Académique Documents

Professionnel Documents

Culture Documents

ALEACIÓN CB-7Cu

Transféré par

Angel R Zacarias BCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ALEACIÓN CB-7Cu

Transféré par

Angel R Zacarias BDroits d'auteur :

Formats disponibles

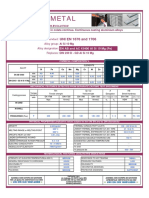

ALLOY DATA SHEET

CORROSION RESISTANT ALLOY

CB-7Cu-1

DESCRIPTION

CB-7Cu-1 is a precipitation hardening, martensitic stainless steel, known in the wrought form as 17-4PH.

Resistance to atmospheric corrosion, organic compounds, sea water and paper mill liquors is intermediate

between that of the hardenable CA alloys and the non-hardenable CF alloy grades. The alloy is particularly suited

to service combining corrosion resistance and high strength at temperatures up to 700oF. Machining is

frequently conducted on castings in the solution annealed condition, followed by hardening at a low temperature

thus alleviating distortion and scaling. Service at temperatures below -40oF should be avoided due to poor

impact properties at this temperature.

COMPOSITION

C

Min %

Max %

Notes:

Mn

Si

Cr

Ni

P

S

Cu(i)

15.5

3.6

2.5

0.07

0.7

1.0

17.7

4.6

0.035 0.03

3.2

(i) Copper should be less than 3% if the castings require welding.

(ii) Niobium should be omitted if the castings are hardened at 900oF.

Nb(ii)

0.20

0.35

N2

0.05

APPLICATIONS

Centrifuge components, food mixers and processing machinery, pump and compressor impellers, pump shafts

and sleeves, screw conveyors,valve bodies and trim, propeller shafts,and hydraulic cylinders

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES

Density (lbs/in3)

0.280

Liquidus( oF)

2750

Thermal Conductivity

(Btu/h/ft2/ft/oF)

9.9 @ 212oF

11.3 @ 500oF

13.0

13.1

@ 860oF

@ 900oF

Aged at Aged at

900oF

1100oF

Thermal Expansion

(10-6in/in oF)

Magnetic Permeability

70-200oF

70-400oF

6.0

6.6

6.1

6.9

70-600oF

70-800oF

6.3

7.1

6.5

7.2

Ferromagnetic

C0RR0SION RESISTANT ALLOY CB 7Cu 1 Page 2

MECHANICAL PROPERTIES

Typical Values at Room Temperature - Solution Annealed 1925oF Air Cooled.

Aging Temperature

oF

900

925

1025

1075

1100

1150

U.T.S.

Y.S.

Elong.

R.A.

Brinell

Charpy key'

K.S.I.

K.S.I.

%

%

HB

ft-lbs

187

161

10

21

412

7

189

165

11

26

412

12

165

158

14

35

350

22

155

141

14

35

319

27

145

132

15

39

315

30

140

120

16

42

307

37

Typical Values at Elevated Temperatures - Solution Annealed at 1925oF,

Air Cooled,.and Aged at 900oF

Aging Temperature

oF

200

400

600

700

800

900

U.T.S.

Y.S.

Elong.

R.A.

K.S.I.

K.S.I.

%

%

181

152

9

21

173

140

8

19

162

128

6

17

158

121

5

15

148

115

6

12

130

100

8

19

WELDABILITY

CB-Cu7-1 may be welded by the SMAW, GTAW or GMAW processes.

Electrodes

Same composition or 308

Preheat

Not required for section less than 0.75" thick. Heavier sections with substantial

welding may be preheated to 500oF.

Post weld heat treatment

900 to 1100oF, Air Cool.

Procedures for welding CB-Cu7-1 alloy are available

RELATED SPECIFICATIONS

ASTM: A747(CB7Cu-1 and CB7Cu-2).

Nearest wrought grade: 17-4PH, 15-5PH.

Vous aimerez peut-être aussi

- 304L MTC Int PDFDocument1 page304L MTC Int PDFTanmoy DuttaPas encore d'évaluation

- YP-WT 11 - Welding of MetalsDocument71 pagesYP-WT 11 - Welding of MetalsAnnisa UrbaningrumPas encore d'évaluation

- Casting Material CF3 & CF8Document3 pagesCasting Material CF3 & CF8Arunprasad MurugesanPas encore d'évaluation

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- MISIF - SS Corrosion and How To Stop It 23 MayDocument66 pagesMISIF - SS Corrosion and How To Stop It 23 Maycelalkeskiner94Pas encore d'évaluation

- Processingand Applicationof IFGradesteeel Prospectsin SAIL3Document19 pagesProcessingand Applicationof IFGradesteeel Prospectsin SAIL3Chhatramani SinghPas encore d'évaluation

- LM4 Alloy DetailDocument5 pagesLM4 Alloy Detailcharles_boyle_3Pas encore d'évaluation

- Zirconium 702C and Zirconium 705C PDFDocument2 pagesZirconium 702C and Zirconium 705C PDFgullenariPas encore d'évaluation

