Académique Documents

Professionnel Documents

Culture Documents

2014-Spring-Ay-Reu Project5 Carbon Nanotubes Final-Poster

Transféré par

api-237577540Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2014-Spring-Ay-Reu Project5 Carbon Nanotubes Final-Poster

Transféré par

api-237577540Droits d'auteur :

Formats disponibles

Synthesis of Carbon Nanotube-Graphene Composites for Supercapacitors

Isaac Dippold, Lu Zhang, Derek DeArmond, Vesselin Shanov

Department of Biomedical, Chemical and Environmental Engineering, University of Cincinnati, OH 45221

Introduction

Carbon nanotubes (CNT) and Graphene (G) show great

promise as supercapacitor electrodes because of their

excellent electrical conductivity, good mechanical

strength, and high specific surface area. However,

there are difficulties in the synthesis of these materials

that can create undesirable properties. The addition of

CNTs to G structures can be beneficial to the overall

structures properties. This project aims to synthesize

a CNT and G hybrid material with the advantages of

both allotropes for use as an electrode in a

supercapacitor.

Fe3O4

nanoparticle

s

1. Pristine:

Nickel

To obtain:

Fe

catalyst

2. Ferrocene:

Objective

Figure 3 and 4. (3) Schematic of synthesis method for

Ni catalyst pellet loaded with Fe3O4 nanoparticles; (4)

Image of FirstNano Easytube CVD furnace that was

utilized

Synthesize a CNT and G composite through chemical

vapor deposition (CVD)

This will be completed by first determining

the optimum synthesis techniques

Physically characterize the hybrid material

Perform electrochemical tests to test for electrode

performance

3. NiCo:

Raman Results

Larger D peak shows the growth of CNTs but can

also show the growth of amorphous carbon

Sample via Ferrocene

Pristine Graphene

G

4. FeCl2:

950

1900

750

1400

2D

Intensity (a.u.)

350

Figure 1. A visual representation of a CNT and G composite material

(tikalon.com)

5. Ni/Fe:

150

-100 0

Methods

Synthesis of CNT and G material through various

methods:

1. Pristine G coated via Ferrocene

2. Pristine G coated in NiCo2O4 particles

3. Pristine G coated in FeCl2 particles

4. Nickel/Iron catalyst pellet

Quality and uniformity determined by Raman

spectroscopy and scanning electron microscopy

imaging (SEM)

400

Intensity (a.u.)

900

550

1000

2000

3000

4000

-50 0

Raman Shift (cm-1)

Sample via NiCo

Sample via Ni/Fe pellet

1150

5900

950

4900

750

3900

2900

1000 1500 2000 2500 3000 3500

Raman Shift (cm-1)

6900

Intensity (a.u.)

500

Intensity (a.u.)

Conclusions

CNTs were produced by some methods, with further

changes, it is probable that all would produce greater

CNT growth

Carbon concentration and catalyst particle size play a

large role in CNT growth

H2O can reduce amorphous carbon growth

550

350

1900

150

900

-50 0

-100

500

1000

1500

2000

2500

3000

3500

Raman Shift (cm-1)

500

1000 1500 2000 2500 3000 3500

Raman Shift (cm-1)

SEM Results

Figure 2. Diagram of chemical vapor deposition for the

growth of G and CNTs (azonano.com)

1. Pristine Graphene

2. Pristine Graphene composite using Ferrocene coating

image 2 shows CNT bundle growth

3. Pristine Graphene composite using NiCo coating

primarily amorphous carbon but coating is uniformly

distributed

4. Pristine Graphene composite using FeCl2 coating

primarily amorphous carbon but CNTs of (>2000nm)

were observed

5. Pristine Graphene composite using Ni/Fe pellet

primarily amorphous carbon but thicker Graphene

produced

Future Work

Change synthesis methods to obtain greater CNT

growth

Fully characterize the new composite if one is found

Perform electrochemical testing on the new composite

to test its performance as a supercapacitor electrode

Acknowledgements

The author would like to thank the NSF for Grant # DUE0756921 for Type 1 Science, Technology, Engineering,

and Mathematics Talent Expansion Program (STEP)

Project and the University of Cincinnati for funding and

providing the opportunity for this research. A special

thanks to Dr. Noe Alvarez for his advice and

contributions to the project.

