Académique Documents

Professionnel Documents

Culture Documents

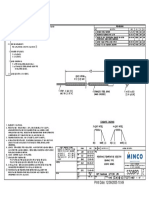

Low Temperature Vessels Block Insulation: Plate 4-810

Transféré par

Gary Clark0 évaluation0% ont trouvé ce document utile (0 vote)

38 vues1 pagethickness and instructions for high temperature insulation of tanks

Titre original

Insulation of Tanks

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentthickness and instructions for high temperature insulation of tanks

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

38 vues1 pageLow Temperature Vessels Block Insulation: Plate 4-810

Transféré par

Gary Clarkthickness and instructions for high temperature insulation of tanks

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Vessels, Tanks, and Equipment

Plate 4-810

Low Temperature Vessels Block Insulation

10

A

12

13

12

C

3

4

1

B

5

11

15

14

2011 MICA

Low temperature below 0C

(32F) installations such as

refrigerant

storage

tanks,

and process equipment may

require multiple layer block

construction, securement of

the insulation with bands and

the design of contraction joints.

Contraction joint is filled with

blanket insulation to absorb linear

contraction of vessel when at

operating temperatures. (Material

is compressed tightly into joint.)

Detail A Contraction joint (typical).

6. Jacketing.

Detail B Double layer staggered joint construction.

7. Bands. (Provide for contraction).

Detail C Joint sealant application.

8. Head insulation shown secured with a floating ring of

cable fastened to another ring of cable under head

flange. (See Detail A, also Plate 4-620, Detail A & B).

Materials: Rigid block insulation, fiber blanket insulation,

jacketing, bands, stranded cable, and vapor retarder mastic.

1.

Vessel surface.

10. Vapor retarder mastic (if required).

2. Contraction joint insulation.

3. Contraction joint. (See Detail A, also Plate 4-620, Detail

B-7).

4. Vapor stop (dam) (See Plate 4-660)

Must

seal outside of the insulation equal to the

insulation thickness.

Seal

annular space .

5. Insulation.

9. Tank head jacket or finish. (See Plate 4-620, Detail B).

11. Bottom insulation. (High compressive strength, water,

vapor resistance, and low coefficient of friction required).

12. Vapor retarder sealant (if required).

13. Vapor retarder jacket.

14. Damp-proof course in between layers.

15. Bottom course bedding sealant to prevent flood

water ingress. (Bedding sealant must serve as a vapor

retarder.) See Plate 4-660.

7th edition mica national insulation standards

Vous aimerez peut-être aussi

- CoilDocument3 pagesCoilGirish JoshiPas encore d'évaluation

- (ERECTION PROCEDURE Insulation-Lagging) - Bidding 0Document5 pages(ERECTION PROCEDURE Insulation-Lagging) - Bidding 0nuntaricherdchaiPas encore d'évaluation

- Pt. Global Power Services: Section 12 - InsulationDocument5 pagesPt. Global Power Services: Section 12 - InsulationDangolPas encore d'évaluation

- (ERECTION PROCEDURE Insulation-Lagging) - BiddingDocument5 pages(ERECTION PROCEDURE Insulation-Lagging) - BiddingnuntaricherdchaiPas encore d'évaluation

- RegulationDocument15 pagesRegulationLuzhengyePas encore d'évaluation

- Electrical Report at BHEL HaridwarDocument48 pagesElectrical Report at BHEL Haridwarप्रतीक सिंहPas encore d'évaluation

- 250 High Voltage Engineering: Previous PageDocument22 pages250 High Voltage Engineering: Previous PageMuhAinun16Pas encore d'évaluation

- External Insulation For Hot ServiceDocument12 pagesExternal Insulation For Hot Servicejirrsama100% (1)

- Insulation Application GuideDocument33 pagesInsulation Application GuideNath BoyapatiPas encore d'évaluation

- 3PS Gaw 006 - 03Document53 pages3PS Gaw 006 - 03Viveck VivekPas encore d'évaluation

- Insulation Heat Transfer MechanismDocument7 pagesInsulation Heat Transfer MechanismMahroosh KhawajaPas encore d'évaluation

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06Pas encore d'évaluation

- Detailed Report On Manufacturing of Turbo Generators at BHEL HaridwarDocument40 pagesDetailed Report On Manufacturing of Turbo Generators at BHEL HaridwarPradip GoswamiPas encore d'évaluation

- Gas Cylinder HeatingDocument1 pageGas Cylinder Heatingnafks jawsdj;lajnPas encore d'évaluation

- Piping & Equipt Insulation - RevDocument7 pagesPiping & Equipt Insulation - RevLuis Gabriel BautistaPas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1Pas encore d'évaluation

- Pages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationDocument1 pagePages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationMelih SENTURKPas encore d'évaluation

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaPas encore d'évaluation

- UntitledyDocument15 pagesUntitledySàávâñ VàśànthàñPas encore d'évaluation

- HVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsDocument40 pagesHVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsjgonzaloPas encore d'évaluation

- (HDO) Specification For Insulation PDFDocument63 pages(HDO) Specification For Insulation PDFhacenescribd100% (1)

- Polyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationDocument7 pagesPolyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationmacPas encore d'évaluation

- Insulation ProcedureDocument3 pagesInsulation ProcedureabimanyubawonoPas encore d'évaluation

- Di 2013Document5 pagesDi 2013SANGAVI TPas encore d'évaluation

- Kaiflex Specification DomesticDocument5 pagesKaiflex Specification Domesticnaseema1Pas encore d'évaluation

- Thermal Insulation Types, System and StandardsDocument6 pagesThermal Insulation Types, System and StandardsAmarKumarPas encore d'évaluation

