Académique Documents

Professionnel Documents

Culture Documents

Iso 1090 2 2008

Transféré par

eghashangzadehDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Iso 1090 2 2008

Transféré par

eghashangzadehDroits d'auteur :

Formats disponibles

BS EN 1090-2:2008

EN 1090-2:2008 (E)

Non destructive testing (NDT) methods shall be selected in accordance with EN 12062 by personnel qualified

according to Level 3 as defined in EN 473. Generally ultrasonic testing or radiographic testing applies to butt

welds and penetrant testing or magnetic particle inspection applies to fillet welds.

NDT, with the exception of visual inspection, shall be performed by personnel qualified according to Level 2 as

defined in EN 473.

If the inspection plan requires a check of the fit-up before the welding of hollow sections prepared for branch

welding, the following locations shall be given particular attention:

for circular sections: the mid-toe, mid-heel and two mid-flank positions;

for square or rectangular sections: the four corner positions.

12.4.2 Inspection after welding

12.4.2.1

Timing

The supplementary NDT of a weld shall generally not be completed until after the minimum hold time after

welding shown in Table 23.

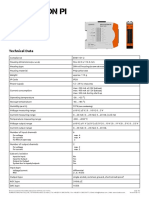

Table 23 Minimum hold times

Weld size

a

(mm)

Heat input Q

b

(kJ/mm)

a or s 6

All

3

>3

3

>3

6 < a or s 12

a or s > 12

Hold time

c

(hours)

S235 to S420

S460 and above

Cooling period only

24

8

24

16

40

16

40

40

48

Size applies to the nominal throat thickness a of a fillet weld or the nominal material thickness s of a full

penetration weld. For individual partial penetration butt welds the governing criterion is the nominal weld depth

a, but for pairs of partial penetration butt welds welded simultaneously it is the sum of the weld throats a.

b

Heat input Q to be calculated in accordance with Clause 19 of EN 1011-1:1998.

The time between weld completion and commencement of NDT shall be stated in the NDT report. In the

case of cooling period only this will last until the weld is cool enough for NDT to commence.

For welds requiring preheat, these periods may be reduced if the weldment is post-heated for a period after

welding is complete in accordance with Annex C of EN 1011-2:2001.

If a weld will become inaccessible through subsequent work, it shall be inspected prior to subsequent work

being carried out.

Any weld located in a zone where unacceptable distortion has been corrected shall be inspected again.

12.4.2.2

Scope of inspection

All welds shall be visually inspected throughout their entire length. If surface imperfections are detected,

surface testing by penetrant testing or magnetic particle inspection shall be carried out on the inspected weld.

Unless otherwise specified no supplementary NDT is required for EXC1 welds. For EXC2, EXC3 and EXC4

welds the extent of supplementary NDT is as specified below.

The extent of NDT covers both testing of surface or internal imperfections if applicable.

For the first 5 joints made to the same new WPS the following requirements shall be fulfilled:

Vous aimerez peut-être aussi

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989D'EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookPas encore d'évaluation

- Amersham 880 Delta Manual PDFDocument88 pagesAmersham 880 Delta Manual PDFRussell ClarkPas encore d'évaluation

- Din 17175Document0 pageDin 17175Ahmed SaadPas encore d'évaluation

- DIN EN 10002-1-2001 金属材料.拉力试验.第1部分室温下的试验方法 PDFDocument54 pagesDIN EN 10002-1-2001 金属材料.拉力试验.第1部分室温下的试验方法 PDFakifPas encore d'évaluation

- Is 9902 2004 PDFDocument11 pagesIs 9902 2004 PDFAgniva DuttaPas encore d'évaluation

- European Standard EN 14584 Norme Europeenne Europaische NormDocument15 pagesEuropean Standard EN 14584 Norme Europeenne Europaische Normvassili_iuPas encore d'évaluation

- PAUT - Mode ConversionDocument8 pagesPAUT - Mode ConversionMohsin IamPas encore d'évaluation

- BS en Iso 3059-2012 - 2018-04-04 - 10-24-59 AmDocument10 pagesBS en Iso 3059-2012 - 2018-04-04 - 10-24-59 AmarbabPas encore d'évaluation

- High Voltage Holiday DetectorDocument3 pagesHigh Voltage Holiday DetectorKamen RPas encore d'évaluation

