Académique Documents

Professionnel Documents

Culture Documents

Mini Rice Mill

Transféré par

cheat2vinDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mini Rice Mill

Transféré par

cheat2vinDroits d'auteur :

Formats disponibles

NSIC Project Profiles

MINI RICE MILL

1. INTRODUCTION

India is the second largest producer of rice in the world. The major portion of the paddy

is being processed through hullers.

The hullers are usually low capacity mills. In these hullers, both shelling and polishing

operations are carried out simultaneously. Hence, there is no control on the polishing

of rice, bran adn a higher breakage of rice occurs.

To overcome all these a mini rice mill was designed to meet the needs of the villagers

and a substitute for a huller mill, to get polished rice, rice bran and paddy husk.

2. MARKET

Rice being the staple food of majority population, no problem is envisaged in marketing.

Besides, the mill can be utilised as a service unit for custom milling. It also noticed the

tribals are going for long distance to convert paddy to rice for domestic consumption.

Thus, there exists demand for non-trading rice mill in some important centres.

3. MANUFACTURING PROCESS

The mini rice mill consists of a paddy cleaner, sheller, separator and a polisher. The

most important feature of the mill is that the shelling and polishing are kept separate.

Because of the low capacity, a centrifugal sheller is most commonly employed.

Different units could be used as polisher. For maximum advantage, it is necessary also

to use a paddy separator, whereby need of a high polish can be avoided thus avoiding

unnecessary loss of rice.

4. PRODUCTION CAPACITY PER ANNUM

Sale of rice, husk, bran Rs. 1600000 per annum

5. PROJECT COST/CAPITAL INVESTMENT

S.No Description Amount Rs.

1 Fixed Capital 450000

2 Working Capital for 1 month(s) 109700

3 Preliminary & Preoperative Expns 5000

Total Project Cost 564700

NSIC Project Profiles

6. MEANS OF FINANCE

S.No Description %age Amount Rs.

1 Promoter Contribution 15% 84705

2 Subsidy/Soft Loan 20% 112940

3 Term Loan 65% 367055

Total 564700

7. FINANCIAL ASPECTS

A. FIXED CAPITAL

i. Land and Buildings

Land Rs. 50000

Buildings Rs. 200000

ii. Machinery and Equipment

S.No Description Qty. Rate Amount Rs.

1 Total plant and machinery LS 200000

Total 200000

B. WORKING CAPITAL

i. Salaries & Wages (per month)

S.No Description Nos. Sal/mon. Amount Rs.

1 Supervisor/Entrepreneur 1 2500 2500

2 Skilled worker 1 2000 2000

3 Unskilled worker 1 1500 1500

Total 6000

ii. Raw Material (per month)

S.No Description Unit Qty. Rate Amount Rs.

1 Paddy tons LS 100000

Total 100000

iii. Utilities (per month)

S.No Description Unit Amount Rs.

1 Power LS 1000

2 Water LS 200

Total 1200

iv. Other Expenses (per month)

S.No Description Amount Rs.

1 Postage, Telephones & Stationery Expenses 200

2 Transportation & Conveyance Expenses 1000

3 Consumeble Stores 300

4 Reparis and Maintenance Expenses 500

5 Miscellaneous Expenses 500

Total 2500

NSIC Project Profiles

v. Total Working Capital (per month)

S.No Description Amount Rs.

2 Salaries and Wages 6000

3 Raw Material 100000

4 Utilities 1200

5 Other Expenses 2500

Total 109700

8. COST OF PRODUCTION (PER ANNUM)

S.No Description Amount Rs.

1 Total Working Capital 1316400

2 Depreciation

- Buildings 5% 10000

- Plant and machinery 15% 30000

3 Interest on term loan @ 12% 44047

Total 1400447

9. TURNOVER (PER YEAR)

S.No Description Qty. Rate Rs. Amount Rs.

1 Sale of rice, husk, bran LS 1600000 1600000

Total 1600000

10.FIXED COST (PER YEAR)

S.No Description Amount Rs.