Vous aimerez peut-être aussi

- Research (Edible Cutlery)Document9 pagesResearch (Edible Cutlery)Reylsea MayPas encore d'évaluation

- Preparation of Nickel-Carbon Nanofiber Composites by A Pulse-Reverse Electrodeposition ProcessDocument5 pagesPreparation of Nickel-Carbon Nanofiber Composites by A Pulse-Reverse Electrodeposition ProcessEka Puspa RiniPas encore d'évaluation

- V8I4 (13) Q. WeiDocument6 pagesV8I4 (13) Q. WeiAsif Fareed QaisraniPas encore d'évaluation

- Synthesis Mwcnts Using CVD On Fe Catalyst Prepare in D.C Diode SputteringDocument4 pagesSynthesis Mwcnts Using CVD On Fe Catalyst Prepare in D.C Diode SputteringInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Ctubes Ni OKDocument6 pagesCtubes Ni OKMartaPas encore d'évaluation

- 1 s2.0 S000862231200111X MainDocument10 pages1 s2.0 S000862231200111X MainŞebnem İlarslanPas encore d'évaluation

- 1 s2.0 S1876610215003860 Main PDFDocument7 pages1 s2.0 S1876610215003860 Main PDFWendy HerreraPas encore d'évaluation

- Karbon - Meso - Supercapacitor - 2011 PDFDocument5 pagesKarbon - Meso - Supercapacitor - 2011 PDFAndiQonitaPas encore d'évaluation

- Synthesis and Processing of Nanomaterials: (α) tip-growth mechanism and (β) root-growth mechanismDocument8 pagesSynthesis and Processing of Nanomaterials: (α) tip-growth mechanism and (β) root-growth mechanismKhairani AriffinPas encore d'évaluation

- Synthetic Metals: Hsi-Chao Chen, Yin-Cheng Wang, Kuo-Ting HuangDocument11 pagesSynthetic Metals: Hsi-Chao Chen, Yin-Cheng Wang, Kuo-Ting HuangSonakshi SinghPas encore d'évaluation

- Effects of Phosphorous-Doping and High Temperature Annealing On CVD Grown 3C-SicDocument12 pagesEffects of Phosphorous-Doping and High Temperature Annealing On CVD Grown 3C-SicBlade8Pas encore d'évaluation

- Li 2007Document7 pagesLi 2007Daniel ReyesPas encore d'évaluation

- Out-Of-Plane Growth of CNTs On Graphene For Supercapacitor ApplicationsDocument8 pagesOut-Of-Plane Growth of CNTs On Graphene For Supercapacitor ApplicationsJutt KhanPas encore d'évaluation

- Hydrothermal Synthesis of Phosphate-Functionalized Carbon Nanotube-Containing Carbon Composites For Supercapacitors With Highly Stable PerformanceDocument7 pagesHydrothermal Synthesis of Phosphate-Functionalized Carbon Nanotube-Containing Carbon Composites For Supercapacitors With Highly Stable PerformanceLee Banticil BasaloPas encore d'évaluation

- Carbon NanotubesDocument15 pagesCarbon NanotubesLaraib HabibPas encore d'évaluation

- Materials Research Bulletin: SciencedirectDocument10 pagesMaterials Research Bulletin: Sciencedirectawan anggaraPas encore d'évaluation

- Nanotubes by CVD and ApplicationsDocument9 pagesNanotubes by CVD and ApplicationsGovind RajanPas encore d'évaluation

- 1 s2.0 S0925838822021570 MainDocument9 pages1 s2.0 S0925838822021570 MainPankaj AtalPas encore d'évaluation

- nn501124h - ArticleDocument10 pagesnn501124h - ArticleLee Banticil BasaloPas encore d'évaluation

- Iit MadrasDocument43 pagesIit MadrasPawan BonyPas encore d'évaluation

- Carbon NanotubesDocument26 pagesCarbon NanotubesTanuj JoshiPas encore d'évaluation

- 1 s2.0 S000862231100621X MainDocument9 pages1 s2.0 S000862231100621X MainŞebnem İlarslanPas encore d'évaluation

- Synthesis and Magnetic Characterization of Ni Nanoparticles and Ni Nanoparticles in Multiwalled Carbon NanotubesDocument8 pagesSynthesis and Magnetic Characterization of Ni Nanoparticles and Ni Nanoparticles in Multiwalled Carbon Nanotubesapi-3773399Pas encore d'évaluation

- Synthesis of GrapheneDocument7 pagesSynthesis of GrapheneMostafa DadashbabaPas encore d'évaluation

- Power Generation Using An Activated Carbon Fiber Felt Cathode in An Up OwDocument6 pagesPower Generation Using An Activated Carbon Fiber Felt Cathode in An Up OwEstuning Mugi RahajengPas encore d'évaluation

- CNT PaperDocument7 pagesCNT PaperAustin LanePas encore d'évaluation

- Fe O - CNT Nanocomposite For Binary Gas Detection Monika Joshi, R.P Singh & Vidur RajDocument5 pagesFe O - CNT Nanocomposite For Binary Gas Detection Monika Joshi, R.P Singh & Vidur RajVidur Raj SinghPas encore d'évaluation

- CNT Composite FibersDocument23 pagesCNT Composite FibersShashwat YadavPas encore d'évaluation