- Replica PDFDocument10 pagesReplica PDFssoares1989Pas encore d'évaluation

- BS en 1371-1 2011 PDFDocument30 pagesBS en 1371-1 2011 PDFMaximiliano O.Pas encore d'évaluation

- General Requirements For Alloy and Stainless Steel PipeDocument12 pagesGeneral Requirements For Alloy and Stainless Steel Pipebehzad mohammadiPas encore d'évaluation

- Mandatory Appendix Viii - Asme VDocument3 pagesMandatory Appendix Viii - Asme VAngelTinocoPas encore d'évaluation

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Asme B31.3-2016 CC 181Document3 pagesAsme B31.3-2016 CC 181MubeenPas encore d'évaluation

- Iso 3452-5 - 2008Document12 pagesIso 3452-5 - 2008jesonelite100% (1)

- Certificat QSA GlobalDocument20 pagesCertificat QSA GlobalLouis HardyPas encore d'évaluation

- E127 15 PDFDocument9 pagesE127 15 PDFDaniel Mauricio Prieto ValderramaPas encore d'évaluation

- ISO 9916 1991 Aluminium and Magnesium Alloy Castings - Liquid Penetrant TestingDocument9 pagesISO 9916 1991 Aluminium and Magnesium Alloy Castings - Liquid Penetrant TestingJOSUE RIOSPas encore d'évaluation

- Tangential RadiographyDocument9 pagesTangential Radiographykirubha_karan2000Pas encore d'évaluation

- Reducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresDocument5 pagesReducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresAgustin Fabian HaddadPas encore d'évaluation

- ISOndtDocument8 pagesISOndtNooruddin SheikPas encore d'évaluation

- Asme NDT MethodDocument1 pageAsme NDT Methodkinglordofato100% (1)

- 2771947Document2 pages2771947aakashPas encore d'évaluation

- BS en Iso 14731-2019Document20 pagesBS en Iso 14731-2019Hüseyin BuğdaycıPas encore d'évaluation

- Fabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference BlocksDocument16 pagesFabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference BlocksharryPas encore d'évaluation

- As 2168.2-2009 Non-Destructive Testing - Computerized Radiography Testing of Metallic Materials Using X-RaysDocument7 pagesAs 2168.2-2009 Non-Destructive Testing - Computerized Radiography Testing of Metallic Materials Using X-RaysSAI Global - APACPas encore d'évaluation

- Astm E1065 E1065m 20Document10 pagesAstm E1065 E1065m 20Mohamed AboelkhierPas encore d'évaluation

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- E 215 - 98 R04 - Rtixnq - PDFDocument7 pagesE 215 - 98 R04 - Rtixnq - PDFLeón SuárezPas encore d'évaluation

- Penetrant Penetrant: Non-Destructive Non-Destructive Testing Testing Testing-TestingDocument12 pagesPenetrant Penetrant: Non-Destructive Non-Destructive Testing Testing Testing-TestingQC HSDPas encore d'évaluation

- Asme B31.3 2020Document4 pagesAsme B31.3 2020Tuugii OtgooPas encore d'évaluation

- EN ISO 11699-2 (2011) (E) CodifiedDocument3 pagesEN ISO 11699-2 (2011) (E) CodifiedIrfan RomansyahPas encore d'évaluation

- 2-EN - ISO - 19285 - 2017 PAUT - Англ+Перевод - 05.01.2018Document27 pages2-EN - ISO - 19285 - 2017 PAUT - Англ+Перевод - 05.01.2018123Pas encore d'évaluation

- En Iso 9346 - 1996 Mass TransferDocument13 pagesEn Iso 9346 - 1996 Mass Transferbabis1980100% (1)

- BS en 12668-1-2010Document48 pagesBS en 12668-1-2010lamhuu quangPas encore d'évaluation

- Bs en 1330 1 2014 Non Destructive Testing Terminology Api Asme PublicationDocument30 pagesBs en 1330 1 2014 Non Destructive Testing Terminology Api Asme Publicationudom0% (1)

- AGR Field Operations TD Focus-Scan Data SheetDocument2 pagesAGR Field Operations TD Focus-Scan Data SheetJeganeswaranPas encore d'évaluation

- BS EN 1291 1998, Nondestructive PDFDocument11 pagesBS EN 1291 1998, Nondestructive PDFRajan SteevePas encore d'évaluation