1 Depreciation 40000

2 Interest 44047

3 Salaries & Wages @ 40% 28800

4 Other Expenses incl. Utilities @ 40% 17760

Total 130607

11.PROFIT ANALYSIS & RATIOS

1 Net Profit Rs. 199553

2 Percentage of Profit on Sales 12%

3 Percentage of Return on Investment 35%

4 Break Even Point 40%

Vous aimerez peut-être aussi

- Bricks Project Report 10 LakhDocument9 pagesBricks Project Report 10 LakhManju Mysore100% (1)

- Mango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalDocument16 pagesMango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalVimal AnbalaganPas encore d'évaluation

- Groundnutdpr 04.08.23Document17 pagesGroundnutdpr 04.08.23TNRTP SALEMPas encore d'évaluation

- Project Profile On Manufacturing of Palm PlateDocument9 pagesProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajPas encore d'évaluation

- Paper Bags and PouchesDocument9 pagesPaper Bags and Pouchessam krPas encore d'évaluation

- Project Report On Vermi Compost PDFDocument2 pagesProject Report On Vermi Compost PDFsrisairamcomputersPas encore d'évaluation

- Rice Milling Industry: Diagnostic Study ReportDocument62 pagesRice Milling Industry: Diagnostic Study ReportVigneshwaran AiyappanPas encore d'évaluation

- Project Report ON Ladies Garments (Tailoring-Unit)Document4 pagesProject Report ON Ladies Garments (Tailoring-Unit)Global Law FirmPas encore d'évaluation

- Ginger Cultivation Project Report, Farming Economics - Agri FarmingDocument1 pageGinger Cultivation Project Report, Farming Economics - Agri FarmingSulemanPas encore d'évaluation

- Model Proj On Sheep Breeding FarmDocument4 pagesModel Proj On Sheep Breeding FarmSreenbabu0% (1)

- SMEDA Dehydration PlantDocument68 pagesSMEDA Dehydration PlantUmar NaseerPas encore d'évaluation

- Coconut Products: 1.0 Product and Its ApplicationsDocument6 pagesCoconut Products: 1.0 Product and Its ApplicationsAgri NetPas encore d'évaluation

- Dry Fruits Marketing Ideas PDFDocument36 pagesDry Fruits Marketing Ideas PDFGhouse BaigPas encore d'évaluation

- Project Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)Document6 pagesProject Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)EIRI Board of Consultants and PublishersPas encore d'évaluation

- Project Report Tenthouse PDFDocument10 pagesProject Report Tenthouse PDFsinghPas encore d'évaluation

- 09 Peanut Processing PDFDocument8 pages09 Peanut Processing PDFkalaamolPas encore d'évaluation

- Project Profile On Groundnut Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Groundnut Oil and Oil Cake ManuafcuringprtmPas encore d'évaluation

- Rice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Document22 pagesRice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Junaid AhmedPas encore d'évaluation

- Pulses MillDocument2 pagesPulses Millram100% (1)

- Detailed Project Report On Rice Milling Unit at GelephuDocument19 pagesDetailed Project Report On Rice Milling Unit at GelephuHarpy happyPas encore d'évaluation

- Dairy Farm Project-Self WorkDocument12 pagesDairy Farm Project-Self WorkPankaj Narendrasinh RajPas encore d'évaluation

- Project Report: Manufacturing of Masala PowderDocument10 pagesProject Report: Manufacturing of Masala PowderSuraj Singh RajvanshiPas encore d'évaluation

- Tent House UnitDocument18 pagesTent House UnitSrinivasa NPas encore d'évaluation

- Shri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryDocument9 pagesShri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryNeerajSinghPas encore d'évaluation

- Project Report On Grape Squash ManufacturingDocument13 pagesProject Report On Grape Squash ManufacturingPhanisreePas encore d'évaluation

- Operational Guidelines Milling SchemeDocument45 pagesOperational Guidelines Milling SchemeDeep SarmahPas encore d'évaluation

- Plastic Carry BagsDocument8 pagesPlastic Carry BagsRavi PrakashPas encore d'évaluation

- Onion Dehydration: Project ProfileDocument4 pagesOnion Dehydration: Project ProfileMallikarjunReddyObbineniPas encore d'évaluation

- Dal Mill Project ReportDocument8 pagesDal Mill Project ReportMohan Rao Paturi80% (5)

- Bankable Project Report & Quotation For GreenhouseDocument40 pagesBankable Project Report & Quotation For Greenhousetiyasee25Pas encore d'évaluation

- Mustard Oil KanpurDocument10 pagesMustard Oil KanpurVinay YadavPas encore d'évaluation

- Agro Seed Processing Plant PDFDocument9 pagesAgro Seed Processing Plant PDFNagendra Patel100% (1)

- Project Profile FinalDocument183 pagesProject Profile Finalvenkateswaran.M venkateswaran.MPas encore d'évaluation