- Compsoiye ManufacturingDocument12 pagesCompsoiye ManufacturingMuhammad Bilal SahiPas encore d'évaluation

- K Kumar Integrated Ferro (2010)Document8 pagesK Kumar Integrated Ferro (2010)Tarun YadavPas encore d'évaluation

- Osswald 2005Document6 pagesOsswald 2005dilla zainudinPas encore d'évaluation

- Nitrogen-Rich Graphitic Carbon Nitride Controllable Nanosheet-LikeDocument8 pagesNitrogen-Rich Graphitic Carbon Nitride Controllable Nanosheet-Likealejandro sifuentes clementePas encore d'évaluation

- UTMFR GrantDocument6 pagesUTMFR GrantNur Isarah Che RaimiPas encore d'évaluation

- Current Applied PhysicsDocument8 pagesCurrent Applied PhysicsSamah SamahPas encore d'évaluation

- Value-Added Synthesis of Graphene: Recycling Industrial Carbon Waste Into Electrodes For High-Performance Electronic DevicesDocument10 pagesValue-Added Synthesis of Graphene: Recycling Industrial Carbon Waste Into Electrodes For High-Performance Electronic DevicesMALIK ZARYABBABARPas encore d'évaluation

- Yue, 2014Document11 pagesYue, 2014Amanda XavierPas encore d'évaluation

- High E Ciency Graphene Solar Cells by Chemical DopingDocument6 pagesHigh E Ciency Graphene Solar Cells by Chemical DopingSnowdenn BreddPas encore d'évaluation

- TV Guide, May 2011Document4 pagesTV Guide, May 2011emediagePas encore d'évaluation

- SD ArticleDocument8 pagesSD ArticleJajar NavakulPas encore d'évaluation

- tmpD7F4 TMPDocument6 pagestmpD7F4 TMPFrontiersPas encore d'évaluation

- Taken Authorreprints RSC 2Document7 pagesTaken Authorreprints RSC 2abhijitPas encore d'évaluation

- Ahmed Moosa NanoDocument16 pagesAhmed Moosa Nanojojim52Pas encore d'évaluation

- Optimizing The Magnetocuring of Epoxy Resins Via Electromagnetic AdditivesDocument12 pagesOptimizing The Magnetocuring of Epoxy Resins Via Electromagnetic AdditivesRichaPas encore d'évaluation

- 1 s2.0 S2468023021000833 MainDocument9 pages1 s2.0 S2468023021000833 Maincuc12cptPas encore d'évaluation

- A Carbon Nanotube-Reinforced Noble Tin Anode Structure For Lithium-Ion BatteriesDocument8 pagesA Carbon Nanotube-Reinforced Noble Tin Anode Structure For Lithium-Ion BatteriesdiskysmPas encore d'évaluation

- Journal of Power Sources: Short CommunicationDocument6 pagesJournal of Power Sources: Short CommunicationAniket BondePas encore d'évaluation

- Composites: Part B: Chih-Chun Teng, Chen-Chi M. Ma, Kuo-Chan Chiou, Tzong-Ming LeeDocument7 pagesComposites: Part B: Chih-Chun Teng, Chen-Chi M. Ma, Kuo-Chan Chiou, Tzong-Ming LeeamirswtPas encore d'évaluation

- UTMFR Grant - RevDocument5 pagesUTMFR Grant - RevNur Isarah Che RaimiPas encore d'évaluation

- Processing of Copper-Carbon Nanotube Composites by Vacuum HotDocument7 pagesProcessing of Copper-Carbon Nanotube Composites by Vacuum HotUriel PeñaPas encore d'évaluation

- Developmentandapplicationsofcarbonnanotubenanocompositeمهم حداا Compre-sDocument7 pagesDevelopmentandapplicationsofcarbonnanotubenanocompositeمهم حداا Compre-smohamed aliPas encore d'évaluation

- In Situ Synthesis of Super-Long Cu Nanowires Inside Carbon Nanotubes With Coal As Carbon SourceDocument3 pagesIn Situ Synthesis of Super-Long Cu Nanowires Inside Carbon Nanotubes With Coal As Carbon SourceRamon Roman DovalPas encore d'évaluation

- Evaluations of Discharge Capacity and Cycle Stability For A Graphene-AddedDocument5 pagesEvaluations of Discharge Capacity and Cycle Stability For A Graphene-AddedjosePas encore d'évaluation

- G - Nanoribbon TEGDocument7 pagesG - Nanoribbon TEGAmir RostamiPas encore d'évaluation

- Polymer Naocomposite For Areospace ApplicatoinsDocument10 pagesPolymer Naocomposite For Areospace ApplicatoinsUmer FarooqPas encore d'évaluation

- Paper 6Document7 pagesPaper 6AdityaPas encore d'évaluation

- Electro Active Graphene Nafion ActuatorsDocument11 pagesElectro Active Graphene Nafion ActuatorsCh'ng Ying YingPas encore d'évaluation

