF9001 Plano Facet para ConstrucciónWermer Melgar GutierrezPas encore d'évaluation

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- Upgrading/Modifikasi Fasilitas Injeksi Airpilot Waterflood Lapangan Rantau - Region SumateraDocument32 pagesUpgrading/Modifikasi Fasilitas Injeksi Airpilot Waterflood Lapangan Rantau - Region SumateraAriesComunityPas encore d'évaluation

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAlePas encore d'évaluation

- VB71 ValveDocument1 pageVB71 Valvescribd_thakurPas encore d'évaluation

- GWC Valve International Flanged Floating Ball ValveDocument16 pagesGWC Valve International Flanged Floating Ball ValveGWC Valve InternationalPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- Valves & Controls: Kunkle Safety and Relief ProductsDocument2 pagesValves & Controls: Kunkle Safety and Relief ProductsgbogboiwePas encore d'évaluation

- CVC Steel Valvulas LunkenheimerDocument28 pagesCVC Steel Valvulas LunkenheimerAlex WilmerPas encore d'évaluation

- Yanbu: Export Refinery ProjectDocument7 pagesYanbu: Export Refinery ProjectJanakiraman MalligaPas encore d'évaluation

- Valvula ContraincendioDocument6 pagesValvula ContraincendiowidPas encore d'évaluation

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDocument1 pagePiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyPas encore d'évaluation

- Yhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerDocument1 pageYhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerMargaret DaughertyPas encore d'évaluation

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDocument1 pagePiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyPas encore d'évaluation

- Piping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFDocument1 pagePiping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFMargaret DaughertyPas encore d'évaluation

- 9 07sek PDFDocument1 page9 07sek PDFMargaret DaughertyPas encore d'évaluation

- Piping and Instrumentation Diagram - Legend Sheet 3 of 9 - EDocument1 pagePiping and Instrumentation Diagram - Legend Sheet 3 of 9 - EMargaret DaughertyPas encore d'évaluation

- Agco Type81sek PDFDocument15 pagesAgco Type81sek PDFMargaret DaughertyPas encore d'évaluation

- Big Joe Type 630SEK PDFDocument12 pagesBig Joe Type 630SEK PDFMargaret DaughertyPas encore d'évaluation

- 9 08sek PDFDocument1 page9 08sek PDFMargaret DaughertyPas encore d'évaluation

- astroSEK PDFDocument9 pagesastroSEK PDFMargaret DaughertyPas encore d'évaluation

- Cat & DdsekDocument1 pageCat & DdsekMargaret DaughertyPas encore d'évaluation

- Cat D-3600sek PDFDocument2 pagesCat D-3600sek PDFMargaret DaughertyPas encore d'évaluation

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDocument3 pagesCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyPas encore d'évaluation

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDocument3 pagesCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyPas encore d'évaluation

- DB GB PDFDocument8 pagesDB GB PDFMargaret DaughertyPas encore d'évaluation

- Drum Gauges PDFDocument2 pagesDrum Gauges PDFMargaret DaughertyPas encore d'évaluation

- Proposal Budgetary LevelGauges - KLINGER - 200110 PDFDocument2 pagesProposal Budgetary LevelGauges - KLINGER - 200110 PDFMargaret DaughertyPas encore d'évaluation

- Cat D-3600sek PDFDocument2 pagesCat D-3600sek PDFMargaret DaughertyPas encore d'évaluation

- Klinger Product CatalogueDocument248 pagesKlinger Product Cataloguemar_marcusPas encore d'évaluation

- CATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFDocument16 pagesCATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFMargaret DaughertyPas encore d'évaluation

- 03 Tablas Catsek PDFDocument10 pages03 Tablas Catsek PDFMargaret DaughertyPas encore d'évaluation

- Water HammerDocument39 pagesWater HammercharbelPas encore d'évaluation

- Webtec Products LimitedDocument20 pagesWebtec Products LimitedtecnicomanelPas encore d'évaluation

- General Arrangement Drawing Generator Cooler Expansion TankDocument1 pageGeneral Arrangement Drawing Generator Cooler Expansion TankHassan SleemPas encore d'évaluation

- ABV ValvesDocument1 pageABV ValvesJamesTorresPalmaPas encore d'évaluation

- CH-PVDF-1018: Socket FittingsDocument7 pagesCH-PVDF-1018: Socket FittingsAlejandro MartinezPas encore d'évaluation

- BOQ For Bought Out Items (Condensate & Flash) PDFDocument1 pageBOQ For Bought Out Items (Condensate & Flash) PDFsppatilPas encore d'évaluation

- PeerlessDocument12 pagesPeerlessRizalPas encore d'évaluation

- 2 Piping Requirements Pme CodeDocument44 pages2 Piping Requirements Pme CodeVincent MartinezPas encore d'évaluation

- Lecture 1 Introduction TurbomachinesDocument9 pagesLecture 1 Introduction TurbomachinesYash KalaPas encore d'évaluation

- Mustang Series M116-5 or M6116-5 (Globe), M1116-5 or M61116-5 (Angle) Installation InstructionsDocument2 pagesMustang Series M116-5 or M6116-5 (Globe), M1116-5 or M61116-5 (Angle) Installation InstructionsWattsPas encore d'évaluation

- 314b PDFDocument70 pages314b PDFSiva baalanPas encore d'évaluation

- Technical Standards Committee Local Water Utilities Administration Accredited Manufacturers January 2017 To December 2017Document4 pagesTechnical Standards Committee Local Water Utilities Administration Accredited Manufacturers January 2017 To December 2017Abegael PenaredondoPas encore d'évaluation

- Lab 5Document6 pagesLab 5AimiWaniPas encore d'évaluation

- Mitsubishi Electric PUHY-P YJM-A PUHY-EP YJM-A Installation Manual EngDocument24 pagesMitsubishi Electric PUHY-P YJM-A PUHY-EP YJM-A Installation Manual Engasas0% (1)

- Hydraulic GraphicsDocument26 pagesHydraulic GraphicsMohamed BakheetPas encore d'évaluation

- HDM HDS - 100 P 000040 e 02Document10 pagesHDM HDS - 100 P 000040 e 02Eng-Mohammed SalemPas encore d'évaluation

- Laporan Tugas Khusus Nermass Kiln SystemDocument7 pagesLaporan Tugas Khusus Nermass Kiln SystemSuci SetianingsihPas encore d'évaluation

- Bernouli's EquationDocument45 pagesBernouli's Equationsujay09Pas encore d'évaluation

- Fire Protection Hydraulic CalculationsDocument25 pagesFire Protection Hydraulic CalculationsVaibhav SawantPas encore d'évaluation