Académique Documents

Professionnel Documents

Culture Documents

Body Flange Bolt Torque

Transféré par

Lcm Tnl100%(1)100% ont trouvé ce document utile (1 vote)

510 vues1 pageBody Flange Bolt Torque

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBody Flange Bolt Torque

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

510 vues1 pageBody Flange Bolt Torque

Transféré par

Lcm TnlBody Flange Bolt Torque

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

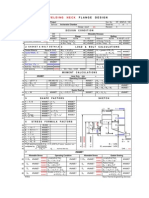

BOLT TORQUE REQUIRED FOR SEALING FLANGES 25-D-109A/B

(Ref: ASME Sec.VIII Div.2 and Pressure Vessel Design Manual - Dennis Moss )

FLANGE - "M" Body Flange

Rev.0

Gasket Details :

Gasket Material

Effective gasket width, b

Diameter of Gasket load reaction, G

=

=

=

Modulus of elasticity of gasket material, Eg

Gasket thickness, tg

SS 316L With SS Inner & CS Outer ring

8.98 mm

(From Flange Design.)

988.64 mm

2

2.04E+06 Kg/cm

(Ref: ASME Sec II Part D)

4.5 mm

Bolting Details :

Stud Size

Bolting material

Pitch diameter of threads, dm

Root diameter of threads, d

Number of bolts, n

=

=

=

=

=

2-1/2" UNC

SA 193 Gr.B7M

20.4 mm

18.77 mm

12

2

270 mm

Root area of bolts, Ab

Modulus of elasticity of bolting material, Eb

Effective length of bolt, lb

Hydrostatic End Force, H

Total joint-contact surface load, Hp

=

=

=

110

1300 Kg

8660.0 Kg

Minimum required bolt load, W m2

Friction Factor, K

=

=

38269.0 Kg

0.2

2

2.06E+06 Kg/cm

(From Flange Design)

(Dennis moss)

Calculation :

Actual joint area contact for gasket, Ag

Ag = 2*3.14* bG

=

mm2

55782.04

Decreasing Compression force in gasket, F*

F* = H / (1+ (Ab Eb tg / Ag Eg lg))

= 1.30E+03

Kg

Initial required tightening force, Fbo

Fbo = Hp + F*

= 9959.742

Kg

Total tightening force required to seal joint, W

W = Max ( Fbo (or) W m2 )

=

38269

Kg

Required Torque, T(Max)

T = K W *dm / n

=

13.01

Kg.m

T = K Wm2*dm / n

=

13.01

128.00

Kg.m

N.m

Required Torque, T(Min)

(Ref: ASME Sec II Part D)

Vous aimerez peut-être aussi

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezPas encore d'évaluation

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongPas encore d'évaluation

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Document2 pagesASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Mr Incognito100% (1)

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGDocument12 pagesAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhalePas encore d'évaluation

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalPas encore d'évaluation

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanPas encore d'évaluation

- Calculation of Target Torque for Bolts (ASME PCC-1Document1 pageCalculation of Target Torque for Bolts (ASME PCC-1daniel oliveiraPas encore d'évaluation

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrPas encore d'évaluation

- Collar bolt sizing calculationDocument2 pagesCollar bolt sizing calculationMohammad Zahid50% (2)

- Mechanical design calculations for air cooler header boxDocument50 pagesMechanical design calculations for air cooler header boxSyedZainAliPas encore d'évaluation

- ASME PCC-1 Bolt Stress and Torque CalculationDocument11 pagesASME PCC-1 Bolt Stress and Torque Calculationndrarly100% (1)

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975Pas encore d'évaluation

- Torque BoltDocument1 pageTorque Boltmuchamad yasin0% (1)

- Bolt Torque Calculation For FlangeDocument1 pageBolt Torque Calculation For Flangevishnudno1Pas encore d'évaluation

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Document2 pagesPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayPas encore d'évaluation

- Assembly Bolt Stress As Per Asme Pcc-1 2013Document12 pagesAssembly Bolt Stress As Per Asme Pcc-1 2013Anonymous RytT6uvX1Pas encore d'évaluation

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahPas encore d'évaluation

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- PTB E4.18.5 Fixed TubesheetDocument83 pagesPTB E4.18.5 Fixed TubesheetNicolaSaviliPas encore d'évaluation

- Bolt Torque Calculation - Apr19Document69 pagesBolt Torque Calculation - Apr19Raj SPas encore d'évaluation

- Bolt Torque Calculation For FlangeDocument1 pageBolt Torque Calculation For FlangeSaravanan Koomidi AnnaduraiPas encore d'évaluation

- Bolt TorqueDocument20 pagesBolt TorqueArjun Singh AroraPas encore d'évaluation

- Allowable External Forces on Vessel NozzlesDocument3 pagesAllowable External Forces on Vessel Nozzlesvenkatrangan2003Pas encore d'évaluation

- ASME B31.3 bend thickness calculationDocument7 pagesASME B31.3 bend thickness calculationvijayakumar2015100% (1)

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelPas encore d'évaluation

- Calculating bolt torque for sealing a 30Document4 pagesCalculating bolt torque for sealing a 30souren1975Pas encore d'évaluation

- Burst PR Calculation PDFDocument1 pageBurst PR Calculation PDFAranga KeerthiPas encore d'évaluation

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyPas encore d'évaluation

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBEPas encore d'évaluation

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Mechanical Calculations for Air Receiver Pressure VesselDocument32 pagesMechanical Calculations for Air Receiver Pressure VesselAndiWSutomoPas encore d'évaluation

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliPas encore d'évaluation

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanPas encore d'évaluation

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Test Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )Document7 pagesTest Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )alokbdasPas encore d'évaluation