- Rice Mill COSTDocument8 pagesRice Mill COSTzohaibssPas encore d'évaluation

- Plywood Project Report by Yogesh AgrawalDocument22 pagesPlywood Project Report by Yogesh AgrawalYOGESH AGRAWALPas encore d'évaluation

- Plant Desin Report For Spice ProductionDocument7 pagesPlant Desin Report For Spice ProductionUmar Mohammad Mir0% (1)

- Project Report On Namkeen and Chips ManufactureDocument8 pagesProject Report On Namkeen and Chips ManufactureSachin SharmaPas encore d'évaluation

- Final Dinesh ProjectDocument16 pagesFinal Dinesh ProjectAravindhan LPas encore d'évaluation

- Role of Agriculture Processing in Export Growth of Agricultural ProductsDocument8 pagesRole of Agriculture Processing in Export Growth of Agricultural ProductsAwadhesh YadavPas encore d'évaluation

- Assessment of Water Quality Using GISDocument8 pagesAssessment of Water Quality Using GISSudharsananPRSPas encore d'évaluation

- Project Report On Galvanised Nut & BoltDocument6 pagesProject Report On Galvanised Nut & BoltEIRI Board of Consultants and PublishersPas encore d'évaluation

- Srisairice Mill ProjectDocument59 pagesSrisairice Mill Projectnational courses100% (1)

- Basmati Rice Manufacturing ProcessDocument4 pagesBasmati Rice Manufacturing ProcessShamli Karumannil100% (1)

- DPR For Walnut ProcessingDocument74 pagesDPR For Walnut ProcessingMohd touseefPas encore d'évaluation

- Fishery (Icdp)Document3 pagesFishery (Icdp)Shyamal Dutta100% (1)

- Analysis of Various Brands of Soyabean Refined Oil in The MarketDocument38 pagesAnalysis of Various Brands of Soyabean Refined Oil in The MarketDouglas OrtizPas encore d'évaluation

- Two Wheeler Repair and Service UnitDocument8 pagesTwo Wheeler Repair and Service UnitSurendra SharmaPas encore d'évaluation

- Project Report On Sheep FarmingDocument8 pagesProject Report On Sheep Farminganon_660904920Pas encore d'évaluation

- Almond Plant FinalDocument18 pagesAlmond Plant Finalv.arumedryfruitsPas encore d'évaluation

- Utensils Production Project RepotDocument9 pagesUtensils Production Project Repotarun1417Pas encore d'évaluation

- Eastern SilkDocument47 pagesEastern SilkVish Nu VichuPas encore d'évaluation

- DADTCO Presentation PDFDocument34 pagesDADTCO Presentation PDFIngeniería Industrias Alimentarias Itsm100% (1)

- Introduction of The Company: Administrative Management CollegeDocument63 pagesIntroduction of The Company: Administrative Management CollegeShivu PatilPas encore d'évaluation

- Profile On The Production of Weighing ScaleDocument26 pagesProfile On The Production of Weighing ScaleDagim GBZPas encore d'évaluation

- FAO Report On GROUNDNUT OIL PDFDocument16 pagesFAO Report On GROUNDNUT OIL PDFVIRTU 8 HR & IT LLPPas encore d'évaluation

- N.k.proteins Ltd.Document65 pagesN.k.proteins Ltd.mbawarriorssiem67% (3)

- Automatic Coir Yarn SpinningDocument3 pagesAutomatic Coir Yarn SpinningSasi MPas encore d'évaluation

- Project Report PAPADDocument3 pagesProject Report PAPADsagayapriya0% (1)

- Corrugated BoxesDocument3 pagesCorrugated BoxesAditya GhatgePas encore d'évaluation

- Dairy Farming: Nsic Project ProfilesDocument3 pagesDairy Farming: Nsic Project Profilesrengachen100% (3)

- P23-7 (SCF-Direct and Indirect Methods From Comparative Financial Statements) ChapmanDocument4 pagesP23-7 (SCF-Direct and Indirect Methods From Comparative Financial Statements) Chapmanintan dwi cahaya100% (1)

- Mid Sem Sample Exam ABDADocument11 pagesMid Sem Sample Exam ABDALeah StonesPas encore d'évaluation

- Vijayakumar Project ReportDocument6 pagesVijayakumar Project ReportkaranPas encore d'évaluation

- VLS - GMBH FS FY 19 20Document44 pagesVLS - GMBH FS FY 19 20Elizabeth Sánchez LeónPas encore d'évaluation