- 904LDocument5 pages904LManish542Pas encore d'évaluation

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoPas encore d'évaluation

- Casting Material CF3Document3 pagesCasting Material CF3ZakariaPas encore d'évaluation

- Table 7.7 (Continued) : 7.3.12 Stainless SteelsDocument21 pagesTable 7.7 (Continued) : 7.3.12 Stainless SteelsumairPas encore d'évaluation

- Corrosion resistant alloy CF-3M data sheetDocument2 pagesCorrosion resistant alloy CF-3M data sheetnguyenPas encore d'évaluation

- Guidelines For Stainlesssteel WeldingDocument90 pagesGuidelines For Stainlesssteel Weldingquiron2010Pas encore d'évaluation

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekPas encore d'évaluation

- Nitric Acid StorageDocument7 pagesNitric Acid StorageEr Bali PandharePas encore d'évaluation

- Ferritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesDocument4 pagesFerritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesrkukgPas encore d'évaluation

- Corrosion Guide - Stainless Internation NickelDocument20 pagesCorrosion Guide - Stainless Internation NickelJohn BurkePas encore d'évaluation

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocument93 pagesSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuPas encore d'évaluation

- Shipbuilding Materials and Metallurgy: Alloy Steels and Their PropertiesDocument41 pagesShipbuilding Materials and Metallurgy: Alloy Steels and Their PropertiesMahadi HasanPas encore d'évaluation

- AISI 1015: Digest DDocument2 pagesAISI 1015: Digest DGovinda RajPas encore d'évaluation

- Chapter 8Document5 pagesChapter 8Eisha MalikPas encore d'évaluation

- Stainless Chromium-Nickel-SteelsDocument26 pagesStainless Chromium-Nickel-SteelscesargamboaPas encore d'évaluation

- Ca 15Document2 pagesCa 15naraen9790579455Pas encore d'évaluation

- Steel FachaDocument59 pagesSteel FachaviyfPas encore d'évaluation

- Prepared by Monir Hamed Feb. 2012Document11 pagesPrepared by Monir Hamed Feb. 2012Vasu RajaPas encore d'évaluation

- AVESTA How To Weld Duplex SteelDocument20 pagesAVESTA How To Weld Duplex SteelGMacella100% (1)

- 2005 Carbon SteelDocument65 pages2005 Carbon SteelmageshkumarPas encore d'évaluation

- Acerto Steel 2Document51 pagesAcerto Steel 2viyfPas encore d'évaluation

- Wear Resistance of High C High Si Steel With Low RDocument11 pagesWear Resistance of High C High Si Steel With Low RChristina Christina ChristinaPas encore d'évaluation

- A New Zinc Alloy Ilzro 12Document9 pagesA New Zinc Alloy Ilzro 12uzairmetallurgistPas encore d'évaluation

- Copper and Copper AlloysDocument3 pagesCopper and Copper Alloyskevin herryPas encore d'évaluation

- En 43400Document2 pagesEn 43400shivendrakumarPas encore d'évaluation

- Acero MadridDocument46 pagesAcero MadridviyfPas encore d'évaluation

- 1 4713 4724 4742 4762Document4 pages1 4713 4724 4742 4762Ján KožičkaPas encore d'évaluation

- C 61400Document2 pagesC 61400ghetto_bmx_boyPas encore d'évaluation

- Arc Welding Cracks SolidificationDocument3 pagesArc Welding Cracks SolidificationShaher YarPas encore d'évaluation

- Steel Material PropertiesDocument2 pagesSteel Material PropertiescadhoaPas encore d'évaluation

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghPas encore d'évaluation

- WELDS IN DUPLEX STAINLESS STEEL MICROSTRUCTUREDocument8 pagesWELDS IN DUPLEX STAINLESS STEEL MICROSTRUCTUREkamal touilebPas encore d'évaluation

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazPas encore d'évaluation

- Chapter 5-Metal AlloysDocument74 pagesChapter 5-Metal AlloysMohd AziziPas encore d'évaluation

- Weldability of Materials - Copper and Copper AlloysDocument5 pagesWeldability of Materials - Copper and Copper AlloysmanimaranPas encore d'évaluation

- DZR BrassDocument3 pagesDZR BrassAlfredo Cumbi CumbiPas encore d'évaluation

- Austral Wright Metals: CuttingDocument10 pagesAustral Wright Metals: CuttingScribdSnake123100% (1)

- Martensitic Stainless SteelsDocument8 pagesMartensitic Stainless SteelsAdilmar E. NatãnyPas encore d'évaluation

- Production of Large Diameter Pipes Grade X 70 With High Toughness Using Acicular Ferrite MicrostructuresDocument14 pagesProduction of Large Diameter Pipes Grade X 70 With High Toughness Using Acicular Ferrite MicrostructuresdgkmurtiPas encore d'évaluation

- Hard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1Document1 pageHard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1convmech enggPas encore d'évaluation

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelD'EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopD'EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Corrosion: Corrosion ControlD'EverandCorrosion: Corrosion ControlL L ShreirÉvaluation : 5 sur 5 étoiles5/5 (1)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsD'EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkD'EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkPas encore d'évaluation