- 1 2013 t1 GostomskaDocument4 pages1 2013 t1 GostomskaVidhya EVidhyaPas encore d'évaluation

- Ball Milling Effect On The Structure of Single-Wall Carbon NanotubesDocument7 pagesBall Milling Effect On The Structure of Single-Wall Carbon NanotubesLondon BridgePas encore d'évaluation

- Thin Solid Films: Youna Choi, Geunjin Kim, Heejoo Kim, Sun Hee Kim, Kwanghee LeeDocument5 pagesThin Solid Films: Youna Choi, Geunjin Kim, Heejoo Kim, Sun Hee Kim, Kwanghee LeeBhabani Sankar SwainPas encore d'évaluation

- Nanocarbons for ElectroanalysisD'EverandNanocarbons for ElectroanalysisSabine SzuneritsPas encore d'évaluation

- Carbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsD'EverandCarbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsWen LuPas encore d'évaluation

- Swimming Pool PresentationDocument22 pagesSwimming Pool Presentationkhurshidoman123Pas encore d'évaluation

- General Electric - Inlet Air RecommendationDocument28 pagesGeneral Electric - Inlet Air Recommendationhussain mominPas encore d'évaluation

- Argus General Brochure V8Document20 pagesArgus General Brochure V8danieldayettddPas encore d'évaluation

- 2-1393774-1 - P1 Relay V23026Document5 pages2-1393774-1 - P1 Relay V2302606111981Pas encore d'évaluation

- 4KN Enuk V3 1Document8 pages4KN Enuk V3 1MustaphaMehdiHamaminePas encore d'évaluation

- General Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDocument47 pagesGeneral Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDan PopescuPas encore d'évaluation

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganPas encore d'évaluation

- Typical Exchanger & Reboiler Piping-BNDocument12 pagesTypical Exchanger & Reboiler Piping-BNManan100% (2)

- Mobil Type 8000 Turbine OilDocument4 pagesMobil Type 8000 Turbine OilJJPas encore d'évaluation

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićPas encore d'évaluation

- MASABA Overland ConveyorDocument2 pagesMASABA Overland ConveyoraswarPas encore d'évaluation

- BOQ KosongDocument6 pagesBOQ Kosongkhairil mohdPas encore d'évaluation

- IGCSE Chemistry DefinitionsDocument5 pagesIGCSE Chemistry DefinitionsTanmay Karur100% (1)

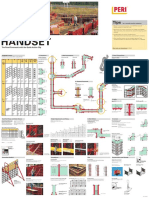

- HANDSET - Poster Idioma InglesDocument3 pagesHANDSET - Poster Idioma InglesJuan Francisco Mora ZeladaPas encore d'évaluation

- Ueg 36Document2 pagesUeg 36PRADO_COMETA50% (2)

- Pannaipatty - Compound WallDocument38 pagesPannaipatty - Compound WallrkpragadeeshPas encore d'évaluation

- 2016good and ImportantDocument4 pages2016good and ImportantMahdi koolivandPas encore d'évaluation

- Dry WallDocument5 pagesDry WallNakul NayanPas encore d'évaluation

- CuNi NUFITDocument16 pagesCuNi NUFIT9823458877Pas encore d'évaluation

- Industrial Instrumentation - II Unit 1: 2 Marks & Question-AnswersDocument10 pagesIndustrial Instrumentation - II Unit 1: 2 Marks & Question-Answerslakshg11Pas encore d'évaluation

- Arvedi Brief Presentation Modernisation ProgrammeDocument30 pagesArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitPas encore d'évaluation

- Rate Book - 2011-NCP Building DPTDocument244 pagesRate Book - 2011-NCP Building DPTthak_raj84Pas encore d'évaluation

- Location Planning and AnalysisDocument42 pagesLocation Planning and AnalysisSobhit Gupta100% (2)

- Boiler-Turbine Operation Start Up ExplainedDocument35 pagesBoiler-Turbine Operation Start Up ExplainedSteven100% (1)

- Experiment 1Document4 pagesExperiment 1Kathrine E. BautistaPas encore d'évaluation

- Conceptual Design: Thulhiriya Textile City Comprehensive Design ProjectDocument14 pagesConceptual Design: Thulhiriya Textile City Comprehensive Design ProjectAmila DayarathnaPas encore d'évaluation

- Student Safety Sheets: EthanolDocument1 pageStudent Safety Sheets: EthanolNina FairuzPas encore d'évaluation

- Static Tests On Complete StructuresDocument40 pagesStatic Tests On Complete StructuresZain AhmedPas encore d'évaluation

- American Top Loader Washing Machine + SerialDocument67 pagesAmerican Top Loader Washing Machine + SerialMandragora officinarum100% (1)