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- COMPARISON OF LIMIT LOAD, LINEAR AND NONLINEAR FE ANALYSIS OF A VESSEL NOZZLEDocument6 pagesCOMPARISON OF LIMIT LOAD, LINEAR AND NONLINEAR FE ANALYSIS OF A VESSEL NOZZLEVaraprasad EthaPas encore d'évaluation

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- Bolt Torque Appendix-ODocument1 pageBolt Torque Appendix-OSachin5586100% (1)

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Design and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016Document13 pagesDesign and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016renu rani100% (1)

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemPas encore d'évaluation

- Bolt Torque As Per ASME PCC-1 - MDocument31 pagesBolt Torque As Per ASME PCC-1 - Mmechengg01100% (2)

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizPas encore d'évaluation

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- EN1591 Flange DesignDocument9 pagesEN1591 Flange DesignmadodandembePas encore d'évaluation

- Tube Expansion Report Format r.0Document1 pageTube Expansion Report Format r.0fizanlamin100% (2)

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007Pas encore d'évaluation

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyPas encore d'évaluation

- Anchor Bolt DesignDocument15 pagesAnchor Bolt Designamit8808Pas encore d'évaluation

- SUBMIT (Rev1.0) MicroPileCalculationSheet GTL5Document37 pagesSUBMIT (Rev1.0) MicroPileCalculationSheet GTL5Suneel MatchalaPas encore d'évaluation

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Blind Flange (10 Bar)Document7 pagesBlind Flange (10 Bar)SyedZainAliPas encore d'évaluation

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaPas encore d'évaluation

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzPas encore d'évaluation

- Left blind flange stress analysis and designDocument6 pagesLeft blind flange stress analysis and designkamardheen majithPas encore d'évaluation

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocument8 pagesPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalPas encore d'évaluation

- Blind Flange Calculation11Document3 pagesBlind Flange Calculation11jaymuscatPas encore d'évaluation

- Foundation Load Table.Document1 pageFoundation Load Table.Lcm TnlPas encore d'évaluation

- Tolerance-E and Chord LengthDocument2 pagesTolerance-E and Chord LengthLcm TnlPas encore d'évaluation

- Hariram Thejus vedic astrology blogDocument81 pagesHariram Thejus vedic astrology blogLcm TnlPas encore d'évaluation

- UG-6 (B) Forged Rod or Bar May Only Be Used Within TheDocument1 pageUG-6 (B) Forged Rod or Bar May Only Be Used Within TheLcm TnlPas encore d'évaluation

- FormulaeDocument33 pagesFormulaeLcm TnlPas encore d'évaluation

- Foundation Load Table.Document1 pageFoundation Load Table.Lcm TnlPas encore d'évaluation

- Support Lug Be Greater Than or Equal To 1/3 of The Bottom Plate Radial Width (WPL) Plus The Pad Thickness (Padthk), If There Is A PadDocument1 pageSupport Lug Be Greater Than or Equal To 1/3 of The Bottom Plate Radial Width (WPL) Plus The Pad Thickness (Padthk), If There Is A PadLcm Tnl0% (1)

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlPas encore d'évaluation

- Guide To DOT CylindersDocument85 pagesGuide To DOT Cylindersm_aliamjad7231Pas encore d'évaluation

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzPas encore d'évaluation

- (Report) Storage Tanks (Japan)Document179 pages(Report) Storage Tanks (Japan)RAJENDRA PRASADPas encore d'évaluation

- Heat TreatingDocument5 pagesHeat TreatingLcm TnlPas encore d'évaluation

- Dish EndDocument1 pageDish EndLcm TnlPas encore d'évaluation

- Chord LengthDocument3 pagesChord LengthLcm TnlPas encore d'évaluation

- Lecture Notes in Structural Engineering Analysis DesignDocument142 pagesLecture Notes in Structural Engineering Analysis DesignPankaj_Taneja_9684100% (1)

- VB Sel Tab 2Document1 pageVB Sel Tab 2Lcm TnlPas encore d'évaluation

- Chord Length and DeviationDocument2 pagesChord Length and DeviationLcm TnlPas encore d'évaluation

- Chord Length and DeviationDocument2 pagesChord Length and DeviationLcm TnlPas encore d'évaluation

- Csvol PDFDocument6 pagesCsvol PDFLcm TnlPas encore d'évaluation

- Apco Air Valve GuideDocument12 pagesApco Air Valve Guideanon_711152122Pas encore d'évaluation

- Shell Seam Efficiency and Nozzle C Factor CalculationsDocument1 pageShell Seam Efficiency and Nozzle C Factor CalculationsLcm TnlPas encore d'évaluation

- Foundation Loading Data: NotesDocument1 pageFoundation Loading Data: NotesLcm TnlPas encore d'évaluation

- WRC-368 Shell Reinforcement Plate Width CalculationDocument1 pageWRC-368 Shell Reinforcement Plate Width CalculationLcm TnlPas encore d'évaluation

- Reference For Sizing of Vacuum Breaker Valve PDFDocument2 pagesReference For Sizing of Vacuum Breaker Valve PDFLcm Tnl50% (2)

- Apco Air Valve GuideDocument12 pagesApco Air Valve Guideanon_711152122Pas encore d'évaluation

- R 745Document53 pagesR 745cabpcabpPas encore d'évaluation

- Base Plate CalculationDocument7 pagesBase Plate CalculationLcm TnlPas encore d'évaluation

- Anchor Bolt CalculationDocument1 pageAnchor Bolt CalculationLcm TnlPas encore d'évaluation

- Joint EfficiencyDocument1 pageJoint EfficiencyLcm TnlPas encore d'évaluation