- S4 Financial Projections Spreadsheet Feb2019Rev1Document36 pagesS4 Financial Projections Spreadsheet Feb2019Rev1Ruffa Mae MatiasPas encore d'évaluation

- Chapter 5: Audit of Property, Plant & EquipmentDocument121 pagesChapter 5: Audit of Property, Plant & EquipmentShaneen AdorablePas encore d'évaluation

- A8 Audit of Prepayments, Ip and Other NciDocument7 pagesA8 Audit of Prepayments, Ip and Other NciKezPas encore d'évaluation

- Preparation of Published Financial StatementsDocument19 pagesPreparation of Published Financial StatementsRuth Nyawira100% (1)

- Basic Appraisal Questions & AnswersDocument10 pagesBasic Appraisal Questions & AnswersJuan Carlos Nocedal100% (4)

- Basic Terminal ValueDocument4 pagesBasic Terminal ValueVinPas encore d'évaluation

- Principles of Managerial Finance: Chapter 11Document54 pagesPrinciples of Managerial Finance: Chapter 11Crystal Nedd100% (3)

- Profit and Loss Statement TemplateDocument6 pagesProfit and Loss Statement TemplateyashveerPas encore d'évaluation

- How To Audit Payroll Expense and Fixed AssetsDocument11 pagesHow To Audit Payroll Expense and Fixed AssetsAngie MagnayePas encore d'évaluation

- 547 Roshan K Patel Financial Accounting Departmental AccountingDocument6 pages547 Roshan K Patel Financial Accounting Departmental AccountingRoshan PatelPas encore d'évaluation

- 3 - As-5 Net Profit or Loss For The Period, Prior Period Items and Changes in Accounting PoliciesDocument10 pages3 - As-5 Net Profit or Loss For The Period, Prior Period Items and Changes in Accounting PoliciesKrishna JhaPas encore d'évaluation

- FI-AA-08 Presentation PDFDocument46 pagesFI-AA-08 Presentation PDFAnupam SamantaPas encore d'évaluation

- Robert Allen Kepner - Principles of Farm Machinery-The AVI Publishing Company (1978) - Pages-1,39-63,128-175Document74 pagesRobert Allen Kepner - Principles of Farm Machinery-The AVI Publishing Company (1978) - Pages-1,39-63,128-175Minal MoonPas encore d'évaluation

- IAS 40 Investment Property PresentationDocument29 pagesIAS 40 Investment Property PresentationNollecy Takudzwa BerePas encore d'évaluation

- Questionmark Perception PDFDocument73 pagesQuestionmark Perception PDFPrashin VermaPas encore d'évaluation

- Creative AccountingDocument13 pagesCreative Accountinghhazlina66Pas encore d'évaluation

- Greenwald Class Notes 5 - Liz Claiborne & Valuing GrowthDocument17 pagesGreenwald Class Notes 5 - Liz Claiborne & Valuing GrowthJohn Aldridge Chew100% (2)

- Level 3 SyllabusDocument17 pagesLevel 3 SyllabusBon Bon ChanPas encore d'évaluation

- Operations Management: Financial DimensionsDocument6 pagesOperations Management: Financial DimensionsDinda putriPas encore d'évaluation

- Intangible Assets Lecture and ExercisesDocument16 pagesIntangible Assets Lecture and ExercisesRPas encore d'évaluation

- Instructio NS:: 1 2 3 Your Answer Will Be Valued As A Whole 4 5 6 7Document7 pagesInstructio NS:: 1 2 3 Your Answer Will Be Valued As A Whole 4 5 6 7ikushalpatilPas encore d'évaluation

- SAP Implementation Chklist 18-03-2019Document38 pagesSAP Implementation Chklist 18-03-2019Muhammed ASPas encore d'évaluation

- Solutions To Assignment - Pre 571.Document23 pagesSolutions To Assignment - Pre 571.Isibor CaptainPas encore d'évaluation

- Eng ConDocument27 pagesEng Consaythename.smmaPas encore d'évaluation

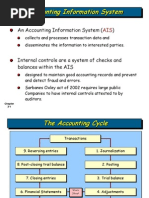

- Wiley - Chapter 3: The Accounting Information SystemDocument36 pagesWiley - Chapter 3: The Accounting Information SystemIvan BliminsePas encore d'évaluation

- DeductionsDocument31 pagesDeductionsJane Tuazon50% (2)