- Astm E1001Document10 pagesAstm E1001Jon DownPas encore d'évaluation

- Requirements For Viewers Bsen25580 PDFDocument13 pagesRequirements For Viewers Bsen25580 PDFThe Normal HeartPas encore d'évaluation

- Chapter 2 Material 2014 PDFDocument363 pagesChapter 2 Material 2014 PDFGOPINATH KRISHNAN NAIRPas encore d'évaluation

- BS EN ISO 13588-2019 Ultrasonic Testing - Use of Automated PAUT TechnologyDocument34 pagesBS EN ISO 13588-2019 Ultrasonic Testing - Use of Automated PAUT TechnologylequanghocPas encore d'évaluation

- E 310 - 99 - Rtmxma - PDFDocument4 pagesE 310 - 99 - Rtmxma - PDFUpul Eranda AbeyrathnaPas encore d'évaluation

- Radiography of Cast Metallic Surgical Implants: Standard Practice ForDocument2 pagesRadiography of Cast Metallic Surgical Implants: Standard Practice ForSüleyman ÖzkahramanPas encore d'évaluation

- A-Star Training & Consultancy Pte LTD: Phased Array Ultrasonic Testing Level Ii - SpecificDocument3 pagesA-Star Training & Consultancy Pte LTD: Phased Array Ultrasonic Testing Level Ii - SpecificDu Xuan BinhPas encore d'évaluation

- Astm 494Document7 pagesAstm 494JOSEPH REFUERZO100% (1)

- BS en 583-6-2008Document26 pagesBS en 583-6-2008sheldonPas encore d'évaluation

- Iso 22825 2012Document12 pagesIso 22825 2012rameshqcPas encore d'évaluation

- NDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Document6 pagesNDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Mark BrailsfordPas encore d'évaluation

- NDT Level 2 in Leak - TestingDocument9 pagesNDT Level 2 in Leak - TestingRichard MitchellPas encore d'évaluation

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartNejat AbabayPas encore d'évaluation

- BS 2452 (1954)Document30 pagesBS 2452 (1954)siswou100% (1)

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDocument4 pagesHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesPas encore d'évaluation

- CBT Questions: (2) Peel TestDocument18 pagesCBT Questions: (2) Peel TestMOHAMEDPas encore d'évaluation

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgePas encore d'évaluation

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanPas encore d'évaluation

- Shipbuilding PDFDocument44 pagesShipbuilding PDFSaid Alauddeen FaiszPas encore d'évaluation

- KFLEXDocument6 pagesKFLEXeghashangzadehPas encore d'évaluation

- Sep 09 IssueDocument12 pagesSep 09 IssueeghashangzadehPas encore d'évaluation

- InTech-Porous Metals and Metal Foams Made From PowdersDocument17 pagesInTech-Porous Metals and Metal Foams Made From PowdersJosé H. Ramírez VeluetaPas encore d'évaluation

- Isiri 5006 Inspection Report MethodDocument13 pagesIsiri 5006 Inspection Report MethodeghashangzadehPas encore d'évaluation

- Cleaning MethodsDocument30 pagesCleaning Methodseghashangzadeh100% (1)

- ASQC E2-96 Guide For Inspection Planning PDFDocument12 pagesASQC E2-96 Guide For Inspection Planning PDFeghashangzadehPas encore d'évaluation

- Makhazen Book IntroductionDocument5 pagesMakhazen Book IntroductioneghashangzadehPas encore d'évaluation

- 4x4 Product Specifications1008Document1 page4x4 Product Specifications1008eghashangzadehPas encore d'évaluation

- 10 Procedure For PWHT PDFDocument5 pages10 Procedure For PWHT PDFeghashangzadeh100% (1)

- Amoozeshe Ashpazi PDFDocument63 pagesAmoozeshe Ashpazi PDFeghashangzadehPas encore d'évaluation

- 970 enDocument16 pages970 eneghashangzadehPas encore d'évaluation

- Bruker-S1Turbo SDDocument12 pagesBruker-S1Turbo SDeghashangzadehPas encore d'évaluation

- Isiri 5006 Inspection Report MethodDocument13 pagesIsiri 5006 Inspection Report MethodeghashangzadehPas encore d'évaluation