- Document 5Document56 pagesDocument 5Ajin SPas encore d'évaluation

- Kaiflex MasterSpecificationDocument8 pagesKaiflex MasterSpecificationnaseema1Pas encore d'évaluation

- Multi Layer Pressure VesselsDocument8 pagesMulti Layer Pressure VesselsprivatehomePas encore d'évaluation

- Gel Handbook Part 2Document73 pagesGel Handbook Part 2Ajay PatilPas encore d'évaluation

- Elastomeric Insulation Versus Polyisocyanurate in Low Temperature ApplicationsDocument8 pagesElastomeric Insulation Versus Polyisocyanurate in Low Temperature Applicationsmarkme026679Pas encore d'évaluation

- E - Lead Sheath CableDocument34 pagesE - Lead Sheath CableNelson GarvizuPas encore d'évaluation

- C610 PDFDocument4 pagesC610 PDFGLADYS2714Pas encore d'évaluation

- SIKA Waterproofing - External and TankingDocument10 pagesSIKA Waterproofing - External and TankingmarklesterPas encore d'évaluation

- 941 - 82A1 Rev.: 0 Date: May, 2006: Enap Refineria Bio-Bio Interconexiones Unidad DGC External Insulation Hot ServiceDocument24 pages941 - 82A1 Rev.: 0 Date: May, 2006: Enap Refineria Bio-Bio Interconexiones Unidad DGC External Insulation Hot Servicepablo padronPas encore d'évaluation

- TIAC Standards 2005 e PDFDocument201 pagesTIAC Standards 2005 e PDFMohammad RawoofPas encore d'évaluation

- Insulation SpecificationDocument19 pagesInsulation SpecificationmnsPas encore d'évaluation

- Wire Jacketing Nylon FirestoneDocument14 pagesWire Jacketing Nylon FirestoneAndres Valencia MiraPas encore d'évaluation

- Standalone 90KW Modular Data Center Specification V1.0Document17 pagesStandalone 90KW Modular Data Center Specification V1.0tekatiwariPas encore d'évaluation

- Technical Specification Joint Kits and TerminationsDocument10 pagesTechnical Specification Joint Kits and TerminationsYörükPas encore d'évaluation

- Kanthal HeatersDocument48 pagesKanthal HeatersAnonymous 95dlTK1McPas encore d'évaluation

- Design of Pressure VesselsDocument23 pagesDesign of Pressure VesselsSuryaprakashPas encore d'évaluation

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530Pas encore d'évaluation

- 07 2100 - Building InsulationDocument7 pages07 2100 - Building InsulationAngelo Carlo MalabananPas encore d'évaluation

- Ficha Tecnica PikotekDocument2 pagesFicha Tecnica Pikoteking_arriagaPas encore d'évaluation

- FPR SpecificationsDocument15 pagesFPR SpecificationsHector Manuel Leon JimenezPas encore d'évaluation

- Constructional Features of Optical Fibre Cable: in This ChapterDocument6 pagesConstructional Features of Optical Fibre Cable: in This ChapterlvsaruPas encore d'évaluation

- Armaflex Insulation + Fire Rated DuctworkDocument7 pagesArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnPas encore d'évaluation

- Types of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausesDocument14 pagesTypes of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausessantoshkumarPas encore d'évaluation

- Rowan University Design Guide 2013Document10 pagesRowan University Design Guide 2013zelitePas encore d'évaluation

- S308PD3T24 Example of Model Number Makeup S308 Specifications Drawing Number. PD Sensing ElementDocument1 pageS308PD3T24 Example of Model Number Makeup S308 Specifications Drawing Number. PD Sensing ElementMaxim VolkovPas encore d'évaluation

- Advantages of Membrane TechnologyDocument5 pagesAdvantages of Membrane TechnologyGopalPas encore d'évaluation

- Duct InsulationDocument9 pagesDuct Insulationphyolwin ooPas encore d'évaluation

- Pitched RoofingDocument60 pagesPitched RoofingOmaidTanhaPas encore d'évaluation

- Advances in Solid Oxide Fuel Cells XD'EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Ceramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLD'EverandCeramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLHua-Tay LinPas encore d'évaluation

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIID'EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiPas encore d'évaluation

- U.S. Army Explosives and Demolitions HandbookD'EverandU.S. Army Explosives and Demolitions HandbookPas encore d'évaluation

- The Power Source: The 25 Amp & 60 Amp RectifierDocument0 pageThe Power Source: The 25 Amp & 60 Amp RectifierraschensPas encore d'évaluation

- Methanol Ferment Ion of GlycerolDocument7 pagesMethanol Ferment Ion of GlycerolGary ClarkPas encore d'évaluation

- Basic Principles For Sizing Grease InterceptorsDocument5 pagesBasic Principles For Sizing Grease InterceptorsSharon LambertPas encore d'évaluation

- Reference Manual For The 54 Mbps Wireless Router WGR614 v6Document154 pagesReference Manual For The 54 Mbps Wireless Router WGR614 v684dineshPas encore d'évaluation

- Estrification of Glycerol KineticsDocument144 pagesEstrification of Glycerol KineticsGary ClarkPas encore d'évaluation

- DesigningVacuumtower (VDU)Document26 pagesDesigningVacuumtower (VDU)Bilal KhanPas encore d'évaluation

- Foxboro Flow MeterDocument44 pagesFoxboro Flow MeterGary ClarkPas encore d'évaluation

- MISGuidelines PalmOilIndustryDocument91 pagesMISGuidelines PalmOilIndustryGary Clark100% (2)

- Ar001Document10 pagesAr001Gary ClarkPas encore d'évaluation