- Laser 910124Document5 pagesLaser 910124eghashangzadehPas encore d'évaluation

- CIT160kV MDocument2 pagesCIT160kV MeghashangzadehPas encore d'évaluation

- Pigging Valve Brochure Argus ValvesDocument7 pagesPigging Valve Brochure Argus ValvesIsares PodkohPas encore d'évaluation

- Architecture Ebook Outstanding Wood Buildings - CWCDocument28 pagesArchitecture Ebook Outstanding Wood Buildings - CWCAc Arquitetos Associados50% (2)

- RBC NiceDocument56 pagesRBC NiceTIOCA01Pas encore d'évaluation

- D758-Et Minipurge ManualDocument39 pagesD758-Et Minipurge ManualNicholas marcolan (nmarcolan)Pas encore d'évaluation

- Acf DifferencesDocument71 pagesAcf DifferencesMorrisPas encore d'évaluation

- HZS120F8Document2 pagesHZS120F8saimunPas encore d'évaluation

- SYLVANIA W6413tc - SMDocument46 pagesSYLVANIA W6413tc - SMdreamyson1983100% (1)

- C Library Math.h Functions - GeeksforGeeksDocument11 pagesC Library Math.h Functions - GeeksforGeeksSoumadip Banerjee100% (1)

- Datasheet RevPi AIODocument2 pagesDatasheet RevPi AIOsebadansPas encore d'évaluation

- PW5 Basic Double Busbar Dis 20Document12 pagesPW5 Basic Double Busbar Dis 20Shanthiyaah ArumugamPas encore d'évaluation

- Flash 8Document75 pagesFlash 8rickoPas encore d'évaluation

- Robot Arm TutorialDocument16 pagesRobot Arm TutorialFarshad yazdi100% (4)

- JavaScript and XHTML DocumentsDocument40 pagesJavaScript and XHTML Documentstech2click100% (3)

- P357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFDocument35 pagesP357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFParvezPas encore d'évaluation

- Sue's Rendezvous Illegal Certificate of OccupancyDocument3 pagesSue's Rendezvous Illegal Certificate of OccupancySamuel L. RiversPas encore d'évaluation

- Difference Between PPM and PPMVDocument2 pagesDifference Between PPM and PPMVKhanh TrangPas encore d'évaluation

- DEMKA Catalogue New2010Document44 pagesDEMKA Catalogue New2010Mike NomikosPas encore d'évaluation

- PERFORMANCEDocument4 pagesPERFORMANCEKorong KapampanganPas encore d'évaluation

- Comparative Study of BS5930 and EN ISO PDFDocument14 pagesComparative Study of BS5930 and EN ISO PDFNathan VincentPas encore d'évaluation

- White Products CatalogDocument49 pagesWhite Products CatalogjesusPas encore d'évaluation

- CHAPTER 7: Benchmark Test ResultsDocument10 pagesCHAPTER 7: Benchmark Test Resultsnapoleon_velasc3617Pas encore d'évaluation

- Work Method Bridge Sleeper Replacement - 2014Document8 pagesWork Method Bridge Sleeper Replacement - 2014Irham M AFPas encore d'évaluation

- ASTM A395 - A 395M - 99 (Reapproved 2009)Document8 pagesASTM A395 - A 395M - 99 (Reapproved 2009)raulPas encore d'évaluation

- Itp PWHTDocument1 pageItp PWHTTridib DeyPas encore d'évaluation

- MCC Landscape Pre Commencement and Construction Hold PointsDocument3 pagesMCC Landscape Pre Commencement and Construction Hold PointsBillyPas encore d'évaluation

- The Chengdu Jian-20Document20 pagesThe Chengdu Jian-20Cat CrysisPas encore d'évaluation

- Solutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageDocument3 pagesSolutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageMazen A. TaherPas encore d'évaluation

- 343 - 135 - 278 - 80 7 Stud Vulkollan Drive Wheel - Wet GripDocument1 page343 - 135 - 278 - 80 7 Stud Vulkollan Drive Wheel - Wet GripASIFPas encore d'évaluation

- A Preliminary Literature Review of Digital Transformation Case StudiesDocument6 pagesA Preliminary Literature Review of Digital Transformation Case StudiesLucija IvancicPas encore d'évaluation

- HVAC Dampers Installation Method StatementDocument3 pagesHVAC Dampers Installation Method StatementDong VanraPas encore d'évaluation

- Manual Book 500XDocument72 pagesManual Book 500XDadung PrakosoPas encore d'évaluation